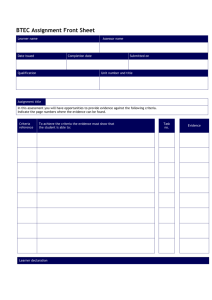

Level 2 Diploma in Heating and Ventilating (7188

advertisement