Diagnostic Ability of the Daniel Four Path Ultrasonic Flow Meter

page 1

DANIEL MEASUREMENT AND CONTROL WHITE PAPERS

Diagnostic Ability of the Daniel Four Path Ultrasonic Flow Meter

www.daniel.com

1 INTRODUCTION

3 VELOCITY PROFILE

The primary function of the ultrasonic meter is to measure the

The four chordal velocities give an indication of the velocity

actual volume flow rate. The process involves measuring four

profile in the meter, established by the flow through the upstream

velocities on chords located in four different radial positions and

pipe work. Three helpful ratios can be defined as: Asymmetry =

in two different vertical planes. The eight transducers are fired

(VA + VB)/(VC + VD), Cross flow = (VA + VC)/(VB + VD) and Swirl

about 50 times per second and the transit times to traverse each

chord in both directions are measured. This vast array of data

= (VB+ VC)/(VA + VD).

The asymmetry compares the flow in the top half of the pipe with

can be processed to yield useful diagnostic information, which

that in the bottom half; in good condition it should be close to 1.

forms the subject of this paper and shows that the four-path

The cross flow compares the chords in one plane with those in

ultrasonic meter does much more than just measure the flow

the other plane at right angles: in good condition it should be

rate. It has sufficient diagnostic ability to confirm the authenticity

close to 1. The swirl compares the inner chords to the outer

of the measurement, and develop the source for conditional

chords and it is an indicator of swirl due to both the different

based maintenance and re-calibration.

radial locations and planes. In good condition the swirl should

be close to 1.042/0.89 = 1.17 [1].

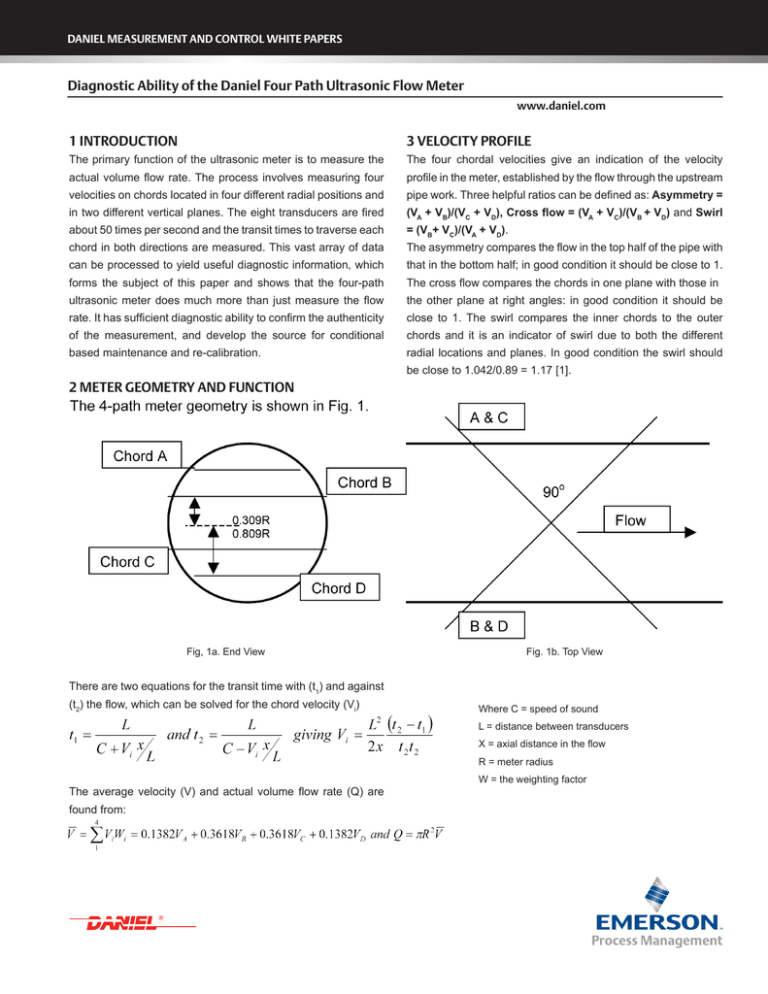

2 METER GEOMETRY AND FUNCTION

Fig, 1a. End View

Fig. 1b. Top View

There are two equations for the transit time with (t1) and against

(t2) the flow, which can be solved for the chord velocity (Vi)

Where C = speed of sound

L = distance between transducers

X = axial distance in the flow

R = meter radius

The average velocity (V) and actual volume flow rate (Q) are

found from:

W = the weighting factor

DANIEL MEASUREMENT AND CONTROL WHITE PAPERS

Examples of analytical flow profiles with swirl are shown in Fig.

