The Taylor Clamp Carrier

advertisement

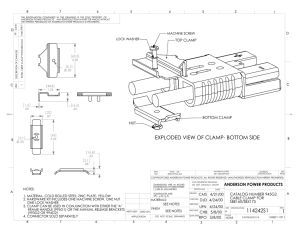

The Taylor Clamp Carrier Model - #CC-M2, #80V, #80DU SN - ________ 108 Parker Ave. Poughkeepsie, NY 12601 Tel: (845)-452-3780 Fax: (845)-452-0764 E-mail: info@jamesltaylor.com Web: http://www.jamesltaylor.com D#CC-#80V-#80DU-R3 TABLE OF CONTENTS #80V Hydraulic Clamp INTRODUCTION....................................................................4 Limited Warranty.................................................................................... 6 RULES FOR SAFE OPERATION..........................................7 Types of Warnings.................................................................................. 8 General Safety Rules............................................................................. 9 INSTALLATION....................................................................10 Clamp Carrier Specifications.............................................................. 11 Clamp Carrier Section Installation..................................................... 16 Motor Drive Installation....................................................................... 22 Installing the Front Rest...................................................................... 24 Hooking Up the Hydraulic Motor Drive Hoses.................................. 25 Hooking Up the Clamp Tightener Hoses............................................ 26 Installing the Breather Cap................................................................. 28 Hooking Up the Electrical Power........................................................ 28 Installing the Clamps........................................................................... 31 Starting the Hydraulic Power Unit...................................................... 32 Testing the Hydraulic Motor Drive...................................................... 32 Testing the Panel Flattener.................................................................. 33 Adjusting the Panel Flattener.............................................................. 33 Testing and Adjusting the Clamp Tightener and Hydraulic Motor Drive........................................................................................................... 34 Installing Optional Clamp Equipment................................................ 36 OPERATION........................................................................39 Safety & Training.................................................................................. 40 Coating the Clamps............................................................................. 41 Setting up the clamps.......................................................................... 41 Loading the Clamp Carrier.................................................................. 41 Operating the Clamp Tightener, Panel Flattener & Hydraulic Motor Drive........................................................................................................... 41 Panel Flattener Safety.......................................................................... 42 Shutting Down at Night........................................................................ 42 Clamping Force vs. Clamp Tightener Hydraulic Pressure............... 44 D#CC-#80V-#80DU-R3 TABLE OF CONTENTS Glue Line Clamping Pressure............................................................. 45 General Operation................................................................................ 46 TROUBLESHOOTING.........................................................48 Wiring Diagram..................................................................................... 49 Tightener Troubleshooting.................................................................. 50 Panel Flattener Will Not Extend.......................................................... 51 Panel Flattener Pneumatic Schematic............................................... 52 MAINTENANCE...................................................................53 Maintenance Checklist......................................................................... 54 PARTS & SERVICE..............................................................55 Recommended Lubricants for the Air Motor Drive Gear Box:......... 56 800220 Tightener Model Sheet............................................................ 57 800198 Front Rest Model Sheet.......................................................... 60 #CC-M2 Clamp Carrier Model Sheet................................................... 63 #202 & #302 Clamp Model Sheet........................................................ 64 800216 Flattener Model Sheet............................................................. 65 Bates Boothcoating - Glue Release................................................... 66 Parts Order Form.................................................................................. 72 D#CC-#80V-#80DU-R3 INTRODUCTION INTRODUCTION INTRODUCTION D#ALL-1-R2 4 INTRODUCTION This manual contains important information about the installation, operation and maintenance of your Clamp Carrier. We urge you to read it carefully, become familiar with the components and features it describes, and follow its recommendations, to help make your edge gluing trouble-free and productive. D80-210-R2 5 INTRODUCTION We at James L. Taylor Mfg. Co. would like to thank you and your company for selecting the Taylor Clamp Carrier. With proper care, your Clamp Carrier will provide you with many years of the highest quality, most trouble-free edge gluing available. INTRODUCTION (This supersedes all previous warranties) James L. Taylor Manufacturing guarantees all products of its manufacture to be free of defects in ­workmanship or material when properly installed, serviced and maintained under normal conditions. James L. Taylor Manufacturing’s obligation under this warranty is limited to repair­ing or replacing any part or parts thereof which shall within one (1) year after shipment to the original user, be returned to its factory, transportation charges prepaid, and which James L. Taylor Manufacturing’s examination shall disclose to be defective. James L. Taylor Manufacturing assumes no liability for labor charges incidental to the adjustment, service, repairing, or removal or replacement of parts or other losses, or for ex­pense of repairs made outside of its factory, except when made pursuant to James L. Taylor Manufacturing’s PRIOR written consent. James L. Taylor Manufacturing does not guarantee equipment furnished by us, but manufactured by others, such as belts, electric motors, starters, controls or other electrical equip­ment or accessories, as they are guaranteed separately by their respective manufacturers. James L. Taylor Manufacturing assumes no liability whatever for any of these parts claimed to be defective or for damages or delays caused by defects beyond making such repair or furnishing duplicate parts within the manufacturer’s warranty, nor shall we be liable for any defective material repaired or replaced without our consent. The foregoing shall constitute the fulfillment of all of our obligations under this warranty and there are no other warranties or guarantees, expressed or implied except as stated herein. D#ALL-2-R2 6 INTRODUCTION Limited Warranty RULES FOR SAFE OPERATION RULES FOR SAFE OPERATION RULES FOR SAFE OPERATION D#ALL-3-R2 7 RULES FOR SAFE OPERATION Types of Warnings This is the safety alert symbol. It is used to alert you to potential injury hazards. ! RULES FOR SAFE OPERATION Obey all safety messages that follow this symbol to avoid possible injury. DANGER in white letters on a safety red background with a safety red exclamation point. ! DANGER ! WARNING ! CAUTION This indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious injury. WARNING in black letters on a safety orange background with a safety orange exclamation point. This indicates a potentially hazardous situation which, if not avoided, COULD result in death or serious injury. CAUTION in black letters on a safety