U.S. Department of Energy`s Clean Cities Program

advertisement

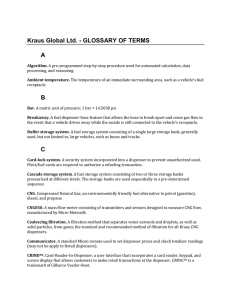

U.S. Department of Energy’s Clean Cities Program CNG Deployment in the United States: Approach and Lessons Learned Marcy Rood Argonne National Laboratory mroodwerpy@anl.gov September 10, 2015 eere.energy.gov Agenda Background of U.S. Natural Gas Vehicle Deployment Federal Role Clean Cities Lessons Learned National Renewable Energy Laboratory (NREL) Image Galleryeere.energy.gov #14922 & #23854 Infrastructure: Natural Gas Station Availability CNG and LNG Station Growth Over Time CNG LNG Source: AFDC Station Locator, May 2014; includes public and private stations eere.energy.gov Station growth has been especially strong in states with incentives and/or large price advantages In 2000, most stations operated by LDCs; in 2013 most by fuel retailers Price advantage may incentivize CNG in CA, WI, OK, UT, OH States with most public stations include populous (CA, NY) and gas-rich (OK, UT) Other state incentives: Tax credits for vehicle purchase Grants for station development State fleet purchasing requirements (CO, TX, OK) HOV lane access (CA) Memorandum of Understanding (22 states) Bulk Purchases Sources: U.S. DOE, AFDC, www.afdc.energy.gov;HSIP Gold 2012; NAVTEC; FRA; ESRI; Shaded Relief Copyright 2013 ESRI. 4 Janeere.energy.gov 2014 TRB Natural Gas Price Stability April 2015 Alternative Fuel Price Report Natural Gas (CNG) 5 $2.09/GGE Propane $2.92/gallon Gasoline $2.42/gallon Diesel $3.06/gall eere.energy.gov U.S. Incentives and Mandates for Alternative Fuel Vehicles Industry would like to eliminate a 12% federal excise tax on natural gas trucks Income Tax Credit for Infrastructure (expired, however usually reinstated the end of the year) In July 2015, Congress passed that LNG is now taxed on an energy content that is equal to diesel, rather than a volumetric gallon $0.243 CNG taxed $0.183/gge Income Tax Credit for AFVs (expired) Excise Tax Credit of 50-cent per gge of fuel sold (expired, however usually reinstated the end of the year) Mandates for Federal, State, and Fuel Provider Fleets 6 eere.energy.gov Fleet Applications Light-Duty NGVs Suitable for light-duty needs in private and government fleets Taxi fleets Medium-Duty NGVs Vans and shuttles Airports and taxi fleets Heavy-Duty NGVs Refuse haulers Transit buses School buses Long-haul trucks Street sweepers Snowplows Short-haul delivery trucks Cement trucks 7 Natural Gas Vehicles for America www.ngvamerica.org eere.energy.gov Current State of the Market for NGVs • 120-150K NGVs – 66K LDVs using 22M GGE – 23K MDVs using 20M GGE – 32K HDVs using 205M GGE • Current niche markets – Transit bus • 20% Natural Gas – Refuse haulers • 50% of new sales • Navigant projects growth from today to 2024 – From 18K to 24K HDVs sold/yr – From 29K to 49K pickups sold/yr eere.energy.gov Federal Level Role National Support Framework for Industry, Local Governments, Fleets to Gather Around Clean Cities Model Quality, unbiased, fuel neutral information and analysis Connection to technical assistance, training and expertise Federal Fleet Federal Role Leadership Consistent Message and Policy Research and Development Safety and Environmental Standards and Enforcement 9 eere.energy.gov Clean Cities’ Unique Assets Local Strategy to Advance a National Goal 10 Coordinators and Coalitions Technical Information and Resources eere.energy.gov What is U.S. DOE Clean Cities? A voluntary, locally based industry/government partnership Established Network of Coalitions Coordinated by U.S. Department of Energy, with Argonne as one of the lead laboratory’s for Clean Cities support ~100 coalitions & partnerships in 47 states, covering 78% of the U.S. population Builds markets for cleaner-burning CNG and other alternative fuel vehicles to reduce dependence on petroleum Fleet customers primary audience Clean Cities is on track to meet its goal of reducing 2.5 billion gallons of petroleum per year by 2020. 