Ayrshire Steel Framing User Manual: Design & Application

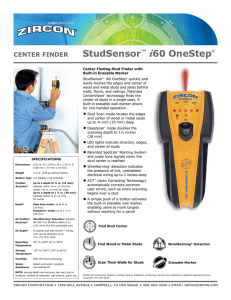

advertisement