SUBMITTAL

Ortega Industrial Contractors

6415 GREENLAND RD

JACKSONVILLE, FL 32258-2495

Phone: (904) 268-2181

Fax: (904) 260-5181

NO:

16130001

DATE: 07/03/14

PAGE: 1 of 1

SPEC:

16130 - Conduits

START:

FINISH:

07/03/14

PACKAGE:

Normal

COPIES:

4

JOB:

GRU DEWATERING PROJECT (#1402)

3901 SW 63RD BLVD

GAINESVILLE, FL 32608

CO#:

TRACK #:

N/A

N/A

PRIORITY:

STATUS:

Normal

Open

PREPARED BY:

SENT TO:

CH2M HILL

3011 SW WILLISTON RD

GAINESVILLE, FL 32608

TIM PTAK

COGBURN BROS. ELECTRIC, INC.

3300 FAYE RD

JACKSONVILLE, FL 32262-2329

ITEM #

DESCRIPTION

PRIORITY

STATUS

00001

Conduits

Normal

Open

USER FIELDS:

Approved

Approved/N

Amend/Re-Submit

Rejected

This material has been “Approved” for

Submission to CH2MHILL for review covering

GRU Dewatering Project.

Ortega Industrial Contractors, Inc.

BY: John Kaschak, VP Field Operations

DATE: 7/3/2014

Cogburn Bros., Inc.

3300 Faye Rd.

Jacksonville, FL 32226

Office: 904-358-7344

Fax: 904-358-2805

LEITER OF SUBMITTAL

TO:

Ortega Industrial

6415 Greenland Road

Jacksonville, FL 32258

SUBMITTAL#

DATE:

June-14

ICogburn # C1426

Attn: John Kaschak

RE:

Kanapaha WRF

C1426-16130-001: Conduit

Enclosed are the following shop drawings and/or data for your approval

Spec No.

16130 2.01 A

16130 2.01 B

16130 2.01 c

16130 2.01 D

16130 2.01 E

16130 2.01 F

16130 2.01 H

16130 2.02 A

16130 2.02 B

16130 2.02 c

16130 2.02 D

16130 2.02 E

16130 2.02 F

16130 2.03 B

16130 2.10

16130 2.11 A 1

16130 2.11 B 2

Notes:

Description

Rigid Stainless Steel

EMT

Rigid Aluminum

PVC Schedule 40

PVC Schedule 80

PVC Tubing (EB)

Type UA Sealtite

Stainless Steel Fitting

EMT Fittings

Aluminum Fittings

PVC Fittings

PVC Aluminum

Sealtite Fittings

Cast Aluminum FS Boxes

Precast Handholes

Duct Bank Spacers

Red Detectable Warning Tape

Tab

Made in America Plus

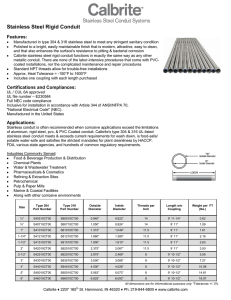

Stainless Steel Application Data

Stainless Steel Rigid Conduit is recommended for highly corrosive environments and is often used in conjunction with

Rigid Aluminum Conduit as a cost effective solution for the most demanding applications.

Typical Applications

•

Chemical Plants

• Extraction & Refining

• Food Processing

• Marine & Coastal

• Petrochemical Facilities

• Pharmaceutical Facilities

• Pulp & Paper Mills

Stainless Steel Specification Data

Material:

Products:

Standards:

UL File#:

304 & 316 Stainless Steel- All Products are polished to a bright finish

Conduit- Standard NPT Threads, Includes One Coupling per Length

Couplings- Standard NPS Straight Threads

Elbows- Standard NPT Threads, Color Coded Thread Protectors on Both Ends

UL 6A "Standard for Electrical Rigid Metal Conduit- Aluminum, Red Brass, and Stainless Steel

ANSI C80.1

CSA Standard C22.2 no 45.2-08

File# E337297

Stainless Steel Rigid Conduit Data

Approx Wt Per

100 Feet (30.5M)

kg

Metric

lb

16

82.0

37.2

21

109.0

49.4

73.0

27

161.0

35

218.0

98.9

41

263.0

119.3

158.8

53

350.0

253.6

63

559.0

329.8

78

727.0

103

1008.0

457.2

129

1461.0

662.7

155

1897.0

860.5

Trade Size

u.s.

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

4

5

6

•

I

Nominal Outside

Diameter

in

mm

0.840

21.3

1.050

26.7

1.315

33.4

1.660

42.2

48.3

1.900

2.375

60.3

73.0

2.875

3.500

88.9

4.500

114.3

5.563

141.3

6.625

168.3

••

Nominal Wall

in

0.104

0.107

0.126

0.133

0.138

0.146

0.193

0.205

0.225

0.245

0.266

mm

2.64

2.72

3.20

3.38

3.51

3.71

4.90

5.21

5.72

6.22

6.76

Length without

Coupling

ft

mm

9' 11-1/4"

3030

9' 11-1/4"

3030

9' 11"

3025

9' 11"

3025

9' 11"

3025

9' 11"

3025

9' 10-1/2"

3010

9' 10-1/2"

3010

9' 10-1/4"

3005

9' 10"

2995

9' 10"

2995

Part Number

Type 304

1-012-3045

1-034-3045

1-100-3045

1-114-3045

1-112-3045

1-200-3045

1-212-3045

1-300-3045

1-400-3045

1-500-3045

1-600-3045

Type 316

1-012-3165

1-034-3165

1-100-3165

1-114-3165

1-112-3165

1-200-3165

1-212-3165

1-300-3165

1-400-3165

1-500-3165

1-600-3165

I

'·

~

Stainless Steel Coupling Data

Trade Size

u.s.

1/2

3/4

1

1-1/4

1-1/2

2

2-1/Z

3

4

5

6

Metric

16

21

27

35

41

53

63

78

103

129

155

Approx Wt Per

10 Pieces

kg

lb

1.7

0.8

1.2

2.6

3.4

1.5

2.3

5.1

6.1

2.8

9.0

4.1

19.3

8.8

26.0

11.8

39.7

18.0

86.6

39.3

100.0

45.4

Nominal Outside

Diameter

mm

in

1.080

27.4

33.8

1.330

1.560

39.6

49.5

1.950

2.220

56.4

69.8

2.750

3.280

83.3

100.8

3.940

5.000

127.0

6.300

160.0

187.7

7.390

length

in

1.56

1.62

2.00

2.06

2.06

2.12

3.12

3.25

3.50

3.75

4.00

Part Number

mm

39.6

41.1

50.8

52.3

52.3

53.8

79.2

82.6

88.9

95.3

101.6

Type 304

2-012-3045

2-034-3045

2-100-3045

2-114-3045

2-112-3045

2-200-3045

2-212-3045

2-300-3045

2-400-3045

2-500-3045

2-600-3045

Type 316

2-012-3165

2-034-3165

2-100-3165

2-114-3165

2-112-3165

2-200-3165

2-212-3165

2-300-3165

2-400-3165

2-500-3165

2-600-3165

Stainless Steel Elbow Data- 90 Degree Standard Radius

Trade Size

u.s.