yellow background with a safety yellow exclamation point. This indicates a potentially hazardous situation which, if not avoided, COULD result in minor or moderate injury. D#ALL-3-R2 8 RULES FOR SAFE OPERATION General Safety Rules • Follow lockout procedure before servicing. • Read and understand manual before operating machine. • See the plant supervisor to determine what protective equipment each job requires. • Follow electrical and fire codes. • Do not wear loose clothing, jewelry or long hair around operating equipment. • Keep guards in protective position when machine is operating. • Keep clear of belts chains and moving parts. ! DANGER Lockout ALL energy sources before servicing. D#ALL-3-R2 9 RULES FOR SAFE OPERATION • Wear eye protection. INSTALLATION INSTALLATION Clamp Carrier Specifications Production 126 Panels per day Electrical Requirements None Air Requirements None 8 1/2' 12 Section Clamp Carrier w/ Swing Style CT/PF, SDAMD 315 panels per day None 14cfm @90 psi 8 1/2' 20 Section Clamp Carrier w/ Semi Auto. CT, PF, HDAMD 360 panels per day None 14cfm @90 psi (1" Air Line) 8 1/2' 20 Section Clamp Carrier 360 panels w/ Semi Auto. Hyd. CT, PF, HMD per day 240/480v Three phase 4 cfm @90 psi(3/8" Air Line) 8 1/2' 40 Section Automated Clamp Carrier 840 Panels per day 120v Single Phase 20 cfm @90 psi(1" Air Line) 8 1/2' 40 Section Hydraulic Automated Clamp Carrier 980 Panels per day 240/480v Three Phase None 8 1/2' 60 Section Dual Hydraulic Auto. Clamp Carrier 1930 panels per day 240/480v Three Phase None #128 Polyvinyl Glue Pump 6 gal. per hour 120v Single Phase None Plate Spreader For up to 20 sec. CC None None 16' Conveyorized For 20 sec. & up CC 240/480v 3-Phase None Opti-Sizer 6' For 20 sec. & up CC 240/480v 3-phase 1cfm @ 60 psi. INSTALLATION Machine 8 1/2' -6 Section Clamp Carrier Manual Clamp Carrier A. Height: 8'4" + 2" for every inch of clamp opening over 32" B. Length: Number of sections: 6 Overall length: 7'9" 12 9'4" 20 11'6" 30 13'11" 40 16'4" Notes: Add 2" to the dimension above for every inch of clamp opening over 32". The distance from the rear shaft to the rear wall should be at least 50" + 1" for every inch of clamp opening over 32". C. Width: Machine size: Overall Width: 8 1/2' 10'1/4" 10 1/2' 12'1/4" Unglued Stock 12 1/2' 14'1/4" 16 1/2' 18'1/4" A C B Glued Stock 3'-0" D80-178-R4 11 INSTALLATION Swing Style Clamp Carrier A. Height: 8'4" + 2" for every inch of clamp opening over 32" B. Length: Number of sections: 6 Overall length: 7'9" 12 9'4" 20 11'6" Notes: Add 2" to the dimension above for every inch of clamp opening over 32". The distance from the rear leg to the rear wall should be at least 50" + 1" for every inch of clamp opening over 32". C. Width: Machine size: Overall Width: 8 1/2' 10'1/4" 10 1/2' 12'1/4" B Unglued Stock A C INSTALLATION Glued Stock 3'-0" Semi-Automatic Clamp Carrier A. Height: 8'4" + 2" for every inch of clamp opening over 32" B. Length: Number of sections: 6 Overall length: 7'9" 12 9'4" 20 11'6" 30 13'11" 40 16'4" 60 21'2" Notes: Add 2" to the dimension above for every inch of clamp opening over 32". The distance from the rear leg to the rear wall should be at least 50" + 1" for every inch of clamp opening over 32". C. Width: Machine size: Overall Width: 8 1/2' 10'1/4" 10 1/2' 12'1/4" 12 1/2' 14'1/4" 16 1/2' 18'1/4" B A C Unglued Stock Glued Stock 3'-0" D80-178-R4 12 INSTALLATION Automated Clamp Carrier A. Height: 8'4" + 2" for every inch of clamp opening over 32" B. Length: Number of sections: 20 Overall length: 11'6" 30 13'11" 40 16'4" 60 21'2" 80 26' Notes: Add 2" to the dimension above for every inch of clamp opening over 32". The distance from the rear shaft to the rear wall should be at least 50" + 1" for every inch of clamp opening over 32". C. Width: Machine Size: Overall Width: 8 1/2' 11'7" 10 1/2' 13'7" 12 1/2' 15'7" 14 1/2' 17'7" 16 1/2' 19'7" 20 1/2' 23'7" C 3'-0" Glued Stock D80-178-R4 Unglued Stock 13 INSTALLATION A B INSTALLATION Dual-Automated Clamp Carrier A. Height: 8'9" + 2" for every inch of clamp opening over 32" B. Length: Number of sections: 60 Overall length: 22'1" 80 26'11" Notes: Add 2" to the dimension above for every inch of clamp opening over 32". The distance from the rear shaft to the rear wall should be at least 50" + 1" for every inch of clamp opening over 32". C. Width: Machine Size: Overall width: 8 1/2' 14'7" 10 1/2' 16'7" C Glued Stock HPU Glued Stock B Unglued Stock D80-178-R4 14 INSTALLATION A ++- INSTALLATION INSTALLATION Overview of Machine Installation 1st 2nd 3rd 4th D#CC-1-R3 Install Clamp Frame Install Carrier Drive Install Front End (Tightener/Flattener) Install Clamps 15 INSTALLATION Clamp Carrier Section Installation When unpacking your machine, make sure that you have all the necessary frame pieces: Cross Channel Right Side Runway Left Side Runway Front Shaft Assembly INSTALLATION Rear Leg Center Leg Front Leg 1. Number of Runways: Width of Machine 8 1/2' 10 1/2' 12 1/2' 14 1/2' 16 1/2' 20 1/2' 2. Number of Legs: Number of Sections 20 30 & 40 60 80 # of Runways 2 side 2 side, 1 center 2 side, 2 center 2 side, 2 center 2 side, 2 center 2 side, 3 center 3. Number of Cross Channels: # of Legs 2 front & 2 rear 2 front, 2 rear & 2 center 2 front, 2 rear & 4 center 2 front, 2 rear & 6 center # of Cross Channels 2 3 4 5 Note: On larger width machines, the frame may be partially assembled. D#CC-1-R3 16 INSTALLATION Other Frame Configurations Due to the width of the frame and its number of sections, many frames may appear different: INSTALLATION Rear Shaft Rings MUST be assembled as shown and tensioned. If they are not kept tight, damage to your machine will result. D#CC-1-R3 17 INSTALLATION Assembling the Frame The frame pieces are marked "RF" (Right Front), "LR" (Left Rear), etc. to aid in their identification: RR Rear Center RF LR Front LF RF LR INSTALLATION L LF Note: The frame was marked at the factory with hash marks" to aid in the identification of mating pieces. 1. Attach the "RF" end of the right side runway to the right front leg (also marked "RF") with (1) 1/2" x 1-1/4" hex cap screws and (1) socket head cap screw. Place (2) 1/2 X 2" Hex cap screws into the top two holes on the rear of the side runway. These bolts will be used for the cross channels. Leave them loose for now. Attach the "RR" end of the right side runway to the right rear leg ("RR") with (1) 1/2" x 1-1/4" hex cap screws and (1) socket head cap screw. The socket head cap screws go in the top holes in the legs. 2. Attatch the "LF" end of the left side runway to the left front leg ("LF") with (1) 1/2" x 1-1/4" hex cap screws and (1) socket head cap screw. Again, place (2) 1/2 X 2" Hex cap screws into the top two holes on the rear of the side runway. These bolts will be used for the cross channels. Leave them loose for now.Attach the "LR" end of the left side runway to the left rear leg ("LR") with (1) 1/2" x 1-1/4" hex cap screws and (1) socket head cap screw. The socket head cap screws go in the top holes in the legs. 3. Slide the "Front" and "Rear" cross channels through the left, and right runways. After removing the 1/2" x 1-1/4" socket head cap screws that were installed in steps 1 and 2, fasten each end of each cross channel to the side runways with (2) 1/2" x 2" and (1) 1/2" x 1-1/4" socket head cap screws. D#CC-1-R3 18 INSTALLATION 4. Bolt the right ("R") and left ("L") center legs (if provided) to the left and right side runways with (2) 1/2" x 1-1/4" flat head screws per leg. 5. Slide the "Center" cross channel(s) (if provided) through the left and right runways, and bolt it (them) to the side runways with (3) 1/2" x 2" hex cap screws per leg. Installing the Front Shaft 1. Set the assembled shaft on the front legs. (Note: The ends of the front shaft assembly are marked "R" and "L" respectively on the keyways and bearings.) 