Design Guide Torch Application

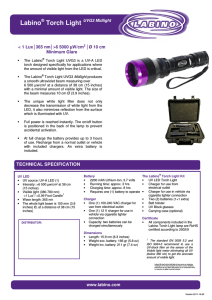

advertisement

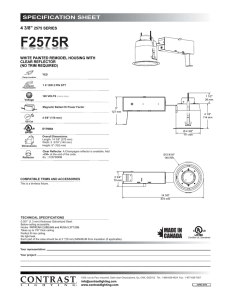

for Design Guide Torch Application rev1.2 (16. July. 2014) Samsung Electronics LH351A, LH351Y 1.Torch Application 1. Torch application general in torch application, structure 2 2. Reflector beam pattern, yellow ring effect 3 3. LED source powerful, reliable, compatible 5 4. Driving constant current driving from battery 8 5. Heat transfer Cu heat slug PCB, 1st heat slug 9 1.1 General in Torch application Thanks to compact size of battery having high performance and powerful single LED of spot lighting source, recently new concept of torch with small size and light body but having powerful performance comes out. These combination makes long lifetime, durability, advanced light quality and portability. In this design guide, some useful information will be introduced briefly with respect to reflector, LED source, driving and heat transfer 1.2 Torch structure Battery & Driver (inside) Body PCB HP LED Ring Reflector [ Figure 1. Torch structure ] Torch is composed of several function blocks – single high power LED, PCB board, reflector, connection ring, battery and driving circuit. In torch application, high quality of light distribution such as concentrated and clean intensity is combined with single high power LED and proper reflectors. 2 2.Optic guide for reflector 2.1 Generate beam pattern Normally LED emit light quite similar as lambertian surface. So to get spot light as a beam pattern, proper 2nd optic solution is required. Generally there are two kinds of optic ways. One is lens solution which is difficult to get wanted beam pattern and have a lower luminous transfer efficiency. Another is reflector solution which has high efficiency and could make excellent beam pattern. Without reflector, beam angle is just changed not making spot inner circle. Thus normally output beam pattern is made by combination between reflector and LED. To get wanted hot spot light, width and length of reflector is main design parameter. Jig [ With Jig ] Body Jig [ With Body ] The length of output beam and inner circle size – or length of focus - for torch is decided by the luminous flux of LED and angle of reflector. And outer circle is decided through the width of reflector Reflector L 3 L1 = L2 Heat sink Heat sink W1 W2 [ With Reflector ] 3 Heat sink W3 2.Optic guide for reflector 2.2 Control yellow ring effect Yellow ring Jig Heat sink [ With Jig ] [ With Reflector ] Generally the density ratio between phosphor thickness and the strength of blue wavelength from chip does not perfectly equal. This means color over angle does not same and at the side area of LED light source, phosphor portion is slightly higher than center area. Therefore yellow ring phenomenon might comes into sight at side angle. This yellow ring could be directly presented to the output color of beam through the reflector. yellowish effect less Scattered reflection more Specular reflection [ Comparison between scattered reflector and specular reflector ] Even though the securing of LED with equivalent color characteristics over the angle does not so easy way, some other simple techniques could be help to reduce yellow ring effect. One of them is scattering way through the scattered reflector. From this way, yellow ring effect could be reduced rather than that of specular reflector. And besides, various other ways exist in torch application. 4 3.Optic guide for lens 3.1 Generate beam pattern [ Consumer] Beam Intensity Heat sink Heat sink Reflector Lens [ 2nd optic solution ] [Military, Camping, Bicycle, Dive] In torch, there are two kinds of optic solutions. One is reflector type and another is lens type solution and these different types make different beam patterns. At the first, reflector type makes narrow bright center beam which makes possible to reflect spot area more brightly from the long distance. And most of consumer torch adopted this reflector type solution. Secondly, lens type is more proper solution to reflect large circle area uniformly at the near distance. Military , camping and bicycle applications are more suitable for lens solution. 5 3.Optic guide for lens 3.2 Lens function & Symbol mark of LH351Y Zoom out Zoom in [ Torch with lens solution] LH351Y distance Heat sink Lens (Short distance) Heat sink Lens (Long distance) [ Zoom in/out function ] Pure square beam quality [ Samsung LH351Y beam pattern] Lens solution have some merits and one of them is variable zoom-in & out function. Long distance between LED and Lens makes small center circle and concentrates beam emission to spot area. When distance of body is setting to maximize, zoom in, chip pattern could be appeared. Samsung high power LED has a unique pattern which has no any bonding pad and any electrical metal pattern. These clean beam pattern makes pure quality for lens solution. 