Variable Inductance Transducers

advertisement

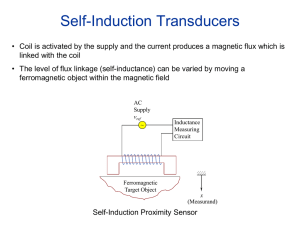

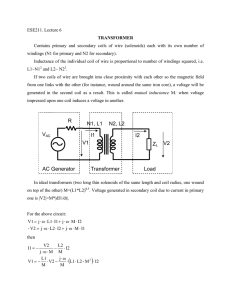

Variable Inductance Transducers • These motion transducers employ the principle of electromagnetic induction • Types of variable inductance transducers include • Mutual induction transducers • Self-induction transducers • Permanent magnet transducers • Variable inductance transducers that use a non-magnetized ferromagnetic medium to alter the reluctance of the flux path are known as variable reluctance transducers • Some mutual induction transducers and most self-induction transducers are variable reluctance type • But permanent magnet transducers are not variable reluctance type Mutual Induction Transducers and Differential Transformers vo Secondary Coil Core Primary Coil • An AC excitation in the primary winding induces an AC voltage in the secondary winding • The amplitude of the induced voltage depends on the flux linkage between the two coils vref • In mutual induction transducers change in the flux is effected by either Moving a ferromagnetic material on the flux path – LVDT, RVDT, mutual induction proximity probe Moving one coil with respect to the other – resolver, synchro-transformer Linear Variable Differential Transformer vo (Measurement) Primary Coil Insulating Form Ferromagnetic Core Secondary Coil Segment vref Secondary Coil Segment vo Voltage level Housing Core Displacement x (Measurand) Displacement x Linear Range LVDT Operation vo Secondary Coil Core Primary Coil vref • When the core moves the reluctance of the flux path changes and the degree of flux linkage depends on the core position • Since the two secondary windings are connected in series opposition, when the core is at the centre the output is zero (null position) • In the linear operating range o/p voltage is proportional to the core displacement • It provides magnitude as well as the direction. Direction can be obtained by • Demodulating the signal or • Phase angle of the o/p signal • To measure transient motions accurately the reference signal frequency has to be at least 10 times larger than the largest freq. component of the measurand Example 3.3 An equivalent circuit for a differential transformer is shown below. The resistance in the primary winding is denoted by Rp and the magnetizing inductance is denoted by Lm. The resistance of the secondary winding is Rs. The net leakage inductance, due to magnetic flux linkage, in the two segments is denoted by Ll. The load resistance is RL and the load inductance is LL. Derive an expression for the phase shift in the output signal. Ll Rp Rs + RL Core vo ~ LL vref − Lm Load ~ Primary Circuit Secondary Circuit x Measurand Signal Conditioning Rectification Carrier Frequency Generator Displacement (Measurand) DC Power Supply Primary Excitation Rectifier LVDT Secondary Circuit Output DC Amplifier Low-Pass Filter Measurement • AC output from the LVDT is rectified to obtain a DC signal • Phase shift of the LVDT output has to be checked separately to determine the direction of motion Demodulation DC Power Supply Carrier Frequency Generator Phase Shift Displacement (Measurand) LVDT Amplitude Matching Demodulator DC Amplifier Low-Pass Filter Measurement • Carrier frequency component is rejected from the output signal by comparing it with a phase-shifted and amplitude adjusted version of the reference signal • Differential transformers with built in signal conditioning are commonly available today • DC differential transformers have built in oscillators to generate the carrier signal. The supply voltage is usually 25V and output voltage is 5V. Example 3.4 R x(t) C Carrier Signal v1 vp sinωct + v2 v3 R1 _ Output vo _ R2 + R1 R1 LVDT Amplifier Multiplier Low-pass Filter 1. Write equations for the amplifier and filter circuits and, using them, give expressions for the voltage signals v1, v2, v3, and vo 2. Suppose that the carrier frequency is ω c = 500 rad s and the filter resistance R = 100 kΩ . If carrier component to be less than 5% through the filter, estimate the required value of the filter capacitance C. Also, what is the useful frequency range (measurement bandwidth) of the system in rad/s, with these parameter values? 