1/Z

3/4

1

1-1/4

1-1/2

2

2-1/2

3

4

5

6

Metric

16

21

27

35

41

53

63

78

103

129

155

Approx Wt Per

10 Pieces

kg

lb

7.3

3.3

10.6

4.8

9.0

19.8

30.9

14.0

43.0

19.5

70.0

31.8

128.1

58.1

204.5

92.7

331.3

150.3

754.9

342.4

1154.0

523.4

Nominal Dimensions

B

mm

mm

in

101.6

6.50

165.1

114.3

184.2

7.25

146.1

8.38

212.7

184.2

10.25

260.6

209.6

301.6

11.88

241.3

355.6

14.00

266.7

400.1

15.75

330.2

476.3

18.75

406.4

23.00

584.2

914.4

609.6

36.00

762.0

42.50

1079.5

A

in

4.00

4.50

5.75

7.25

8.25

9.50

10.50

13.00

16.00

24.00

30.00

Part Number

c

in

2.50

2.75

2.88

3.00

3.63

4.50

5.25

5.75

7.00

11.00

12.50

mm

63.5

69.9

73.0

76.2

92.1

114.3

133.4

146.1

177.8

279.4

317.5

Type 304

3-012-3045

3-034-3045

3-100-3045

3-114-3045

3-112-3045

3-200-3045

3-212-3045

3-300-3045

3-400-3045

3-500-3045

3-600-3045

Type 316

3-012-3165

3-034-3165

3-100-3165

3-114-3165

3-112-3165

3-200-3165

3-212-3165

3-300-3165

3-400-3165

3-500-3165

3-600-3165

NEMRA:.·'

. · ·. ·~

.

.

'

.

;

.

Where to Buy

.

Patriot

ALU~1INU~1

PRODUCTS

Made in America Plus

Call434-510-1776 or visit

www.patriotaluminum.com

for your loca I Representative

Patriot Aluminum Products, LLC

Factory Address:

205 Ferncliff Drive

Louisa VA 23093

Phone:

434-510-1776

434-510-177 6

Fax:

Website:

www.patriotaluminum.com

© Copyright 2014 Patriot Aluminum Products, LLC All Rights Reserved

QUALITY_}__EASY-TO-INSTALL ELECTRICAL

METALLIC TUBING

MAf-.JtJFACTURED FOR LONG UFE

Allied EMT is precision manufactured

from high grade mild strip steel for exceptional durability and long-lasting life.

Allied EMT is hot galvanized using

Allied's patented in-line Flo-Coat®

process. This process combines zinc,

chromate, and a clear organic polymer

top-coat to form a triple layer of protection against corrosion and abrasion.

Allied EMT provides radiation

protection and magnetic shielding,

while its uniform wall thickness

provides resistance to physical

damage from impact or crushing.

INSTALLS QUICKLY AND EASILY

Allied EMT's quality steel combines

damage resistant strength with

ductility to provide easy bending,

cutting and joining to prevent waste of

time and material. It resists flattening,

kinking or splitting, resulting in faster

and easier installations.

Allied EMT provides smooth

continuous raceways for fast wirepulling. The interior wall of Allied EMT

is protected with a specially

formulated corrosion resistant

lubricating coating for easier fishing

and wire-pulling. No need to worry

about damage to the conduit system

even when pulling through multiple goo

bends.

FULL CODES AND STANDARDS

COMPLIANCE

Allied EMT is U.L. listed and

recognized by the National Electrical

Code. It meets the Underwriters

Laboratories' Standard for EMT, U.L.

797. Allied EMT is also manufactured

to meet the requirements of ANSI

C80.3. Federal Specifications now use

U.L. 797 and ANSI C80.3 in lieu of

WWC 563. Recognized as an

equipment grounding conductor (NEC

Article 250-91 b).

KW!K~FIT

EMTw. A NEW

FROM THE

CONDUIT LEADER

~NNOVATION

Allied's Kwik-Fit EMT has an integral

steel set-screw coupling formed on

one end of each length of EMT.

Specifying U.L. listed Kwik-Fit EMT

ensures an all steel system-both

conduit and coupling-for excellent

strength and ground return, as well as

economy. Contact Allied for detailed

specifications on Kwik-Fit EMT.

Available in trade sizes 2 - 4.

Installation of EMT shall be in

accordance with the National

Electrical Code and U.L. General

Information Card #FJMX.

Master bundles conform to NEMA

Standard RN2.

SPECIFICAT~ON

following: Electrical Metallic Tubing

shall be equal to that manufactured by

Allied Tube & Conduit Corporation.

EMT shall be hot galvanized steel

O.D. with an organic corrosion

resistant I.D. coating and shall be

produced in accordance with U.L.

Safety Standard #797 and ANSI

C80.3 and shall be listed by a

nationally recognized testing

laboratory with follow-up service.

Where Kwik-Fit EMT is used it shall

also meet U.L. Safety Standard #514B. It is noted that these U.L. and ANSI

standards have been adopted by the

federal government and separate

military specifications no longer exist.

DATA

To specify Allied EMT, include the

Weights and Dimensions for Electrical Metallic Tubing

Trade

Size

Designator

U.S. Metric

16

1/2

21

3/4

1

27

35

1-1/4

41

1-1/2

53

2

2-1/2

63

78

3

91

3-1/2

103

4

Approx. Wt.

Per 100Ft.

(30.5M)

kg

lb.

13.6

30

20.9

46

30.4

67

45.8

101

52.6

116

148

67.1

98.0

216

263 119.3

349 158.3

393 178.2

Nominal

Outside

Diameter1

in.

mm

0.706 17.9

0.922 23.4

1.163 29.5

1.510 38.4

1.740 44.2

2.197 55.8

2.875 73.0

3.500 88.9

4.000 101.6

4.500 114.3

Nominal

Wall

Thickness

mm

in.

0.042 1.07

0.049 1.25

0.057 1.45

0.065 1.65

0.065 1.65

0.065 1.65

0.072 1.83

0.072 1.83

0.083 2.11

0.083 2.11

Quantity

In Primary

Bundle

ft.

m

100

30.5

30.5

100

100

30.5

15.2

50

15.2

50

-

-

Master Bundles

Quantity

mm

ft.

7000

5000

3000

2000

1500

1200

610

510

370

300

2135.0

1525.0

915.0

610.0

457.5

366.0

186.1

155.6

112.9

91.5

1Outside diameter tolerances: +1- .005 in. (.13mm) for trade sizes 1/2" (16mm) through 2" (53mm); +1- .010 in. (.25mm) for

trade sizes 2-1/2 (63mm) +1- .015 in. (.38mm) for trade size 3" (78mm) +1- .020 in. (.51 mm) for trade sizes 3-1/2 (91 mm)

and 4" (1 03mm).

~\\ed Tll!J~

NOTE: Length = 10 ft. (3.05m) with a tolerance of t .25" (6.35 mm).

Approx. Wt.

kg

lb.

