Mul\-‐Scale Renewable Energy Storage

advertisement

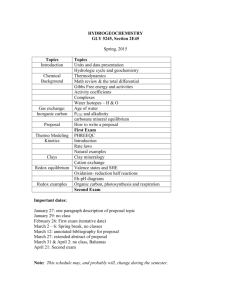

Mul=-­‐Scale Renewable Energy Storage Northeastern University Boston, MA August 19, 2014 “Recent Progress in Redox Flow Ba5ery Energy Storage Systems” H. Frank Gibbard, CEO The image cannot be displayed. Your computer may not have enough memory to open the image, or the image may have been corrupted. Restart your computer, and then open the file again. If the red x still appears, you may have to delete the image and then insert it again. Energy Storage An Exci=ng Opportunity "We liken the current commercial energy storage market to the U.S. solar market of 2005. The technology is sophis=cated enough to allow for widespread adop=on (though s=ll expensive), and the business models are just beginning to emerge." GreenTechMedia Research 2014 2 Wide Range of Applica=ons For Flow Ba5eries 1 3 Why Redox Flow Ba5eries? § Highly flexible and scalable § Separa=on of Power and Energy o More POWER = larger stack o More ENERGY = larger tank § Highly durable: 10,000+ cycles § Safe, non-­‐flammable liquid § Lowest CapEx & OpEx § Large applica=on space § High energy efficiency 4 Limita=ons of Current SOA Aqueous Redox Flow Ba5eries • Low specific energy (Wh/kg) and energy density (Wh/L) • Low specific power (W/kg) and power density (W/L) • Limited temperature range of several systems • Side reacLons, cross-­‐over, “rebalancing” • Not commercial; costs s=ll too high This presenta=on reports some progress towards removing these limita=ons 5 Why Omit Nonaqueous Redox Flow Ba5eries (NARFBs)? • LimitaLon on area-­‐specific power (mW/cm2) due to low electrolyte conducLvity1 • Variables considered (assumed perfect kineLcs) o Electrolyte conducLvity (10-­‐5 S/cm to 10-­‐2 S/cm) o Ohmic loss in electrolyte; ohmic loss in electrodes o Electrode thickness (0.16 mm to 1.6 mm) • Other factors: safety, cost • Conclusion: NARFB’s limited to possible high-­‐specific-­‐energy, niche-­‐market applicaLons 1Spring 2014 ECS MeeLng, Sun, Mench, Zawodzinski 6 Redox Flow Ba5eries: Desirable system characteris=cs • High cell voltage • High solubility of acLve materials • High efficiency o Rapid electrode kineLcs o Low ohmic resistance o Low mass-­‐transfer polarizaLon o Minimal (ideally no) side reacLons • Wide operaLng temperature range • Low electrolyte toxicity • Low-­‐cost materials • Minimal consequences of mixing of anolyte and catholyte 7 Interes=ng Aqueous Redox Flow Ba5ery Systems System Pros Cons • NegaLve potenLal of Cr2+/Cr3+ leads to H2 evoluLon • Slow negaLve electrode kineLcs Iron-­‐Chromium • Low-­‐cost acLve materials All-­‐Vanadium • Most advanced RFB system • High cost • Simple rebalancing • Limited temperature range • Cycle life demonstrated • Low energy & power density Vanadium-­‐Bromine • Higher energy density than all-­‐vanadium • Lower cost than all-­‐V • Poor control of Br2 acLvity • Immature state of development • SelecLon of separator Non-­‐Metal • Low-­‐cost, readily available acLve materials • Reversible electrode kineLcs • • • • Immature state of development Unknown long-­‐term stability Low RT energy efficiency Low cell voltage 8 Redox Flow Ba5eries: Inven=on, Early Development 1973-­‐85 NASA Lewis Research Center (L. Thaller et al.) – Many redox couples , electrode substrates, electrocatalysts and separator membranes evaluated – Iron/chromium system selected as most promising NegaLve: Cr2+ ⇌ Cr3+ + e-­‐ PosiLve: Fe3+ + e-­‐ ⇌ Fe+2 Net: Cr2+ + Fe3+ ⇌ Cr3+ + Fe+2 9 Chromium-­‐Iron Redox Flow Ba5ery Features • In principle, low cost of acLve materials • Moderately high cell voltage (Eo = 1.178, Eformal = 1.05 V) • • • • • • Only moderate solubility of acLve materials (! 