2. Insert one roll pin into each end bearing and front leg. Pull the end bearings down and bolt them onto the front legs. Installing the Rear Shaft Placing the Machine 1. Place the frame in the exact position it is to occupy. Use the dimensions from the "Clamp Carrier Specification Sheet" in this manual. Note: Be sure to either place the rear of the Clamp Carrier against a wall or otherwise guard the rear of the Carrier to prevent injury to passersby that may inadvertently walk into the exposed clamps. Squaring the Frame 1. Square the machine by measuring the diagonals from the vertical angle irons attached to the front and rear legs. 2. Level the runways from front to rear and the cross channel(s) from right to left, shimming the legs as necessary. 3. Shim the center legs, if the Carrier is equipped with them, as necessary, to avoid pulling the side runways downward at their centers. 4. Lag the legs to the floor. D#CC-1-R3 19 INSTALLATION 1. Slide a collar, a rear sprocket (has grease fitting, no keyway) with grease fitting facing out, and a second collar onto each end of the rear shaft. Leave the collars loose for now. 2. Lift the shaft and insert the ends of the shaft into the yokes in the rear legs. 3. Rotate the rear shaft such that the tapped holes in the ends of the shaft are horizontal, with the over-bored ends of the holes toward the rear of the machine. Insert two 1/2" x 6" full thread bolts through the yokes. Thread on lock nut between the yoke and the shaft and then insert bolts into the tapped holes in the ends of the shaft. Tighten the bolts only a few turns. (Note: The rear shaft remains stationary when the Carrier rotates.) INSTALLATION Installing the " I " Beams The I beam sections are shipped partially assembled. They look something like this: The Section number and "L" for "Left" (1L, 2L, 3L, etc.) is Stamped into the first side link of each section 8' or more Rope Rope Rope Rope 3. Find I beam section number 2. Lift it onto the front of the Carrier frame, in front of section number 1. Be sure that the "2L" mark is on the left side of the machine. 4. Using the spare 5/8" hex cap screws, and wheels, join the side links of the two sections together. Tighten the 5/8" hex cap screw, allowing just enough clearance for the wheel to turn freely. Lock the screw in place with a 5/8" hex nut. Leave the center links unconnected for now. 5. Install the remaining I beam sections in the same manner. Notes: At each interval, be sure to secure the ropes to prevent the I beam sections from running off the back end of the machine. Also, in rolling the I beams around the rear shaft, the assembly must be kept taut by pulling on both ropes simultaneously. The side link joints will fit into the large tooth spaces of the sprockets. D#CC-1-R3 20 INSTALLATION 1. Find I beam section number 1. Lift it onto the front of the Carrier frame, onto the upper tracks of the side and center runways. Be sure that the "1L" mark is on the left side of the machine, with the mark toward the rear of the machine. 2. Attach two ropes to I beam section number one. You will pull on these ropes to advance the sections around the frame and to keep the sections from falling off the front or rear of the machine: INSTALLATION D#CC-1-R3 21 Front INSTALLATION 6. The closing of the assembly is done on the front sprockets. The two open ends of the side links must enter a tooth space of the sprocket simultaneously in order for them to fit together properly. 7. Join the center links between each I beam section with hex cap screws. 8. Position the rear sprockets on the rear shaft such that all of the clearance between the side rollers and the side runways is on the left side of the machine; there should be no clearance between the side rollers and the side runways on the the right side of the machine.. Position the collars against the sprockets and tighten the set screws to lock them in place. 9. Tighten the I beam/chain assembly with the adjusting screws in the rear shaft. Remove all slack from the chain. Tighten the lock nuts to keep the adjusting screws in place. 10. Check that the I beam/chain assembly rotates freely on the frame. If not, make adjustments as necessary. 11. Grease the side runways (particularly the right side runway) and side roller bolt heads to minimize friction between the side roller bolt heads and the vertical faces of the side runways. Rear Adjusting Screw Lock Nut INSTALLATION Motor Drive Installation If your Carrier Rotation Motor Drive has not been installed at the factory, you will find a package of parts used in for the installation. Your Carrier Rotation Motor Drive may be Standard Duty, Medium Duty or Heavy Duty and either pneumatic or hydraulic powered depending upon your machine selection and may be slightly different from the unit shown in the photos and drawings. Installation will be the same. Spacer Key Hydraulic Motor Drive Bolt Lock Washer Disc Flat Washers (May or may not be needed) Reaction Plate 1. Slide the large (painted) spacer onto the right end of the front shaft. 2. Slide the Motor Drive onto the right end of the front shaft until the Drive contacts the large spacer. The plate at the bottom of the Motor Drive should enter between the two uprights of the front leg. 3. Rotate the front shaft to align the keyway in the shaft with the keyway in the Motor Drive. 4. Insert the longest key possible. 5. Several pipe spacers have been supplied, each of different length. You will use only one of them. Select the pipe spacer that will project slightly beyond the right end of Motor Drive's hollow shaft as the other end of the spacer contacts the front shaft. Use flat washers if you have difficulty obtaining the correct length. 6. Secure the Motor Drive with the disc, 1/2" lockwasher, and 1/2" hex head bolt. 7. Remove the plug (shown in black) from the Motor Drive and replace it with a plastic vented plug (supplied). This will minimize pressure build-up in the Motor Drive. D#80S-1-R2 Plugs 22 Right Hand Motor Drive (Heavy Duty Hydraulic Shown) INSTALLATION Mounting the Motor Drive on the Front Shaft Large Spacer INSTALLATION The Standard Duty Air Motor Drive Installed on the Front shaft of a Tubular Clamp Carrier INSTALLATION Rear view of the Standard Duty Air Motor Drive Installed on the Front shaft of a Tubular Clamp Carrier IMPORTANT Make sure that the vented plugs have been installed and the small plugs have been removed from them. Oil may have leaked from the motor drive during shiping. Check the oil level and fill as necessary BEFORE STARTING THE MOTOR DRIVE. A low oil level may result in damage. D#80S-1-R2 23 Cylinder Bracket Front Rest Carriage Cylinder Positioning Plate Installing the Front Rest 1. Attach the cylinder brackets to the front legs of the Clamp Carrier, approximately 12" from the tops of the legs. 2. Secure the two positioning plates to the front legs of the Carrier frame with the U-bolts supplied. 3. Attach the base of the front rest to the two positioning plates. Secure with 1/8 x 1-1/2 cotter pins. 4. Swing the front rest up and attach the cylinders to the front rest. 5. Lag the positioning plates to the floor. 6. Adjust the cylinder brackets for proper placement on the front legs. The ends of the clamps should just overlap the top rail of the front rest when the front rest is in its upright position. D80-211-R3 Installing the Clamp Tightener 1. Remove the carriage retaining bolt from one end of the front rest carriage track. Slide the Clamp Tightener carriage onto the front rest. Replace and tighten the retaining bolt. 2. Mount the cam ring on the Hydraulic Motor Drive. Tighten the set screw lightly. The cam ring will be adjusted later. 3. Mount the cam valve on the Hydraulic Motor Drive as shown. Hooking Up the Hydraulic Motor Drive Hoses Carriage Retaining Bolt Foot Valve Assembly D80-211-R3 Air Filter/ Lubricator Assembly 1. Mount the air filter/lubricator assembly on the right front leg of the Clamp Carrier. 2. Connect the air supply line. It must be 3/8" pipe or larger. 3. Position the foot valve assembly to the right side of the front rest in a comfortable position. Note: Place the foot valve assembly 48" from the right front of the clamp carrier. Fasten it to the floor. 