2100

952.4

2300 1043.1

2010

911.6

2020

916.1

1740

789.1

1776

805.4

597.7

1318

1341

608.2

585.5

1291

1179

534.7

~10-'L

~

~~~

© Allied Tube & Conduit

.t-so 9oo'J..

Volume

cu ft.

cum

28.7

0.81

35.6

1.01

33.7

0.95

35.0

0.99

0.97

34.2

46.7

1.32

41.5

1.18

48.9

1.38

48.6

1.38

1.37

48.3

Qiallied

TUBE & CONDUIT

ELECTRICAL

16100 South Lathrop Ave

Harvey. Illinois 60426

(708) 339-1610

A

f:qC:O

INTERNATIONAL LTD. COMPANY

June 1, 2012

Manufacturer 1s Certification

Patriot's Rigid Metal Conduit- Aluminum

This certification applies to Rigid Metal Conduit- Aluminum that has been manufactured in

the United States, at Patriot Aluminum Products, LLC located in Earlysville, VA.

It is hereby certified that the above referenced product:

1.

2.

3.

4.

5.

6.

7.

Meets the provisions of the Buy American Act

Meets the provisions of the American Recovery and Reinvestment Act (ARRA}

Meets or exceeds the UL 6A Standard For Electrical Rigid Metal Conduit- Aluminum,

Bronze, and Stainless Steel requirements and are listed with the Underwriters

Laboratories, File# E337297

Meets or exceeds the American National Standard Institute (ANSI} C80.5 Standard

Meets or exceeds Federal Specification WW-C-540c

Meets or exceeds ASTM Specification B221

Meets or exceeds CSA Standard C22.2 No. 45.2

Under penalty of perjury, I declare that I have examined this certification statement, and to

the best of my knowledge and belief, the facts presented are true, correct and complete.

All the best,

Tom Click

President & CEO

Patriot Aluminum Products, LLC

tom.click@patriotaluminum.com

Cell - 434-825-2652

June 1, 2012

Specification Notes

Rigid Metal Conduit- Aluminum

Architects desiring to specify Rigid Metal Conduit- Aluminum from Patriot Aluminum Products

should include the following description:

Electrical conductors shall be enclosed in Patriot Aluminum Products' Rigid Metal ConduitAluminum in accordance with the National Electrical Code (NEC). Rigid Metal ConduitAluminum shall be 6063 Aluminum, manufactured and produced to the following

specifications:

•

ANSI- American National Standard for Electrical Rigid Aluminum Conduit (ERAC)

AN,SI, C80.5

• UL Standard for Electrical Rigid Metal Conduit- Aluminum, UL 6A, File# E337297

• National Electric Code, 2008 Article 344

• 2008 NEC Section 250.118(2} recognizes Rigid Metal Conduit as an equipment

grounding conductor

• Federal Specification WW-C-540C

• All Trade Sizes (1/2"- 6"} shall be manufactured and produced in the United States

of America, including:

• The Shells

• The Couplings

• The Thread Protecting Caps

• The UL Labels

• All Trade Sizes (1/2"- 6"} shall be processed using a Threading Lubricant which is:

• Manufactured from Renewable Raw Materials, and contains no phenolics,

nitrites, glycol ethers, DEA, formaldehyde, chlorine or silicone

Please email or call Tom Click with any technical questions.

All the best,

Patriot Aluminum Products, LLC

tom.click@patriotaluminum.com

Cell - 434-825-2652

Page 8

Product Specifications

Conduit Data

Approx Wt Per

100 Feet (30.5M)

kg

u.s. Metric lb

28.1

12.7

16

1/2

21

37.4

17.0

3/4

1

27

54.5

24.7

71.6

32.5

1-1/4

35

88.7

41

40.2

1-1/2

118.5

53.8

2

53

85.0

187.5

2-1/2

63

246.3

111.7

3

78

295.6

3-1/2

91

134.1

350.2

103

155.8

4

478.9

217.2

5

129

6

155

630.4

285.9

Trade Size

Nominal Outside

Diameter

in

mm

0.840

21.3

1.050

26.7

1.315

33.4

1.660

42.2

48.3

1.900

60.3

2.375

2.875

73.0

3.500

88.9

4.000

101.6

4.500

114.3

141.3

5.563

6.625

168.3

Nominal Wall

in

0.104

0.107

0.126

0.133

0.138

0.146

0.193

0.205

0.215

0.225

0.245

0.266

mm

2.64

2.72

3.20

3.38

3.51

3.71

4.90

5.21

5.46

5.72

6.22

6.76

Master Bundle

ft

2500

2500

2000

1000

1000

450

300

200

zoo

200

80

60

m

762.5

762.5

610.0

304.8

304.8

137.2

91.5

61.0

61.0

61.0

23.4

18.3

lb

702.5

935.0

1090.0

716.0

887.0

533.3

562.5

492.6

591.2

700.4

383.1

378.2

Part Number

kg

317.5

425.0

494.0

325.0

402.0

242.1

255.0

223.4

268.2

311.6

173.8

171.5

Coupling Data

Trade Size

u.s.

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

3-1/2

4

5

6

Metric

16

21

27

35

41

53

63

78

91

103

129

155

Approx Wt Per

100 Pieces

kg

lb

6.1

2.8

9.1

4.1

12.5

5.7

18.9

8.6

23.3

10.6

34.6

15.7

68.3

31.0

91.4

41.5

108.0

49.0

142.0

64.4

109.7

241.9

321.0

145.6

Nominal Outside

Diameter

in

mm

1.080

27.4

1.330

33.8

1.560

39.6

1.950

49.5

2.220

56.4

2.750

69.8

3.280

83.3

3.940

100.8

4.440

112.8

5.000

127.0

6.300

160.0

7.390

187.7

Length

in

1.56

1.62

2.00

2.06

2.06

2.12

3.12

3.25

3.37

3.50

3.75

4.00

mm

39.6

41.1

50.8

52.3

52.3

53.8

79.2

82.6

85.6

88.9

95.3

101.6

Standard

Package Part Number

Pieces

100

2-012

2-034

50

2-100

so

2-114

so

2-112

so

2-200

so

25

2-212

25

2-300

2-312

10

10

2-400

2-500

5

2-600

5

Elbow Data

Trade Size

u.s.

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

3-1/2

4

5

6

Metric

16

21

27

35

41

53

63

78

91

103

129

155

Approx Wt Per

100 Pieces

lb

29.0

43.0

71.0

110.0

153.0

249.0

437.0

767.0

1036.0

1228.0

2490.0

3850.0

kg

13.2

14.5

32.2

49.9

69.4

112.9

198.2

347.9

469.9

557.0

1129.5

1746.3

A

in

4.00

4.50

5.75

7.25

8.25

9.50

10.50

13.00

15.00

16.00

24.00

30.00

Patriot

ALUl\1INlJM PRODUCTS

mm

101.6

114.3

146.1

184.2

209.6

241.3

266.7

330.2

381.0

406.4

609.6

762.0

Nominal Dimensions

B

in

mm

165.1

6.50

184.2