6 4.LED source 4.1 Powerful LED light source In torch, the most important part is actually LED component which could make actual beam and color performance. LH351A/Y has powerful performance optimized torch application. [ LH351A ] In LH351A, wide operating range could be possible up to 1.5A, 3W, 400lm for high-end torch application. Various CCT - 5700K, 6500K, 7600K is ready for supply and from design support tool (Circle-B), it is convenient for designer to estimate expected performance and range of mass production. [ LH351Y ] LH351Y has almost same size of package. This light solution is optimized for economic torch application. Up to 1A, 2W, almost 300lm could be possible. 6500K, 7000K and 7600K CCT is ready for torch application. 7 4.LED source 4.2 Reliable LED light source High durability and reliability is required for torch due to its characteristics of mobility and bad weather in outdoor. LH351A/Y has passed high level test item, especially thermal shock, on going life test, temperature humidity cycle on/off test, EMI/ESD and temperature storage test, etc,. Under LM80 test, expected lifetime could be calculated through TM21 method. And great lifetime is expected like as following graph. [ LH351A and expected life time ] [ LH351Y and expected life time ] 8 4.LED source 4.3 Compatible LED light source [ Compact size of LH351A and LH351Y ] In torch, One of the important requirement for designing and choosing LED, the size of LED, form factor, is major selection point. Single LED light source is recommended for torch rather than multi LED light sources as for quality of output beam shape. From these design issue, small spot size and high performance of LED is optimal solution for torch. Thus LH351A/Y is quite proper light source for torch. [ Compatible reflector with LH351A and LH351Y ] There are so many kinds of reflector for torch lamp. Most of all reflectors could be matched with LH351A/Y for its compact size. 9 5.Driving 5.1 Driving light source from battery (+) (+) (+) (+) Changeable VF Battery Constant Voltage Driving Battery (-) (-) [ Battery direct drive mode ] (+) Constant VF Constant Current Driving Battery (-) (+) Constant IF (-) (-) (-) [ Constant voltage mode ] [ Constant current mode ] Usually torch is driven from battery. Therefore it doesn’t need AC/DC converter but DC/DC converter and driver. Optimal circuit topology like as linear regulator, buck-down, boost-up could be adopted considering battery supply voltage. For example if voltage of battery is 2.7V, boost-up converter is required, but most of these case, two battery is connected in series. Then voltage becomes as 5.4V, and thus more simple topology of buck converter or linear regulator could be adoptable. If LED is directly driven by battery like as battery direct drive mode, lighting output could be unstable due to changeable voltage output quality from battery. Thus LED driving is recommended that constant current mode which is more suitable for LED rather than constant voltage mode. That reason could be known as follows. 1200 1000 800 600 400 200 25℃ 50℃ 75℃ 100℃ 0 1600 3.4 1400 3.3 1200 1000 800 600 25℃ 400 50℃ 75℃ 200 100℃ 0 2.7 2.8 2.9 3 3.1 3.2 3.3 3.4 Forward Voltage (V) [ Forward current vs. forward voltage ] Forward Voltage (V) 1400 Forward Current (mA) Forward Current (mA) 1600 3.2 3.1 3 25℃ 50℃ 75℃ 100℃ 2.9 2.8 2.7 0 1 2 3 4 5 6 Power Consumption (W) [ Forward current vs. power consumption ] 0 1 2 3 4 5 6 Power Consumption (W) [ Forward voltage vs. power consumption ] Electrical current & voltage sweep curve is like as general diode properties. From these IV-curve, some graph of current vs. power consumption and voltage vs. power consumption could be drawn. If LED is driven by constant voltage, as temperature rise higher, output power could vary with large variation range. But if LED is driven by constant current mode, stable output power could be obtained even though LED solder temperature changes. 10 6.Heat transfer 6.1 Heat transfer LH351A/Y could make high output performance. But excellent performance including reliable lifetime is closely depends on how thermal dissipation system is built in. In most of all cases, substrate board is metal PCB which has isolation layer between thermal pad and Al-substrate. But copper is easy material to manufacture wanted shape and if copper heat slug PCB which has non-isolation layer between thermal paths is used for substrate, luminous flux degradation is less than normal Al-metal PCB due to low thermal resistance. Also the robust reliability of LED could be acquired. Cu Luminous flux Copper heat slug PCB 5~10% luminous flux difference Al Normal metal PCB Forward driving current [ Flux improving effect through Cu heat slug PCB] Heat Slug Driver Battery 1W ~ Power consumption Body Body Driver Battery ~ 1W Power consumption [ Connection of heat slug and body for heat transfer] Also body is the major part of torch and anodizing is very important technique to the quality of body. For maintain the heat transfer of LED, body also play role as a heat sink. Normally if power consumption is operated over 1watt, then it would had been better small heat slug should be inserted with metal PCB. Under 1watt power consumption, body itself might cover heat transfer well. 11