4. Attach the 1/4" hose from the fitting on the foot valve assembly to the union fitting on the filter/lubricator assembly. Note: The ends of the hoses are color coded for easy identification. 5. Move the Hydraulic Power Unit into position at the right front of the Clamp Carrier. Note: On machines built with two tighteners and flatteners there are two hydraulic power packs supplied. The power pack which has one valve removed will be located on the left side of the machine. 6. Attach the 1/8" Air hoses from the Foot Valve to the Hydraulic Power Unit. 7. Attach the 1/2" Hydraulic Hoses from the Hydraulic Power Unit to the Hydraulic Motor Drive. Note: If the machine is supplied with two hyraulic motor drives, the right power pack will supply both hydraulic motor drives. Hooking Up the Clamp Tightener Hoses 1. Attach the 1/2" Hydraulic hoses to the clamp tightener motor. 2. Attach the 3 pieces of 1/8" tubing to the coupling block at the bottom of the carriage. 3. Attach the 1/4" hose to the coupling block at the bottom of the carriage. 4. Connect the free end of the long 1/2" hoses to the Hydraulic Power Unit. 5. Connect the 1/4" hose from the tightener to the tee on the filter/lubricator/regulator assembly. 6. Connect the 2 pieces of 1/8" tubing to the hydraulic power unit. The remaining piece of 1/8" tubing will connect to the panel flattener beam. Note: If you did not order a panel flattener with your machine, you will need to discard the 1/8" hose for the safety circuit. Also, you will need to plug the port for the safety circuit on the carriage with the 1/8" pipe plug that is included. 7. Connect the short 1/4" tube from the cam valve to the tee on the top of the air filter/lubricator/regulator assembly. 8. Connect the long 1/4" tube from the cam valve to the left end of the pilot operated valve D80-211-R3 3 Phase Power Disconnect Switch Carrier Index Speed Control D80-211-R3 on the foot pedal assembly. 9. Feed the long 1/4" tubes from the center of the valve on the foot pedal assembly through the tunnel at the bottom of the front rest. Connect the free ends of these tubes to the front rest cylinders, according to their color coding. Installing the Breather Cap 1. Remove the solid cap on the Hydraulic Power Unit that is in place for shipping only. Install the breather cap. Hooking Up the Electrical Power 1. Connect the three phase power and ground to the disconnect switch on the Hydraulic Power Unit. Check to be sure the motor is wired for the voltage being used. Refer to the motor name plate and connections in the junction box on the motor. D80-211-R3 INSTALLATION WARNING: Make sure the Clamp Carrier is lagged to the floor before beginning. Cable Bracket Installing the Overhead Track: "A D80-294-R1 29 INTSTALLATION Brace " 1. The uprights and braces have been atTrack tached to the Overhead Track for shipping. Upright Remove the uprights from the track. The braces will be found inside the uprights. Slide the braces out of the uprights. 2. The Overhead Track is actually two tracks back to back, with one side slightly lonBrace ger than the other so that the upright can Mount be bolted to the track. Lay the track on the floor, in front of the Clamp Carrier, so Front that shorter side of the track is facing the Rest clamp carrier and the longer side is facing away. Make sure that the metal flange or Positioning "Friction Stop" is on top. Plate 3. If not already done, separate the Panel Flattener carriage (the roller assembly that will sit inside of the tracks) from the Panel Flattener by removing the clevis pin and hoses (See photos on the following page) . Slide the carriage of the flattener into the short side of the track that is facing toward the Carrier, so that the vertical wheels are towards the ground. 4. Attach the end of the uprights with a single hole to the outsides of the positioning plates using 1/2" X 3" hex head cap screws and lay the free end on the floor. Attach the end of the braces with a single hole ­to the outside of the uprights using 1/2" X 3" hex head cap screws. 5. Lay the track long side down to attach the uprights to the track. Be sure to place the cable brackets on the side of the uprights opposite the track. Make sure the one with the larger 1/2" elbow is on the right, and the one made from 1" square steel is on the left. Use 1/2" X 4" hex head cap screws, 1/2" lock washers, and two 1/2" flat washers per screw to sandwich the uprights between the track and the cable brackets (See photos on the following pages). 6. Attach the brace mounts (angles) to the side runways (or front legs for a 6-section Carrier) with 1/2" X 1" hex head cap screws. Tubular 12 and 20 section machines come with brace mount blocks welded to the sides. 7. Swing the Overhead Track upward and attach the free ends of the braces to the brace mounts with 1/2" X 1-1/4 hex head cap screws. INSTALLATION Mounting the Panel Flattener 1. Line up the Panel Flattener with the corresponding holes in it's carriage. Insert the clevis and hitch pins, and reconnect the hoses. Hooking up the Panel Flattener Hoses: Panel Flattener Carriage D80-294-R1 30 INTSTALLATION 1. Attach one side of the cable to one of the holes on either of the cable brackets. Do this by double nutting the 3/8" hex nuts. Be sure to leave it loose so that it will easily attach to the other side. 2. On the side that faces toward the carrier, slide a 1/8" coiled hose and the 1/4" coiled hose on to the cable and attach it to the other end using the same method. 3. Attach one end of the 1/4" coiled hose to the Flattener carriage and the other end to the right cable bracket. Attach one end of the 1/8" coiled hose to the carriage and the other end to the left cable bracket. 4. Attach one end of the 1/4" coiled hose to the elbow on the carriage and the other end to the right cable bracket. Attach one end of the long 1/8" coiled hose to the elbow on the regulator and the other end to the right cable bracket. 5. Attach one end of the 1/4" air hose to the right bracket and the other end to the 1/4" air regulator located on the side of the clamp carrier. 6. Attach the free end of the 1/8" clear safety pilot hose to the left cable bracket. Attach this hose to the left upright. INSTALLATION Installing the Clamps Mount a clamp to the I-Beam sections using two stampings, a 1/4" x 3-13/16" spacer, a 1/4" x 5" hex cap screw, and a 1/4" elastic stop nut as shown below: 2. Tighten the screw and nut firmly. The clamp will still move in and out 3/16" when pushed or pulled; this is an intentional "floating" feature of the Taylor clamp. 3. Repeat steps 1 and 2 above for each clamp, installing the desired number of clamps on each section. 4. To maintain clamp carrier balance, place clamps on the front and back of the clamp carrier simultaneously. D#202-5-R2 Beveled corners "up" INSTALLATION 1. 31 INSTALLATION Starting the Hydraulic Power Unit 1. Turn the disconnect switch on and then instantly off again while looking at the fan inside the top of the motor. Check to see if the motor is rotating in the direction indicated by the arrow on the outside of the motor case. If the motor is not rotating in the correct direction, switch any two of the three-phase wires. 2. Check again to be sure the direction is correct. 3. Start the Hydraulic Power Unit. Testing the Hydraulic Motor Drive D80-290-R1 32 INTSTALLATION 1. Fill the lubricator bowl with SAE #10 non-detergent oil. 2. Turn the air on. Start the Hydraulic Power unit (if you have not already). 3. Depress the right hand foot pedal on the foot valve assembly marked "reverse". This should cause the front rest to swing outward and the Carrier to rotate in reverse (clamps at the front of the machine moving upward). Depress the left hand foot valve. This should cause the Carrier to rotate forward. INSTALLATION Testing the Panel Flattener Adjusting the Panel Flattener 1. Set the Panel Flattener air pressure as desired, from 10 psi to 90 psi. 2. The Panel Flattener is spring loaded, so that the Flattener cylinder does not hang straight down, but rather at a slight angle toward the Clamp Carrier. This angle can be adjusted, if desired, with two 7/8" x 7/8" socket set screws that are located inside the two 3/4" i.d. x 9" pipes (visible in the lower photo on the previous page) on the Panel Flattener carriage. A special wrench (a bent 1/4" bolt) has been supplied for making this adjustment. D80-289-R1 33 INSTALLATION 1. Fill the lubricator bowl on the air filter/lubricator/regulator assembly (on the Clamp Carrier leg) with SAE #10 non-detergent oil. 2. Turn on the air. Adjust the Panel Flattener air regulator to 10 psi. 3. Engage the Clamp Tightener on a clamp. 