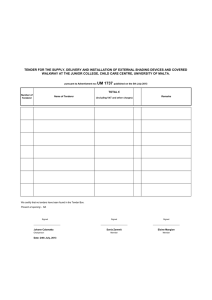

tender technical specification for supply, installation, erection

advertisement