7.25

8.38

212.7

10.25

260.6

11.88

301.6

14.00

355.6

15.75

400.1

18.75

476.3

21.75

552.5

23.00

584.2

36.00

914.4

42.50

1079.5

c

in

2.50

2.75

2.88

3.00

3.63

4.50

5.25

5.75

6.75

7.00

11.00

12.50

Part Number

mm

63.5

69.9

73.0

76.2

92.1

114.3

133.4

146.1

171.5

177.8

279.4

317.5

3-012-905

3-034-905

3-100-905

3-114-905

3-112-905

3-200-905

3-212-905

3-300-905

3-312-905

3-400-905

3-500-905

3-600-905

1-012

1-034

1-100

1-114

1-112

1-200

1-212

1-300

1-312

1-400

1-500

1-600

Product Specifications

Specification Data

UL File#:

Alloy:

Standards:

File# E337297

6063 Aluminum with Copper Content <=0.10%

UL 6A {/Standard for Electrical Rigid Metal Conduit- Aluminum, Red Brass, and Stainless Steel

ANSI C80.5 (Replaces Federal Specification WWC-540C}

ASTM Specification B221

CSA Standard C22.2 No. 45.2

Conduit Weight Chart

FEET

100

200

300

400

500

600

700

800

900

1,000

1,100

1,200

1,300

1,400

1,500

1,600

1,700

1,800

1,900

2,000

1/2"

28.1

56.2

84.3

112.4

140.5

168.6

196.7

224.8

252.9

281.0

309.1

337.2

365.3

393.4

421.5

449.6

477.7

505.8

533.9

582.0

3/4"

37.4

74.8

112.2

149.6

187.0

224.4

261.8

299.2

336.6

374.0

411.4

448.8

486.2

523.6

561.0

598.4

635.8

673.2

710.6

748.0

1"

54.5

109.0

163.5

218.0

272.5

327.0

381.5

436.0

490.5

545.0

599.5

654.0

708.5

763.0

817.5

872.0

926.5

981.0

1,035.5

1,090.0

1-1/4"

71.6

143.2

214.8

286.4

358.0

429.6

501.2

572.8

644.4

716.0

787.6

859.2

930.8

1,002.4

1,074.0

1,145.6

1,217.2

1,288.8

1,360.4

1,432.0

1-1/2"

88.7

177.4

266.1

354.8

443.5

532.2

620.9

709.6

798.3

887.0

975.7

1,064.4

1,153.1

1,241.8

1,330.5

1,419.2

1,507.9

1,596.0

1,685.3

1,774.0

2"

118.5

237.0

355.5

474.0

592.5

711.0

829.5

948.0

1,066.5

1,185.0

1,303.5

1,422.0

1,540.5

1,659.0

1,777.5

1,896.0

2,014.5

2,133.0

2,251.5

2,370.0

2-1/2"

187.5

375.0

562.5

750.0

937.5

1,125.0

1,312.5

1,500.0

1,687.5

1,875.0

2,062.5

2,250.0

2,437.5

2,625.0

2,812.5

3,000.0

3,187.5

3,375.0

3,562.5

3,750.0

3"

246.3

492.5

738.9

985.2

1,231.5

1,477.8

1,724.1

1,970.4

2,216.7

2,463.0

2,709.3

2,955.6

3,201.9

3,448.2

3,694.5

3,940.8

4,187.1

4,433.4

4,679.7

4,926.0

3-1/2"

295.6

591.2

886.8

1,182.4

1,478.0

1,773.6

2,069.2

2,364.8

2,660.4

2,956.0

3,251.6

3,547.2

3,842.8

4,138.4

4,434.0

4,729.6

5,025.2

5,320.8

5,616.4

5,912.0

4"

350.2

700.4

1,050.6

1,400.8

1,751.0

2,101.2

2,451.4

2,801.6

3,151.8

3,502.0

3,852.2

4,202.4

4,552.6

4,902.8

5,253.0

5,603.2

5,953.4

6,303.6

6,653.8

7,004.0

5"

478.9

957.8

1,436.7

1,915.6

2,394.5

2,873.4

3,352.3

3,831.3

4,310.1

4,789.0

5,267.9

5,746.8

6,225.7

6,704.6

7,183.5

7,662.4

8,141.3

8,620.2

9,099.1

9,578.0

6"

630.4

1,260.8

1,891.2

2,521.6

3,152.0

3,782.4

4,412.8

5,043.2

5,673.6

6,304.0

6,934.4

7,564.8

8,195.2

8,825.6

9,456.0

10,086.4

10,716.8

11,347.2

11,977.6

12,608.0

Typical Installation Practices

Cutting"' A hacksaw may be used to cut trade sizes Yz" thru 1 }{;''. Power cut-off tools are recommended for

larger sizes.

Bending"' Standard EMT Benders (one size larger than the size being bent) may be used for trade sizes ')12'' thru

1". Conventional Bending equipment is recommended for larger sizes.

Threading"' Sharp dies and conventional cutting oil are recommended. Contact Customer Service for a list of

recommended {/Aluminum-Specific" Cutting lubricants.

Fittings"' Aluminum fittings are recommended, however galvanized fittings may be used for most installations.

Fishing & Wire Pulling"' For trade sizes ')12'' thru 1 W', and on runs <100 feet, polyethylene fish tapes or

speedometer type steel cables may be used. Avoid the use of flat steel tapes. For trade sizes 2" and above,

and on runs >100 feet, polypropylene rope is recommended.

Soil or Concrete Installation"' UL's Electrical Construction Equipment Directory (UL Green Book) states that

supplementary corrosion protection is required for aluminum conduit used in concrete or in contact with soil.

Supplementary protection examples include paints (bitumastic) or wraps approved for the purpose, or PVC

coated aluminum conduit.

Page 10

•

•

•

•

•

•

•

•

ETL Listed to UL651 in compliance with the NEC

Heavy Wall EPC

Listed for underground applications encased in concrete or direct burial.

Also for use in exposed or concealed applications aboveground.

Sunlight resistant

Rated for use with gooc conductors

Superior weathering characteristics

Made in USA

*With Integral Bell

Notes:

1. Rigid nonmetallic conduit is normally supplied in standard 10' lengths, with one belled end per length. For specific

requirements, it may be produced in lengths shorter or longer than 10', with or without belled ends

2. Special conduit sizes will be quoted on request.

3. DON'T FORGET TO ORDER CEMENT.

4. Use RNC Fittings with Schedule 40 and Schedule 80 Conduit

5. Prime Conduit reserves the right to ship to the nearest unitized quantity.

23240 Chagrin Blvd Suite 405 • Cleveland, OH 44122 • 216-464-3400 • www.primeconduit.com

2

•

•

•

•

•

•

•

•

ETL Listed to UL651 in compliance to the NEC

Extra Heavy Wall EPC-80

Listed for use in aboveground and belowground applications

including areas subject to physical damage.

Sunlight resistant

Rated for use with 90°C conductors

Superior weathering characteristics

Identified for use in areas subject to physical damage in accordance to 352. 12(C)

Made in the USA

*With Integral Bell

Notes:

1. Rigid nonmetallic conduit is normally supplied in standard 10' lengths, with one belled end per length. For specific

requirements, it may be produced in lengths shorter or longer than 10', with or without belled ends

2. Special conduit sizes will be quoted on request.

3. DON'T FORGET TO ORDER CEMENT.

4. Use RNC Fittings with Schedule 40 and 80 Conduit

5. Prime Conduit reserves the right to ship to the nearest unitized quantity.

23240 Chagrin Blvd Suite 405 • Cleveland, OH 44122 • 216-464-3400 • www.primeconduit.com

3

~us

Sales Information:

•

ETL Listed to UL 651 in compliance with the NEC.

•

Meets NEMA TC3- Polyvinyl Chloride (PVC) Fittings for

Use with Rigid PVC Conduit and Tubing.

•

Not all configurations are stocked.

•

Elbows 72" and larger may be shipped in segments.

•

Contact you local Rep for more information.

•

Consult factory for additional sizes/configurations.

11-1/4°

1"'-l~-~

Elbow

Dimensional Information:

•

Dimensions are nominal.

•

Average outer diameter per UL651, Table 4.1

•

Minimum standard radius per UL 651, Table 4.10

•

Minimum tangent length per UL651, Table 4.10

See part

number list on

the special

radius elbow

pages.

*See

calculation

below.

*Arc Length "D" =[2 *Radius]* n * [Angle/360]

Example: Arc LengthuA3Ao = [2*4] * 3.14 * [11.25/360] = 0.79"

23240 Chagrin Blvd Suite 405 • Cleveland, OH 44122 • 216-464-3400 • www.primeconduit.com

5

&C®Duct

Prime Conduit nonmetallic P&C Duct Type EB is manufactured from Prime Conduit's exclusive high modulus PVC

compound, developed especially for power and communications applications, and is designed for use in concrete

encased installations. Type EB is rated for 90°C Cable.

"'''"'':

1

::?(.

-~/'4?,'"'

'

,

I RUS Accepted I

~

ETL Listed

to UL 651A in

compliance

to the NEC

P&C Duct Type EB-20

Meets NEMA Standard TC-6 & 8

EB-20/ASTM F-512

~w"Aff.JV~,~~

P&C DUCT 'fYP£ E8

J

*Min. wall thickness relates to 500,000 modulus

Note: One belled end per 10' and 20' length

P&C Duct Type EB-35 Heavy Wall

Meets NEMA Standard TC-6 & 8

EB-35/ASTM F-512

*Min. wall thickness relates to 500,000 modulus

**Special order item

Note: One belled end per 10' and 20' length

Use DB Sweeps with EB Duct.

www. prime conduit. com

3

Construction

• Constructed of continuously lntertocked hot dipped

zinc galvanized steel core for exceptional crush and

corrosion resistance.

• Durable, sunlight resistant and flame retardant

thermoplastic PVC jacket that resists heat, oil and

chemical breakdown.

• Convenient markings in feet for easy measurement

Square-Locked Design with Integral bonding wire 3fS" through

M/4~

~nstallation

• Conduit used with standard liquid~tight connector

for easy installation. IP 67 Rated when installed with

approved connectors.

• Approved for both exposed and concea.led locations.

Rated for temperature ranges -4°F to + 140°F (··20°C

to +60°C).

• Approved as an equipment grounding conductor in

sizes 3/8" through 1-1/.4/' if the total grounding path is 6

ft. or less and the circuit conductors are protected by

over 20 amps for 31811 and 112" and 60 amps or less for

314" through 1-1/411•

• Suitable for use in hazardous locations per NE.C

Articles 501 Class I Div. 2, Article 502 Class II

Div. 1 & 2, Article 503 Class III Div. 1 & 2.

• Manufactured in a full range of trade siz.es from 318M

through 4".

• Approved for direct burial and in concrete trade sizes

3/8,' through 4;1•

• Complies with Ut Standard 360 File No. E.18917; CSA

C22.2 File No. 158897; and NEC Article 350.

U.L LISTED® • CSA CERTIFIED

tnteriocket:l Design 1-11:2"' througl14" 'With no bcmding Wlre

•

•

"

•

•

•

•

•

Article 250.118 Equipment Grounding

Article 300.22 Air Plenum

Article 350 Liquid-Tight Flexible Metal Conduit (LFMC)

Article 501.10 (B) (2) Class f Div. 2

Article 502.10 (A) (2) and (B) (2) Class n Div. 1 & 2

Article 503.1 0 (A) and (B) Class HI Div. 1 & 2

Article 620.21 Elevator Wiring Methods

Article 645.5 (D) (2) Information Technology Equipment

wvvHwf.com

www.nfpa.org

\tV\41\<\t:nema. org

www.csa.-intemational.org

wv>"w.naed.org

~Vl.wt.anametelectrfcal.com

o. •

RoHS WEEE COMPLIANT

Type UA

Gray or Black thermoplastic PVC jacket wi.th integral

bonding wire 3/811 through 1-1/411

Product S ecitications

Approx

Inside

Electrical

Trade Size

Inches

Outside Diameter

Jnside Diameter

Bend

Radius

Approx

Weight

lbs.

Standard Reels

mm

3/B

12

.484-.504

t4AED

PIN

Length

feet

Len th

Feat

PIN

34201

BOO

1500

34203

.···?4~13

34229

1~

iff' . ' . ~$~;.:;.•;§42.

:~2:11

3/4

.820- .840

34221

500

<4.®i

1.380-1.410

··~~~i

34241

2.020-2.045

~~51

34261

: ·.1•··. ·

1-114

1~1/?

2

2~11?

3

.~1/2

4

~tqU.-+1·;~

:

. ·1,$~~r;1:®t)

,; ~.${);.;:;?:®5'·

3.070- 3.100

s;~¢ti;~:§.to '.·•

4.000-4.040

.

;~~1:?

34281

. ·34~01

34291

. 5ijo :• '

1.®6·

1000

NAED

250

. 1!i0 '.

100

11lQ ... 34274

100

34284

ioo

3$s04

100

34294

Note: 1. Gray- Specification above.

2:. Black- Change third number in NAED code to "0".

3. Other Colors are available upon request.

TYPICAL SPECIFICATION:

Conduit shall be Anaconda SEALTITE~ Type UA. Conduit shaU provide a flexible liquid-tight rae&Nay for wiring and shall be constructed of continuously

interlocked hot dipped zinc galvanized steel core with an integral bonding wire in sizes 318" thru 1-1:14..-.. Conduit shall have a sunlight resistant and flame

retardant PVC jacket in electrical trade sizes 3/8" thru 4". Conduit shall be ULlisted, CSA certified and IP 67 rated when installed with approved end connectors.

7

Myers Hubs

9F-33

1

