System Manual SENTRON Switching/protection devices 3VL

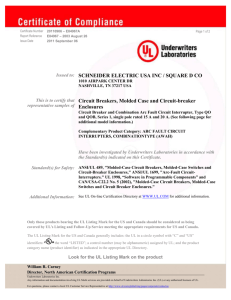

advertisement