2, and how the swirl ratio can estimate the magnitude of the

swirl angle in Fig. 3.

Fig. 2 VELOCITY PROFILE WITH SWIRL

Fig. 3 SWIRL RATIO (Vb+Vc)/(Va+Vd)

Actual measured ratios are shown in Fig. 4 for a 20” meter.

Fig. 3 SWIRL RATIO (Vb+Vc)/(Va+Vd)

page 2

Diagnostic Ability of the Daniel Four Path Ultrasonic Flow Meter

page 3

Because of tolerances in the manufacture of the ultrasonic

is higher on the outer chord, nearer the pipe wall where there is

meter and the difficulty of achieving ideal fully developed flow,

more shear.

the actual ratios are never exactly at their theoretical values,

and give the meter a unique fingerprint. However they are

If flow pulsations or fluctuations are present, this turbulence

usually within ±2%, which is sufficient to say that the flow profile

parameter will increase above the 2% to 5% value associated

is near perfect, which is not surprising since Fig.4 comes from

with good flow.

a lab calibration.

In general, four paths are not sufficient to resolve any arbitrary

3-dimensional flow field containing asymmetry, swirl and cross

flow. However, fiscal flow measurement practice attempts to

establish good flow conditions, which can certainly be verified

by these ratios. Never the less, if the ratios differ significantly

from their ideal value they can give a reasonable indication of

the type of disturbance, especially if only one of the ratios has

4 SPEED OF SOUND

The speed of sound can be evaluated from the same two transit

times for each chord:

The average speed of sound C is just the average of the chords

C = (CA +CB + CC +CD)/4

changed significantly.

The speed of sound can be used as a diagnostic in several

3.1 Turbulence, pulsation and fluctuation

4.1 Compare a measured and calculated value

In discussing the velocity profile we have been considering the

The speed of sound can be calculated from independent

average velocity obtained from a batch of transit times from all

eight transducers. The velocity depends upon the transit time

difference Δt = (t2 – t1). Typically a batch of 20 Δt values is used

to determine an average Δt and hence the average velocity. The

batch of 20 also allows the calculation of a standard deviation

σΔt, and then the ratio σΔt/Δt is a measure of turbulence or

ways:

measurements of gas composition, pressure and temperature,

using methods described in AGA 10 [2]. This is an independent

check on the transit time measurement and is important because

the ultrasonic meter basically measures transit times.

An example is shown in Fig. 6 for a 4” meter. Note that 4” is

velocity fluctuation.

the smallest ultrasonic meter typically used and the small length

Some typical values are given in Fig. 5, for the inner and outer

determine the speed of sound.

chords of a meter during calibration in good flow.

The turbulence varies from 2 to 5% of the velocity. The inner

chord-C has an average turbulence of 3%, while the outer

chord-D has an average turbulence of 4%. This is in keeping

with typical point values in pipe flow of 6% at z/R = 0.309 and

9% at z/R = 0.809, and the general concept that the turbulence

Fig. 5 TURBULENCE % = 100* STD-DEV Dt / Dt

and short transit time make it the most difficult size to accurately

Despite the small size the agreement between measured

and calculate speed of sound is good to within ± 0.02%. This

calibration at SwRI re-circulates the same gas in a closed loop;

hence there is no change in gas composition for the results in

Fig. 6.

Fig. 6 4” METER SOS DEVIATION FROM AGA 10

DANIEL MEASUREMENT AND CONTROL WHITE PAPERS

page 4

Fig 9. SOS LONG - SOS SHORT %

4.2 Compare the 4 chordal values with one

another

At a reasonable gas velocity (say > 5 ft/s), the gas composition

and temperature should be uniform over the pipe cross-section

and all chords should read the same speed of sound. See Fig.

7 for an example from a 12” meter. If all four values agree, it is

more likely that they are all correct than all in error by exactly

the same amount.