11 Industry, all levels of government, academia, and fleets working together to build a safe and sustainable market place. eere.energy.gov Clean Cities Portfolio of Technologies Alternative fuels Ethanol (E85) Biodiesel Compressed and liquefied natural gas (CNG/LNG) Propane Electricity Hydrogen Fuel economy Hybrids Ecodriving Idle-reduction Photo courtesy of East Tennessee Clean Fuels eere.energy.gov Clean Cities’ Stakeholders & Accomplishments Coalitions are made up of local and national stakeholders (15,000+) • Stakeholders from businesses, city & state governments, transportation industry, community organizations, fuel providers, fleet operators, such as transit 48% private sector 475,000 AFVs deployed in 2013 20,000 AFV stations public and private Cumulative GHGs Adverted 34.4 million tons Cumulative Petroleum Displaced 6.5 billion gallons 13 eere.energy.gov Current Clean Cities Activities in NGVs • • • • • NGVs ~60% of Clean Cities AFV petroleum displacement – Coordinator project development – Recovery Act – Community Planning Communication products – AFDC – MotorWeek – Toolkits – Clean Cities Now Partnerships – Natural Gas Vehicle Technology Forum – National Clean Fleet Partnership – Tank Inspection Working Group Technical assistance – Tiger Teams – Technical reports Tools – AFDC Station Locator – AFLEET Tool – VICE Model – JOBS NG – PREP Tool eere.energy.gov Other Considerations: Return on Investment Tools afdc.energy.gov/tools eere.energy.gov Clean Cities’ Accomplishments April 2011 - President Announces Clean Fleets Partnership with 5 charter partners • Challenge to top fleets across the country to adopt alt-fuels, advanced vehicles, petroleum reduction plans • Pace-setters for others to follow (photo courtesy of White House) April 2012 – Program has grown To 26 National CF Partners (logos used with permission of companies represented) Direct Impact: The l00 largest commercial fleets account for more than 1 million vehicles. Every 2,000 vehicles converted to alternative fuel = 1M gal/year petroleum displacement. eere.energy.gov Clean Cities’ Accomplishments National PBS Partnership 100+ segments on alternative fuels, advanced vehicles, fuel economy Success stories Clean Cities TV YouTube Online video catalog Training: first responder & vehicle safety, workforce development, coordinators http://www.youtube.com/user/ CleanCitiesTV 17 eere.energy.gov Signage/Visibility Effective signage is essential to communicating and promoting information on alternative fuel vehicles. 18 eere.energy.gov Web-Based Resources DOE maintains sites with information in detail on current technology, regulations, incentives, training, and strategies Clean Cities FuelEconomy.gov Alternative Fuels Data Center 19 eere.energy.gov Clean Cities’ Publications Clean Cities Publications Natural Gas Basics Guide to Alternative Fuel and Advanced Medium- and Heavy-Duty Vehicles Clean Cities 2015 Vehicle Buyer’s Guide Business Case for CNG in Municipal Fleets Clean Cities Vehicle and Infrastructure Cash-Flow Evaluation (VICE2.0) Model to evaluate the return on investment and payback period for natural gas vehicles and fueling infrastructure Case Study—Compressed Natural Gas Refuse Trucks– August, 2014, A. Burnham, ANL; M.Laughlin, Energetics Costs Associated with CNG Vehicle Fueling Infrastructure— September, 2014, M. Smith, New West Technologies; J. Gonzales, NREL Compressed Natural Gas (CNG) Transit Bus Experience Survey April 2009 — April 2010, R. Adams, Marathon Technical Services and D.B. Horne, Clean Vehicle Education Foundation www.afdc.energy.gov/publications 20 eere.energy.gov LNG, CNG, and Propane Case Studies - Overview • Key findings: LNG tractors – LNG and diesel fuel economy similar (~5.5 MPDGE) – Fuel cost savings of 33 cents per mile (payback of about 3 years for vehicle costs) • Key findings: Propane school buses – Propane and diesel fuel economy similar (~7 MPDGE) – Fuel cost savings of around 18 cents per mile (payback of vehicle and fueling station costs in 3-8 years) – Positive feedback from fleets • Key findings: CNG refuse haulers – CNG and