1 M) Moderately wide operaLng temperature range (25-­‐65oC) Low electrolyte toxicity (for low Cr oxidaLon states) Moderate electrolyte corrosivity (≈ 1M HCl?) Fast iron electrode kineLcs on carbon felt substrate Slow reacLon kineLcs at negaLve electrode – solved? 10 Iron-­‐Chromium Scale-­‐up and Demonstra=ons • Mitsui Engineering – 1985, scale-­‐up of system to 10 kW and 80 kWh, 6000 cm2 electrodes • “Moonlight Project” iniLated in Japan in 1978 to evaluate five baneries for potenLal energy savings. o o o o o Advanced Pb-­‐acid Zinc-­‐bromine Iron-­‐chromium redox flow Vanadium redox flow Sodium-­‐sulfur • Only Iron-­‐chromium not selected for further development • More than 20-­‐year hiatus for iron-­‐chromium development 11 Iron-­‐Chromium Redox Flow Ba5ery Demo Turlock, CA Almond Farm • • • • 250 kW and 1 MWh nominal power and energy, largest iron-­‐chromium system to date Note four tanks instead of usual two for redox flow baneries Cascade™ architecture provides one-­‐pass electrolyte flow Cross-­‐over of dissimilar metal ions ameliorated – include Fe and Cr ions on both sides Redox redux – 1970’s NASA system shows new life. 12 Iron-­‐Chromium Redox Flow Ba5ery Some QuesLons • • • • • • • How extensive will Turlock tesLng be? CriLque of test results? Ever tested at full capacity? What is uLlizaLon of Turlock? Hours/day, days/week? Is surplus energy from PV/ESS systems fed to electric grid? Planned length of operaLonal period? Four-­‐tank design – problems from very large head space? What is next grid-­‐scale order? ApplicaLon? Long-­‐term tesLng? Redox Flow Ba5ery Energy Storage Needs Unqualified Successes 13 All-­‐Vanadium RFB (Skyllas-­‐Kazacos, 1986) A Chemical/Electrochemical “Tour de Force” • Four (!) “stable” oxidaLon states in aqueous soluLon • Appropriate cell voltage • Adequate electrode kineLcs Nega=ve: V2+ ⇌ V3+ + e-­‐ Posi=ve: VO2+ + 2H+ + e-­‐ ⇌ VO2+ + H2O Net: VO2+ + 2H+ + V2+ ⇌ VO2+ + H2O + V3+ Eo = 1.26 V <EOCV> ≈ 1.4 V 14 All-­‐Vanadium RFB (Skyllas-­‐Kazacos, 1986) A Chemical/Electrochemical “Tour de Force” All-­‐Vanadium Redox Flow Ba5ery Features • Ionic crossover causes coulombic inefficiency but does not require separaLon of ionic species. • Energy efficiency ~ 80% • LifeLme 10+ years, 15,000 cycles • RelaLvely rapid electrode kineLcs • Lower and upper operaLng temperatures limited • Limited solubility of acLve materials – large tanks needed • Sulfuric acid supporLng electrolyte (∼5M) • Demonstrated scalability to mulL-­‐MWh capacity • High and historically variable cost of vanadium • Ion-­‐exchange membrane expensive (e.g., Nafion!) • Low power density – large-­‐area cells required • System cost high for commercial applicaLons 15 Proven Vanadium Durability Highly Stable Electrolyte – No Aging Effects Vanadium electrolyte, 20 kWh, 60 cell stack with deep discharge cycles 1 Sumitomo Electric 16 Recent Advances in Redox Flow Ba5ery Science and Technology Office of Electricity Energy Storage Program Dr. Imre Gyuk Mul=-­‐Million Dollar Funding of Early R&D College of Engineering Electrochemical Energy Storage Lab Technical Teams That Developed Wa5Joule-­‐Licensed Technology 17 ORNL/UTK High-­‐Power, Zero-­‐Gap Architecture Cell Max power 2588 mW/cm2 Result of higher power density: much lower cell stack costs T. Zawodzinski, InternaLonal Flow Banery Forum 2013 18 Advances in All-­‐Vanadium RFB At Pacific Northwest NaLonal Lab (PNNL) Subs=tu=on of HCl for some H2SO4 in Electrolyte Simple Electrolyte Change Pays Big Performance Dividends Problem Result of Change Effect on Product Poor Energy Density; 23 Wh/L 46 Wh/L Lower cost due to smaller volume low solubility of V species 1.6 mol/L à ≥2.5 mol/L of electrolyte, smaller footprint Limited Temperature Range 10-­‐40° C à -­‐5-­‐60° C No need for acLve cooling; lower costs; higher reliability