when installed in

accordance with the NEC.

Class I, Div. 2

Class II, Div. 1 and 2

Class Ill

'

(

CROUSE-HINDS"

HUB BASIC SCRU-TITE<"- NEMA 2, 3, 3R. 4, 4X, 11 and 12

ZINC- Optional nickel-chrome plate finish available.t

Unit

Standard Weight Lbs.

UL File No. E-27258

Size Quantity

Package

Per 100

Cat.#

ST-02

ST-03

ST-1

®

~'

1/4''

3fa"

1fz"

3f4''

25

25

25

250

250

375

8

12

20

ST-2

ST-3

ST-4

1"

1114''

25

25

10

250

250

100

32

40

60

ST-5

ST-6

ST-7

ST-8

11/z"

2"

21fz"

3"

10

10

5

2

100

60

50

30

70

90

200

250

ST-9

ST-10

ST-11

ST-12

31fz"

4"

5"

6"

12

12

8

8

300

350

600

BOO

HUB BASIC SCRU-TITE®- NEMA 2, 3, 3R, 4, 4X, 11 and 12

ALUMINUM

UL File No. E-27258

25

STA-1

375

1fz"

3f4''

25

250

STA-2

25

250

STA-3

1"

®

~·

Applications: Ideal for pharmaaceutical, chemical and food

processing, pulp/paper and nuclear industries. Resistant to a variety

of chemicals, including acetic, citric and salt water. The 0-ring is a

special "Viton (75)" and has excellent chemical resistance. Hub is

provided with a stainless steel ground nut.

GROUND HUBS- PVC COATED

ZINC- PVC COATED

11z"

STG-1PVC

3f4''

STG-2PVC

STG-3PVC

1"

5

5

5

30

30

43

5

5

3

55

73

95

STG-7PVC

STG-BPVC

STG-9PVC

21fz"

3"

31/z"

190

263

300

4"

5"

6"

350

625

750

80

100

150

4"

5"

6"

12

8

8

150

300

300

E-Z INSTALL HUB- NEMA 2, 3, 3R, 4, 4X, 11 and 12

ZINC- Optional nickel-chrome plate finish available.t

Patented #5704400

1/z"

•m~ STCHG-1

\PW~ STCHG-2

3!4''

STCHG-3

1"

STG-10PVC

STG-11PVC

STG-12PVC

GROUND HUB- NEMA 2, 3, 3R, 4, 4X, 11 and 12

ZINC- Optional nickel-chrome plate finish available.t

UL File No. E-59509

Weight

Catalog!

Unit

Std.

Lbs. Per

Number

Size

Quantity

Pkg.

100

Max. Copper

Grd. Wire Size

CSA

UL

30

50

70

STG-1

STG-2

STG-3

1/z"

1"

25

25

25

325

225

150

20

30

43

#8

#8

#8

#8

#8

#8

85

110

160

STG-4

STG-5

STG-6

1114''

11/z"

2"

10

10

10

100

90

60

55

73

95

#8

#6

#4

#8

#8

#8

STG-7

STG-8

STG-9

21fz"

3"

31/z"

35

26

12

190

263

300

#2

1/0

2/0

#6

#6

#6

4"

5"

6"

12

8

8

350

625

750

2/0

2/0

3/0

#4

#2

#1

10

14

18

#8

#8

#8

#8

#8

#8

E-Z INSTALL HUB- NEMA 2, 3, 3R, 4, 4X, 11 and 12

ALUMINUM

Patented #5704400

!il.l'&m~

Unit

Standard Weight Lbs.

\PW~ -=C-=a::.:.t...::.#_ _.......::.S=iz=e---=Q:o..::u=a:.:..:n::.:.tit""y_P:.._a:.:..:c:.:..:k=a,_ge=----P=--e:..:r_1:...:0.:.0_

1

1

20

STACHG-1

1fz"

3f4''

STACHG-2

1

1

30

STACHG-3

1

1

35

1"

11/4''

11fz"

2"

55

73

95

30

30

50

50

30

12

STACHG-4

STACHG-5

STACHG-6

11f4"

11/z"

2"

20

30

43

100

100

60

21fz"

3"

31fz"

1114''

11/z''

2"

SSTG-4

SSTG-5

SSTG-6

10

10

10

10

10

10

1114''

11/z"

2"

STA-7

STA-B

STA-9

STCHG-3

STCHG-5

STCHG-6

1/z"

3/4"

1"

STG-4PVC

STG-5PVC

STG-6PVC

11/4''

11/z"

2"

STA-10

STA-11

STA-12

®~'

SSTG-1

SSTG-2

SSTG-3

8

16

16

STA-4

STA-5

STA-6

25

10

10

STAINLESS STEEL HUB- NEMA 2, 3, 3R, 4, 4X, 11 and 12

STAINLESS STEEL- Type 316

UL File No. E-59509

Weight

Lbs. Per

Unit

Standard

Package

100

Cat.#

Size

Quantity

40

50

70

t Zinc products are available with optional Nickel-Chrome Plate Finish, add suffix "-CP". See

price list.

STG-10

STG-11

STG-12

3f4''

GROUND HUB- NEMA 2, 3, 3R, 4, 4X, 11 and 12

ALUMINUM

STAG-1

1fz"

25

375

STAG-2

3f4''

25

250

STAG-3

1"

25

250

®

~·

STAG-4

STAG-5

STAG-G

1114''

11fz"

2"

10

10

10

100

100

60

25

33

45

#8

#6

#4

#8

#8

#8

STAG-7

STAG-S

STAG-9

21fz"

3"

31fz"

5

2

50

30

12

90

125

138

#2

1/0

2/0

#6

#6

#6

12

8

8

150

325

350

2/0

3/0

3/0

#4

#2

#1

STAG-10

STAG-11

STAG-12

Copyright0 1999 Cooper Industries, Inc.

4"

5"

6"

2

April1999

(2nd Proof 4-19-99)

Stainless Steel For 8 Conduit utlet Bodies

Ideal for Use in Corrosive Environments

For corrosion resistance combined with strength, durability and ease of installation,

Type 316 stainless steel offers performance that's hard to match. T&B® Fittings

Stainless Steel Conduit Outlet Bodies are designed to safeguard your electrical

system against the corrosion that can result in costly downtime and repairs.

They offer high resistance to chemicals and extreme temperatures (-40° F to 150° F),

low maintenance and exceptional value.

Features

• Marine-grade Type 316 stainless steel construction in rugged Form 8 design

• Suitable for use in food and beverage, pharmaceutical, petrochemical, wastewater

treatment, pulp and paper processing and other corrosive environments

Tshape

• Available in body shapes LB, T, TB and the new LU® Universal Conduit Elbow

(see opposite page for details)

• Hub sizes from

w~

to 211

• Tapered (NPT) threads and integral bushings to protect wire insulation

• Ship complete with covers, gaskets and screws included

• UL Listed and CSA Certified

Application

Conduit Bodies are installed in conduit systems to:

• Connect conduit sections

• Act as pull outlets when conductors are being installed

• Provide easy access for splices in branch conductors

• Make 90° bends in conduit runs

• Act as mounting outlets for wiring devices and lighting fixtures

• Provide access to conductors for maintenance and future system changes

Specifications

Standard Material:

Bodies: Type 316 stainless steel

Covers: Cast and stamped Type

316 stainless steel with

stainless steel screws

Gaskets: Neoprene (1 05° C/221 o F)

Standard Finish:

Bodies and Covers: Polished

Listings/Compliances:

UL Standard: 514A, 514B

Fed. Spec: W-C-5860