Fig. 7 CHORDAL SPEED OF SOUND FT/S

= 2.7R giving a length ratio = 2.7/1.7 = 1.6. If the speed of sound

is the same on chords of different length, this indicates that both

the transit times and delay times (time not spent in the gas) are

correct. The normal way of determining the delay time is with a

gas of known speed of sound, typically nitrogen. Another way is

to use two different lengths in the same, but unknown, speed of

The values of speed of sound on all four chords agree to within

sound. Thus the different chord lengths allow a dynamic method

± 1 ft/s This is not quite as good a test as the one in section 4.1,

of checking the delay times.

but it has the advantage of not requiring any additional external

inputs (pressure, temperature & composition).

4.3 Use the difference between the chordal and

average value

Fig. 9 shows very small variation of 0.002% SOS or about 20 ns

in transit time, which is close to the stability limit of the metering

system.

Because of manufacturing tolerances the four chordal values

Note: three examples have been shown where the SOS

of speed of sound will never be exactly equal. These small

variations are 0.1%, 0.02% and 0.002%. A good value for the

differences can be used as another fingerprint of the meter.

average field application would be 0.05%.

See Fig.8 as an example

Fig. 8 SOS DIFFERENCE FROM AVERAGE %

4.5 Correction for stratification

An example is given for a velocity of 2 ft/s in a 12” pipe with the

gas temperature at 70o F and the ambient temperature at 90o F,

in a long un-insulated pipe, shown in Figs 10 & 11.

Fig 10. TEMPERATURE [SOS] GRADIENT

4.4 Check the agreement between chords of

different length

Fig.9 shows an example for a 12” meter under stable zero flow

conditions.

The 4-path Daniel meter has paths of different length. The outer

chords (A & D) have L = 1.7R and the inner chords (B&C) have L

The 4 chords are horizontal and spaced vertically, so they

see the temperature stratification: low density gas, with high

temperature and higher speed of sound floats on top of the

Diagnostic Ability of the Daniel Four Path Ultrasonic Flow Meter

page 5

higher density gas, with lower temperature and lower speed of

•

An upstream flow control valve being adjusted

sound. In this case a SOS gradient of 8 ft/s corresponds to the

•

An upstream branching flow of varying proportion to

temperature gradient of 6oF. This temperature difference also

the metered flow

drives a natural convection current: gas heated by the pipe wall

•

A flow conditioner trapping debris

rises to the top of the pipe, while cold gas in the center falls to

•

Erosion, corrosion or deposition changing the

the bottom of the pipe. This convection current, which is normal

to the axial flow, pushes the maximum axial velocity down from

upstream pipe roughness

the center of the pipe, and the effect is seen in the velocity

5.1 Pipe roughness

profile shown in Fig. 11.

The meter can detect an increase in pipe roughness by its effect

on the velocity profile [3]. In general the velocity profile depends

non-

upon both roughness and Reynolds Number, but at the high Re

representative gas temperature measurement. A reasonable

No associated with natural gas transport the roughness effects

approach to the correct gas temperature is a Flow Weighted

dominate. The profile can be described by the ratio (VB+ VC)/(VA

Mean Temperature (FWMT) based on using the same velocity

+ VD), but here we are looking for change from a flatter profile to

flow weighting factors Wi for the chordal temperatures. The result

a more pointed profile (Fig.12) with time, and not swirl.

in this case is FWMT = 73.5o F seen in Fig.10. Unfortunately

The ratio (VB+ VC)/(VA + VD) can be linked to pipe roughness (Fig.

the high pipe temperature and the highest gas temperature

13) in terms of relative roughness k/D, where k = the roughness

influence the thermo-well located on top of the pipe, and reads

height and D = the pipe diameter.

Another

consequence

of

stratification

is

a

poor

a temperature = 77.8o F. This error of 4.3o F in 530 o R will give

a 0.8% error in the corrected volume flow. The SOS gradient can

Again the idea is that fixed piping gives a fixed velocity profile, so

be used to recognize and correct the error; this is unique to the

a changing profile with time is an indication of pipe roughness. If

chordal ultrasonic meter, while non-chordal ultrasonic meters

the velocity profile does not change with time, it is an indication

and other flow meters would suffer from stratification without

that surface roughness has probably remained unchanged.

knowing.

Fig.12 VELOCITY PROFILE - ROUGH

Fig11. VELOCITY PROFILE WITH CONVECTION

5. TRENDING

All the diagnostics discussed above can be trended to see if

anything is changing with time, by recording the data at suitable

intervals. The time interval depends on the specific application,

but it can be extended if nothing is seen to change.

