HSA Filter Housing Physical Characteristics Ordering Information

advertisement

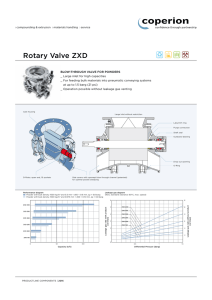

HSA Filter Housings HSA Filter Housing Physical Characteristics • sanitary air / gas Bowl Height ‘A’ Dimensions (mm) ‘B’ ‘C’ Weight (Kg) Bowl Head Total 5¨ (125 mm) 157 337 194 1.0 3.5 5.1 10¨ (250 mm) 157 487 313 1.6 3.5 5.7 20¨ (500 mm) 157 737 561 2.6 3.5 6.7 Vent / Gauge Port 11/2¨ Tri-Clamp Dimensions are based on illustration shown (HSACE011YT-C-S). For accurate dimensions, please contact Parker domnick hunter. • Flow efficient sanitary range of air / gas housings Bowl • Designed specifically for the food and beverage industry • Sanitary vent, tri-clamp and drain connections as standard Dim ‘A’ • Sanitary tri-clamp body closure as standard Body Clamp Dim ‘C’ Bowl Removal Height Body Seal Dim ‘B’ Specification Materials of Construction Housing: Seals: 316L Stainless Steel Silicone FDA Surface Finish Internal: External: Polished 0.4 µm Ra Polished 0.25 µm Ra All finishes pickled & passivated. Welding Working Condition PED 97/23/EC Fluid Group State Maximum Pressure Temperature Non Dangerous Gas / Vapour 150 °C (302 °F) Dangerous Gas / Vapour 150 °C (302 °F) 01K 011 10.00 barg (145.03 psig) 10.00 barg (145.03 psig) 10.00 barg (145.03 psig) 8.00 barg (116.03 psig) 8.00 barg (116.03 psig) 8.00 barg (116.03 psig) PED Conformity Assessment Category SEP SEP SEP Volume (litres) 1.9 3.1 5.0 Head Inlet Port 012 Outlet Port Drain Port 1 /2¨ Tri-Clamp All assembly welds are full penetration. All welds are crevice and undercut free. Weld finish & detail drawings available upon request. Certification Supplied as standard with vessel inspection certificate. Material Test Certification EN10204 3.1 supplied upon request. Design Code Housings designed in accordance with the European Council Pressure Equipment Directive (PED) 97/23/EC and the UK statutory Pressure Equipment Regulations (PER) 1999 N° 2001. PED / PER conformity assessments based on Fluid Group 2 Gas (harmless) including steam. Only housings over PS.V 50 bar / litres bear the CE mark. Design Basis Ordering Information HSA 01 - - Code ǀ Vessel Class Code ǀ Length (Nominal) Code ǀ Connection Size Code ǀ Standard Code ǀ Cartridge Code ǀ Seal CE K 1 2 Y T C Standard 5¨ 10¨ 20¨ (125 mm) (250 mm) (500 mm) 11/2¨ (38.1 mm) Tri-Clamp 226 S Silicone Note: For accessories, i.e. gauges, please contact Parker domnick hunter - Process Division for full availability. For additional features, Parker domnick hunter offer this housing as part of its Standard PLUS Range. Please see HSA⊕ datasheet for more information. ASME VIII Division 1. 12 | | 13 HSA⊕ Filter Housings HSA⊕ Filter Housing Physical Characteristics • sanitary air / gas Bowl Height Dimensions (mm) ‘A’ ‘B’ ‘C’ Typical Weight (Kg) Bowl Head Total 5¨ (125 mm) 229 337 205 0.9 1.9 3.3 10¨ (250 mm) 229 487 324 1.5 1.9 3.9 20¨ (500 mm) 229 737 572 2.5 1.9 4.9 30¨ (750 mm) 229 982 820 3.5 1.9 5.9 40¨ (1000 mm) 229 1232 1068 4.5 1.9 6.9 Vent / Gauge Port Sample Port Sample Port Valve Dimensions shown are for a vessel with 2¨ tri-clamp ports, sample port and drain valve. For other formats, please contact Parker domnick hunter. • Sanitary range of air / gas housing Bowl • Available in 4 different housing classes: Atex, CE, High Pressure and Oxygen Service • Both beverage and pharmaceutical surface finishes available Dim ‘A’ • A choice of easy to use sanitary vent and drain options Body Clamp* Body Seal Dim ‘C’ Bowl Removal Height Specification