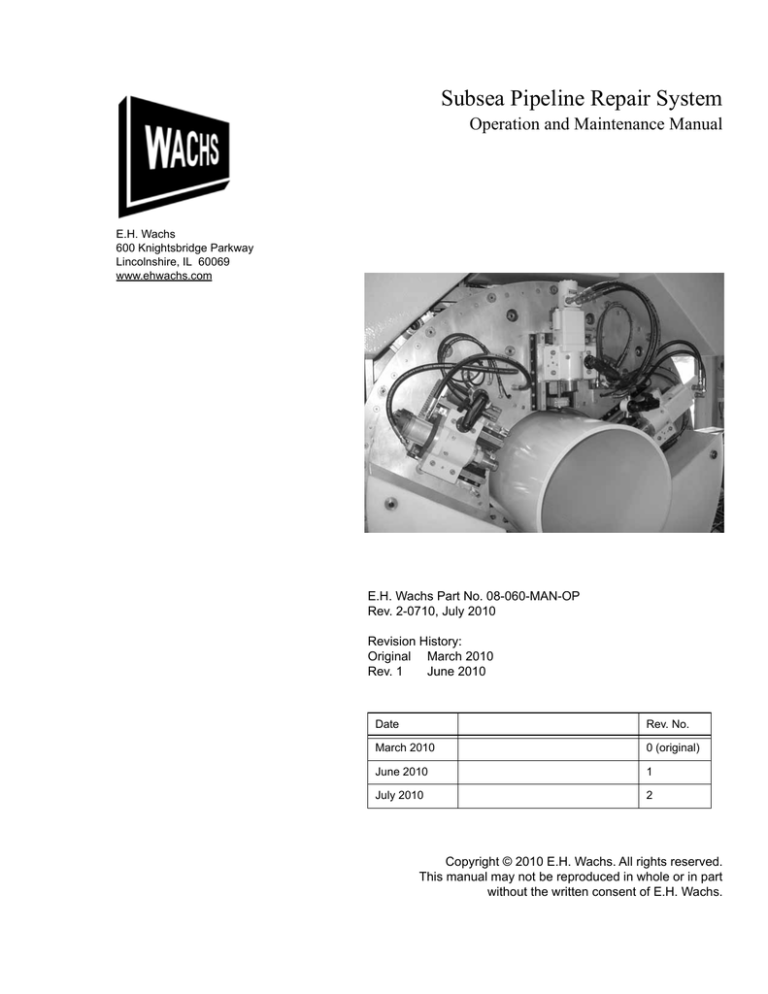

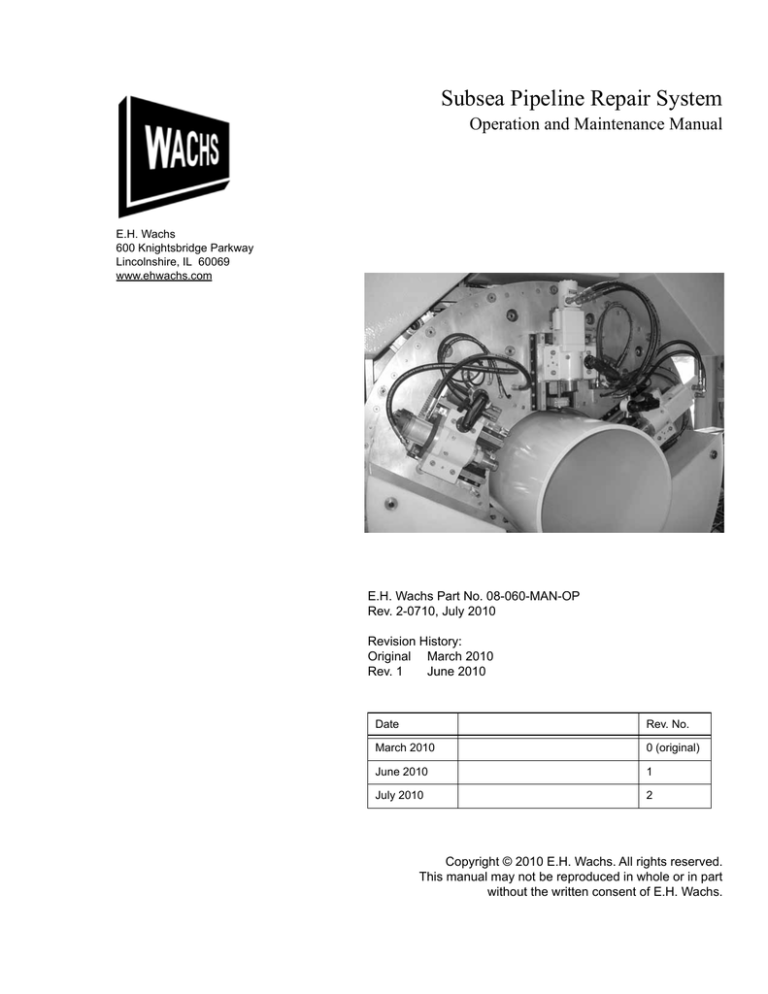

Subsea Pipeline Repair System

Operation and Maintenance Manual

E.H. Wachs

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

E.H. Wachs Part No. 08-060-MAN-OP

Rev. 2-0710, July 2010

Revision History:

Original March 2010

Rev. 1

June 2010

Date

Rev. No.

March 2010

0 (original)

June 2010

1

July 2010

2

Copyright © 2010 E.H. Wachs. All rights reserved.

This manual may not be reproduced in whole or in part

without the written consent of E.H. Wachs.

Subsea Pipeline Repair System

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Table of Contents

Table of Contents

Chapter 1: About the Pipeline Repair System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

How to Use The Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Symbols and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Manual Updates and Revision Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power Unit Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Physical Data and Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2: Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operator Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Hydraulic Injection Injuries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Protective Equipment Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 3: Test Certifications and Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Rigging Pull Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CPT Pull Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Deployment Frame Pull Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 4: Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Rigging and Lifting the CPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Lifting the CPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mounting the CPT on the Deployment Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Lifting the CPT on the Deployment Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

ROV Manipulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Using the CPT iVP Controller Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Deployment/Recovery Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Water Ingress Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operating the Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Closing and Opening Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Walking the Machine on the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Walking the CPT Forward In the Tool Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Walking the CPT Backward Away from the Tool Direction . . . . . . . . . . . . . . . . . . . . . 23

Rotating the Face Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setting the Tool Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

1

Subsea Pipeline Repair System

Set-Up and Deployment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tooling Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Pre-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weld Seam Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subsea Deployment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting the CPT on the Pipeline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Severing Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O.D. Bevel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.D. Bevel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weld Seam Removal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single Clamp Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FBE Coating Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the FBE Removal Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre-Configuring the FBE Replacement Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Old FBE Pad at the Deployment Site . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the New FBE Pad at the Deployment Site . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the CPT from the Pipeline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contingency Recovery Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rotating Frame Disabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clamps Disabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rotating Frame and Clamps Disabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30

30

31

32

34

34

36

38

39

41

42

43

44

45

49

53

56

58

58

60

61

Chapter 5: Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bearing Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

69

69

72

73

73

Chapter 6: Storage and Mobilization Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Packing and Inventory Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage for Less than 3 Days . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Less than 2 Week Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Less than 1 Year Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mobilization and Shipping Plans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

77

77

77

80

81

81

Chapter 7: Reference Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ordering Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Return Goods Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

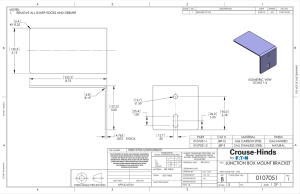

Drawings and Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

83

83

83

83

84

84

84

2

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 1, About the Pipeline Repair System

Chapter 1

About the Pipeline

Repair System

In This Chapter

PURPOSE OF THIS MANUAL

PURPOSE OF THIS MANUAL

HOW TO USE THE MANUAL

This manual explains how to operate and maintain the coating removal tool for pipeline repair. It includes instructions

for set-up, operation, and maintenance. It also contains

parts lists, diagrams, and service information to help you

order replacement parts and perform user-serviceable

repairs.