The velocity profile is determined by the pipe and fittings

upstream of the meter. The pipe and fittings are fixed, so one

would normally not expected the velocity profile to change.

However there are some exceptions where the velocity profile

would change, due to:

DANIEL MEASUREMENT AND CONTROL WHITE PAPERS

Fig. 13 VELOCITY RATIO (B + C) / (A + D) - ROUGHNESS

page 6

useful diagnostic.

As part of the signal detection many checks are made:

•

The noise, found upstream of the signal

•

The ratio of signal to noise

•

The standard deviation of the transit times

•

The signal quality, a measure of how quickly the

signal rises

•

A comparison between the transmitted and received

signals

•

A comparison between the upstream and downstream

received signals

5.2 Speed of Sound

The SOS will change with gas composition, temperature and

pressure, and can be a useful check on plant operation. In

particular, if nitrogen purging is required for safety, the SOS can

detect the nitrogen to natural gas change over.

The speed of sound depends only on the distance between the

transducers and the transit time. If it is not changing with time,

either internally between the chords or externally compared to

independent calculations, it is a very good sign that the meter

is functioning correctly, and the other inputs (P, T & gas

composition) needed for the calculation must be correct. If

it does change it could be due to deposits on the transducer

face or transducer damage. Deposits on the transducer would

probably be accompanied by deposit on the pipe wall, which

would also show in the velocity profile.

The SOS and velocity profile can certainly confirm that the

meter is functioning correctly, but if they reveal a problem then a

deeper level of diagnostics is required.

6 DIAGNOSTIC LEVEL

The discussion so far has made use of the four chord velocities

and the four chord values of SOS, which are directly available

from the meter output. There is a deeper level of diagnostic

associated with the digital signal processing.

6.1 Digital Signal Processing

The detection of the received ultrasonic signal must find

a consistent reliable zero crossing to use for the transit time

measurement. The transmitted signal strength is limited by

intrinsic safety considerations, so the received signal amplitude

is a function of the acoustic impedance of the gas, the meter size

and the gas velocity. An automatic gain control (AGC) is applied

to the received signal to always achieve the same amplitude,

to simplify detection. The value of the gain is a measure of the

health of the transducer or attenuation in the path, and is a

•

A check for peak switching

•

The tracking of a consistent zero crossing

If a signal does not pass all these tests it is not used for a

transit time measurement and an alarm is given that is decoded

to explain why the signal was rejected. This is a very useful

diagnostic. The number of signals used in a batch is reported

as Performance. A 100% performance is a sign that the meter

is working well, and is the normally expected performance up to

the full rated capacity of the meter. Anything less than 100% is

another useful diagnostic.

An example of the power of this deeper diagnostics is the ability

to detect wet gas [4]. The presence of liquid drops dispersed in

the gas affect the SOS, gain, standard deviation, signal to noise,

signal quality and performance.

Deposits on the pipe wall change the velocity profile and deposits

on the transducer may change the SOS, but they would also

affect the gain and signal to noise.

6.2 Multiple diagnostic parameters

The velocity profile gives a fingerprint, detects asymmetry, swirl

and cross flow, while the standard deviation of the velocity

indicates turbulence (5 parameters). The SOS gives another

fingerprint. It can be compared with calculations from gas

composition, pressure & temperature, and gives four values

from two different chord lengths, that can detect stratification &

convection currents, and can correct temperature measurements

(6 parameters). The DSP and AGC add a further 9 parameters

for each of the eight transducers. The waveform and spectra

(frequency content) can be displayed, another 2 parameters.

This gives a total of 22 potentially useful diagnostic parameters.

If all 22 parameters are normal, then there is no doubt that the

meter is working correctly. If the meter fails, there is sufficient

information to diagnose and fix the problem. If there are problems

with the flow metering system, and one has sufficient confidence

Diagnostic Ability of the Daniel Four Path Ultrasonic Flow Meter

page 7

that the meter is working correctly, it is then possible to look

To change this situation, a manufacturer could offer a “health

for other system problems. Typical system problems are swirl,

check” service where say once a month he had remote access

turbulence, pulsations, fluctuations and noise.

to all the diagnostic data to give the meter a clean bill of health, or

raise warning signs. This should be mutually beneficial, leading

If a transducer is short circuited to the body by liquid or debris,

to conditional based maintenance and recalibration instead of

noise through the body will show on all transducers, while

fixed routine maintenance and mandatory recalibration intervals.

external noise will be much more on the transducers facing the

noise source. The meter will indicate where to look for the noise

source, upstream or downstream. The waveform and spectra

will also give information on the noise as well as the signal.

