Sizing of Dual-VT Gates for Sub-VT Circuits

advertisement

Sizing of Dual-VT Gates for Sub-VT Circuits

Babak Mohammadi, S.M. Yasser Sherazi, and Joachim Neves Rodrigues

Electrical and Information Technology, Lund University, 22100 Lund, Sweden

{babak.mohammadi, yasser.sherazi, joachim.rodrigues}@eit.lth.se

I. I NTRODUCTION

Scaling down the supply voltage (VDD ) to the sub-threshold

(sub-VT ) regime is well known as an effective method for energy reduction [1]. Unfortunately, the exponential dependence

of the sub-VT currents on process parameters like threshold

voltage (VT ), makes the transistor performance and functionality extremely vulnerable to process variations [2]. Thus, the

transistor’s performance in terms of delay and reliability is

considerably degraded compared to super-VT operation [3].

This reduces the maxima of the attainable throughput and

adds extra energy overhead to the design. Sub-VT optimized

designs are often realized by full-custom cells (FCL) [4], [5].

In this case, the impact of process variations is combated by

transistor up-sizing. Transistor sizing improves the timing, i.e.,

equalized rise/fall time, and increased noise margins at the cost

of higher area and energy [5].

Modern sub-micron CMOS technologies are offered with

different threshold options which gives designers the opportunity to address the leakage energy by employing high-VT

gates, whereas performance is improved by using low-VT

devices [6]. However, this method is mainly employed on

gate level. The advantages of using different threshold options

on schematic level, i.e., inside gates is not well explored in

literature.

Contribution: In this work the performance and reliability

degradation of gates operated in the sub-VT regime is addressed. To speed-up the performance bottlenecks in gates

and balance the driving strength of pull-up and pull-down

networks (PUN and PDN), selected transistors are replaced by

their lower-VT equivalent. This method is referred as dual-VT

(DVT) in this study. The performance gain of the proposed

optimization techniques is analyzed by means of extensive

Monte-Carlo (MC) simulations of an inverter, a NAND3, and

NOR3 gate.

4

ION−NMOS/ION−PMOS

Abstract—This paper presents a novel method to improve the

performance of sub-threshold (sub-VT ) gates in 65-nm CMOS

technology. Faster transistors with a lower threshold voltage are

introduced in the weaker network of a gate. It is shown that

the employed method significantly enhances the reliability and

performance of the gate, with an additive advantage of a lower

area cost compared to traditional transistor sizing. Extensive

Monte-Carlo simulations are carried out to verify the proposed

optimization technique. The simulation results predict that the

NAND3 and NOR3 testbench shows a 98% higher noise margin.

Furthermore, the inverter and NAND3 gates show an speed

improvement of 48% and 97%, respectively.

1 Wp

3

2 Wp

2

5 Wp

1

0

10 Wp

0.2

0.4

VDD [V]

0.6

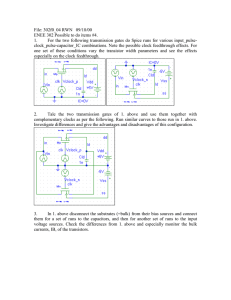

Fig. 1. The ratio of active currents of HVT-NMOS and HVT-PMOS in

sub-VT . VT of transistors ∼700 mV. WP is the min size allowed in the

technology. The NMOS transistor has the minimum width.

The remaining of the paper is structured as follows: Sec. II,

describes the theory behind the method employed. In Sec. III,

the Dual-VT approach is presented for basic combinational

gates and elaborated by means of MC simulations. Finally,

conclusions are drawn in Sec. IV.