SYMBOLS AND WARNINGS

MANUAL UPDATES AND

REVISION TRACKING

EQUIPMENT DESCRIPTION

Before operating the coating removal tool, you should read

through this manual and become familiar with all instructions.

HOW TO USE THE MANUAL

This manual is organized to help you quickly find the information you need. Each chapter describes a specific topic on

using or maintaining your equipment.

Throughout this manual, refer

to this column for warnings,

cautions, and notices with

supplementary information.

Each page is designed with two columns. This large column

on the inside of the page contains instructions and illustrations. Use these instructions to operate and maintain the

equipment.

The narrower column on the outside contains additional

information such as warnings, special notes, and definitions. Refer to it for safety notes and other information.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

1

Subsea Pipeline Repair System

SYMBOLS AND WARNINGS

The following symbols are used throughout this manual to

indicate special notes and warnings. They appear in the outside column of the page, next to the section they refer to.

Make sure you understand what each symbol means, and

follow all instructions for cautions and warnings.

WARNING

A WARNING alert with the

safety alert symbol indicates

a potentially hazardous situation that could result in serious injury or death.

This is the safety alert symbol. It is used

to alert you to potential personal injury

hazards. Obey all safety messages that

follow this symbol to avoid possible

injury or death.

CAUTION

A CAUTION alert with the

safety alert symbol indicates

a potentially hazardous situation that could result in

minor or moderate injury.

CAUTION

A CAUTION alert with the

damage alert symbol indicates a situation that will

result in damage to the

equipment.

This is the equipment damage alert

symbol. It is used to alert you to potential equipment damage situations.

Obey all messages that follow this symbol to avoid damaging the equipment or

workpiece on which it is operating.

IMPORTANT

An IMPORTANT alert with

the damage alert symbol indicates a situation that may

result in damage to the

equipment.

2

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 1, About the Pipeline Repair System: Manual Updates and Revision Tracking

NOTE

NOTE

This symbol indicates a user note. Notes

provide additional information to supplement the instructions, or tips for easier

operation.

A NOTE provides supplementary information or operating tips.

MANUAL UPDATES AND REVISION TRACKING

Occasionally, we will update manuals with improved operation or maintenance procedures, or with corrections if necessary. When a manual is revised, we will update the

revision history on the title page.

You may have factory service or upgrades performed on the

equipment. If this service changes any technical data or

operation and maintenance procedures, we will include a

revised manual when we return the equipment to you.

Current versions of E.H.

Wachs Company manuals

are also available in PDF format. You can request an

electronic copy of this manual

by emailing customer service

at sales@wachsco.com.

EQUIPMENT DESCRIPTION

The following Basis of Design and PRS General Arrangement documents describe the CPT system and its modes of

operation.

Power Unit Requirements

If you use the CPT with a customer-supplied hydraulic

power unit (HPU), make sure the HPU meets the following

requirements:

•

•

25 gpm flow

pressure-side filter with 10 micron filtration.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

3

Subsea Pipeline Repair System

Physical Data and Capacities

Hydraulic Requirements

20 gpm @ 3000 psi

(91 l/min @ 207 bar)

Electrical Requirements

24 V DC

Operating Depth Range

0-10,000 ft (0-3000 m)

Pipeline O.D. Clamping Range

12”, 20”, 24”

Severing Tool Feed Stroke

6” (152 mm)

Weld Seam Removal Tool Feed Stroke 6” (152 mm)

4

FBE Removal Tool Feed Stroke

6.625” (168 mm)

Rotating Frame Travel Range

0-200° from top in both directions

Walk Cylinder Stroke

8” (203 mm)

Severing Tool Spindle RPM

max 750 RPM

Weld Removal Tool Spindle RPM

max 750 RPM

FBE Removal Tool Spindle RPM

max 3500 RPM

CPT Tool Weight (with buoyancy, in

air)

6145 lb (2793 kg)

CPT Tool Dimensions (H x W x L)

106.6” x 70” x 88.5”

(2708 x 1778 x 2248 mm)

Deployment Stand Weight

4860 lb (2209 kg)

Deployment Stand Dimensions

(H x W x L)

With lift arm up:

139.8” x 90” x 92.4”

(3551 x 2286 x 2347 mm)

With lift arm down:

83.4” x 90” x 146.4”

(2118 x 2286 x 3719 mm)

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 2, Safety

Chapter 2

Safety

In This Chapter

The E.H. Wachs Company takes great pride in designing

and manufacturing safe, high-quality products. We make

user safety a top priority in the design of all our products.

OPERATOR SAFETY

Read this chapter carefully before operating the pipeline

repair system. It contains important safety instructions and

recommendations.

OPERATOR SAFETY

Follow these guidelines for safe operation of the equipment.

•

•

•

•

READ THE OPERATING MANUAL. Make sure

you understand all setup and operating instructions

before you begin.

INSPECT MACHINE AND ACCESSORIES.

Before starting the machine, look for loose bolts or

nuts, leaking lubricant, rusted components, and any

other physical conditions that may affect operation.

Properly maintaining the machine can greatly decrease

the chances for injury.

ALWAYS READ PLACARDS AND LABELS. Make

sure all placards, labels, and stickers are clearly legible

and in good condition. You can purchase replacement

labels from E.H. Wachs Company.

KEEP CLEAR OF MOVING PARTS. Keep hands,

arms, and fingers clear of all rotating or moving parts.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

Look for this symbol throughout the

manual. It indicates

a personal injury

hazard.

5

Subsea Pipeline Repair System

•

•

Always turn machine off before doing any adjustments

or service.

SECURE LOOSE CLOTHING AND JEWELRY.

Secure or remove loose-fitting clothing and jewelry, and

securely bind long hair, to prevent them from getting

caught in moving parts of the machine.

KEEP WORK AREA CLEAR. Keep all clutter and

nonessential materials out of the work area. Only people

directly involved with the work being performed should

have access to the area.

Hydraulic Injection Injuries

Pinhole punctures in high-pressure hydraulic lines can

inject hydraulic fluid through the skin if there is direct contact with the hydraulic line.

•

•

Always use puncture-resistant gloves when handling

hydraulic lines and fittings.

Do not use hands to check hydraulic lines for leaks. Pass

a solid item (such as a piece of wood or cardboard)

along the hydraulic line to check for fluid spraying out.

If an operator experiences a hydraulic injection wound,

immediately seek emergency medical assistance. Injection

wounds can cause serious, permanent injury such as tissue

damage or loss of limb. It is recommended that you have a

predetermined emergency medical site with experience in

treating injection injuries.

Safety Symbols

This icon is displayed with any safety alert that indicates a

personal injury hazard.

WARNING

This safety alert indicates a potentially hazardous situation

that, if not avoided, could result in death or serious injury.

6

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 2, Safety: Operator Safety

CAUTION

This safety alert, with the personal injury hazard symbol,

indicates a potentially hazardous situation that, if not

avoided, could result in minor or moderate injury.

Protective Equipment Requirements

WARNING

Always wear impact resistant eye protection while operating or working near

this equipment.

