Transformer Temperature-Rise Test Certificate - 1000 kVA

advertisement

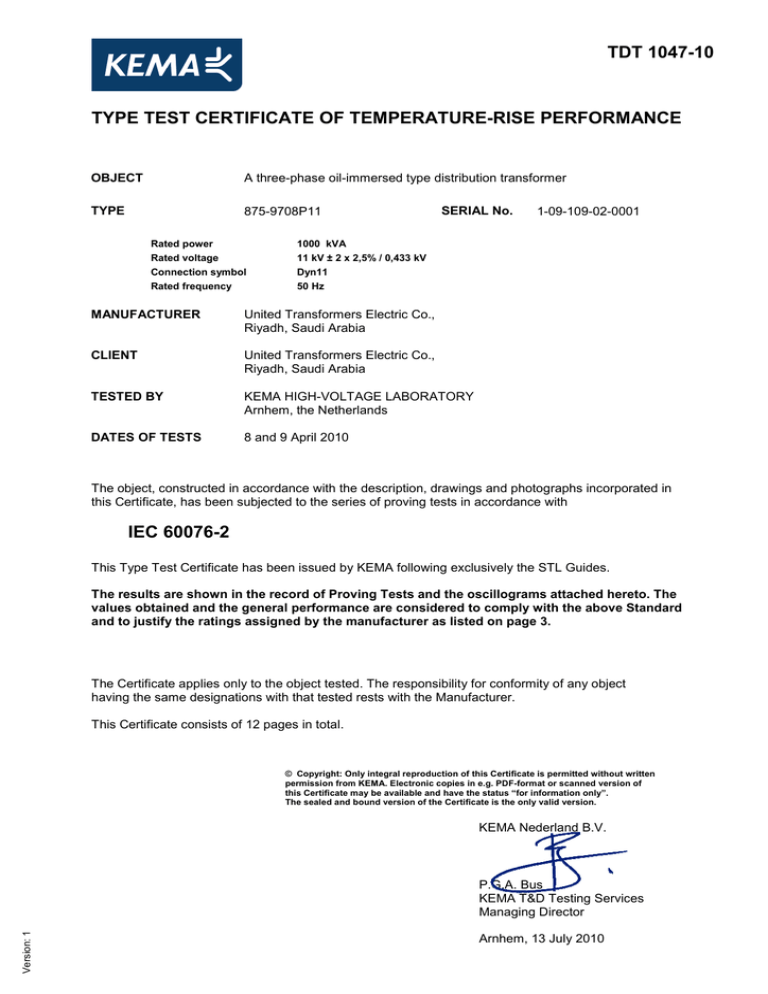

TDT 1047-10 TYPE TEST CERTIFICATE OF TEMPERATURE-RISE PERFORMANCE OBJECT A three-phase oil-immersed type distribution transformer TYPE 875-9708P11 Rated power Rated voltage Connection symbol Rated frequency SERIAL No. 1-09-109-02-0001 1000 kVA 11 kV ± 2 x 2,5% / 0,433 kV Dyn11 50 Hz MANUFACTURER United Transformers Electric Co., Riyadh, Saudi Arabia CLIENT United Transformers Electric Co., Riyadh, Saudi Arabia TESTED BY KEMA HIGH-VOLTAGE LABORATORY Arnhem, the Netherlands DATES OF TESTS 8 and 9 April 2010 The object, constructed in accordance with the description, drawings and photographs incorporated in this Certificate, has been subjected to the series of proving tests in accordance with IEC 60076-2 This Type Test Certificate has been issued by KEMA following exclusively the STL Guides. The results are shown in the record of Proving Tests and the oscillograms attached hereto. The values obtained and the general performance are considered to comply with the above Standard and to justify the ratings assigned by the manufacturer as listed on page 3. The Certificate applies only to the object tested. The responsibility for conformity of any object having the same designations with that tested rests with the Manufacturer. This Certificate consists of 12 pages in total. Version: 1 Order No: 70971230 © Copyright: Only integral reproduction of this Certificate is permitted without written permission from KEMA. Electronic copies in e.g. PDF-format or scanned version of this Certificate may be available and have the status “for information only”. The sealed and bound version of the Certificate is the only valid version. KEMA Nederland B.V. P.G.A. Bus KEMA T&D Testing Services Managing Director Arnhem, 13 July 2010 -2- TDT 1047-10 TABLE OF CONTENTS Version: 1 TABLE OF CONTENTS .......................................................................................................................... 2 1 Identification of the test object......................................................................................................3 1.1 1.2 Ratings assigned by the manufacturer and proved by tests ........................................................3 Description of the test object........................................................................................................3 1.3 List of drawings ............................................................................................................................4 2 2.1 General information......................................................................................................................5 The tests were witnessed by........................................................................................................5 2.2 The tests were carried out by.......................................................................................................5 2.3 2.4 Purpose of the test .......................................................................................................................5 Measurement uncertainty.............................................................................................................5 2.5 Applicable standards and sequence of tests ...............................................................................5 3 Temperature-rise test ...................................................................................................................6 3.1 3.2 Readings taken after total losses injection (in steady-state condition) ........................................6 