II. T HEORY

CMOS processes are designed and optimized for superVT operation. Consequently, all the optimization techniques

in super-VT need to be carefully analyzed for their efficiency

in the sub-VT domain. The transistor strength balancing is

one of these techniques which has an important effect on

design’s performance and reliability. The driving balance of

a circuit depends on different process parameters, i.e., the

primary process parameter VT and secondary parameters drain

induced barrier lowering (DIBL) and subthreshold slope. The

traditional method to equalize the imbalance is transistor

sizing. This is done by a relatively low size-ratios of PMOS

and NMOS in the super-VT regime. However, the transistor

size-ratios become very large in the sub-VT domain, see

Fig. 1. The peak current ratio between PMOS and NMOS is

found in the sub-VT regime. Furthermore, it is observed that

by upsizing the PMOS transistor by 10×, a strength balancing

is still not achieved. The imbalance between the PUN and PDN

worsens even more when transistor stacking is required to form

a complex gate (architectural dependency), as this reduces the

current driving capability. In this case the transistor size ratios

reach impractical large values.

The balanced strength improves the gate’s stability and

robustness, as the switching threshold voltage (Vm ) moves to

its ideal value (VDD /2) and increases the noise-margins (N M ).

Unbalanced switching threshold and low NMs are among the

main sources of functionality and stability failures in sub-VT

regime. Therefore, designing the gates with maximum possible

NM (N ML = N MH ) is of vital importance.

In this study, the use of different threshold options in the

PUN and PDN as an alternative to traditional transistor sizing

is investigated. The lower-VT transistors are introduced in the

slowest network, either PUN or PDN, to improve their driving

capability. The best VT option for PUN and PDN transistors

depends on VDD and the architecture of the gate. However,

finding the best VT option for each VDD and architecture is out

of the scope of this study. The effectiveness of the proposed

method is demonstrated on 3 logic gates; an inverter, a NAND,

and a NOR gate at 300 mV. To consider more extreme cases

with stacked transistors in PUN or PDN, 3 input NAND

and NOR gates are used in simulations, since they contain

3 stacked transistors in PDN and PUN, respectively.

III. R ESULTS

The driving imbalance has a strong exponential dependency

on mismatch of process parameters (VT , slope factor and

DIBL coefficient) in PMOS and NMOS transistors, where the

transistor width has a linear relation in sub-VT regime [7].

Consequently, small differences in exponential process parameters require large changes in the linear current coefficient, i.e.,

device dimensions to compensate for the changes in exponential process parameter mismatch to compensate. Therefore, this

method has a large area penalty.

Figure 2(a) shows the NMOS and PMOS sizes for an ideal

Vm in inverters implemented with different threshold options

at 300 mV. The process used in this study has 3 different

threshold options which are 1) high-VT (HVT) with a VT

of ∼ 700 mV, 2) standard-VT (SVT) with a VT of ∼ 560 mV

and 3) low-VT (LVT) with a VT of ∼ 450 mV. It is observed

that in the LVT and HVT inverters, the required minimum

transistor width is ∼ 8× the Wmin (minimum allowed width

of transistor in the technology), whereas for the SVT inverter

the ratio is ∼13×.

The voltage transfer characteristic (VTC) of a balanced

inverter based on the DVT method is shown in Fig 2(b). It is

observed that Vm of pure LVT and SVT inverters is 127 mV,

however, by replacing the PMOS transistor in the SVT inverter

by a LVT transistor, an ideal Vm (VDD /2) is achieved. To

get the VTC with pure HVT, SVT and LVT transistors, the

PMOS transistors need to be upsized by 6.8×, 12.4× and

7.7×, respectively, while keeping the NMOS at minimum size.

Thus, the area cost of this proposed technique is much lower,

compared to the traditional transistor sizing.

A commonly practised functionality metric in the static

logic is static noise margin (SNM) measurement. This metric

is mainly used in SRAM stability analysis, however, it is

shown in [8] that the SNM of two back to back gates is

equal to maximum noise that can be applied to a long chain

of the same gates. Fig. 2(c) shows the benchmark used for

SNM analysis. The reason for the selection of NAND and

NOR is because they give the worst input low voltage (VIL )

and input high voltage (VIH ). The input number of NAND

and NOR is selected to be 3 to consider worst case output

swing, as each gate has 3 stacked transistors which reduces the

driving capability. The DVT approach for NAND3 and NOR3

for 300 mV and the process used in this study is shown in

Fig. 2(c). The best balanced Vm match for NAND3 is SVT

transistors for PUN and LVT transistors for the PDN. The best

balanced Vm match for NOR3 gate is LVT for the PUN and

HVT for PDN. The transistor sizes of DVT-NAND3 and DVTNOR3 is the same in PUN and PDN. However, the NOR3 gate

in a standard-cell library (SCL), employs 85% and 25% wider

transistors in the PUN and PDN, respectively.

