VT VARIATION EFFECTS ON LIFETIME RELIAbILITy

advertisement

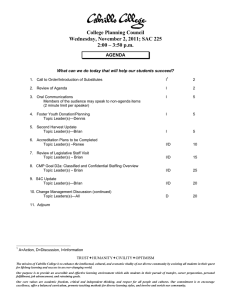

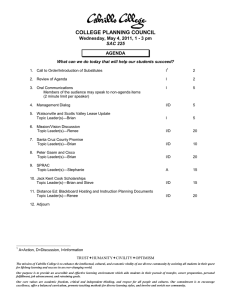

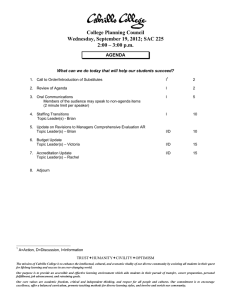

Vt Variation Effects on Lifetime Reliability Brian Greskamp Smruti R. Sarangi Josep Torrellas University of Illinois at Urbana-Champaign Motivation • Chips are wearing out faster as technology scales • >>180nm: 20 year design lifetime • 130nm: 10 years • 65nm: 7 years • 32nm: ??? • How does process variation affect this trend? Brian Greskamp 2 Vt Variation Random Within-Die Brian Greskamp 3 FPQ FPMap FPMul FPAdd FPReg BPred Vt Variation UL2cache1 L1D IntMap UL2cache2 IntQ L1I IntExec IntReg DTB ITB LdStQ UL2cache3 Systematic Within-Die Brian Greskamp 4 Vt Variation Die-to-Die Brian Greskamp 5 Vt Variation Component Variation σ/µ Random WID 5.2% Systematic WID 5.2% Die-to-Die 5.2% Total Vt variation σ/µ = 9% Brian Greskamp 6 Time To Failure lognormal PDF with mu = 1.0, sigma = 0.5 1.20 Probability probability density -> 1.00 0.80 0.60 0.40 0.20 0.00 0.00 0.50 TTF1% 1.50 2.00 2.50 Time to Failure MTTF TTF 1.00 Brian Greskamp 3.00 7 Failure Mechanisms • TTF depends mostly on temperature • Exponential temperature dependence • Time-Dependent Dielectric Breakdown (TDDB) • Electromigration (EM) • Stress Migration (SM) • Quadratic temperature dependence • Thermal Cycling (TC) Brian Greskamp 8 !""# $%&'() *+,-%&./(0 1+ 12( $%&'() ◦%1 34◦ 56 "2( !"#$%&'( !""# $%&'() *+,-%&./(0 1+ 12( $%&'() 56 "2( !"#$%&'( "+ &.*( )2+7) 12( 8+-9.*(0 (::(81 +: %1 %&&34:+', :%.&',( -(82%*.)-)6 Lifetime vs Temperature &.*( )2+7) 12( 8+-9.*(0 (::(81 +: %&& :+', :%.&',( -(82%*.)-)6 Normalized MTTF Normalized MTTF 10 1 10 Combined Combined TC TC TDDB TDDB SM SM EM EM *%-. 72.&( ')( 12 :,+)'CC& C,+C+ 1 W* T −1. 65 70 75 80 85 90 95 100 105 60 65 70 75 80 85 90 95 100 105 ?T0 @A Temperature (C) Temperature (C) 12( 12 #.;6 <6 =+,-%&./(0 !""# :+, "2(,-%& 5>8&.*; ?"5@A ".-( B(C(*0(*1 8+*)1 #.;6 <6 D,(%E0+7* =+,-%&./(0 !""# :+,Greskamp "2(,-%&?F!@A 5>8&.*; ".-( B(C(*0(*1 9 Brian B.(&(81,.8 ?"BBD@A F1,()) !.;,%1.+* %*0 ?"5@A G&(81,+-.;,%1.+* [L*0.1 0.1 60 Lifetime vs Temperature MTTF as a function of Junction Temperature for various voltages Microprocessor MTTF (180nm SOI) MTTF (Years) 100,000 10,000 1,000 100 55 65 75 85 95 105 115 Junction Temperature (C) 1.3 V 1.2 V 1.4 V Image: Freescale Semiconductor Revision History: Brian Greskamp Revision History 10 0 105 hermal Cycling Migration (SM), ould change re dominant. tems; if any capture this 0 small cells. ognormally- R