4. Press down the tee handle on the Panel Flattener. The Panel Flattener cylinder should extend downward. Release the tee handle. The Flattener should stay down until the tee handle is pulled upward. 5. Make sure that the Panel Flattener cylinder will not extend unless the Clamp Tightener is engaged on a clamp. If it will, recheck the pilot (safety) air circuit. 6. Check the maximum stroke of the Panel Flattener cylinder. You should be able to flatten 1/2" thick stock. If not, recheck the "A" dimension described at the beginning of this Panel Flattener Installation section. INSTALLATION Testing and Adjusting the Clamp Tightener and Hydraulic Motor Drive Note: If clamps are installed only on every other section, remove every other socket head cap screw (3 of the 6) from the cam ring. This will prevent the front rest from swinging in on vacant sections. Likewise, if clamps are installed only on every third section, remove all but two (180 degrees apart) of the 6 screws. 2. If necessary adjust the speed of the Hydraulic Motor drive with the needle valve on the Hydraulic Motor Drive. Closing the valve will slow the rotation of the Clamp Carrier, making it easier to control. D80-284-R2 34 INTSTALLATION 1. Depress the right hand foot pedal on the foot valve assembly marked "reverse". This should cause the front rest to swing outward and the Carrier to rotate in reverse (clamps at the front of the machine moving upward). Depress the left hand foot valve. This should cause the Carrier to rotate forward. At the proper time during rotation, the front rest should swing back in automatically. If the front rest swings in too soon or too late, adjust (turn) the cam ring on the Hydraulic Motor Drive hollow shaft. Once the proper action is obtained, tighten the set screw in the cam ring securely. INSTALLATION CL D80-284-R2 C L 35 INTSTALLATION 3. Check that the Clamp Tightener smoothly engages the nuts on the clamps as they lie on the front rest. The distance from the front of the driver to the nut should be set such that the driver engages the nut completely and evenly on each side of the machine. This is accomplished by sliding the two front rest cylinder brackets up and down the front legs of the Carrier. Be sure to lock these plates securely in place after making the final adjustment. Check this on each side of the machine. The Clamp Tightener height adjustment is made by removing the tightener cover and adjusting the two nuts on the 5/16" threaded rod that supports the wrench mount. The height of the driver should be set such that it's center line is slightly above the center line of the nut. This accommodates give in the suspension as the driver is extended. 4. Adjust the lubricator such that five drops of oil drip (in the sight bubble at the top of the lubricator) for each stroke of the front rest cylinders, in or out. The Clamp Carrier should use at least 1/3 of a bowl of oil per week. INSTALLATION Installing Optional Clamp Equipment Installing Rocker Plates 1. While pulling outward on the spring-loaded clips on the sides of the Rocker Plates, slide one Rocker Plate onto each jaw of the clamp. 2. Adjust the Rocker Plates such that the pivot points of the Rocker Plates are centered on the stock to be glued. D#202-3-R2 36 INSTALLATION When gluing thin panels (less than 3/4"), or laminatining (2" to 6" thick), special additions are needed. Holddown bars are designed for edge gluing thin panels (less than 3/4"). They prevent the boards from springing out of the clamps during tightening and curing. They are easily removed when not needed. Rocker plates are used for laminating (2" to 6" thick) and are needed for two reasons. First, they extend the height of the jaws to cover the full thickness of the material. Secondly, since our clamps have "toe-in", rocker plates are necessary to evenly distribute the clamping force from top to bottom. They can be installed or removed in seconds. Hook Slides In Side of Front Jaw Easily Adjustable for Different Stock Thicknesses 37 Shoe adjusts easily to Center of Panel New Bracket Replaces Mounting stamping. Easily installed in field with one bolt. Detent Mechanism to hold bar up. Move bar to left to release detent. Material: Scale: 1/6 11/23/98 V.J.L S80-2000 Poughkeepsie, N.Y., U.S.A. James L. Taylor Mfg. Co. #202 Clamp w/ Detented Holddown This Holddown assembly is designed to work in conjuction with the Automated, Semi Automated, and Conventional Clamp Tighteners. When gluing thin panels it helps reduce the problem of boards popping out of the clamps. The holddown bar is hooked in first and then the panel is tightened and flattened 80-613 Spring Holds Hook in place 2 1/2" INSTALLATION D#202-3-R2 High Jaw S80-2000 INSTALLATION Installing Holddown Bars INSTALLATION DISMANTLING: To dismantle the machine, reverse the Installation (Assembly) instructions. INSTALLATION D#CC-6-R2 38 OPERATION D#ALL-5-R2 39 OPERATION OPERATION OPERATION Safety & Training According to many OSHA, ANSI, STATE, and LOCAL CODES it is the EMPLOYER'S RESPONSIBILITY to: • Permit only trained and authorized employees to operate equipment. • Inspect and maintain guards, safety devices, and start/stop controls. • Instruct, train, and supervise the safe method of work ! Be sure personnel are properly trained and safety rules are clearly understood before operating or performing maintenance! OPERATION D#ALL-5-R2 40 OPERATION The intended use of this Semi-Auto Clamp Tightener is to apply clamping pressure to wood during a gluing operation. Coating the Clamps A 16-oz. spray bottle is supplied with your machine for coating the clamps with Bates Boothcoating. Pour the Boothcoating directly from the 1-quart can into the spray bottle and adjust the nozzle. Spray a light mist of Boothcoating over all areas that will come in contact with the glue. You may also want to spray some on the horizontal tee bars to make sliding the clamps from side to side easier. Additional quantities of Boothcoating can be purchased from: U.C. Chemical Corp. P.O. Box 1066 2250 Fillmore Avenue Buffalo, NY 14215 Phone: 716-833-9366 See the brochure at the back of this manual for further details. 1. Clamps should be spaced no more than 18" apart. 2. For laminating or face gluing, be sure to use Rocker Plates to insure even pressure across the face of the stock. Loading the Clamp Carrier The Clamp Carrier should be kept relatively balanced at all times . When first loading an empty machine with heavy stock it may be necessary to first load one section of clamps, then rotate the machine one-half turn (180 degrees) and load the second section. Continue rotating the Carrier by one-half turns while loading the remaining sections. The same method may also be used in unloading. Operating the Clamp Tightener, Panel Flattener & Hydraulic Motor Drive 1. Load stock into the clamps on one section (row of clamps) of the Clamp Carrier. 2. Start at the left side of the Clamp Carrier. Using the tee handle, slide the Panel Flattener along the beam until it is located between the first two clamps to be tightened. At the same time, with the other hand, slide the Clamp Tightener along the front rest until it is in front of the first clamp to be tightened. Push and pull the tee handle on the Panel Flattener to center the Flattener shoe on the panel. Twist the handle left and right to dodge the jaws of the clamps if necessary. D80-213-R2 41 OPERATION Setting up the clamps OPERATION Engage the Clamp Tightener on the first (left) clamp. 