For additional information on eye and face protection, refer

to Federal OSHA regulations, 29 Code of Federal Regulations, Section 1910.133., Eye and Face Protection and

American National Standards Institute, ANSI Z87.1, Occupational and Educational Eye and Face Protection. Z87.1 is

available from the American National Standards Institute,

Inc., 1430 Broadway, New York, NY 10018.

CAUTION

Personal hearing protection is recommended when operating or working near

this tool.

Hearing protectors are required in high noise areas, 85 dBA

or greater. The operation of other tools and equipment in the

area, reflective surfaces, process noises, and resonant structures can increase the noise level in the area. For additional

information on hearing protection, refer to Federal OSHA

regulations, 29 Code of Federal Regulations, Section

1910.95, Occupational Noise Exposure and ANSI S12.6

Hearing Protectors.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

7

Subsea Pipeline Repair System

8

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 3, Test Certifications and Procedures

Chapter 3

Test Certifications

and Procedures

In This Chapter

RIGGING PULL TESTS

RIGGING PULL TESTS

Perform the following rigging lift tests every 6 months to

verify the integrity of the CPT and deployment frame lifting attachments:

• verify that the CPT lift attachments support 150%

of the CPT’s weight

• verify that the deployment frame’s lift arm supports

300% of the deployment frame and CPT’s total

weight.

CPT Pull Test

1.

The load test is conducted by evenly distributing 50%

of the tool's dry weight to a pallet. The CPT is set on

the pallet and strapped to it.

• The dry weight of the CPT machine is approximately 5430 lb.

• The pallet should be loaded with approximately

2700 lb.

• The combined weight for the rigging test is approximately 8130 lb.

2.

Using a strain gauge attached between the tool and

the lift hook, lift the tool with the crane to establish a

dry weight measurement.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

9

Subsea Pipeline Repair System

3.

Lower the tool onto the pallet prepared with 50% of

the tool's dry weight (~2,700 lbs).

4.

Lift the combined tool and pallet and hold suspended

for 15 minutes. The strain gauge will verify the combined weight.

5.

Set the CPT down and inspect all connection points on

the lift attachment for signs of damage.

Deployment Frame Pull Test

10

1.

For the 300% lift test, mount the CPT on the deployment frame. See the instructions in Chapter 4.

2.

The weight of the CPT machine (5,430 lbs) plus the

weight of the deployment frame (4,850 lbs) combine

to 10,280 lbs.

3.

Secure the bottom of the deployment frame so that it

cannot be lifted.

4.

Using a strain gauge, perform the load testing to

30,840 pounds.

5.

Inpect the lift arm and attachment points for signs of

damage.

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures

Chapter 4

Operating

Procedures

In This Chapter

This chapter contains step-by-step instructions for setting

up the CPT and for performing the pipe prep operations.

Refer to the appropriate section of the chapter for the operation you are performing.

RIGGING AND LIFTING THE CPT

USING THE CPT IVP

CONTROLLER PROGRAM

SET-UP AND DEPLOYMENT

Two checklists are provided at the end of this chapter:

SEVERING OPERATION

•

O.D. BEVEL OPERATION

•

Pre-dive checklist—steps to be completed before

deploying the CPT to the subsea operating site.

Post-dive checklist—steps to be completed after raising

the CPT from the subsea operating site and before storing the machine.

Each checklist includes signatures spaces for all steps of the

procedure. The operator responsible for each step signs the

checklist when the step is completed.

I.D. BEVEL OPERATION

WELD SEAM REMOVAL

OPERATION

FBE COATING REMOVAL

REMOVING THE CPT FROM THE

PIPELINE

CONTINGENCY RECOVERY

PROCEDURES

Always monitor the inegrity of the hydraulic fluid during

operation. If any water is observed in the hydraulic system

at any time, purge and replace the hydraulic fluid immediately. Leaving water in the system for any length of time

can cause corrosion and damage of hydraulic components.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

11

Subsea Pipeline Repair System

RIGGING AND LIFTING THE CPT

Lifting the CPT

The CPT is equipped with 3 lifting eyes, two on the ROV

docking station and one on top of the rear clamp assembly

(between the ballast blocks). When lifting the CPT topside

by itself, rig to these three lift points. Always attach to all

three points for balanced lifting. The weight of the CPT by

itself in air is approximately 6145 lbs (2793 kg).

Figure 4-1. When lifting the CPT by itself, attach rigging to the three lift points shown.

Mounting the CPT on the Deployment Frame

Follow this procedure to mount the CPT on the deployment

frame. Reverse the procedure to remove the CPT.

Before you mount the CPT, make sure the machine is prepared as follows:

•

•

•

•

12

It is recommended that you remove the tooling from the

three pipe tools on the rotating frame.

The feed drives on all three tools should be fully

retracted.

The rotating frame must be in the loading position, with

the opening straight down.

The clamps must be fully open.

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Rigging and Lifting the CPT

•

The walk cylinder should be fully extended (clamps

apart at maximum).

1.

Make sure the deployment frame is on a flat, level surface, with the lifting arm in the down position.

2.

Rig the CPT as described in the previous section.

3.

Lift the CPT and position the fore (rotating) end of it

next to the mounting pipe on the deployment frame.

Align the opening in the CPT with the mounting pipe.

Figure 4-2. Lift the CPT and align it with the mounting pipe on the deployment stand.

4.

Move the CPT along the length of the mounting pipe.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

13

Subsea Pipeline Repair System

Figure 4-3. Move the CPT back along the mounting

pipe on the deployment frame.

5.

There are four pins on the base of the deployment

frame that fit into brackets on the bottom of the CPT

frame. Move the CPT back until the pins engage the

holes in the brackets.

Figure 4-4. Move the CPT back so that the deployment frame pins engage the brackets. See closeup

photo in sidebar.

6.

14

Set the CPT down onto the deployment frame.

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Rigging and Lifting the CPT

7.

Swing the deployment frame latch over the end of the

CPT frame to secure the machine. Pull the handle

firmly to lock it into place.

Figure 4-5. Pull the deployment frame latch handle to

lock the latch in place over the end of the CPT frame.

8.

Remove the rigging from the CPT lift points.

Lifting the CPT on the Deployment Frame

When the CPT is mounted on the deployment frame, lift the

entire system from above using the deployment frame lift

arm. The deployment frame is designed so the entire assembly will be balanced lifting on a single point. The weight of

the deployment frame and CPT combined is approximately

11,000 lbs (5000 kg), depending on tooling installed,

amount of hydraulic oil in the system, etc.

Do not lift the combined CPT and deployment frame by the

CPT lift eyes or by any other fixture. Severe damage to the

equipment could result.

WARNING

Make sure the deployment

frame latch is secured over

the end of the CPT before lifting the machine on the

deployment frame. The CPT

could slide off the frame if it is

not latched, with a risk of

equipment damage and serious injury or death.

Lift the deployment frame arm to the vertical position and

latch the arm in the vertical channel before lifting.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

15

Subsea Pipeline Repair System

Connect rigging to the top

eye and lift the arm

Latch arm in vertical channel

before lifting

Figure 4-6. With the CPT on the deployment frame,

use the eye on the lift arm to pick up the equipment.

ROV Manipulation

When using an ROV to move the CPT, lift on the ROV

docking station on top of the CPT.

Figure 4-7. To move the CRT underwater, engage the

ROV lifting attachments in the holes of the docking

station.