Gain can be useful, but remember it is dependent on the gas

Klaus J. Zanker, Daniel Industries, USA

7 REFERENCES

1. Klaus J. Zanker, INSTALLATION EFFECTS ON SINGLE-

pressure, or more precisely the gas acoustic impedance = SOS

AND MULTI-PATH ULTRASONIC METERS, Flomeko 2000

* density. If gain increase with time (for the same pressure) there

2. AGA Report No 10, SPEED OF SOUND IN NATURAL GAS

can be two causes: transducer damage or obstruction of the

AND OTHER RELATED HYDROCARBON GASES, July

acoustic path. Further diagnostic can follow from a series of

2002

questions:

3.

Klaus J. Zanker, THE EFFECTS OF REYNOLDS NUMBER,

•

Are one or more transducers involved?

WALL ROUGHNESS, AND PROFILE ASYMMETRY ON

•

Are one or more chords involved?

SINGLE- AND MULTI- PATH ULTRASONIC METERS,

•

Is it the bottom D-Chord, most likely to accumulate

NSFMW, Oct 1999

debris and liquid?

4. Klaus J. Zanker & Gregor J. Brown, THE PERFORMANCE

•

Has the velocity profile changed?

OF A MULTI-PATH ULTRASONIC METER WITH WET

•

Has the SOS profile changed?

GAS, NSFMW Oct 2000.

•

Has the signal quality changed?

In general, if any diagnostic parameter is suspect, and one

can postulates a cause, it then becomes possible to find other

parameters to try to confirm or refute the postulate.

7 CONCLUSIONS

A major advantage of the ultrasonic meter is that it produces an

abundance of diagnostic data.

If all the diagnostic parameters are normal, one can have

complete confidence that the meter is working correctly. This

confidence is very important, because one can then look for

problems in other parts of the metering system.

If a meter fails, the diagnostics quickly reveals the problem and

solution.

The range of decline between perfect performance and complete

failure is more difficult to quantify. Trending the diagnostic

parameters will certainly show if changes are occurring, but

knowing how much change is tolerable, before intervention is

necessary, is at present very much a judgment call.

As a meter manufacturer, we basically only see the extremes of

new meter calibrations and field failures. We do not have access

to long-term normal operational data in typical fiscal applications.

Emerson Process Management

Daniel Measurement and Control, Inc.

www.daniel.com

North America / Latin America:

Headquarters

USA - Houston, Texas

T +1.713.467.6000

F +1.713.827.3880

USA Toll Free 1.888.FLOW.001

Europe: Stirling, Scotland, UK

T +44.1786.433400

F +44.1786.433401

Middle East, Africa: Dubai, UAE

T +971.4.811.8100

F +971.4.886.5465

Asia Pacific: Singapore

T +65.6777.8211

F +65.6777.0947 / 0743

Daniel Measurement and Control, Inc. is a wholly owned subsidiary of Emerson Electric Co., and a

division of Emerson Process Management. The Daniel name and logo are registered trademarks

of Daniel Industries, Inc. The Emerson logo is a registered trademark and service mark of

Emerson Electric Co. All other trademarks are the property of their respective companies. The

contents of this publication are presented for informational purposes only, and while every

effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, expressed or implied, regarding the products or services described herein or their use

or applicability. All sales are governed by Daniel’s terms and conditions, which are available upon

request. We reserve the right to modify or improve the designs or specifications of such products

at any time. Daniel does not assume responsibility for the selection, use or maintenance of any

product. Responsibility for proper selection, use and maintenance of any Daniel product remains

solely with the purchaser and end-user.

©2010 Daniel Measurement and Control, Inc. All Rights Reserved. Unauthorized duplication in whole or in part is prohibited. Printed in the USA.

DAN-TECHNOLOGIES-DIAGNOSTIC-ABILITY-OF-THE-DANIEL-FOUR-PATH-ULTRASONIC-FLOW-METER