4. While holding the joystick control forward of the tightener, press down the tee handle on the Panel Flattener. The Flattener cylinder should extend downward. You may release the lever and tee handle. The Flattener should stay down until the tee handle is pulled upward. 5. Tighten the clamp that is to the left of the Panel Flattener (or both clamps if there are only two clamps on the panel). You tighten a clamp by pressing the lever on the carriage away from the operator and holding this lever until the motor comes to a stall. The clamp force achieved corresponds to the pressure setting on the hydraulic power unit. You can adjust this pressure by turning the appropriate knob on the hydraulic unit. Note that you will only be able to read the pressure setting while the tightener motor is stalled on a clamp. See the section on "Clamping Force" to determine the proper setting for your panel. 6. Release the Panel Flattener by pulling upward on the tee handle. 7. Position the Panel Flattener between the next pair of clamps to be tightened. Engage the Flattener. 8. Tighten the clamp that is to the left of the Flattener. If the Flattener is between the two last clamps on the panel, tighten both clamps. 9. Repeat the above steps for the remaining clamps on this section. 10. Slide the Panel Flattener to one side so it will clear the clamps when the Clamp Carrier is rotated. 11. Briefly depress the right foot pedal on the foot valve assembly. The Clamp Carrier will rotate backwards and the front rest will swing outward. Depress the left D80-213-R2 42 OPERATION 3. OPERATION foot pedal to rotate the Carrier forward. The front rest will swing back to its upright position automatically. At the appropriate time, release the foot pedal. This may take a little practice, as you'll want the machine to rotate far enough that all of the clamps make good contact with the front rest, but not so far that the clamps are pinned too tightly against the front rest to be slid easily from side to side. 12. Loosen the clamps and remove the glued panels. Panel Flattener Safety 1. You should have no more than one Clamp Carrier operator per Panel Flattener. The Panel Flattener produces up to 750 pounds of force; this is more than enough to injure a man's hand. 2. Once each day, depress the Panel Flattener tee handle without touching the Clamp Tightener. The Panel Flattener cylinder should not extend. If it does, check the safety air circuit. Do not use the Panel Flattener until proper repairs have been made. Shutting Down at Night D80-213-R2 43 OPERATION 1. Before shutting down at the end of the day, depress the right foot pedal briefly to rotate the Clamp Carrier in the reverse direction. The front rest will swing outward. The air supply to the machine may then be turned off safely. If this procedure is not followed, the front rest will swing outward by itself when the air is turned off. Then, when the air is turned on again in the morning, the ends of the clamps will be hanging down low enough that they will be caught by the front rest when it returns to its upright position. OPERATION Clamping Force vs. Clamp Tightener Hydraulic Pressure The graph below shows the clamping force, per clamp, for Clamp Tightener hydraulic pressures between 0 and 1500 psi. Note: The Tightening Pressure needs to be adjusted while the motor is tightening. Press the joystick forward to tighten to stall. Read the peak pressure on the gage and adjust the knob accordingly. Loosen the clamps and check pressure again while tightening if necessary. Caution: The Hydraulic Clamp Tightener must not be operated to produce more than 3000lbs of force per clamp or damage to your clamps will occur. Note: After the clamps have broken in the actual Clamping Force may be higher than the chart shows. Check your force with a Clamp Force gauge for confirmation. See Taylor for more information. Hydraulic Clamping Force 3500 OPERATION 3000 Clamp Force (lbs) 2500 2000 1500 1000 500 0 0 200 400 600 800 Pressure Setting (psi) D80-214-R2 44 1000 1200 1400 OPERATION Glue Line Clamping Pressure 1. What is your desired glue line pressure (psi)? 2. What is the glue line area (sq. in.)? Glue line area = Length of Panel (in.) x Thickness of panel (in.). 3. Glue line pressure (psi) x glue line area (sq. in.) = total clamping force (lbs). 4. Divide total clamping force by the number of clamps used on the panel. 5. Read the chart above to get the regulator setting (psi). Clamp Iighten Pressure D80-214-R2 45 OPERATION Carrier Index Pressure OPERATION General Operation Coating the Clamps A 16-oz. spray bottle is supplied with your machine for coating the clamps with Bates Boothcoating. Pour the Boothcoating directly from the 1-quart can into the spray bottle and adjust the nozzle. Spray a light mist of Boothcoating over all areas that will come in contact with the glue. You may also want to spray some on the horizontal I-Beams to make sliding the clamps from side to side easier. Additional quantities of Boothcoating can be purchased from: U.C. Chemical Corp. P.O. Box 1066 2250 Fillmore Avenue Buffalo, NY 14215 1. For evenness of joint pressure, clamps on each panel should be spaced no more than 18" apart. 2. For laminating or face gluing, be sure to use Rocker Plates to insure even pressure across the face of the stock. 3. To avoid interference with the panel flattener(s), the clamps must have a minimum spacing of 7" center to center. 4. The edge of each panel must either be flush with the clamp jaw plates or extend 2" beyond the jaw plates. If the panel is between 0" and 2" beyond the jaw plates, the panel flattener(s) may not flatten the panel properly. Loading the Clamp Carrier The Clamp Carrier should be kept relatively balanced at all times. When first loading an empty machine with heavy stock it may be necessary to first load one section of clamps, then rotate the machine one-half turn (180 degrees) and load the second section. Continue rotating the Carrier by onehalf turns while loading the remaining sections. The same method may also be used in unloading. D#CC-2-R2 46 Keep ends flush with jaws or Let ends stick out past jaw 2 -2 1/2" Instruction-placement of wood Scale: Material: James L. Taylor Mfg. Co. Poughkeepsie, N.Y., U.S.A. 8/23/06 JLM OPERATION Setting up the clamps OPERATION Tightening Sequence of the clamps When tightening long members in a clamp carrier, the following sequence should be used to ensure that the finished product remains straight: 1. The center clamp should be tightened. 2. The clamps that are one quarter of the way in from each end of the product should be tightened. 3. The remaining clamps can be tightened from left to right. OPERATION D#CC-2-R2 47 TROUBLESHOOTING TROUBLESHOOTING TROUBLESHOOTING D#ALL-6-R2 48 D#80V-1-R1 49 19 Light Stop 16 27 22 14 6 4 Fuses 16 15 7 5 Fuse Transformer Ground Ground TROUBLESHOOTING Start T2 A1 L2 T3 A2 L3 Magnetic Starter N.O. 3 phase Motor OL 32 14 13 Disconnect Switch Material: Scale: 80W-20 2/27/09 JLM 80W-20 Poughkeepsie, N.Y., U.S.A. James L. Taylor Mfg. Co. #80V Wiring Diagram Ground T1 L1 Incoming 3 Phase Power TROUBLESHOOTING Wiring Diagram TROUBLESHOOTING Tightener Troubleshooting 1. If the machine does not tighten, make sure the "B" - port pressure reducing valve is set to 1000psi. ELBST0004 1/4" Street Elbow FIT.435 1/8NPT x 5/32 Tubing Fitting (14 Times) VALVE02PO.6 1/8 LSC-3200-LPI Versa Valve 80-2167 Cylinder ELBST0002 1/8 Street Elbow E BUSHR0402 1/4 x 1/8 Reducing Bushing ELBST0002 1/8 Street Elbow TUBEPL03.1NY 5/32 Nylon Tubing VALVE02PI.6 1/8 3-Way Pilot - Versa FIT.436 5/32" "Y" Fittings (5 Times) Red Tape Yellow Tape Orange Tape COUST0002 1/8 Steel Pipe Coupling (2Pcs) Safety Tighten D80-215-R2 Loosen Supply 50 TROUBLESHOOTING VALVE03OR.1 5/32 "OR" Valve TROUBLESHOOTING Panel Flattener Will Not Extend 1. Check the air supply. You must have at least a 3/8" pipe air supply, at 90 psi. 2. Check that the Panel Flattener's safety interlock with the Clamp Tightener (the pilot air circuit) is operating properly. If not, make repairs as needed. 