To consider the local variations, 1000 point Monte-carlo

simulations at 300 mV and 27 ◦ C are performed. The same

setting and simulations is performed for the gates with NAND3

and NOR3 gates in SCL. The simulation results are shown in

Fig. 3. By comparing the butterfly curves, it is observed that

the DVT approach, despite of having narrower transistors in

the NOR3 gate, has higher symmetrical curves and the SNM

windows are larger. By comparing the SNM distributions in

Fig 3, it is concluded that the DVT approach, by having a mean

SNM voltage of 105 mV, is ∼ 47% better than single threshold

gates. Furthermore, the SNM variation is ∼ 82% lower than

other cases, and worst-case SNM is found at 90 mV, which in

average is 96% lower than other single-VT approaches.

The same gates in the SNM testbench, i.e. NAND3 and

NOR3 are used for timing analyses. Fig. 4 represents the

delay distributions of a NAND3 gate with different threshold

options. All the inputs in the benchmark toggled simultaneously. As expected, the mean fall delay in HVT-NAND3 gate

is 35× higher than its rise delay and worst-case rise delay

is 93× longer. But as shown in Fig. 4(d), the mean delay of

rise and fall delays are almost equal. The rise delay of the

SVT and LVT gates are shorter than the DVT gate, but since

their their fall delay is equal to or higher than DVT, there is

no overall performance gain. It is observed that by employing

DVT, the performance boosts to LVT gate levels, while the

static energy dissipation remains low in the HVT levels. The

similar behaviour is observed for NOR3 gates.

IV. C ONCLUSION

In this study, it is shown that a dual-VT approach in

schematic level results in a higher both performance and

reliability. The SNM of the NAND3 and NOR3 gates show an

improvement of 47% over the same setting with SCL gates.

The overall performance gain of a DVT-inverter and DVTNAND3 gates is 45 % and 67 %, respectively, compared to the

gates in the SCL. Furthermore, the MC simulations confirm

a lower worst-case delay and noise-margins. Additionally, the

proposed technique is highly area efficient.

ACKNOWLEDGMENT

This work was kindly supported by the Swedish Vetenskapsrådet (621-2011-4540), and Swedish VINNOVA Industrial Excellence Centre (SOS).

R EFERENCES

[1] A. Wang et al., “Optimal supply and threshold scaling for subthreshold

cmos circuits,” in IEEE ISVLSI, 2002, pp. 5 –9.

[2] A. Tajalli et al., “Design trade-offs in ultra-low-power digital nanoscale

cmos,” IEEE Transactions on Circuits and Systems I: Regular Papers,

vol. 58, no. 9, pp. 2189 –2200, sept. 2011.

[3] P. Friedberg et al., “Modeling within-die spatial correlation effects for

process-design co-optimization,” in ISQED, march 2005, pp. 516 – 521.

[4] P. Meinerzhagen et al.

[5] S. Luetkemeier et al., “A 200 mV 32b subthreshold processor with

adaptive supply voltage control,” in IEEE ISSCC Papers, feb. 2012, pp.

484 –486.

[6] D. Bol et al., “A 25 MHz 7 uW/MHz ultra-low-voltage microcontroller

SoC in 65nm LP/GP CMOS for low-carbon wireless sensor nodes,” in

IEEE ISSCC, feb. 2012, pp. 490 –492.

[7] J. Kwong et al., “Variation-driven device sizing for minimum energy subthreshold circuits,” in Proceedings of ISLPED, oct. 2006, pp. 8 –13.

