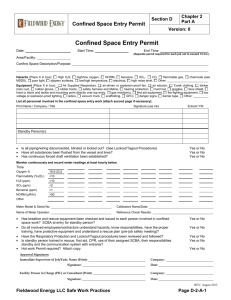

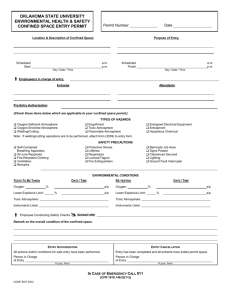

Confined Space Entry Program - University of Hawaii at Manoa

advertisement