3. The Clamp Carrier lubricator should be using approximately 1 bowl of oil per week. If not, adjust the lubricator such that five drops of oil drip (in the sight bubble at the top of the lubricator) for each clamp either tightened or loosened with the Clamp Tightener. 4. If the Panel Flattener has been operated for awhile without oil, the leather cup in the Flattener's air cylinder may be dried out and leaking. New leather cups are available from Taylor. TROUBLESHOOTING D80-119-R2 51 Panel Flattener Pneumatic Schematic TROUBLESHOOTING TROUBLESHOOTING D80-112-R2 52 MAINTENANCE MAINTENANCE MAINTENANCE D#ALL-7-R2 53 MAINTENANCE Maintenance Checklist (Photocopy for use) Weekly Maintenance Checklist Comments Date By Comments Date By • Clean the clamps with a plastic scraper • Apply Bates Boothcoating to the clamps • Oil the screw and thrust washer on each clamp • Check for foreign material underneath the Clamp Carrier • Discharge the accumulated water from the air filter bowl • Fill the air lubricator with SAE #10 motor oil and adjust if necessary • Make sure the Panel Flattener will not extend unless the Clamp Tightener is engaged MAINTENANCE Monthly Maintenance Checklist • Inspect the gear box oil level and add 90 weight extreme pressure lubricant if the level is below midway of the sight glass D#CM-8-R2 54 PARTS & SERVICE PARTS & SERVICE PARTS & SERVICE D#ALL-8-R2 55 PARTS & SERVICE Recommended Lubricants for the Air Motor Drive Gear Box: Atlantic Richfield Co. Chevron Oil Co. Cities Service Oil Co. Continental Oil Co. Gulf Oil Corp. Humble Oil & Refining Co. Kendall Refining Co. Keystone Div.-Penwalt Corp. Mobil Oil Corp. Phillips Petroleum Co. Shell Oil Co. Standard Oil Co. of Br. Columbia, Ltd. Standard Oil Co. of Calif., W. Oper., Inc. Standard Oil Co. (Kentucky) Standard Oil Co. (Ohio) Sun Oil Co. Texaco, Inc. Union 76 Div. Union Oil Co. of CA Warren Refining Div., Parr, Inc. Pennant E.P. S-3150 Cheveron Gear Compound 160 Citgo E.P. Compound 150 or 160 Conoco Milgear L-160 Gulf Transgear Lubricant E.P. 140 Pen-O-Led EP6 Kendall NS-MP-90-140 Hypoid WG-B Mobil Compound GG Philube ILB Gear Oil SAE 140 Macoma 81 Chevron Gear Compound 160 Cheveron Gear Compound 160 Chevron Gear Compound 160 Factolube 6 Sunep 1150 Meropa 6 Union PB Lube 160 882 Gear Lube PARTS & SERVICE D80-66-R2 56 800220 Tightener Model Sheet 800220 57 59 10 58 42 64 65 11 23 15 29 23 1/8" Air Tube 1/4" Air Hose 18 2 30 30 13 1/2" Hydraulic Hose Items 10 and 11 32 19 12 24 22 1 33 4 37 20 28 76 2X 70 3 5 come assembled 33 21 37 76 14 47 9 35 27 34 36 22 24 12 6 77 58 60 10 6 77 57 7 55 26 25 8 69 70 75 68 69 74 71 74 38 69 69 73 72 2X 56 70 48 52 53 49 53 49 50 51 52 49 51 50 51 50 52 46 24 44 24 40 41 43 24 24 67 24 Model 800220 Poughkeepsie, N.Y., U.S.A. James L. Taylor Mfg. Co. Assembly - Semi-Auto Hydraulic Carriage Scale: 1/8 Material: 5/28/04 JTH D80-217-R3 Key # Part Name Description 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. 49. MOTHYD.01SAE FIT.481 SHIM1826.125 BER.WASHER BERTR16 80-2970 80-2975 80-2608 80-2972 FIT.452 HOS.11 PLUGFL02 80-2100 80-2101 CYL.BI.42 101-1009-009 SAE MOTOR 7/8 - 14 'O'RING X #8 JIC STRAIGHT 1 1/8 X 1 5/8 X .125 SHIM 1" ID X .031 THICK WASHER 1" NEEDLE ROLLER THRUST BEARING Collar Assembly - Yoke Driver Wrench Mount - Welded 1/2" DAYCO 8RJ9L-8SA Fitting 1/2" Hydraulic Hose 1/8" Flush Pipe Plug Rod Threaded Tie - Semi-Automated Tube - Delrin - Semi Automated Cylinder SCRSH0524 80-2095 BALLPL30 80-2076 VALVE02PO.9 FIT.447 FIT.435 SCRSH0624 SCRSS0510 80-247 80-2098 NUTES07.14 NUTHX07.20J BUSH0706 WASHFL07 PINCO0116 SCRRH.063216 SPGC06.062.3 NUTHX.0632 SPGC12.062.7 80-2068 5/16 x 1-1/2 Socket Head Cap Screws Wrench Bracket - Welded 1-7/8 Plastic Ball Knob Handle - Assembly 1/8 MV45 Mead 1/4 NPT x 5/32 Tubing Elbow 1/8 NPT x 5/32 Tubing Straight 3/8 x 1 1/2Socket Head Cap Screw 5/16 x 5/8 Socket Set Screw Rod Pivot Rod - Semi Automated 7/16-14 Elastic Stop Nut 7/16-20 Fine Jam Nut 7/16 x .375FK 62486 Bushing 7/16 Flat Washers 3/32 x 1 Cotter Pin 6-32 x 1 Round Head Screws 3/8 x .062 x 2" Compression Spring 6-32 Hex Nut 3/4 x .062 x 1-1/4 Spring Carriage - Body FIT.436 VALVE03OR.1 80-2078 VALVE02PI.6 TUBEPL03.1NY 5/32 "Y" Fitting 5/32 "OR" Valve Wrench Cover 1/8 3-Way Pilot Valve 5/32 Nylon Tubing 80-2077 PINCO0108 80-2165 SCRHH0824 Lower Wheel Mount 3/32 x 1/2 Cotter Pin Upper Wheel Mount - Assembly 1/2 x 1-1/2 HHC Screw D80-217-R3 Quantity 1 2 2 2 1 2 1 1 1 1 Specify Length 2 2 2 1 2 1 1 1 2 2 Specify Qty. 4 1 1 1 4 4 1 2 2 4 2 4 2 1 5 1 1 1 Specify Length 1 2 1 5 Key # Part Name Description 50. 51. 52. 53. 54. 55. 56. 57. 58. 59. 60. 61. 62. 63. 64. 65. 66. 67. 68. 69. 70. 71. 72. 73. 74. 75. 76. 77. WHE.10 BUSH082107 SHIM0812.125 NUTES08.13 Wheel (Bearing) 6203ZZ 1/2 x 21/32 x 7/16 Bushing 1/2 x 3/4 x .125 Shim 1/2-13 Elastic Stop Nut WASHLO05 80-2988 FIT.065 FIT.050 INSHO0402 INSHO0404 5/16" Lock Washer Assembly - Frame MPA 1810 10-32 x 1/8 Reducing Bushing MH-1008-1 1/8PTU x 10-32 MPT 1/4 x 1/8 Hose Insert 1/4 x 1/4 Hose Insert TUBEPL02.1PU HOSAI04 1/8" MUT-1008 Poly U Tube 1/4" Air Hose 80-2968 80-2090 NUTES05.18 GROM.20 80-2091 WASHFL05 SPGC16.125.1 WASHFN05 80-2178 80-2193 WASHFL03 Bracket Threaded Rod 5/16-18 Elastic Stop Nut 5/16 x 1/2 x 11 GA. Grommet Spacer 5/16 Flat Washers 1 x .125 x 1 Compression Spring 5/16 Fender Washer Spacer PVC Spacer 3/16" Flat Washer D80-217-R3 Quantity 5 5 Specify Qty. 5 5 1 2 2 1 1 Specify Length Specify Length 1 1 4 1 1 3 2 2 1 2 2 60 55 2 3 3 2 55 91 78 68 68 91 PARTS & SERVICE D80-218-R2 44 95 1 50 44 78 76 67 67 76 44 44 5 44 44 50 Complete Front Rest Cylinder Assembly 67 67 13 20 64 6 10 5 73 18 17 62 88 89 28 7 27 35 90 26 36 49 24 24 87 23 84 62 71 17 62 11 12 To HYD. PWR. PAC 17 92 56 71 26 56 19 26 56 59 21 22 To FILTER, LUB 21 89 Complete Filter and Lubricator Assembly Complete Foot Valve Assembly 19 72 To HYD. PWR. PAC 25 23 25 Complete Cam Valve w/ mounting plate and air lines 90 Carrier Indexing Motor 9 38 84 62 17 62 14 84 84 60 53 38 31 53 16 Material: Scale: None Model 7/7/98 V.J.L. 800198 Poughkeepsie, N.Y., U.S.A. James L. Taylor Mfg. Co. 120 Heavy Duty Hydraulic Motor Drive 71 17 31 37 To HYD. PWR. PAC 85 8 15 70 54 PARTS & SERVICE PARTS & SERVICE Part Name Description 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. 49. 80-1325CYL.SP.10 CLEVI.10 80-879 80-880 NUTHX06.16 80-1015 80-1174 80-888Red.12 80-299280-824 80-1149 Fit.490 FILO4F20 LUBO4 Fit.065 PD-46 VALVE06PE.1 80-1144 INSHo0404 HOSAI04 Fit.452 Fit.453 HOS.11 Fit.481 80-2704 MOTHYD.02SAE Front Rest - State Overall Length Cylinder 200 X 5 Springville Clevis 1945 Cylinder Bracket-Cylinder-Steel Legs Only Bolt - “U” 80-880 Nut - 3/8" Hex Mounting 32-38", 80-1047 Mounting 40-50" Clamps Bracket - Lub and Filter Front Rest Cylinder Ass’y.(State Clamp Length) Hampton 20:1 - 5GCReducer Complete Valve Assembly ( State Width of Carrier Mounting - foot Valves Key - HDAMD “Shinko” 1/2" sq. - 9" long 1/8 TEE Fitting Filter 1/4 F20 - 02-000 Lubricator 1/4 L20-02-000 MPA 1810 10-32 X 1/8 R. Bushing Washer 3/8" K41EA00-KS6-KF0 Valve Spacer - Front Shaft 2" I.D. - 1/2 long tube 1/4 X1/4 Hose Insert 1/4 Air Hose 1/2"Dayco 8 FJ-8SA Hose Insert 1/2"- 90° Dayco 8RJ9L-8SA 1/2" Hydrau;ic Hose 7/8-14 ‘O’ Ring X #8 JIC Straight Plate - Hyd. Motor Drive 146- 1042-002 SAE Motor SCRHH0856 TEEMA040404 80-1145 Fit.155 Fit.150 80-1148 80-2684 NIP0004 ADP0404 SCRHH0624 WASHL06 NUTHX06.16 HOSAI08 Fit.180 TUBEPL05.2PF NIP0424 Tubepl04.1PF BUSHR0604F COUMA1206 VALVE02LO.2 1/2 X 3 1/2 HHC Screw 1/4 Malleable tee Spacer - 3" long 268P 1/4PTU X 1/4 MPT Straight 268P 1/4PTU X 1/8 MPT Straight Cam - “Shinko” Gear Box 2-15/16 Bore Plate - Steel Leg 1/4 Close Nipple 14 x 1/4 Hose Adapter 3/8 X 1 1/2 HHC Screw 3/8 Lock Waher 3/8-6 Hex Nut 1/2 Air Hose 269P 1/4PTU x 1/8 MPT Elbow 5/16 #55P Poly Flo Tubing 1/4 x 1 1/2 Nipple 1/4 #44P Poly Flo Tube 3/8 x 1/4 Flush Reducing Bushing 3/4 x 3/8 Malleable Coupling 1/8" Lever Valve - VERSA D80-218-R2 Quantity 61 1 2 2 8 8 1 2 1 1 1 1 1 1 1 3 1 2 1 2 Specify Length 2 2 Specify Length 2 1 1 1 1 5 3 3 3 Specify Length Specify Length Specify Length 1 1 1 PARTS & SERVICE Key # PARTS & SERVICE Key # 50. 51. 52 53. 