3. If the displacement x(t) is linearly increasing (i.e., speed is constant), sketch the signals u(t), v1, v2, v3, and vo as functions of time. Signals at various levels v2 v1 x(t) t t t vo v3 t t Advantages of LVDTs • Essentially non-contacting with no frictional resistance. Near ideal electromechanical energy conversion and light weight core result in very small resistive forces. Hysteresis is negligible • Low output impedance ~100Ω • Directional measurements are possible • Available in small size 1cm long with 2mm displacement • Simple and robust construction (inexpensive and durable) • Fine resolutions are possible (better than potentiometer) Rotatory Variable Differential Transformer Measurement vo vo Primary Coil Secondary Coil Rotating Ferromagnetic Core (Measurand) −40° 40° Linear Range Secondary Coil vref Voltage level Rotation Variable Inductance Devices • Induced voltage is generated through the rate of change of magnetic flux • Displacement measurements are distorted by velocity; Velocity measurements are distorted by acceleration • For the same displacement, the transducer reading will depend on the velocity at that displacement • This error is proportional to (cyclic velocity of the core)/(carrier frequency) • Error rates can be reduced by increasing carrier frequency Mutual Induction Proximity Sensor Secondary Coil ~ vo (Measurement) Primary Coil Secondary Coil vref Ferromagnetic Target Object x (Measurand) Output Voltage vo Proximity x Usage of Mutual Induction Proximity Sensor • Generally used to measure • Transverse displacements • Small displacements (nonlinear) • Presence or absence • Mechanical loading is negligible (non contacting) • Applications include • Robotic Measurement and control of the gap between a robotic welding torch head and the work surface • Angular speed measurement at steady state, by counting the number of rotations per unit time • Level detection (e.g., in the filling) • Bottling plant to check whether the lid is placed Proximity Sensor Applications Machine Tools Plating Line Resolver • Mutual induction transducer for measuring angular displacements Output Rotor ~ θ Stator AC Supply vref Output Stator • Rotor has the primary winding and is energized by the supply voltage • Stator has two sets of windings placed 900 apart Supply voltage v ref = v a sin ωt Induced Voltages vo1 = avref cos θ v o 2 = av ref sin θ The induced quadrate signals are vo2 = ava sin θ sin ωt vo1 = ava cosθ sin ωt Multiply each quadrature signal by vref to get 1 vm1 = vo1vref = ava cos θ sin ω t = ava 2 cos θ [1 − cos 2ω t ] 2 1 2 2 v m 2 = vo 2 vref = av a sin θ sin ωt = av a 2 sin θ [1 − cos 2ωt ] 2 2 2 Low pass filter to obtain 1 2 v f 1 = ava cos θ 2 vf 2 = 1 ava 2 sin θ 2 Advantages • Fine resolution and high accuracy • Low output impedance • Small size (10mm diameter) Limitations • Nonlinear output signals • Bandwidth limited by supply frequency • Slip rings and brushes would be necessary if multiple rotations to be measured (a brushless resolver can eliminate this) Synchro Transformer Rotor Rotor AC ~ Supply vref Transmitter Output Receiver (Control Transformer) • Two identical rotor stator pairs • Each stator has three sets of windings 1200 apart • Transmitter rotor is energized with supply voltage. This induces voltages in the three stator windings • Since the windings of the transmitter stator are connected to the receiver stator windings, a voltage is induced in the receiver rotor. • If the angle between the drive rotor and a stator winding is θt the resultant magnetic field on the receiver stator will make the same angle with the corresponding stator winding. • If the receiver rotor is aligned with this magnetic filed the induced voltage will be maximum • If the receiver rotor is at 900 to this resultant magnetic field then the induced voltage will be zero. vo = avref cos(θ t − θ r ) • Synchros are operated near θ r = θ t + 90 o where the output voltage is zero θ r = θ t + 90 o − θ v o = av ref sin θ