diesel fuel economy similar for these vehicles (~2.1 MPDGE) – Fuel cost savings of about 90 cents per mile (payback of vehicle and fueling station costs in 5-7 years) – Very positive feedback from drivers • AFLEET Tool—provided the data on payback periods, GHGs avoided, & petroleum reduced http://greet.es.anl.gov/afleet eere.energy.gov Benefits: CNG and Refuse Trucks Fit Well Together • Refuse haulers – 8000+ refuse trucks use CNG – > 50% of new U.S. sales • Benefits for this application Cost savings Environmental benefits Operational benefits Similar performance Fuel diversity for emergency preparedness – Fleet/driver satisfaction – – – – – Refuse truck used as snowplow 22 eere.energy.gov CNG Refuse Hauler Deployments through ARRA • Clean Cities collected information from Recovery Act-funded CNG refuse hauler projects – – – – Fleet manager/driver & operational data information for 70 vehicles Challenges to deployment and operation and solutions Economic and environmental performance Detailed case study by Argonne National Laboratory and Energetics Incorporated Fleet and Location Trucks Purchased Stations Deployed Republic Services (Boise, ID) 29 4 Groot (Chicago, IL) 20 1 City of Milwaukee (WI) 21 2 23 eere.energy.gov CNG Refuse Hauler Case Study Overview • All trucks in study used 9-L Cummins ISL-G natural gas engines • Wide variety of available configurations for CNG trucks in this study – Manufacturers (Autocar, Crane Carrier, Mack) – Body configurations (front loader, automated side loader, rear loader, recycling) 24 eere.energy.gov CNG Used In Similar Duty Cycles and Applications • CNG vehicles can meet same mission profile as diesel vehicles • • Usage patterns similar between CNG and diesel (VMT/fuel use) Fuel economy also very similar on energy equivalent basis to older diesels being replaced (ARRA Fleet Results) 25 eere.energy.gov CNG Can Have Environmental Benefits • For the 70 trucks studied: • • Annual greenhouse gas reductions of 1,800 tons Annual petroleum displacement of 520,000 DGE (ARRA Fleet Results) 26 eere.energy.gov Low Fuel Costs Lead to Operational Cost Savings • Fuel cost savings • 90 cents per mile, or • $2 per DGE • Average costs for fleets in this study • • • Vehicle incremental cost = $38k Station cost = $1.1 million Garage facility upgrades = $95k • Potential paybacks of vehicle and fueling station costs in 5-7 years (ARRA Fleet Results) 27 eere.energy.gov Infrastructure Considerations • CNG fueling stations – Permitting for stations (negotiation with multiple state and local agencies) – Lead time for equipment – CNG station calibration (weights and measures involvement for public sale) • Garage/repair facility modifications – Methane alarms (audible/visual) and ventilation systems – Modifications can be costly – Need experienced contractors to complete them 28 eere.energy.gov CNG Well-Received by Drivers and Fleet Personnel • Very positive feedback from the fleets on CNG trucks – “Drivers love the trucks” (Republic Services) – Drivers feel better and have more energy after their shifts because of reduced noise and emissions (City of Milwaukee) • Training important for successful deployment – Driver training – Mechanic training – CNG cylinder inspection 29 eere.energy.gov Case Study #1: Kansas City Public Schools Invests in CNG Buses • Replaced 47 of its 120 buses with a transit-style bus with a CNG engine; also converted three Type A buses to CNG • $3.6 million in grant funding for the buses, a fueling station, a mobile refueler, and maintenance facility modifications Just the Numbers • CNG School Buses: 50 • Fuel Cost Savings: $20,000 to $30,000 per month • Petroleum Displacement: 15,000 gallons of diesel fuel per month “Our primary motivation for doing this was fuel costs. They're high, and getting higher, and we're facing budget cuts. Also, CNG is a clean fuel and benefits the environment.” —George Taylor, Director of Transportation Image and More Information: AFDC Case Study Search, Kansas City Kansas Public Schools Invests in CNG