16

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Using the CPT iVP Controller Program

USING THE CPT IVP CONTROLLER PROGRAM

All clamping and cutting operations of the CPT system are

controlled using the Wachs CPT Controller Program. The

program runs on a dedicated laptop computer provided with

the machine. Start the program by double-clicking the icon

on the desktop, or from the Start menu:

Start—>All Programs—>Wachs CTP iVP Controller—>

Wachs CPT iVP Controller

The main screen appears, as shown in Figure 4-8. The following sections describe the features of the software.

The Face Plate Rotation

section lets you control the

face plate. You can set the

direction and speed.

The Spindle Feed section

lets you control the feed

direction and speed of the

currently selected tool.

The Spindle Rotation section lets you operate and

control the spindle of the

currently selected tool.

The ALL STOP

button immediately stops all

CPT motion.

WARNING

If the system is connected

and hydraulic and electrical

power are energized, any

computer commands can

activate machine motion.

Make sure all personnel are

away from the CPT machine

before performing any

machine operations.

The Clamp section lets

you open and close the

clamps, and “walk” the

CPT along the pipe.

The Tool Mode section

lets you select which tool

is operating. One one tool

can be selected at a time.

The Valve Status

section displays

the iVP valves currently activated

The System Status section

displays communications

with the iVP. (As shown,

there is no connection.)

Figure 4-8. The illustration shows the main operating

sections of the CTP Controller screen.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

17

Subsea Pipeline Repair System

NOTE

There may be a slight lag time (a few tenths of a second)

from the time you select a control on the screen and when

the tool responds. You may need to slightly anticipate a stop

point and select the control accordingly.

Deployment/Recovery Mode

IMPORTANT

The Deployment/Recovery Mode button is at the top of the

screen. The status light next to it will light green when the

button is activated.

The ROV must be attached to

the docking station on the

CPT before you release the

clamps. Releasing the

clamps without the CPT

being secured could cause

the CPT to fall from the pipe

and be damaged.

Figure 4-9. Click the Deployment/Recovery Mode

button to activate the mode. This lets you release both

clamps and install or remove the CPT on the pipe.

Use deployment/recovery mode for mounting or dismounting the machine on the pipeline. Deployment/recovery

mode must be active before you can release both clamps.

Make sure the ROV is securely attached to the CPT before

activating deployment/recovery mode.

Water Ingress Alarm

The iVP controller program will signal an alarm if water

gets into the hydraulic system. As you operate the CPT,

monitor the iVP Water Ingress Alarm in the System Status

section of the screen. If the alarm indicates water in the

hydraulic system, stop the machine and recover it topside to

purge and repair the hydraulics.

18

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Using the CPT iVP Controller Program

Figure 4-10. Monitor the Water Ingress Alarm at all

times during operation of the CPT.

Operating the Clamps

Closing and Opening Clamps

There are CLOSE and OPEN buttons for each clamp. If the

clamp is closed, the CLOSED indicator is highlighted in

green.

•

•

To close a clamp that is not closed (CLOSED indicator is

not highlighted), click the 9A or 10A CLOSE button. The

clamp will close and the CLOSED indicator will highlight.

NOTE: A single click will close the clamp.

To release a clamp that is closed (CLOSED indicator is

highlighted), first click the 9A or 10A CLOSE button. An

alert will ask if you want to release it.

NOTE

If you are operating the CPT

with a customer-supplied

HPU, make sure it provides

25 gpm flow and has 10micron filtration on the pressure side.

Click Yes to release the clamp. The CLOSED indicator will

unhighlight. The clamp will be released, but will not

open until you click the 9B or 10B OPEN button.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

19

Subsea Pipeline Repair System

•

To open a clamp, first release it as described above, then

click the 9B or 10B OPEN button. If you click the OPEN

button before you release the clamp, you will get the following alert message.

NOTE: You must click and hold the 9B or 10B OPEN

button to open the clamp, as shown below.

•

To open both clamps, you must be in Deployment/

Recovery Mode, as described in the previous section. If

you try to open the second clamp without first selecting

Deployment/Recovery Mode, you will get an error message:

Walking the Machine on the Pipe

To walk the CPT along the pipe, you must have one clamp

released and one closed, then operate the walk cylinder. If

you try to operate the walk cylinder with both clamps

closed, you will get an error message:

20

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Using the CPT iVP Controller Program

Walking motion is performed by alternately releasing one

clamp and then the other, and operating the walking cylinder to move the clamping frames together and apart. The

CPT walks along the pipe in a “caterpillar” fashion.

Refer to the following procedures and the figures to walk

the CPT.

Walking the CPT Forward In the Tool Direction

1.

Release the Aft clamp (click the 10A button to unhighlight the CLOSED indicator).

2.

Open the Aft clamp by clicking and holding the 10B

button until the OPEN indicator lights.

3.

Click and hold the Walk Cylinder Together button (5B).

The cylinder will retract and pull the Aft clamp assembly forward on the pipe. Hold the button until the cylinder is fully retracted.

4.

Click the 10A button to close the Aft clamp.

5.

Release the Fwd clamp (click the 9A button to unhighlight the CLOSED indicator).

6.

Open the Fwd clamp by clicking and holding the 9B

button until the OPEN indicator lights.

7.

Click and hold the Walk Cylinder Apart button (5A).

The cylinder will extend and push the Fwd clamp

assembly forward on the pipe. Hold the button until

the desired position is reached, or until the cylinder is

fully extended.

8.

Click the 9A button to close the Fwd clamp.

9.

Repeat this process until the rotating frame is in the

desired position.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

NOTE

If you are moving the CPT

farther than the stroke of the

walk cylinder (8”/203 mm),

you will have to perform multiple steps.

21

Subsea Pipeline Repair System

NOTE

10. Release the Aft clamp and hold the 5A button to

extend the walk cylinder fully. Close the Aft clamp.

The clamp assemblies must

be extended apart before cutting. This provides the most

stable mounting on the pipe.

Figure 4-11. Release the Fwd clamp and operate the

walk cylinder Apart to move the front of the machine

forward on the pipe.

22

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Using the CPT iVP Controller Program

Figure 4-12. Release the Aft clamp and operate the

walk cylinder Together to bring the back of the

machine forward on the pipe.

Walking the CPT Backward Away from the Tool

Direction

1.

Release the Fwd clamp (click the 9A button to unhighlight the CLOSED indicator).

2.

Open the Fwd clamp by clicking and holding the 9B

button until the OPEN indicator lights.

3.

Click and hold the Walk Cylinder Together button (5B).

The cylinder will retract and pull the Fwd clamp

assembly back on the pipe. Hold the button until the

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

23

Subsea Pipeline Repair System

desired position is reached, or the cylinder is fully

retracted.

NOTE

If you are moving the CPT

farther than the stroke of the

walk cylinder (8”/203 mm),

you will have to perform multiple steps.

NOTE

4.

Click the 9A button to close the Fwd clamp.

5.

Release the Aft clamp (click the 10A button to unhighlight the CLOSED indicator).

6.

Open the Aft clamp by clicking and holding the 10B

button until the OPEN indicator lights.

7.

Click and hold the Walk Cylinder Apart button (5A).

The cylinder will extend and push the Aft clamp

assembly back on the pipe (away from the rotating

frame). Hold the button until the cylinder is fully

extended.

8.

Click the 10A button to close the Aft clamp.

9.

Repeat this process until the rotating frame is in the

desired position.

10. Release the Aft clamp and hold the 5A button to

extend the walk cylinder fully. Close the Aft clamp.

The clamp assemblies must

be extended apart before cutting. This provides the most

stable mounting on the pipe.