CSA Standard: C22.2 No. 18

LB shape

Stainless teel For

8 Conduit Outlet Bodies

Each Conduit Outlet Body Ships Complete

with Gasket, Cover and Screws

18rB Fillings® Stainless Steel Eorm 8 Conduit

Outlet Bodies witH Covers

Cat.

Number

Dimensions (in.)

Hub Size

A

B

c

D

E

Cu. ln.

UPC Number

LU® Stainless Steel Form 8 Conduit Body with Cover

LB shape

LU68SST

2"

10.61

3.43

5.43

2.45

6.40

56.0

!C[,]Jl

[5!

786209-93115

LB Stainless Steel Form 8 Conduit Body with Cover

I

LB68SST

2"

11.00

4.41

3.75

3.00

8.56

88.0

.d-1

786209-93122

T Stainless Steel Form 8 Conduit Body with Cover

Tshape

T68SST

2"

12.25

3.56

5.00

3.00

8.56

88.0

786209-93167

8.56

88.0

786209-93140

TB Stainless Steel Form 8 Conduit Body with Cover

TB68SST

2"

12.25

4.25

3.75

3.00

Please ask your Thomas & Betts sales representative for a complete catalog of quality

Thomas & Betts electrical products or visit us at www.tnb.com. For customer service,

call1-800-816-7809. For technical questions, call1-888-862-3289.

© 2011 Thomas & Betts Corporation. All rights reserved. Printed in the U.S.A.

04/11/10M GM-8297

Thomas & Betts Corporation

Electrical Division

8155 T&B Boulevard

Memphis, TN 38125

901-252-5000

www.tnb.com

Thomas&Betts

Stainless Steel Pipe Straps

@

Higher degree of corrosion resistance than traditional zinc-plated

or hot-dipped galvanized straps

@

One and two-hole straps for EMT sizes Yz" through 2"

®

One and two-hole straps for Rigid and IMC size Yz" through 4"

~&

303 stainless steel

GAT. NO.

TRADE WT. PER

SIZE

100

HOLE

DIA.

STD.

PKG.

GAT. NO.

Thomas &Betts offers stainless steel pipe straps

to support and securely fasten rigid, IMC and

EMT conduit. One- and two-hole stainless steel

straps are ideal for industrial applications such

as petro-chemical plants, manufacturing plants,

pulp and paper mills, food processing, power

plants, refineries and mining operations.

Stainless steel pipe straps are also useful in

commercial applications in schools, hospitals,

office buildings, airports, casinos and stadiums.

Reduces threaded opening in conduit

bodies or any female threaded fitting!

Reducing

Washers

Threaded

Reducers

~

@

Reduce knockout

hole in outlet box!

Smooth, built-in

bushing completely

covers rough ends

of conduit

Malleable iron or

steel construction

(steel through 606,

also 614 and 615)

UL File No. E-23018

GSA File No. 2884

~

Used in pairs

~

Interlock to form a rib

that centers washers

and conduit in knockout

~

Galvanized steel

construction

TRADE WT. PER

SIZE

100

HOLE

DIA.

STD.

PKG.

~

'85

EMT FITTINGS

~

~

STEEL - COMPRESSION CONNECTORS

Applications

• For use to bond EMT conduit to a box

or enclosure

• RACO® 1/2" to 4" connectors

provide concrete-tight connections

• RACO® compression connectors are

suitable for applications above 6DOV

Product Features

• All steel construction insures mechanical protection for the raceway

• All components are zinc electro plated for corrosion protection

• UPC bar coded fittings are individually

polybagged with a preprinted UPC-A

bar code and packaged in pre-scored

tear top cartons for an attractive

presentation

Compliances

• e®ii.l - Standard 5148

- C22.2 # 18

'

'

Uninsulated Connectors

Steel

Insulated Throat Connectors

Steel

ORDERING INFORMATION

COMPRESSION CONNECTORS- STEEL

INSULATED

CATALOG NUMBER

2912

2912·8

2913

2913-8

2914

2914-8

2915

2916

2918

2960

2962

2964

2966

UN INSULATED

CATALOG NUMBER

2902

2902-8

2903

2903-8

2904

2904-8

2905

2906

2908

2940

2942

2944

2946

TRADE

SIZE

UNIT

CTN. QTY.

SHIP

CTN. QTY.

1/2"

1/2"

3/4"

3/4"

1"

1"

1-1/4"

1-1/2"

2"

2-1/2"

3"

3-1/2"

4"

50

1

25

1

25

1

5

500

25

250

20

100

10

25

20

20

-

5

1

1

1

UPC

BAR CODE

Ill IIIII

IIIII III

IIIII III

-

-

- Bfi -

EMT FITTINGS

~

STEEL • COMPRESSION COUPLINGS

Applications

• For use to couple two ends of EMT

conduit

• RACO® 1/2" to 4" couplings provide

concrete-tight connections

• RACO® compression couplings are

suitable for applications above 600V

Product Features

• All steel construction insures mechanical protection for the raceway

• All components are zinc electro plated

for corrosion protection

• UPC bar coded fittings are individually

polybagged with a preprinted UPC-A

bar code and packaged in pre-scored

tear top cartons for an attractive

presentation

Compliances

• e@U$ - Standard 5148

- C22.2 # 18

Couplings

Steel

ORDERING INFORMATION

COUPLINGS - STEEl.

CATALOG

NUMBER

TRADE

SIZE

UNIT

CTN. QTY.

SHIP

CTN. QTY.

2922

2922-8

2923

2923-8

2924

2924-8

2925

2926

2928

2950

2952

2954

2956

1/2"

1/2"

3/4"

3/4"

1"

1"

1-1/4"

1-1/2"

2"

2-1/2"

3"

3-1/2"

4"

50

1

25

1

25

1

5

500

25

250

15

100

10

25

20

20

5

1

1

1

-

-

UPC

BAR CODE

-

11111111

11111111

-

IIIII III

-

-

'

7F-2

1

Cl. I, Div. 1 & 2, Groups A,B,C,Dt

Cl. II, Div. 1, Groups E,F,G

Cl. II, Div. 2, Groups F,G

Cl.lll

Unions and Elbows

;

CROUSE-HINDS"

Application:

UNY and UNF unions are

installed in threaded thickwall

conduit systems:

• UNY- to connect conduit to a

conduit fitting, junction box or

device enclosure

• UNF- to connect conduit to

conduit, or to provide a means

for future modification of the

conduit system

UNA unions are used in conduit

and fitting installations when

entrance angle is between goo

and 180°.

EL elbows are installed in

conduit run or in box or fitting

hub:

• to change direction in threaded

rigid conduit run by goo, or when

terminating at a box or fitting