ATEX Materials of Construction Fluid Group Housing: Seals: Non Dangerous Gas / Vapour 135 °C (275 °F) 10.00 barg (145.03 psig) 10.00 barg 10.00 barg (145.03 psig) (145.03 psig) 10.00 barg 10.00 barg (145.03 psig) (145.03 psig) Dangerous Gas / Vapour 135 °C (275 °F) 8.00 barg (116.03 psig) 8.00 barg 8.00 barg (116.03 psig) (116.03 psig) 7.20 barg (104.42 psig) 316L Stainless Steel EPDM FDA PTFE FDA Silicone FDA Viton FDA State Pharmaceutical Finish Internal: Polished 0.4 µm Ra and Electropolished External: Polished 0.25 µm Ra CE 1.9 3.1 5.0 6.9 8.8 14 | Drain Port Valve Temperature 01K Non Dangerous Gas / Vapour 150 °C (302 °F) 10.00 barg (145.03 psig) Dangerous Gas / Vapour 150 °C (302 °F) 8.00 barg (116.03 psig) 012 013 014 10.00 barg 10.00 barg (145.03 psig) (145.03 psig) 10.00 barg 10.00 barg (145.03 psig) (145.03 psig) 8.00 barg 8.00 barg (116.03 psig) (116.03 psig) 7.20 barg (104.42 psig) 5.60 barg (81.22 psig) SEP SEP CAT I CAT I CAT I Volume (litres) 1.9 3.1 5.0 6.9 8.8 Non Dangerous Temperature 205 °C (401 °F) 01K 16.00 barg (232.06 psig) 011 012 16.00 barg 16.00 barg (232.06 psig) (232.06 psig) 013 014 16.00 barg 16.00 barg (232.06 psig) (232.06 psig) PED Conformity Assessment Category SEP SEP CAT I CAT I CAT I Volume (litres) 1.9 3.1 5.0 6.9 8.8 State Gas / Vapour Temperature 150 °C (302 °F) 01K 8.00 barg (116.03 psig) 011 012 8.00 barg 8.00 barg (116.03 psig) (116.03 psig) Ordering Information 013 7.20 barg (104.42 psig) 014 5.60 barg (81.22 psig) PED Conformity Assessment Category SEP SEP CAT I CAT I CAT I Volume (litres) 1.9 3.1 5.0 6.9 8.8 01 - Code ǀ Vessel Class Code ǀ Length (Nominal) Code ǀ Connection Size Code ǀ Standard AT CE HP* OX K 1 2 3 4 Y C ATEX Standard High Pressure Oxygen Service * Supplied complete with a double bolted clamp Maximum Pressure Working Condition PED 97/23/EC *Double bolted clamp required for HP and PTFE seal options HSA Maximum Pressure Working Condition PED 97/23/EC Gas / Vapour Oxygen Service Dangerous 011 PED Conformity Assessment Category State Drain Port Maximum Pressure Working Condition PED 97/23/EC Fluid Group Outlet Port 5.60 barg (81.22 psig) Volume (litres) State Head 014 CAT I Weld finish & detail drawings available upon request. ASME VIII Division 1. ATEX 94/9/EC (where applicable) 013 CAT I High Pressure Design Basis 012 CAT I Fluid Group Fluid Group 011 SEP All assembly welds are full penetration. All welds are crevice and undercut free. Housings designed in accordance with the European Council Pressure Equipment Directive (PED) 97/23/EC and the UK statutory Pressure Equipment Regulations (PER) 1999 N° 2001. 01K SEP Welding Design Code Temperature PED Conformity Assessment Category Surface Finish Beverage Finish Internal: Polished 0.4 µm Ra External: Polished 0.25 µm Ra Inlet Port Dim ‘B’ Maximum Pressure Working Condition PED 97/23/EC 5¨ (125 mm) 10¨ (250 mm) 20¨ (500 mm) 30¨ (750 mm) 40¨ (1000 mm) 11/2¨ (38.1 mm) 2¨ (50.8 mm) T Code ǀ Cartridge Code ǀ Seal Tri-Clamp C 226 E P* S V EPDM PTFE Silicone Viton * Double bolted clamp required - Code ǀ Vent Code ǀ Drain C H I M R S T H R S Rectus 21 Vertical 11/2¨ TCF & Hosebarb 11/2¨ TCF & Staubli RBE03 11/2¨ TCF & 1/2¨ TCF 11/2¨ TCF & Rectus 21 Staubli RBE03 Vertical 11/2¨ TCF Only Code ǀ Surface Finish B P Beverage Pharmaceutical T Hosebarb Rectus 21 Staubli RBE03 1 /2¨ TCF Internal External 0.4 µm 0.4 µm EP 0.25 µm 0.25 µm - Code ǀ Tagged For Tagged Options customer identification numbers required at time of ordering T X Yes No | 15