Buses, http://www.afdc.energy.gov/case/1016 eere.energy.gov Tank Inspection Working Group Initial Focus: CNG Transit and School Bus Fleets A growing number of buses purchased each year are fueled by CNG (Industry estimates approximately 25% of new transit buses per year). Over 10,000 CNG Transit and School Buses are now on the road in North America. (With 4-8 fuel tanks per bus this means that some 50,000+ CNG fuel tanks need to be accounted for). – The average transit bus is in service for 12-15 years. School buses are often 20+ years. Buses funded through Federal Transit Administration (FTA) programs are required to remain in service for a minimum of 12 years. A growing number of CNG buses have reached or are approaching the 15 year lifespan of both the bus and fuel tank. – WMATA recently approached DOE for guidance on procedures/best practices associated with the retirement of 164 CNG transit buses from 2001-02, which hold a total of 1,148 fuel tanks (7 per bus). This highlighted the need for training, tools and resources. – The transit industry often has meticulous fueling and maintenance data for CNG fuel tanks. eere.energy.gov Existing Strategies (potential best practices for CNG tanks) 1. State of Texas (linked to annual vehicle safety inspections) – Effective September 1, 2014, when a CNG vehicle comes in for its annual safety inspection, the owner or operator must prove that the vehicle’s CNG fuel tank has been inspected, found to comply with applicable federal compressed natural gas fuel container integrity standards (49 Code of Federal Regulations 571.304), and is not past its expiration date, under rules recently adopted by the Texas Public Safety Commission. – The Texas Department of Public Safety will implement the CNG fuel tank-inspection program. The proof of compliance must document that the vehicle is operated by a fleet that employs a technician who is certified to inspect CNG fuel tanks. 2. Pacific Gas & Electric (linked to fueling station access) – PG&E is addressing CNG fuel tank safety risks with a requirement to provide a signed CNG fuel system inspection certificate for any vehicle to be fueled at a PG&E CNG facility – Completed inspection records for each vehicle be submitted to PG&E by December 12, 2014, to avoid account suspension. – The inspection consists of a completed Certificate of Inspection of Compressed Natural Gas Vehicle Fuel System form accompanied by the automobile repair/inspection business work order showing the business letterhead, date, qualified inspector name and qualifications summary, and the results of the inspection. eere.energy.gov Clean Cities Lessons Learned Incentives Education and Outreach Niche markets are a must, including an anchor fleet Simultaneous development of infrastructure and AFVs Air quality and energy security are strong drivers Program must be flexible to allow local solutions Bridging gap between available technologies and market demand requires technical, financial, and policy assistance Unbiased data on all available fuels and technologies Showcase achievements of fleet managers and recognize them Coordinators are the most important resource available to public decision-makers—Invest in Good Coordinators Coalitions comprised of the public and private sector will achieve success Training, Training, Training 33 eere.energy.gov Clean Cities 20th Anniversary 34 eere.energy.gov Websites and Contact Information Clean Cities Website www1.eere.energy.gov/cleancities/ Clean Cities Coordinators www1.eere.energy.gov/cleancities/coaltions Alternative Fuels Data Center www.afdc.energy.gov Compressed Natural Gas (CNG) Transit Bus Experience Survey April 2009 — April 2010, R. Adams Marathon Technical Services, Heidelberg, Ontario, Canada and D.B. Horne,Clean Vehicle Education Foundation,Acworth, Georgia http://www.nrel.gov/docs/fy10osti/48814.pdf Clean Vehicle Education Foundation http://www.cleanvehicle.org L 35 David Hester Senior Advisor U.S. Department of Energy 1000 Independence Avenue, SW Washington, D.C. 20585 Office: (202) 586-3184 Email: david.hester@hq.doe.gov Marcy Rood Transportation Environmental Analyst Argonne National Laboratory 217-362-9844 Email: mroodwerpy@anl.gov Dr. Jeffrey M. Seisler CEO Clean Fuels Consulting Avenue Louise 200 1050 Brussels Belgium Office: 32.2.647.3218 Mobile:32.473.284.603 www.cleanfuelsconsulting.org eere.energy.gov Thank You Sponsors: U.S. Department of Energy’s Office of International Affairs and Office of Vehicle Technologies, Clean Cities Program Presentations and Expertise: – Doug Horne, Clean Vehicle Education Foundation – Jeff Seisler, Clean Fuels Consulting – Gert-Jan Rap, RAP Clean Vehicle Technology 36 eere.energy.gov Background slides 37 eere.energy.gov Dual Fuel Engine Fleet Applications 20 Questions That Need Answers to Properly Advise Fleets 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Make/Model /Year of Truck Vehicle Identification Number (VIN) Engine Manufacturer/ Model and Size (Liters) Engine Serial Number (different than VIN) Has engine ever been modified/equipped with aftermarket devices to improve mileage or increase horsepower? Odometer Reading Daily/Weekly Miles Traveled Diesel Tank Capacity Average Current Miles Per Gallon Truck Route - Fixed or Varied Size of Fleet Truck Replacement Cycle eere.energy.gov Dual Fuel Engine Fleet Applications 20 Questions That Need Answers to Properly Advise Fleets (page 2) 13. 14. 15. 16. 17. 18. 19. 20. Fueling Preferences – onsite, on route, times a day/times per week Fueling Preferences – driver fuels own truck, dedicated fuelers, on-site wet hosing (fuel service provider) Preference on Choice of Trucks for Conversion – newest, oldest, least odometer miles, highest daily mileage , other Fuel Savings expectations Operational savings expectations Source of funds for conversions – capital funds, grants, combination of both Are you willing to invest in an engine diagnostic test ($250-$500) to confirm the mechanical health of the engine you wish to convert? General reasons for your interest in converting your diesel trucks eere.energy.gov Building A Safe Marketplace EQUIPMENT STANDARDS: • Materials Selection • Factors of Safety • Verification • Testing EDUCATION OF END USERS: Drivers, Fleet Managers, Fueling Station Operators, First Responders, General Public INSTALLATION CODES: • Station Siting • Pressure • Management • Cylinder Safety QUALIFIED PERSONNEL: • Training • Operating and maintenance procedures eere.energy.gov The Facts Natural Gas Vehicles have been used in North America for over 40 years Codes and Standards (C&S) provide opportunity for safe and reliable operation of NGVs C&S evolve with new technology and field experience People make mistakes, continuous training is critical for safe operations Cylinders have a limited life – It is necessary to track cylinders and properly decommission and dispose Source the www.cleanvehicle.org 41 eere.energy.gov SAFETY: CNG Cylinder Severe Abuse Test Only an armor-piercing bullet shot from a NATO-style assault rifle can penetrate a metal cylinder. Source: Dr. Jeff Seisler, Clean Fuels Consulting 42 eere.energy.gov Cylinder Safety: The Fundamental Issues What the United States has experienced: 1. Improper installation of cylinders has led to the majority of cylinder failures 2. Lack of periodic/after-incident cylinder inspections or failure to act on issues found has led to cylinder failures 3. Lack of information on vehicle/cylinder location/ownership has allowed potentially unsafe cylinders to remain in service and fail 4. Failure to properly maintain, operate fueling stations and failure of in tank solenoid valves has been a secondary cause for some cylinder failures Source www.cleanvehicle.org 43 eere.energy.gov Incidents in North America Clean Vehicle Education Foundation has recorded since 1984 98 incidents of which 68 involved CNG vehicles – 37 incidents involve either a CNG leak (15) or a release of CNG by the Pressure Relief Device (PRD) activation (22) – There were 19 cylinder failures: • 4 Type 1 (all steel) - 1 in fire where PRD