sa Heat spreader Closing the Loop R Vt R cs2 Vteff Ps Cell 1 T cs1 MTTF Die surface Fig. 2. Thermal model and electrical equivalent of processor die, heat spreader, and sink. dependence = heat Linear = Exponential dependence and static power are both proportional to: ! "2 ! " −Vtef f − c2 kT Ps ∝ µ exp q c3 kT /q Vtef f = V t − c1 (T − T 0) The mobility µ itself has a temperature dependence; we c /T 4 M T T 65nm F ∝ emodel has c1 = 5.0 × 10−4 , use µ ∝ T −1.5 . HotSpot’s c2 = −3.9 × 10−2 , and c3 = 1.3. With these constants, the leakage model predicts a 41% increase in static power consumption as die temperature changes from 75◦ C to 90◦ C, even Brian Greskamp 11 0 105 hermal Cycling Migration (SM), ould change re dominant. tems; if any capture this 0 small cells. ognormally- R sa Heat spreader Closing the Loop R Vt R cs2 Vteff Ps Cell 1 T cs1 MTTF Die surface Fig. 2. Thermal model and electrical equivalent of processor die, heat spreader, and sink. dependence = heat Linear = Exponential dependence and static power are both proportional to: ! "2 ! " −Vtef f − c2 kT Ps ∝ µ exp q c3 kT /q Vtef f = V t − c1 (T − T 0) The mobility µ itself has a temperature dependence; we c /T 4 M T T 65nm F ∝ emodel has c1 = 5.0 × 10−4 , use µ ∝ T −1.5 . HotSpot’s c2 = −3.9 × 10−2 , and c3 = 1.3. With these constants, the leakage model predicts a 41% increase in static power consumption as die temperature changes from 75◦ C to 90◦ C, even Brian Greskamp 12 0 105 hermal Cycling Migration (SM), ould change re dominant. tems; if any capture this 0 small cells. ognormally- R sa Heat spreader Closing the Loop R Vt R cs2 Vteff Ps Cell 1 T cs1 MTTF Die surface Fig. 2. Thermal model and electrical equivalent of processor die, heat spreader, and sink. dependence = heat Linear = Exponential dependence and static power are both proportional to: ! "2 ! " −Vtef f − c2 kT Ps ∝ µ exp q c3 kT /q Vtef f = V t − c1 (T − T 0) The mobility µ itself has a temperature dependence; we c /T 4 M T T 65nm F ∝ emodel has c1 = 5.0 × 10−4 , use µ ∝ T −1.5 . HotSpot’s c2 = −3.9 × 10−2 , and c3 = 1.3. With these constants, the leakage model predicts a 41% increase in static power consumption as die temperature changes from 75◦ C to 90◦ C, even Brian Greskamp 13 )'9)1,%1( ,().)1%*8( Rcsi 1+ ,(%82 12( 2(%1 )C,(%0(,6 #.*%&&>A 12( 2(%1).*E 0.)).C%1() 2(%1 12,+';2 12(,-%& ,().)1%*8( Rse 1+ 12( (*$.,+*-(*1A 72.82 .) %))'-(0 1+ 9( %1 NL◦ 56 S( %))'-( )1(%0>R)1%1( +C(,%1.+*A 12(,(:+,( .;*+,.*; 2(%1 )1+,%;( .* 12( 12(,-%& 8+-C+*(*1)6 T00.1.+*%&&>A %) )2+7* .* #.;',( PA 7( %&&+7 &%1(,%& 8+*0'81.