Readings taken after 1 hour rated current injection .....................................................................7 3.3 3.4 Cooling-down curves taken after switch-off .................................................................................7 Calculation of average winding temperature-rise.........................................................................8 3.5 Requirements and results ............................................................................................................8 APPENDIX A MEASUREMENT UNCERTAINTIES........................................................................... 9 APPENDIX B MANUFACTURER’S DRAWINGS ............................................................................ 10 -3- 1 IDENTIFICATION OF THE TEST OBJECT 1.1 Ratings assigned by the manufacturer and proved by tests Rated power Rated primary voltage 1000 11 kVA kV Rated secondary voltage Rated primary current 433 52,5 V A Rated secondary current 1333 A Rated frequency 1.2 Hz Description of the test object Manufacturer Version: 1 50 Designation United Transformers Electric Co., Riyadh, Saudi Arabia 1000 kVA Serial number Year of manufacture 1-09-109-02-0001 2009 Number of phases 3 Insulation levels - HV winding 75 / 28 kV - LV winding Tapping range - / 3 kV ± 2 x 2,5% Number of tappings Impedance voltage 5 5,45% Connection symbol Dyn11 Type of cooling Primary winding material ONAN Cu Secondary winding material Reference temperature Cu 75 °C TDT 1047-10 -4- 1.3 TDT 1047-10 List of drawings The manufacturer has guaranteed that the object submitted for tests has been manufactured in accordance with the following drawings. KEMA has verified that these drawings adequately represent the object tested. The following drawings are included in this Certificate. 875-9708 P11 Rev. O 721-9708 P11 Rev. O Version: 1 The following drawings are kept in KEMA’s files and are listed for reference only. 400-0052E Rev. B 850-0004 P Rev. B 061-0392P Rev. O 061-9708P Rev. O 040-7041P Rev. O 040-8072P Rev. O 939-9708P11 Rev. O 105-0921E Rev. O -5- 2 GENERAL INFORMATION 2.1 The tests were witnessed by TDT 1047-10 The tests have not been witnessed. 2.2 The tests were carried out by Name Company Smeenk, S. Jansen, B. KEMA High-Voltage Laboratory, Arnhem, The Netherlands 2.3 Purpose of the test Purpose of the test was to verify whether the material complies with the specified requirements. 2.4 Measurement uncertainty A table with measurement uncertainties is enclosed in appendix A. Unless otherwise indicated in the report, the measurement uncertainties of the results presented are as indicated in this table. 2.5 Applicable standards and sequence of tests When reference is made to a standard and the date of issue is not stated, this applies to the latest issue including amendments, which have been officially published prior to the date of the tests. Version: 1 The sequence of the tests can be derived from the indicated dates and does not necessarily follow the sequence of presentation. -6- 3 TDT 1047-10 TEMPERATURE-RISE TEST Standard and date Standard Test date IEC 60076-2, clause 5.2.2 8 and 9 April 2010 Environmental conditions Ambient temperature Temperature of test object 20 20 °C °C Ambient air pressure Humidity 1023 4 hPa 3 g/m Initial transformer data (in principal tapping position: 3) DC-resistance between terminals B and C DC-resistance between terminals b and c No-load losses Load losses Total losses Rated current 3.1 Rdc-HV Rdc-LV P0 Pcu Ptot In 864,5 1,366 1341 9800 11141 52,49 mΩ mΩ W W W A (75 °C) Readings taken after total losses injection (in steady-state condition) sensor no. top oil (a) (°C) 1 59,39 ambient (a) bottom oil (a) (°C) (°C) 20,45 38,90 for information only phase voltages (V) 2 3 4 59,46 20,48 20,45 38,50 U V W average average 59,43 20,46 38,70 668 666 670 668 currents (A) losses (W) 56,0 55,9 56,0 56,0 total 3688 3762 3685 11135 calculation of top oil and average oil temperature-rise top oil temperature-rise ∆ θ top (a) = θ top (a) - θ amb (a) average oil temperature-rise (a) ∆ θ oil (a) = ((θ top (a) + θ bot (a)) / 2) - θ amb (a) Version: 1 (20,2 °C) (20,2 °C) 39,0 28,6 K K -7- 3.2 Readings taken after 1 hour rated current injection sensor no. 1 2 3 4 average top oil (b) (°C) 61,02 61,08 ambient (b) (°C) 21,55 21,62 21,57 bottom oil (b) (°C) 40,40 40,40 61,05 21,58 40,40 calculation of average oil temperature average oil temperature (b) 3.3 TDT 1047-10 for information only phase voltages (V) U 623 V 626 W 626 average 625 currents (A) 52,4 52,3 52,4 52,4 total θ oil (b) = ((θ top (b) + θ bot (b)) / 2) - θ amb (b) losses (W) 3299 3318 3146 9763 50,73 K Cooling-down curves taken after switch-off temperature [°C] All Cooling Down Curves 75 74 73 72 3 2 y = -0,0018x + 0,07x - 1,5298x + 71,398 71 70 69 68 67 66 65 64 3 2 63 y = -0,0056x + 0,1693x - 2,1866x + 69,923 62 61 60 59 58 57 56 55 0 1 2 3 4 5 6 7 8 9 10 time [min] HV Winding LV Winding Version: 1 extrapolated absolute winding temperatures immediately after switch-off high voltage winding θ HV low voltage winding θ LV 71,40 69,92 °C °C -8- 3.4 TDT 1047-10 Calculation of average winding temperature-rise average temperature difference winding-oil high voltage winding ∆ θ HV (cor) = θ HV - θ oil (b) low voltage winding ∆ θ LV (cor) = θ LV - θ oil (b) 20,7 19,2 °C °C average winding temperature-rise high voltage winding low voltage winding 49,3 47,8 K K 3.5 ∆ θ HV = ∆ θ HV (cor) + ∆ θ oil (a) ∆ θ LV = ∆ θ LV (cor) + ∆ θ oil (a) Requirements and results item determined top oil temperature-rise average winding temperature-rise HV winding average winding temperature-rise LV winding (K) 39 49 48 ∆ θ top ∆ θ HV ∆ θ LV guaranteed value (K) ≤ 45 ≤ 50 ≤ 50 requirement IEC 60076-2 (K) ≤ 60 ≤ 65 ≤ 65 Version: 1 Result The top oil temperature-rise and the average winding temperature-rises of the windings are in compliance with the requirements. -9- APPENDIX A TDT 1047-10 MEASUREMENT UNCERTAINTIES The measurement uncertainties in the results presented are as specified below unless otherwise indicated. measurement measurement uncertainty dielectric tests peak value: ≤ 3% and impulse current tests time parameters: ≤ 10% capacitance measurement 0,3% tan δ measurement ± 0,5% ± 5x10 -5 partial discharge measurement < 10 pC 10 : 2 pC - 100 pC : 5 pC > 100 pC :20% measurement of impedance ac-resistance measurement ≤ 1% measurement of losses ≤ 1% measurement of insulation resistance ≤ 10% measurement of dc resistance 1 µΩ - 5 µΩ : 1% 5 µΩ - 10 µΩ : 0,5% 10 µΩ - 200 µΩ : 0,2% radio interference test 2 dB calibration of current transformers 2,2 x 10 Ii/Iu and 290 µrad calibration of voltage transformers 1,6 x 10 Ui/Uu en 510 µrad measurement of conductivity 5% measurement of temperature -50 °C - -40 °C : 3 K -40 °C - 125 °C : 2 K -4 -4 125 °C - 150 °C : 3 K tensile test sound level measurement 1% type 1 meter as per IEC 651 and ANSI S1.4.1971 Version: 1 measurement of voltage ratio 0,1% -10- APPENDIX B TDT 1047-10 MANUFACTURER’S DRAWINGS Version: 1 2 pages drawing no. description/title date rev. 875-9708 P11 General arrangement drawing 1000 kVA, 11 / 0,433 kV, 50 Hz ground mounted transformer type 20-06-09 O 721-9708 P11 Rating & diagram plate 1000 kVA, 11 / 0,433 kV, 50 Hz 20-06-09 O Version: 1 -11- TDT 1047-10 Version: 1 -12- TDT 1047-10