24

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Using the CPT iVP Controller Program

Figure 4-13. Release the Aft clamp and operate the

walk cylinder Apart to move the back of the machine

backward on the pipe.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

25

Subsea Pipeline Repair System

Figure 4-14. Release the Fwd clamp and operate the

walk cylinder Together to move the front of the

machine backward on the pipe.

Rotating the Face Plate

NOTE

You can operate the face

plate with only one clamp

closed if you are doing weld

seam removal using Single

Clamp Mode. For stability, the

Forward clamp should be

closed.

26

Both clamps must be closed before you can rotate the face

plate. You will get an error message if both clamps aren’t

closed:

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Using the CPT iVP Controller Program

1.

Click the Normal or Fast button to set the maximum

speed. Normal mode is used when operating one of the

cutting tools; it limits the speed for safe operation of

the machine.

• If you try to change the speed mode while the frame

is rotating, you will get an error message:

2.

To rotate the face plate counter-clockwise, click the

4B button. The face plate will start to rotate.

NOTE

You can change the limits for

Fast and Normal operation on

the Tool Setup screen. See

the instructions in Chapter 4.

NOTE

You do not have to hold the

button to keep the face plate

rotating. It will rotate until you

click the STOP button.

Figure 4-15. Click the 4B button to rotate the face

plate counter-clockwise.

3.

To rotate the face plate clockwise, click the 4A button.

The face plate will start to rotate.

Figure 4-16. Click the 4A button to rotate the face

plate clockwise.

4.

Set the rotating speed by dragging the Speed Adjust

slider.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

27

Subsea Pipeline Repair System

Figure 4-17. Move the slider to adjust the rotating

speed. If you are in Normal speed mode, you cannot

increase the speed above the maximum (default 50%).

5.

To stop the rotation, click the STOP button.

Figure 4-18. Click the STOP button to stop the face

plate rotation.

Setting the Tool Operating Mode

Select the tool you want to operate in the Tool Operating

Mode section of the screen. When you click on the button,

the corresponding tool will highlight on the rotating frame.

28

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Using the CPT iVP Controller Program

Figure 4-19. Click the button for the tool you want to

operate. The tool will be highlighted on the rotating

frame.

The Spindle Rotation Speed and Spindle Feed controls are

active for the currently selected tool.

When the FBE Coating Removal tool is selected, the Reverse

Direction button is activated. This is the only tool that can be

operated in reverse. Use the Reverse Direction mode when

mounting a new coating removal pad (see “Operating the

FBE Coating Removal Tool” later in the chapter).

Figure 4-20. You can operate the FBE Coating

Removal tool in reverse for mounting a new coating

removal pad.

When the Weld Removal & I.D. Bevel tool is selected, the Single Clamp Mode button is activated. You can perform weld

seam removal using only one clamp, if necessary because of

an irregular pipe. For stability, operate the machine with the

forward clamp engaged.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

29

Subsea Pipeline Repair System

Figure 4-21. You can operate the weld seam removal

tool using Single Clamp Mode if necessary.

SET-UP AND DEPLOYMENT

Tooling Installation

Install new tooling in all three tools before each deployment. Using new tooling for each repair operation will

reduce the risk of tool or machine failure.

1.

Assemble the severing end mill and O.D. bevel tool

with the tool holder and tighten the two set screws.

Figure 4-22. Assemble the severing/O.D. bevel tooling and secure with the set screws.

2.

30

Insert the tool holder into the spindle shaft of the severing/O.D. bevel tool.

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Set-Up and Deployment

3.

Align the flat of the tool holder with the set screw in

the spindle shaft, and tighten the set screw.

4.

Insert the weld removal/I.D. bevel tool holder into the

spindle shaft of the weld removal/I.D. beveling tool.

5.

Align the flat of the tool holder with the set screw in

the spindle shaft, and tighten the set screw.

6.

Insert the threaded shaft of the FBE removal pad into

the spindle shaft of the FBE removal tool, and screw

the pad all the way into the spindle.

Operational Pre-Test

Start with the CPT mounted on the deployment frame.

Before deploying the system subsea, cycle through all operations and visually verify correct performance.

1.

With the CPT upright on the deployment frame

mounting pipe, connect the hydraulic and electrical

hot stabs. Enable hydraulic and electrical power.

2.

Start up the control computer and start the Wachs CPT

Controller Program. See the previous section for

instructions on using the program.

3.

Close the forward and aft clamps by clicking the button for each clamp. Visually ensure that the clamps

close.

4.

Walk the CPT forward on the mounting pipe. See

“Walking the Machine on the Pipe” in the previous

section.

5.

Walk the CPT backward on the mounting pipe. See

“Walking the Machine on the Pipe” in the previous

section.

6.

Operate the rotating face plate 190° in each direction.

See “Rotating the Face Plate” in the previous section.

7.

Select the Sever Pipe & O.D. Bevel tool and operate the

spindle.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

NOTE

Each time you do the Operational Pre-Test, you must

complete and sign a copy of

the Pre-Dive Checklist at

the end of this chapter.

WARNING

Make sure all personnel are

clear of the machine before

operating it. Severe injury

could result from contact with

the machine during operation.

31

Subsea Pipeline Repair System

8.

With the Sever Pipe & O.D. Bevel tool selected, operate

the spindle feed in both directions.

9.

Select the Weld Removal & I.D. Bevel tool and operate

the spindle.

CAUTION

Stop the spindle feed before

the tool reaches the mounting

pipe. Severe damage to the

tool could result.

10. With the Weld Removal & I.D. Bevel tool selected, operate the spindle feed in both directions.

11. Select the FBE Coating Removal tool and operate the

spindle. Click the Reverse Direction button and operate

the spindle in the reverse direction.

12. With the FBE Coating Removal tool selected, operate the

spindle feed in both directions.

13. Operate the cameras to make sure they are working.

Weld Seam Calibration

For each pipe project, you should adjust the radial travel

limit of the weld seam milling tool. You will need a pipe

section originating from the repair site to do this calibration.

Refer to the detailed instructions in this chapter for mounting and dismounting the CPT on a workpiece. The CPT

must be connected to hydraulic and electrical power to perform the calibration.

32

1.

Remove the CPT from the deployment frame.

2.

Mount and clamp the CPT to the recovered pipe section. Calibration will be easiest if the pipe weld seam

is facing upward.

3.

If the weld seam tooling is not installed, insert the

weld removal/I.D. bevel tool holder into the spindle

shaft of the weld removal/I.D. beveling tool. Align the

flat of the tool holder with the set screw in the spindle

shaft, and tighten the set screw.

4.

Rotate the pivot stop on the weld seam tool to the

enabled position (so that it will stop the feed drive), as

shown in Figure 4-26.

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Set-Up and Deployment

Pivot stop

handle

Stop bolt

Figure 4-23. Turn the pivot stop to the “enabled”

position shown, which stops the feed drive when the

stop bolt contacts the pivot.

5.

At the control computer, click on the Weld Removal &

I.D. Bevel button to select it.

6.

The spindle feed drive should be fully retracted in the

Feed Out direction.

7.

Set the face plate rotate speed to Fast. Click either the

4A or the 4B button to rotate the face plate until the

weld seam tool is just to the right (the clockwise side)

of the weld seam. Stop the rotation.

8.

Operate the spindle feed drive in the Feed In direction

at 50% speed, watching the distance between the weld

seam tool and the pipe surface. Stop the feed drive

when the tool just reaches the surface.

9.

Turn the stop bolt (shown in Figure 4-23) so that it

contacts the pivot stop. This sets the stop position for

the weld seam feed drive.