+* .* 12( 0.( 9> -+0(&.*; % &%,;( 12(,-%& ,().)1%*8( 9(17((* %0U%8(*1 8(&&)6 Temperature Model Environment (45 C) Heatsink R se Heat spreader R R cs2 cs1 Cell 1 Heatsink Heat spreader Package Die Die surface #.;6 P6 "2(,-%& %))(-9&> ?,.;21@ %*0 (&(81,.8%& (V'.$%&(*1 ?&(:1@ +: C,+8())+, 0.(A 2(%1 )C,(%0(,A %*0 2(%1).*E6 Modeled with HotSpot (Skadron et al.) Brian Greskamp 0(*8( %*0 +*&> % :'* 12( FC2(, +61_) M<PO 8(&&) )(C% ,(&%1(06 #+ 12( &(*;12 T:1(, 12 -.*(0A 7( $%,.%1.+* 8 0.() 7.12 1,%*).)1+, "2.) 8+-C %*0 *+ )C D%)(0 σVt0 = 0.0 8+*1,.9'1.+ 7( )(1√ (0.09/ 3 14 Experiment For i = 1 to 20000 do 1. Randomly generate diei Vt variation map 2. Partition die into 1000 equally-sized cells 3. Compute temperature for each cell 4. Generate lifetime distribution for each cell 5. Sample lifetime distribution for each cell 6. Diei lifetime = min(cell_lifetimes) Brian Greskamp 15 Processor Model • Model Intel Core Solo 65nm floorplan • Per-unit dynamic power modeling • SESC cycle-accurate simulator with WATTCH • Profile from crafty SPECint benchmark • Steady-state dynamic power = 14W • HotSpot thermal model Brian Greskamp 16 Example Die Before Variation DTB BPred IntReg IntMap FPMap FPQ IntMap FPMul IntQ FPQ IntQ FPAdd FPReg BPred ITB LdStQ ITB LdStQ FPAdd FPReg FPMul FPMap L1D L1I L1D L1I MTTF=0.90 DTB IntExec IntExec IntReg After Variation MTTF=0.75 MTTF=0.95 MTTF=0.85 MTTF=1.0 UL2cache1 UL2cache2 UL2cache3 UL2cache1 UL2cache2 UL2cache3 MTTF=0.8 Fig. 6. Spatial distribution Brian of cell Greskamp MTTFs before and after variation for an example die. Color and contours indicate MTTF. extreme va temperature than norma C. Future T Assumin on lifetime 17 scales, per- 65< Rse G 3&, %!,!%!P# $.# *#6!&(!6!$) !%A&3$ 5H Vt0 L&*!&$!5, Result: Vt Variation $ &6"5 ".5<" $.&$ *#6&$!L#6) "%&66 3.&,-#" !, Rse 3&, .&L# Impact on <.#, Lifetime $*5,- *#6!&(!6!$) 35,"#]+#,3#" Pleak0 !" .!-.? @NVS1 U ^ 1FM2@U_` U` T T F1% O_^ FUOO1^1`@ aNSM1/ _O J1N@/U`b @J1^QNS ^1/U/@N`21 N`F in _O TTF `_ 7 aN^UN@U_` 0_=1^ ? Reduction Vt Variation 1% due to S1NbNc1 Pleak0 (W ) X?K 9I?I 9T?K 9K?I I?d 7T[ 7T[ 7W[ 79>[ Rse (K/W ) I?X I?W I?e 7:[ 7>[ 7>[ 7d[ 799[ 79e[ 79T[ 7TK[ 7KI[ 7:X[ 7d9[ 7dX[ Ua? 2 _`2SM/U_`/ Brian Greskamp 9?I 7e[ 7:>[ 7dT[ 7d>[ 18 Conclusion • D2D and systematic variations are biggest problem for aging • Potential solutions • Reduce overall leakage • Increase heatsink size Brian Greskamp 19 Vt Variation Effects on Lifetime Reliability Brian Greskamp Smruti R. Sarangi Josep Torrellas University of Illinois at Urbana-Champaign