failed, 1 by external corrosion and 2 by over pressurization by faulty fueling system • 4 Type 2 (hoop wrapped) - 1 by fire where PRD was isolated from cylinder body, 3 from a combination of Stress Corrosion Cracking (SCC) and over pressurization • 8 Type 3 (full wrap and metal liner) – SCC from acid/chemical degradation of e glass wrap • 3 Type 4 (full composite with plastic liner) – 1 in localized fire and 2 by physical damage – Excellent safety record has minimized loss of life Source: the www.cleanvehicle.org 44 eere.energy.gov Installation Issues With NGV market growth and the significant saving in fuel cost, independent conversions of CNG vehicles by untrained mechanics have presented safety concerns Lessons Learned: Develop a nationwide certification program for conversion shops Develop programs to train/test/certify conversion shops and technicians Encourage technicians to be ASE certified to service NGVs through a voluntary program where they receive basic C&S information Source www.cleanvehicle.org 45 eere.energy.gov Installation Issues: Refuse Hauler Fires — PRD Vent Routing 1. 2. PRDs not vented up, away from vehicle—responsible for the rapid inclusion of other trucks in the fire. The vehicle at the center of the fire still had full CNG tanks and hydraulic reservoir. Source www.cleanvehicle.org 46 eere.energy.gov Inspection Issues: Type 1 Cylinder Incidents Type 1 cylinder failed due to extensive external corrosion, the cylinder was not visually inspected for over 10 years The cylinder was also subjected to over pressure by defective fueling system, the 2400 psi cylinder was potentially subjected to 6000 psi Lessons Learned: Adopt Inspection Policies (at a minimum 36,000 miles or every Three Years, whichever comes first) Visual inspect the CNG fuel systems (at this time, the best method of monitoring the overall safety of NGV fuel systems) Create a pool of certified cylinder inspectors 47 Source: www.cleanvehicle.org eere.energy.gov Inspection Issues: Type 3 Cylinder Incidents Example of improper installation and failure to take proper action from an after accident inspection Lessons Learned: Train Inspectors, Mechanics, Fleet Managers, and First Responders Develop enforcement program for periodic and after incident cylinder inspections Source: www.cleanvehicle.org 48 eere.energy.gov Inspection and Information Issues: Type 3 Cylinder Incident Converted 2005 Chevrolet pickup to run on natural gas supplied by a fuel maker using fuel from a well on the property The Type 3 cylinders were 2 years beyond their 15-year useful life Lessons Learned: Cylinders removed at end of life should be destroyed using proven methods—develop standards and process Develop cylinder/vehicle tracking methodology Train Inspectors 49 Source www.cleanvehicle.org eere.energy.gov Inspection and Information Issues: Understand the Label In the United States, we do not know location or owners of vehicles/cylinders Old cylinders (prior to 1996) are still in use Cylinders should be removed at their end of life and disposed properly Lessons Learned: Set up Tracking System so owners track the date or operators of the fueling stations can and take appropriate action Take appropriate action after an accident Train & certify qualified cylinder inspectors 50 eere.energy.gov Fueling Issues: Station Overfilling — Deficiencies No overpressure device as required by code and best practice—2 stations. Overpressure devices on 3000 psig hoses tampered with at 3rd station (see right) High pressure solenoid valves did not provide positive shutoff (ball valves much more effective and reliable). Station designed to fuel both 3000 and 3600 psi vehicles—station is particularly susceptible to overfilling 3000 psi vehicles. Source www.cleanvehicle.org 51 eere.energy.gov Fueling Issues: Tampering To Increase Fill Pressure Safety Relief Valve security wire has been cut, possibly to allow higher fueling pressures on this 3000 psi system Lessons Learned: Train fuel station maintenance & operating personnel Develop contact