10. Operate the spindle feed drive in the Feed Out direction to retract the drive.

11. Return the face plate back to the starting position.

12. Unclamp and remove the CPT from the pipe section.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

33

Subsea Pipeline Repair System

Subsea Deployment

1.

Start with the CPT mounted on the deployment frame

as described in “Mounting the CPT on the Deployment Frame” earlier in this chapter.

2.

Disconnect the topside hydraulic and electrical connections from the CPT. Put the plugs into the connectors on the CPT.

3.

Lift the assembly using the lift arm on the deployment

frame, and lower it to the subsea worksite.

4.

Using the ROV, remove the plug in the hydraulic connector and place it in its storage slot on top of the CPT.

5.

Using the ROV, plug the hydraulic hot stab into the

connector on the CPT.

6.

Using the ROV, remove the plug in the electrical connector and place it in its storage slot on top of the CPT.

7.

Using the ROV, plug the electrical hot stab into the

connector on the CPT.

Mounting the CPT on the Pipeline

Make sure the hydraulic and electrical stabs are connected

to the machine before removing it from the deployment

frame. You will need them connected to operate and open

the clamps.

1.

34

Engage the lift attachments on the ROV with the ROV

docking station on top of the CPT.

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Set-Up and Deployment

Figure 4-24. Engage the ROV lifting attachments in

the holes of the docking station.

2.

At the control computer, click the Deployment/Recovery Mode button.

Figure 4-25. Click the Deployment/Recovery Mode

button to allow the clamps to open.

3.

Click the 9A and 10A buttons to release both clamps.

4.

Click and hold the 9B button until the forward clamp is

fully open.

5.

Click and hold the 10B button until the aft clamp is

fully open.

6.

Using the ROV, lift the CPT off the mounting pipe of

the deployment frame.

7.

Position the CPT over the cutting location on the pipeline, with the rotating frame oriented toward the pipe

end being serviced.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

35

Subsea Pipeline Repair System

8.

Lower the CPT onto the pipeline. Make sure both

clamp assemblies are fully on the pipe.

9.

At the control computer, click the 9A and 10A buttons

to close both clamps.

IMPORTANT

Make sure the clamp pads

are not contacting the pipe on

a weld seam.

10. Click the Deployment/Recovery Mode button to disable deployment/recovery mode.

11. Disengage the ROV from the ROV docking station on

the CPT.

12. Move the CPT to the precise cutting location using the

procedure in the “Walking the Machine on the Pipe”

section earlier in this chapter.

SEVERING OPERATION

NOTE

Perform the severing cut in

three stages, as shown

below. Cut during stage 1,

reposition the tool during

stage 2, and finish the cut in

stage 3.

1. Cut

CW 190°

3. Cut CW

180° to finish

36

2. Reposition

CCW 360°

The sever operation can only cut in the clockwise direction. The cut must finish at the top so that the fall-off

section of the pipe does not damage the cutting tools.

Therefore, you will start at the top and cut 190° clockwise

around to the bottom. Then reposition the frame 360°

counter-clockwise to start in the end of the slot and continue

clockwise cutting back to the top of the pipe.

1.

Make sure the rotating frame is in the open position,

with the sever tool at the top of the pipe.

2.

Click on the Sever Pipe & O.D. Bevel button to activate

the sever tool.

3.

Operate the spindle feed drive in the Feed In direction,

visually observing the position of the tool. Stop the

drive when the tool is about 1 inch from the pipe surface.

4.

Click the spindle rotation START button to start the

spindle. Set the spindle rotation speed to 76%.

5.

Operate the spindle feed drive in the Feed In direction,

and set the feed speed to 60%.

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Severing Operation

6.

Continue feeding in until the end mill breaks through

the pipe and goes beyond about 1 inch. Make sure the

O.D. bevel cutter is not in contact with the pipe. Stop

the spindle feed drive.

7.

Set the rotate speed to Normal, and click the 4A button

to start the face plate rotation in the clockwise direction. Set the speed adjust slider to 50%.

8.

Operate the face plate rotation for about 190°, until the

cutter is just beyond halfway around the pipe. Click

the 4A button to stop the face plate rotation.

NOTE

The spindle feed drive will

stop when you release the 6A

or 6B button, or the speed

control slider.

CAUTION

Sever cuts must be performed in the clockwise

direction.

9.

Operate the spindle feed drive in the Feed Out direction until the tool is fully retracted.

10. Set the rotate speed to Fast, and click the 4B button to

start the face plate rotation in the counter-clockwise

direction.

11. Rotate the face plate 360° around back to the bottom

of the pipe. Click the 4B button to stop the face plate

rotation.

CAUTION

Leave the spindle rotation

drive running while operating

the spindle feed drive. The

tooling could be damaged by

contact with the pipe while it

is not running.

12. Operate the spindle feed drive in the Feed In direction,

with the feed speed at 60%. (The spindle rotation

drive must be running.) Check that the end mill feeds

into the slot made previously.

13. Feed in until the mill is about 1 inch beyond the pipe

I.D. Stop the spindle feed drive.

14. Set the rotate speed to Normal, and click the 4A button

to start the face plate rotation in the clockwise direction. Set the speed adjust slider to 50%.

15. Operate the face plate rotation until the severing operation is complete and the pipe end falls off. Click the

4A button to stop the face plate rotation.

16. Operate the spindle feed drive in the Feed Out direction until the tool is fully retracted.

17. Set the rotate speed to Fast, and click the 4B button to

CAUTION

All sever cuts must end at

the top of the pipe. Otherwise, the falling cut-off piece

may damage the equipment.

start the face plate rotation in the counter-clockwise

direction.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

37

Subsea Pipeline Repair System

18. Rotate the face plate 180° back to the bottom of the

pipe. Click the 4B button to stop the face plate rotation.

19. Leave the machine in its current position for the O.D.

bevel operation.

O.D. BEVEL OPERATION

The O.D. bevel operation is performed with the sever tool

immediately after the severing operation. Do not reposition

the machine after severing.

The O.D. bevel operation must be performed in the

clockwise direction.

1.

The Sever Pipe & O.D. Bevel button should still be

active.

2.

Set the face plate rotate speed to Fast, and click the 4B

button to start the face plate rotation in the counterclockwise direction.

3.

Rotate the face plate 180° counter-clockwise to the

bottom of the pipe. Click the 4B button to stop the face

plate rotation.

4.

Click the spindle rotation START button to start the

spindle. Set the spindle rotation speed to 76%.

5.

Operate the spindle feed drive in the Feed In direction,

with the feed speed at 60%. (The spindle rotation

drive must be running.) While monitoring the cut with

the video camera, feed until the bevel tool reaches the

required chamfer depth, then stop the feed drive.

6.

Set the rotate speed to Normal, and click the 4A button

to start the face plate rotation in the clockwise direction. Set the speed adjust slider to 50%.

7.

Operate the face plate rotation until the bevel is complete around the pipe. Observe the width of the chamfer as the cut is made. Use the spindle Feed In or Feed

Out buttons if necessary to adjust the chamfer.

8.

When the bevel is complete, click the 4A button to

stop the face plate rotation.

CAUTION

O.D. beveling cuts must be

performed in a clockwise

direction.

38

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: I.D. Bevel Operation

9.

Operate the spindle feed drive in the Feed Out direction until the tool is fully retracted.

I.D. BEVEL OPERATION

To perform the I.D. bevel, you must “walk” the rotation

frame forward to position the tool beyond the end of the

pipe. The I.D. bevel is performed with the weld seam

removal tool.

The I.D. bevel cutting operation must be performed in a

clockwise direction. Before starting, you will rotate the

face plate counter-clockwise to the starting position.

1.