[8] J. Lohstroh et al., “Worst-case static noise margin criteria for logic circuits

and their mathematical equivalence,” IEEE JSCC, vol. 18, no. 6, pp. 803

–807, dec. 1983.

0.3

16

SVT

0.25

12

VOUT [V]

Normalized PMOS width

14

10

8

HVT

6

LVT

0.2

Dual−VT

LVT

SVT

VN

LVT

LVT

0.15

127 mV

150 mV

0.1

LVT

SVTX3

LVT

LVT

0.05

4

VN

2

1

1.5

2

2.5

3

Normalized NMOS width

3.5

4

HVTX3

LVT

0

0

0.1

(a)

VIN[V]

0.2

0.3

(b)

(c)

Fig. 2. a) Required NMOS and PMOS widths for having ideal Vm in the HVT, SVT and LVT inverters at 300 mV, b) Voltage transfer curves (VTC) of

SVT, HVT and DVT inverters, c) 3 input DVT-NAND and DVT-NOR gates in the benchmark used for static noise margin (SNM) extraction.

150

0.3

0.3

0.1

100

Occurrences

0.15

0.2

VOUT

0.2

VOUT

150

0.25

Occurrences

0.25

µ:66.3 [mV]

σ :7.87 [mV]

σ / µ :11.9 %

50

0.15

0.1

0.05

µ:69.7 [mV]

σ :8.08 [mV]

σ / µ :11.6 %

50

0.05

0

0

0.1

VIN

0.2

0

0

0.3

0.02

0.04 0.06 0.08

SNM distribution[V]

0

0

0.1

0.1

VIN

0.2

0.25

80

0.2

0.1

0.05

µ:79 [mV]

σ :8.49 [mV]

σ / µ :10.7 %

60

40

0.1

VIN

0.2

0.1

0

0

0.3

250

0.15

0.1

0.05

20

0

0

0.04 0.06 0.08

SNM distribution[V]

300

Occurrences

100

VOUT

0.25

Occurrences

120

0.3

0.15

0.02

(b)

0.3

0.2

0

0

0.3

(a)

VOUT

100

0.02

0.04 0.06 0.08

SNM distribution[V]

µ:105 [mV]

σ :2.19 [mV]

σ / µ :2.08 %

150

100

50

0

0

0.1

200

0.1

VIN

0.2

0.3

(c)

0

0

0.02

0.04 0.06 0.08

SNM distribution[V]

0.1

(d)

50

0

0

W.C.

5

10

15

Normalized delay

(a)

20

25

Rise delay

µ:11.2 [ns]

σ:1.9 [ns]

Fall delay

µ:0.201 [µ s]

σ:54.3 [ns]

100

W.C.

50

0

0

10

20

30

Normalized delay

(b)

40

Rise delay

300 µ:66.2 [ns]

σ:37 [ns]

300

Occurrences

Fall delay

µ:62.3 [ns]

σ:16.8 [ns]

100

150

Occurrences

200

Rise delay

150 µ:6.57 [ns]

σ:1.11 [ns]

Occurrences

Occurrences

Fig. 3. Butter-fly curves and SNM distribution of a) LVT, b) SVT, c) HVT, d) DVT inverters from 1000 point Monte-carlo simulation for local variations

in typical-typical (TT) corner at 300 mV and 27 ◦ C.

Fall delay

µ:2.38 [µ s]

σ:0.744 [µ s]

200

100

0

0

W.C.

20

40

60

Normalized delay

(c)

80

100

Rise delay

µ:66.4 [ns]

σ:35.9 [ns]

200

Fall delay

µ:66 [ns]

σ:16.9 [ns]

100

0

0

2

4

Normalized delay

W.C.

6

(d)

Fig. 4. Delay variations of NAND3 with different configurations at 300 mV and 27 ◦ C for 1000 point MC simulations in TT process corner. All inputs are

toggling simultaneously. The fan-out at the output of all cases is 4. The down-pointing arrows show the worst-case delays. a) LVT, b) SVT, c) HVT, d) DVT