information for each fueling station and provide basic safety information Adopt current codes and standards Source: www.cleanvehicle.org 52 eere.energy.gov Fueling Issues: CNG and LPG are not the same *Courtesy of Gert-Jan Rap, RAP Clean Vehicle Technology Recklinghausen – Germany, 2000 Car mechanic refuels its LPG car at a CNG filling station. He used a “self-made” adapter. Working pressure of LPG tank is only 30 bar. The same happened in Emmendingen – Germany circa five months before. The driver thought : “Gas is Gas” eere.energy.gov Fueling Issues: CNG and LPG are not the same *Courtesy of Gert-Jan Rap, RAP C,lean Vehicle Technology Note: The truck was registered in the Netherlands; the truck driver however came from Lithuania Picture : Pontus Lundahl / Scanpix Göteborg, Sweden 15-01-2010 Truck driver from Lithuania refuels its LPG bottle for his truck based “kitchen” at a CNG filling station. He used a self-made adapter. Only after a couple of tries he was able to start filling. eere.energy.gov Best Practices: Priority Training Subject Requirements • • • • • • • • • • • • Vehicle roadworthy inspection Delivery to customer inspection: regulatory compliance Driver training (driving, emergency response actions) Refueling Mechanics: safety training, engine repair & maintenance, diagnostic repair systems, cylinder inspection Compressor station operation & maintenance Periodic inspections including CNG cylinders and tailpipe emissions Vehicle conversions & conversion workshops Vehicle facility design/redesign (fleet storage, fuelling: fast-fill; slow fill) Design (or upgrading) of indoor maintenance facilities Fire marshals, safety personnel, & local code officials Training the trainers PRIORITIES: First tier (to end 2011) Second tier (2012) Third tier (2013+) Source: Dr. Jeff Seisler, Clean Fuels Consulting 55 eere.energy.gov Organizations to Educate End Users Industry EDUCATION OF END USERS: • Drivers • Fleet Managers • Fueling Station • Operators • First Responders • General Public Video Coming Soon: “Compressed Natural Gas – A Standard for Safety” Clean Vehicle Education Foundation - Production 56 – Clean Vehicle Education Foundation (funded by Clean Cities, States, and industry) • Coordinates Transit Users Group, School Bus Users Group • Produces TUG Bits newsletter • Investigates accidents and notifies other users of corrective actions • Provides scholarships for cylinder safety courses • Conducts studies • Teaches Fleets about NGV issues at “The Compelling Case for Natural Gas Vehicles Workshops” – Gas Technology Institute • Cylinder testing – Private Sector Training Firms eere.energy.gov Organizations to Educate End Users Academia EDUCATION OF END USERS: • Drivers • Fleet Managers • Fueling Station • Operators • First Responders • General Public 57 – National Alternative Fuels Training Consortium (funded by U.S. DOE and member schools) • Network of national training centers, consisting of universities, community colleges, and secondary schools, located across the United States • Train the trainer programs for technicians on Liquefied Natural Gas Vehicles, LightDuty NGVs Heavy-Duty Gaseous Fuel Applications, and Compressed Natural Gas Vehicle Fuel Systems Inspections eere.energy.gov Best Practices: Integrating Training Expertise Notified Bodies: Only types that can certify trainees via established knowledge tests Independent International Training Institutes (& consultants): provide certification of participation, but generally not formal certification Equipment Suppliers: Certify installers to their company specifications & in conformity to international regulations Domestic Training Institutes: Expert trainers who must be ‘trained-to-train’ Educational Institutions: University-level & technical institutes that develop curricula to teach requirements for entry-level employment opportunities Source: Dr. Jeff Seisler, Clean Fuels Consulting 58 eere.energy.gov Best Practices: CNG Transit Training Based on a recent report done for Clean Cities by the Clean Vehicle Education