Use the walk cylinder controls to move the I.D. bevel

cutter forward past the end of the pipe. See the instructions in “Walking the Machine on the Pipe” earlier in

this chapter.

2.

Using the ROV, rotate the pivot stop on the weld seam

tool to the disabled position (out of the way of the feed

drive), as shown in Figure 4-26.

Pivot stop

handle

Stop bolt

Figure 4-26. Turn the pivot stop to the “disabled”

position shown, which allows the feed drive to feed in

past it.

3.

Click on the Weld Removal & I.D. Bevel button to activate the weld seam tool.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

39

Subsea Pipeline Repair System

4.

Operate the spindle feed drive in the Feed In direction

until the tooling is past the I.D. of the pipe.

5.

Use the walk cylinder controls to move the beveling

edge of the I.D. bevel cutter into the end of the pipe.

Stop before the shaft of the tool touches the pipe end.

6.

With the Fwd clamp closed, move the Aft clamp apart

to spread the clamps all the way. Close the Aft clamp.

7.

Set the face plate rotate speed to Fast, and click the 4B

button to start the face plate rotation in the counterclockwise direction.

8.

Rotate the face plate so that the weld seam tool is at

the bottom of the pipe. Click the 4B button to stop the

face plate rotation.

9.

Click the spindle rotation START button to start the

spindle. Set the spindle rotation speed to 85%.

10. While monitoring the cut with the video camera, operate the spindle feed drive in the Feed Out direction

until the I.D. bevel tool reaches the desired chamfer

depth,. Stop the feed drive.

11. Set the rotate speed to Normal, and click the 4A button

CAUTION

I.D. beveling cuts must be

performed in a clockwise

direction, starting at the bottom of the pipe.

to start the face plate rotation in the clockwise direction. Set the speed adjust slider to 50%.

12. Operate the face plate rotation until the bevel is com-

plete around the pipe. Watch using the video camera to

observe the width of the chamfer as the cut is made.

Use the spindle Feed In or Feed Out buttons if necessary to adjust the chamfer.

13. When the bevel is complete, click the 4A button to

stop the face plate rotation.

14. Operate the spindle feed drive in the Feed In direction

to move the tooling inside the I.D. of the pipe.

15. Use the walk cylinder controls to move the I.D. bevel

cutter forward past the end of the pipe.

16. Operate the spindle feed drive in the Feed Out direction until the tooling is past the O.D. of the pipe.

17. Use the walk cylinder controls to move the face of the

weld seam removal/I.D. bevel tool back over the O.D.

40

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Weld Seam Removal Operation

of the pipe. The machine is now in position for the

weld seam removal.

WELD SEAM REMOVAL OPERATION

The weld seam removal is performed in multiple passes performed by the rotating frame. The rotating frame direction for weld seam removal is counter-clockwise. For

each new pass, you will walk the machine along the pipe 3

inches (76 mm).

1.

The Weld Removal & I.D. Bevel button should still be

active.

2.

Using the ROV, rotate the pivot stop on the weld seam

tool to the enabled position (so that it will stop the

feed drive), as shown in Figure 4-26.

Pivot stop

handle

CAUTION

Make sure that you have calibrated the stop bolt position

before deployment, as

described earlier in this chapter.

Stop bolt

Figure 4-27. Turn the pivot stop to the “enabled”

position shown, which stops the feed drive when the

stop bolt contacts the pivot.

3.

The spindle feed drive should be fully retracted in the

Feed Out direction.

4.

Set the face plate rotate speed to Fast. Click either the

4A or the 4B button to rotate the face plate until the

weld seam tool is just to the right (the clockwise side)

of the weld seam. Stop the rotation.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

41

Subsea Pipeline Repair System

5.

Operate the spindle feed drive in the Feed In direction

at 50% speed until the stop bolt contacts the pivot

stop. The clutch will kick out. Stop the spindle feed

drive.

6.

Click the spindle rotation START button to start the

spindle. Set the spindle rotation speed to 85%.

7.

Set the rotate speed to Normal, and click the 4B button

to start the face plate rotation in the counter-clockwise

direction. Set the speed adjust slider to 50%.

8.

When the weld seam tool has fully crossed the seam,

click the 4B button to stop the face plate rotation.

9.

Operate the spindle feed drive in the Feed Out direction to retract the drive.

10. Set the face plate rotate speed to Fast. Click the 4A button to rotate the weld seam tool back across to the

right side of the seam. Stop the rotation.

11. Operate the clamps and the walk cylinder to walk the

machine 3” (76 mm) for the next weld seam pass.

Fully extend the Aft clamp before cutting.

12. Repeat the weld seam procedure for the required number of passes. When finished, fully retract the spindle

feed drive and turn off the spindle rotation.

Single Clamp Mode

You can perform weld seam removal with only one clamp

closed, if necessary because of an irregular pipe.

When the Weld Removal & I.D. Bevel tool is selected, the Single Clamp Mode button is activated. Click on the button to

engage single clamp mode. For stability, operate the

machine with the forward clamp engaged.

Figure 4-28. You can operate the weld seam removal

tool using Single Clamp Mode if necessary.

42

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: FBE Coating Removal

FBE COATING REMOVAL

The FBE coating removal is performed in multiple passes

performed by the rotating frame. For each pass, the frame

goes around the pipe counter-clockwise and then returns

over the same path clockwise. This ensures that the coating

is completely removed.

For each new pass, you will walk the machine along the

pipe about 5 inches (127 mm).

1.

Click the FBE Coating Removal button under Tool Operating Mode.

2.

Make sure that the Reverse Direction button is not

highlighted.

3.

Operate the clamps and the walk cylinder to position

the tool at the desired starting position along the

length of the pipe. Fully extend the walk cylinder and

close the Aft clamp before cutting.

4.

Set the face plate rotate speed to Fast, and click the 4A

button to start the face plate rotation in the clockwise

direction.

5.

Rotate the face plate until the FBE removal tool is at

the bottom of the pipe. Click the 4A button to stop the

face plate rotation.

6.

Operate the spindle feed drive in the Feed In direction.

Watch the spring on the FBE tool as the tool contacts

the pipe surface. Stop the spindle feed when the spring

is compressed to about 1/2 its travel.

7.

Click the spindle rotation START button and set the

spindle speed as follows:

• 70% for a 24 inch pipe

• 75% for a 20 inch pipe

• 82% for a 12 inch pipe (green FBE).

8.

Set the face plate rotate speed to Fast. Click the 4B button to start rotating the face plate counter-clockwise,

and set the face plate rotate speed to 75%.

9.

Operate the FBE tool 380° around the pipe to overlap

the pass at the bottom. Stop the face plate rotation.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

NOTE

The FBE pad wheel life

expectancy is a minimum of 2

passes (both directions) on a

24” pipe, or 4 passes (both

directions) on a 12” pipe.

After making the minimum

number of passes, carefully

monitor the cleaning quality

through the camera. If the

cleaning becomes “spotty”,

you can re-run over the

incomplete areas. If the

wheel leaves too much FBE

material behind, change the

wheel; see instructions at the

end of this section.

CAUTION

Start the face plate rotation

immediately after you start

the spindle rotation. If the

FBE removal pad stays in

one place on the pipe too

long, it can damage the pipe

surface.

43

Subsea Pipeline Repair System

10. Click the 4A button to start the face plate rotation

clockwise, and set the face plate rotate speed to 100%.

Operate the tool all the way back around the pipe to

the original starting position.