and efficiency 19 Stack + Electrolyte Cost $/kWh UTK/ORNL – PNNL Technology Core System Cost Advantage Current Vanadium Flow Ba5ery Cost 65% cost reducLon for 4-­‐ hour discharge Wa5Joule Projected Cost Discharge Time in Hours 20 GEN 2 Vanadium Redox Flow Ba5ery Under Development at WanJoule Corp. • InvenLon announced by Maria Skyllas-­‐Kozakas in 2008 • Two core U.S. patents now owned by WanJoule Advantages over SOA Vanadium Redox Flow Ba5ery • Cost reducLon in the acLve materials -­‐ replace a significant fracLon of the vanadium with less expensive bromine • Increase in the specific energy (Wh/kg) and energy density (Wh/L) over that of the all-­‐vanadium system of up to 50 percent, o Higher concentraLon of vanadium materials in the anolyte o Higher content of bromine in polybromide oil • Wide operaLng temperature range, -­‐5°C to 60°C, saves cost and increases system efficiency. No need for acLve cooling. 21 GEN 2 Vanadium – Bromine System System Concept Builds on Gen 1 NegaLve electrode reacLon: 2𝑉↑3+ +2𝑒↑− →2𝑉↑2+ PosiLve electrode reacLon: 2𝐵𝑟↑− +𝑄𝐵𝑟↓𝑛 →𝑄𝐵𝑟↓𝑛+2 +2𝑒↑ − 23 Wa5Joule Solu=ons to Gen 2 RFB Problems Problem Wa5Joule Solu=on Limited current density (20-­‐50 mA/cm2) High-­‐power UTK/ORNL technology Low round-­‐trip efficiency (<70%) UTK/ORNL technology, improved separator Lack of suitable Br2 complexing agent Proprietary complexaLon technology 23 Comparison of H-­‐Br with V-­‐Br • Hydrogen-­‐halogen regeneraLve fuel cells were evaluated at Brookhaven NaLonal Lab in the 1970’s by McBreen et al. • Recent efforts at commercializaLon at EnStorage in Israel, with a 50-­‐kW, 100-­‐ kWh demonstraLon in 2013; and technology development at LBNL and MIT • Advantages o Low cost of acLve material o High current density • Problems/concerns o Safety – flammable/explosive hydrogen-­‐bromine mixtures o OperaLon at high pressure, e.g. 300 psi; possibility of internal and external leaks o Expense of hydrogen containment/storage o Hydrogen electrode catalyst may degrade over Lme and in presence of bromine or bromide • Vanadium-­‐bromine has the advantage of high current density and none of the above concerns 24 Non-­‐Metal Redox Flow Ba5eries • Recently, aqueous redox flow baneries containing no metal ions have been reported research groups at USC1 and Harvard2 o Harvard group used organic negaLve acLve material but a bromine-­‐bromide couple for the posiLve o USC group reported a rechargeable banery based on all-­‐ organic acLve materials • The organic acLve materials used by both groups are based on quinones, molecules long known to exhibit reversible redox reacLons 1Bo Yang, Lena Hoober-­‐Burkhardt, Fang Wang,a G. K. Surya Prakash, and S. R. Narayanan, Journal of The Electrochemical Society, 161 (9) A1371-­‐A1380 (2014) 2B. Huskinson, M.P. Marshak, C. Suh, S. Er, M.R. Gerhardt, C.J. Galvin, X. Chen, A. Aspuru-­‐Guzik, R.G. Gordon and M.J. Aziz,, Nature 505, 195–198 (2014). 25 Non-­‐Metal Redox Flow Ba5eries • Advantages of these systems include low cost, the ability to tailor organic molecules to vary their redox potenLal, observed high current densiLes, and cycleability without pronounced capacity loss • Disadvantages include many years of development Lme due to technological immaturity; typical low solubiliLes of the acLve species; lack of stability data over several years, necessary for useful large-­‐scale energy storage; quesLonable ability for rebalancing in the event of cross-­‐over; and low cell voltage. • These new systems will be interesLng to follow as they are developed. 26 Thank you Frank Gibbard, Ph. D. CEO & Founder frank@wanjoule.com 603-­‐502-­‐3234 Greg Cipriano VP Business Development & Founder greg@wanjoule.com 508-­‐942-­‐8995 Wa5Joule Corpora=on Unit M2D2 600 Suffolk St. Lowell, MA 01854 27