54. 55. 56. 57. 58. 59. 60. 61. 62. Part Name FIT.438 80-1147 BUSHR0402 NIP0424 ADP0406 80-636NIP0006 ELBMA0806 TEEMA060606 BUSHR0604 NIP0448 Description 5/16" Y Tube Fitting Plug - Vented - 3/32 Hole 1/4 x 1/8 Reducing Bushing 1/4 x 1 1/2 Nipple 1/4 x 3/8 Adapter Extension - Cyl. (State Overall Length) 3/8 Close Nipple 1/2 x 3/8 Malleable Elbow 3/8 Malleable Tee 3/8 x 1/4 Reducing Bushing 1/4 x 3 Nipple FIT.050 MH-1008-1 1/8 CTU x 10-32 MPT 63. 64. 65. 66. 67. 68. 69. 70. 71. 72. 73. 74. 75. 76. 77. 78. 79. 80. 81. 82. 83. 84. 85. 86. 87. 88. 89. 90. 91. 92. 93. 94. 95. TUBEPL02.1PU 80-1727 1/8 MUT-1008 Polyu Tube Plate - Cam Valve FIT.439 FIT.440 268P 5/116PTU x 1/8 MPT Straight 268P 5/16PTU x 1/4 MPT Straight 6 4 VALVE04BA.2 BUSHR0602 NIP0224 VALVE002PI.5 1/4" Ball Valve 3/8 x 1/8 Reducing Bushing 1/8 x 1 1/2 Nipple 1/8 Norgren MKOICDA23A000 1 1 1 1 FIT.050 VALVE02QE.1 MH-1008-1 1/8PTU x 10-32 MPT 1/8 SQE-1 Quick Exhaust 2 NIP0002 1/8 Close Nipple 80-1147 TUBEPL02.1PU FIT.155 Plug - Vented 3/32 hole 1/8 MUT - 1008 Polyu Tube 268P 1/4PTU x 1/4MPT Straight Specify Length 1 80-1730 FIT.180 TUBEPL04.1PF FIT.150 BUSHR0402 80-2991 BUSHR1208 MUF08.1 80-897 Assembly - Cam Valve - 120 269P 1/4PTU x 1/8MPt Elbow 1/4 #44P Poly Flo Tube 268P 1/4PTU x 1/8MPT Straight 1/4 x 1/8 Reduce Bushing Ass’y.-Filter and Lubrication 3/4 X 1/2 Reducing Bushing 1/2" Gast Muffler Bracket 1 1 Specify Length 2 2 1 1 1 2 62 1 2 5 2TEEMA 1 1 1 3 Specify Length 1 PARTS & SERVICE D80-218-R2 Quantity 2 2 2 63 BERFB32 Center Bearing 80-1812- Carrier I-Beam 80-3779 Link-Carrier w/ Tapped Holes NUTHX10.11 5/8"-11 Hex Nut (Qty - 1 per) 80-1063 Center Sprocket Assy. PARTS & SERVICE D#CM-16-R2 BERNP31 Ball NP31 Bearing 80-3780 Link-Carrier w/Thru Holes SCRSS0620 3/8" x 1 1/4" Soc Set Screw (Qty - 2 per) SCRHH1036 5/8" x 2 1/4" HHC Screw (Qty - 1 per) NUTHX06.16 3/8"-16 Hex Nut (Qty - 2 per) 80-3325 Center Link - w/Rollers 80-3326 Center Link - w/Rollers & Shims NUTLO08.13 1/2"-13 Lock Nut (Qty - 4 per) 80-3323 9/16" Spacer (Qty - 2 per) Material: Scale: None 10/3/06 JLM #CC-M2 Poughkeepsie, N.Y., U.S.A. James L. Taylor Mfg. Co. Clamp Carrier Parts SCRHH0832.1 1/2" x 2" Thin HHC Screw (Qty - 2 per) SHIM0812.125 1/2" x 3/4" x 1/8" Shim (Qty - 4 every other link) BUSHOI081012 1/2" x 5/8" Oilite Bushing (Qty - 2 per) ROU80.2489 Center Link Roller (Qty - 2 per) SCRSS0840 1/2" x 2 1/2" Soc Set Screw (Qty - 2 per) SCRHH0848 1/2" x 3" HHC Screw (Qty - 2 per) NUTLO08.13J 1/2"-13 Jam Nut (Qty - 2 per) 80-720 Front Sprocket 80-1371 Rear Sprocket (Qty - 2) 80-1373 Front Shaft Key (Qty - 2) 80-1190 Latch Bracket 80-1382-180 Side Link NUTHX06.16 3/8"-16 Hex Nut SCRSH0632 3/8" x 2" SHC Screw NUTHX10.11 5/8"-11 Hex Nut 80-1805 Side Link Wheel SCRHH1044.1 5/8" x 2 3/4" HHC Screw 80-276 Pawl 80-1383-180 Side Link Assembly SPGT30.1010 Thermostat Spring 80-1191 Latch Assembly #CC-M2 Clamp Carrier Model Sheet PARTS & SERVICE #CC-M2 64 STAM80.1777 Stamping (Qty - 2) SCRHH0596 5/16" x 6" HHC Screw SPGC80.613 Comp. Spring 80-102 Clamp Nut PARTS & SERVICE D#202-2-R2 Drawbar length 80-1707 Rocker Plate NUTES05.18 5/16"-18 Elastic Stop Nut SPGC08.047.1 1/2 x .047 x 1 Comp. Spring (Qty - 2) 80-1706 4" to 6" Rocker Assy (Avail. for #302 Only) Material: Scale: None Clamp Parts SPGC08.047.1 1/2 x .047 x 1 Comp. Spring (Qty - 2) SCRHH0596 5/16" x 6" HHC Screw #202 & #302 80-1704 2" to 4" Rocker Assy 8/18/03 V.J.L #202 & #302 Poughkeepsie, N.Y., U.S.A. James L. Taylor Mfg. Co. NUTES05.18 5/16"-18 Elastic Stop Nut 80-1703 Rocker Plate STAM80.1777 Stamping (Qty - 2) SCRHH0480 1/4" x 5" HHC Screw SPACER.2 1/4" x 3 13/16" Spacer NUTES04.20 1/4" - 20 Elastic Stop Nut NUTLO10.11 5/8" - 11 Lock Nut 80-2131 Latch STAM80.975 Clamp Mounting Stamping RIVRH0342 3/16" x 2 5/8" Rivet 80-1681Complete Draw Bar 80-2489 E-Z Clamp Roller 80-1680 Anti-Rotation Stamping 80-632 Drawbar Screw WASHOL18 Oilite Washer Channel Length 80-1833 (For #202 - 2 1/2" High Jaws) 80-1834 (For #302 - 3 1/2" High Jaws) Rear Jaw 80-2424- (For #202 - 2 1/2" High Jaws) 80-2425- (For #302 - 3 1/2" High Jaws) Clamp Body (Includes Rear Jaw) SPGC90C 90C Compression Spring PARTS & SERVICE PARTS & SERVICE 800216 Flattener Model Sheet 800216 FIT.442 5/16" x 1/4" MPT Elbow (Qty. - 2) SPGE12.094.2 3/4" x .094" x 3" EX SP PINHI.13 #13 Hitch Pin (Qty. - 2) PLA80.0810 Small Taylor Patent Plate BOLEY0548 5/16" x 3" Eye Bolt 80-3035 Assy. Carriage - Flattener NIP0448 1/4" x 3" Nipple NUTHX05.18 5/16 - 13 Hex Nut SHIM0812.031 1/2" x 3/4" x .031" Shim (Qty. - 2) NUTHX08.13 1/2 - 13 Hex Nut (Qty. - 4) 80-3072 Assy. Cylinder - Flattener SCRHH0816 1/2" x 1" HHC Screw (Qty. - 2) PINCL0840 1/2" x 2 1/2" Clevis Pin (Qty. - 2) SHIM0812.125 1/2" x 3/4" x .125" Shim (Qty. - 11) WHE.10 Wheel (Bearing) 6203ZZ (Qty. - 6) BUSH082107 1/2" x 21/32" x 7/16" Bushing (Qty. - 6) VALVE04PI.5 1/4" 250AA Pilot With Booster SCHRR0832 1/2" x 2" HHC Screw SCRHH0824 1/2" x 1 1/2" HHC Screw (Qty. - 4) 80-332 Follower SPGE24.148.1 SES 60-150-148 EX SP (Qty. - 2) COUPLE481208 3" Leather Cup 80-345 Filler 80-325 Guide 80-924 Tube 80-324 PIN PLA80.2560 Panel Flattener Sticker 2 3 80-3347 Rod Cylinder - 43" Reach (#80U Only) 1 FIT.065 MPA 1810 10-32 x 1/8" R Bus (Qty. - 6) FIT.055 MLS 1010 10-32 Ell Stud (Qty. - 5) 2 3 1 FIT.050 MH-1008-1 1/8" PTU x 10-32 MP (Qty. - 6) SPGE16.094.1 1" x .094" x 2 1/2" EX SP (Qty. - 2) VALVE02PO.8 1/8" MAC Palm Button Valve (Qty. - 2) SCRRH.083216 8 - 32 x 1" RD HD Screw (Qty. - 4 ) PINCO0316 3/16" x 1" Cotter Pin (Qty. - 2) TUBEPL02.1PU 1/8" MUT-1008 POLYU Tube TUBEPL05.2PF 5/16" #55P Poly Flo Tube 80-399 Shoe - Weld Scale: Material: James L. Taylor Mfg. Co. Poughkeepsie, N.Y., U.S.A. 5/4/04 JTH D#CM-33-R1 65 800216 PARTS & SERVICE Assembly Cylinder 43" Reach 9" Stroke 1 Hand PARTS & SERVICE Bates Boothcoating - Glue Release PARTS & SERVICE D#202-4-R2 66 PARTS & SERVICE PARTS & SERVICE D#202-4-R2 67 PARTS & SERVICE PARTS & SERVICE D#202-4-R2 68 PARTS & SERVICE PARTS & SERVICE D#202-4-R2 69 PARTS & SERVICE PARTS & SERVICE D#202-4-R2 70 PARTS & SERVICE PARTS & SERVICE D#202-4-R2 71 PARTS & SERVICE Parts Order Form 1. Sold to: 2. Ship to: Company __________________________ Address ___________________________ Address ___________________________ City _______________________________ State _____ Zip _____________________ Your Name _________________________ Phone # ___________________________ Fax # ______________________________ Purchase Order # ___________________ Company __________________________ Address ___________________________ Address ___________________________ City _______________________________ State _____ Zip ____________________ Attention: __________________________ Phone # ___________________________ Fax # _____________________________ Purchase Order # ___________________ 3. Parts Needed: Quantity Part Name (see parts list) Description Price (each) 4. Preferred Shipping Method: UPS Regular UPS Next Day Air (check one) Truck Carrier: _____________ Air Freight Customer Pickup Other:_______________ 5. Fax, Mail, or Phone your Order to: D#ALL-9-R2 72 PARTS & SERVICE James L. Taylor Mfg. Co. 108 Parker Avenue Poughkeepsie, NY 12601 Phone: (845) 452-3780 Fax: (845) 452-0764 Declaration of Conformity We, James L. Taylor Mfg. Co. 108 Parker Avenue Poughkeepsie, NY 12601 (914)-452-3780 (914)-452-0764 Fax declare under our sole responsibility that the product #80V/#80D/#80T Semi-Automatic Tightener/Flattener - Edge gluing machine Model 800128, 800130, 800151, 800161, 800201 Serial Number: to which this declaration relates is in conformity with the following standards and other normative documents EN 292 Safety of Machinery, Basic Concepts, General Principles for Design pr EN 1050 Principles for Risk Assessment EN 294 Safety distances to prevent danger zones being reached by upper limbs EN 349 Safety distances to avoid crushing of human body following the provisions of the following directives. 89/392/EEC 91/368/EEC 93/44/EEC The Technical Construction File is maintained at the above address. Place of Issue: Poughkeepsie NY Date of Issue: Authorized Signature: D80-263-R2