11. Stop the spindle rotation.

12. Operate the spindle feed drive in the Feed Out direction to retract the drive.

13. Operate the clamps and the walk cylinder to walk the

machine about 5” (127 mm) for the next pass. Fully

extend the Aft clamp before cutting.

14. Repeat the FBE coating removal procedure for the

required number of passes. When finished, fully

retract the spindle feed drive and turn off the spindle

rotation.

Replacing the FBE Removal Pad

The FBE coating removal pad may need to be replaced,

depending on how much FBE is being removed. You will

need to have 2 FBE pad replacement jigs at the worksite,

one empty and one pre-loaded with a new FBE pad.

There is a mounting post on the coating removal tool for the

FBE pad replacement jigs. When you mount the jigs on the

post, they are correctly aligned for removing and installing

the FBE pads.

44

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: FBE Coating Removal

Jig mounting

post

Figure 4-29. The mounting post holds and aligns the

FBE pad replacement jigs.

Pre-Configuring the FBE Replacement Tools

Before deploying the CPT, you will need to configure the 2

FBE replacement jigs. The two jigs are identical, but you

will pre-configure them differently:

•

•

one jig (the removal jig) will be used to remove the old

FBE pad

the second jig (the installation jig) will be used to install

the new FBE pad.

1.

Install an FBE pad into the spindle of the coating

removal tool and screw it in securely.

2.

Mount the first replacement jig (the removal jig) on

the jig mounting post on the coating removal tool.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

45

Subsea Pipeline Repair System

Mount jig

on post

Jig

mounting

post

Figure 4-30. Mount the pad replacement jig on the

mounting post.

3.

Pull the frame locking pin out of the jig.

Figure 4-31. Pull out the frame locking pin in the jig.

4.

46

Swing the spring arm toward the coating removal tool

so that the pad holder on the jig is in position to load

the FBE pad.

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: FBE Coating Removal

Figure 4-32. Swing in the spring arm on the jig.

5.

If the pad holder is not precisely aligned to accept the

pad, use the adjustment screws shown in the following

figures to align it.

Figure 4-33. Use the indicated adjustment screw to

set the radial position of the FBE pad holder.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

47

Subsea Pipeline Repair System

Figure 4-34. Use the two adjustment screws shown to

set the axial stop position of the swing arm.

Figure 4-35. The 8 adjustment screws shown are in

slotted holes. Loosen them and move the arm on the

bracket to center the FBE pad holder on the spindle.

48

6.

When the pad holder is aligned, swing the spring arm

back to the open position and re-insert the frame locking pin.

7.

Take the removal jig off the jig mounting post.

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: FBE Coating Removal

8.

Insert the replacement FBE pad into the pad holder of

the installation jig. Press it in firmly to seat it all the

way.

Figure 4-36.

9.

Make sure the spring arm on the installation jig is in

the open position and that the frame locking pin is

installed.

Removing the Old FBE Pad at the Deployment Site

Both the FBE removal jig and pre-loaded installation jig

must be deployed at the worksite and available for the ROV.

1.

At the control computer, select the FBE Removal tool

mode.

Figure 4-37. Click the FBE Coating Removal button

to select it.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

49

Subsea Pipeline Repair System

NOTE

The spindle feed drive must

be fully retracted for the

removal jig to align with the

FBE pad.

2.

Operate the spindle feed drive all the way in the Feed

Out direction.

3.

Using the ROV manipulator, pick up the FBE removal

jig by the ROV interface handle.

4.

Using the ROV, mount the removal jig on the jig

mounting post on the coating removal tool. Push it

securely onto the post.

Lift jig by ROV interface handle

Mount jig

on post

Jig

mounting

post

Figure 4-38. Lift the jig by the ROV interface handle

and mount it on the mounting post.

5.

50

Using the ROV, pull out the jig frame locking pin.

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: FBE Coating Removal

Figure 4-39. Pull out the jig frame locking pin.

6.

Grasp the ROV interface handle on the jig, and swing

the spring arm down to engage the pad holder onto the

FBE pad. Push the arm in to fully seat the pad in the

holder.

IMPORTANT

To remove the old pad, you

must operate the FBE Coating Removal tool in Reverse

Direction mode.

Figure 4-40. Swing the spring arm in to engage the

FBE removal pad (shown in pad holder in this photo).

7.

At the control computer, click the Reverse Direction

button under FBE Coating Removal to highlight it.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

51

Subsea Pipeline Repair System

Figure 4-41. Click on the Reverse Direction button.

8.

Operate the coating removal spindle at 100% speed.

The shaft of the FBE pad will thread out of the spindle

as it rotates.

9.

When the shaft is fully threaded out, stop the spindle

drive.

10. Click the Reverse Direction button to de-select it.

Figure 4-42. Click the Reverse Direction button to deselect it.

11. Grasp the ROV interface handle on the jig, and swing

the spring arm to the open position.

Figure 4-43. Swing the spring arm out to the open

position.

52

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: FBE Coating Removal

12. Pull the removal jig off the jig mounting post and

return it to the deployment area.

Installing the New FBE Pad at the Deployment Site

1.

Using the ROV manipulator, pick up the FBE installation jig by the ROV interface handle.

2.

Using the ROV, mount the installation jig on the jig

mounting post on the coating removal tool. Push it

securely onto the post.

Lift jig by ROV interface handle

Mount jig

on post

Jig

mounting

post

Figure 4-44. Lift the jig by the ROV interface handle

and mount it on the mounting post.

3.

Using the ROV, pull out the jig frame locking pin.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

53

Subsea Pipeline Repair System

Figure 4-45. Pull out the jig frame locking pin.

4.

Grasp the ROV interface handle on the jig, and swing

the spring arm down to position the pad holder against

the spindle.

Figure 4-46. Swing the spring arm in to position the

FBE removal pad for installation.

5.

54

Pull the ROV interface handle on the jig in the radial

direction (toward the center of the CPT) until the shaft

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: FBE Coating Removal

of the new FBE pad can “snap” into position over the

end of the spindle.

Figure 4-47. Use the ROV to pull the replacement

FBE pad into installation position.

6.

Release the ROV interface handle.

7.

At the control computer, make sure the Reverse Direction button under FBE Coating Removal is not highlighted.

IMPORTANT

To install the new pad, you

must operate the FBE Coating Removal tool with

Reverse Direction mode

disabled.

Figure 4-48.

8.

Operate the coating removal spindle at 40% speed.

The shaft of the FBE pad will thread into the spindle

as it rotates.

E.H. Wachs

Part No. 08-060-MAN-OP, Rev. 2-0710

55

Subsea Pipeline Repair System

NOTE

There may be a slight lag

time (a few tenths of a second) from the time you select

a control on the screen and

when the tool responds. You

may need to slightly anticipate a stop point and select

the control accordingly.

9.

When the shaft is fully threaded on, stop the spindle

drive. You may stop early to prevent the threads from

impacting too tightly. (The shaft will snug into the

spindle when the tool is operated.)

10. Grasp the ROV interface handle on the jig, and swing

the spring arm out to release the FBE pad.

Figure 4-49.

11. Pull the installation jig off the jig mounting post and

return it to the deployment area.

REMOVING THE CPT FROM THE PIPELINE

56

1.

Make sure that the spindle feed drives on all three

tools are fully retracted.

2.

Make sure that the spindle rotation drive is stopped.

3.

Operate the rotating frame drive so that the rotating

frame is in the open position for removal.

4.

Engage the lift attachments on the ROV with the ROV

docking station on top of the CPT.

Part No. 08-060-MAN-OP, Rev. 2-0710

E.H. Wachs

Chapter 4, Operating Procedures: Removing the CPT from the Pipeline