Foundation and Marathon Technical Services that surveyed CNG transit operators in the United States (a total of 10 garages and 4,071 CNG buses ) Most agencies stressed the need for initial and ongoing technician training to prepare technicians for new bus orders Initial training done by equipment vendors Annual and periodic refreshers training and new employee training done by inhouse trainers 59 eere.energy.gov Best Practices: CNG Transit Training Bus Training (typically provided by the bus manufacturer) – 160-200 hours with each new bus order, ~40 to 60 hours is engine related – Cylinder inspection training (typically 2 days) for two or more technicians that will be inspecting cylinders; rotate new staff – Driver training for operating a CNG bus; including emergency response Station Training (typically provided by station manufacturer) – Direct correlation between amount of training and the bus agency’s involvement in the maintenance of the facility – Basic training in the safe fueling for all affected staff – Training on how to deal with emergency situations—shutdown procedures, fire response, gas leak response 60 eere.energy.gov Best Practices: CNG Transit Training Emergency Responder Training (typically provided by the transit agency) – Orientation after commissioning of the CNG station for local fire departments and for all shifts Topics include: location of shutoffs, hydrants – Orientation for each series of bus orders for local fire departments Topics include: Proper function of Pressure Relief Device; preventing the use of an axe near cylinders or high pressure lines 61 – Emergency response binder for fire and police departments should be developed – Similar training for police departments eere.energy.gov Risk-Informed LNG/CNG Maintenance Facility Codes and Standards – Phase I Phase II Phase I Project Scope Conducted by Chris LaFleur, Sandia National Laboratory Detailed survey of existing codes Hazard identification and quantification Conduct HAZOP study to provide a comprehensive list of credible hazard scenarios Scenario modeling of four credible releases Development of best practices to mitigate hazards Facility design guidance Proposed changes to existing fire protection codes Soon to be published by CVEF http://www.cleanvehicle.org/committee/technical/PDFs/GuidelinesDocumentFinal.pdf 62 eere.energy.gov References and Resources • • • • • • • • • • • • • • AFDC Light-Duty Vehicle Search (http://www.afdc.energy.gov/vehicles/search/light/) AFDC Heavy-Duty Vehicle and Engine Search (http://www.afdc.energy.gov/vehicles/search/heavy) AFDC Station Locator (http://www.afdc.energy.gov/locator/stations/) AFDC Vehicle Cost Calculator (http://www.afdc.energy.gov/calc/) AFDC Federal and State Laws and Incentives (http://www.afdc.energy.gov/laws/) AFDC Natural Gas Fueling Infrastructure Development (http://www.afdc.energy.gov/fuels/natural_gas_infrastructure.html) AFDC interactive fueling animation (http://www.afdc.energy.gov/vehicles/cng_tank_animation.html) Clean Cities, Costs Associated with CNG Vehicle Fueling Infrastructure (http://www.afdc.energy.gov/uploads/publication/cng_infrastructure_costs.pdf) Clean Cities, Case Study – CNG Refuse Fleets (http://www.afdc.energy.gov/uploads/publication/casestudy_cng_refuse_feb2014.pdf) NREL, VICE 2.0 (http://www.afdc.energy.gov/uploads/publication/vice2-0.pdf) Alternative Fuel Life-Cycle Environmental and Economic Transportation (AFLEET) Tool (https://greet.es.anl.gov/afleet) Clean Vehicle Education Foundation, Guideline for Determining Modifications Required for Adding CNG and LNG Vehicles to Existing Maintenance Facilities (http://www.cleanvehicle.org/committee/technical/PDFs/GuidelinesDocumentFinal.pdf) Natural Gas Vehicle Institute, Facilities Modification for Natural Gas Vehicles (http://www.ngvi.com/Documents/FacilitiesModificationforNaturalGasVehiclesPaper_000.pdf) NFPA 52, Vehicular Gaseous Fuel Systems Code, and NFPA 30A, Code for Motor Fuel Dispensing Facilities and Repair Garages (http://www.nfpa.org/) eere.energy.gov