Features:

UNY, UNF and UNL unions have:

• compact design which permits

assembly with a minimum of

clearance to other adjacent

conduit and/or equipment

• strong and durable

construction

UNA unions:

• have a single clamping nut on

angle, making it both a union

and a connector

• permit conduit joints at angles

between goo and 180°

Certifications and

Compliances:

• NEC/CEC:

Class I, Division 1 & 2, Groups

A,B,C,D

Class II, Div. 1, Groups E,F,G

Class II, Division 2, Groups F,G

Class Ill

EL Vz", 3/4'', 1"

UNF, UNY Vz" -1"

UNL Vz", 314''

Class I, Division 1 & 2, Groups C,D

Class II, Division 1, Groups E,F,G

Class II, Division 2, Groups F,G

Class Ill

EL, UNF, UNL, UNYall sizes

Class I, Division 1 & 2, Group D

Class II, Division 1, Groups E,F,G

Class II, Division 2, Groups F,G

Class Ill

UNA

• UL Standard: 886

• CSA Standard: C22.2 No. 30

Standard Materials:

Standard Finishes:

• Steel - electrogalvanized with

chromate treatment

• Feraloy iron alloy, malleable

iron- electrogalvanized and

aluminum acrylic paint

1/z" • 4"

1/z". 4"

Class I, Division 1 & 2, Groups B,C,D

Class II, Division 1, Groups E,F,G

Class II, Division 2, Groups F,G

Class Ill

UNF/UNY406, -506,

-606, -706, -806,

.go5, -1005

EL elbows have a smooth interior

and are both strong and

compact.

• UNY, UNF unions- Vz" to 1"steel

• UNY, UNF unions -11/4'' to 6"Feraloj' iron alloy

• UNL, UNA unions- Feraloy

iron alloy

• EL elbows- Feraloy iron alloy

or ductile iron

UNL

5". 6"

5". 6"

UNY

UNF

Male

Female

Size

Cat.#

1/z

UNY105

1/z female to 3f4 male UNY215

3/4

1

11/4

11/4

11fz

11fz

2

2

21fz

21fz

3

3

31fz

4

5

6

UNY205

UNY305

UNY405

UNY406

UNY505

UNY506

UNY605

UNY606

UNY705

UNY706

UNY805

UNY806

UNYg05

UNY1005

UNY012

UNY014

Size

1/z to 1/z

3/4 female to Vz male

1/z female to 3f4 male

3/4 to 3/4

Cat.#

UNL105

UNL125

UNL215

UNL205

Dimensions

Options:

UNY

Size

1/z

3/4·1fz

3/4

1

11f4

11/z

2

21/z

3

31/z

4

5

6

Cat.#

UNF105

UNF215

UNF205

UNF305

UNF405

UNF406

UNF505

UNF506

UNF605

UNF606

UNF705

UNF706

UNF805

UNF806

UNFgo5

UNF1005

UNF012

UNF014

3/4 to 1/z

3/4

1

11/4

11/4

11fz

11fz

2

2

21/z

21fz

3

3

31/z

4

5

6

Length

23/s

2 7116

2 7116

2 3/4

3 3/16

3 9/16

3 3/4

4 5/s

5

51/z

5 5/s

51/4

5 3/s

UNF

Max.

Dia.

11fz

113f16

113/16

17/s

2 3/4

31/16

313f16

4 5116

51/16

511/16

63hs

8 3hs

g 5hs

Length

113f16

1314

1314

2

21/4

2 5/s

2 9116

3 3116

37/16

41/s

41/s

313f1s

313f16

Max.

Dia.

11fz

113f16

113f16

17/s

2 3/4

31f16

3 13/16

4 5/16

51/16

5 11/16

6 3/16

8 3/16

g 5f1s

125

211/16

113f16

21/16

Phs

215

27/s

113f1s

21/4

1 5/s

205

27/s

113f16

21/4

Ws

UNL

t

See compliances for classification of each

product.

Dim.

a

b

c

d

(4-19-99 2nd Proof)

Size

1/z

90° Angle

• Copper-free aluminum- add

suffix SA to Cat. No. (not

available on UNL)

April1999

Explosionproof

Dust -lgnitionproof

Copyright0 1999 Cooper Industries, Inc.

105

211f1s

117!Jz

21/16

17/16

Myers Hubs

9F-33

1

(

t $ 1

when installed in

accordance with the NEC.

Class I, Div. 2

Class II, Div. 1 and 2

Class Ill

'

CROUSE·HIND5°

HUB BASIC SCRU-TITE"'- NEMA 2, 3, 3R, 4, 4X, 11 and 12

ZINC- Optional nickel-chrome plate finish available.t

Standard Weight Lbs.

UL File No. E-27258

Unit

Cat.#

Size Quantity Package

Per 100

®

®·

ST-02

ST-03

ST-1

1f4''

3/s"

11z"

25

25

25

250

250

375

8

12

20

ST-2

ST-3

ST-4

3f4''

1"

11/4''

25

25

10

250

250

100

32

40

60

ST-5

ST-6

ST-7

ST-8

11/z"

2"

21/z"

3"

31/z"

10

10

5

2

100

60

50

30

70

90

200

250

12

12

8

8

300

350

600

800

ST-9

ST-10

ST-11

ST-12

4"

5"

6"

HUB BASIC SCRU-TITE®- NEMA 2, 3, 3R, 4, 4X, 11 and 12

ALUMINUM

UL File No. E-27258

11z"

STA-1

375

25

3f4''

STA-2

25

250

250

STA-3

25

1"

®

@·

STG-7PVC

STG-BPVC

STG-9PVC

80

100

150

4"

5"

6"

12

8

8

150

300

300

E-Z INSTALL HUB- NEMA 2, 3, 3R, 4, 4X, 11 and 12

ZINC - Optional nickel-chrome plate finish available. t

Patented #5704400

1/z"

fliihffi

STCHG-1

151111W

STCHG-2

3f4''

STCHG-3

1"

10

10

10

20

30

43

55

73

95

30

30

43

11f4"

11fz"

2"

2 1/z"

STG-10PVC

STG-11PVC

STG-12PVC

55

73

95

3"

3 1/z"

190

263

300

4"

5"

6"

350

625

750

GROUND HUB- NEMA 2, 3, 3R, 4, 4X, 11 and 12

ZINC - Optional nickel-chrome plate finish available. t

UL File No. E-59509

Weight

Catalog!

Unit

Std.

Lbs. Per

Number

Size

Pkg.

100

Quantity

Max. Copper

Grd.WireSize

GSA

UL

30

50

70

STG-1

STG-2

STG-3

1fz"

3f4''

1"

25

25

25

325

225

150

20

30

43

#8

#8

#8

#8

#8

#8

85

110

160

STG-4

STG-5

STG-6

1114''

11fz"

2"

10

10

10

100

90

60

55

73

95

#8

#6

#4

#8

#8

#8

STG-7

STG-8

STG-9

21fz"

3"

31fz"

35

26

12

190

263

300

#2

1/0

2/0

#6

#6

#6

4"

5"

6"

12

8

8

350

625

750

2/0

2/0

3/0

#4

#2

#1

10

14

18

#8

#8

#8

#8

#8

#8

100

100

60

25

33

45

#8

#6

#4

#8

#8

#8

E-Z INSTALL HUB- NEMA 2, 3, 3R, 4, 4X, 11 and 12

ALUMINUM

Patented #5704400

6m~

Unit

Standard Weight Lbs,

ll_PW- ..:.C_a_t...:.#_ _........:S..:.iz.,_e_Q..:.:.:..:u"-anc.:..t::..it,._y_P_a_c_k_a,._ge_ _ _P_er'--10:...0'-STACHG-1

1

1

20

1fz"

3f4''

STACHG-2

1

1

30

STACHG-3

1

1

35

1"

11f4"

11fz"

2"

10

10

10

GROUND HUBS- PVC COATED

ZINC- PVC COATED

STG-1PVC

1fz"

STG-2PVC

3!4''

STG-3PVC

1"

30

30

50

50

30

12

STACHG-4

STACHG-5

STACHG-6

11/4''

1112''

2"

100

100

60

21fz"

3"

3112"

1W'

1112"

2"

SSTG-4

SSTG-5

SSTG-6

STG-4PVC

STG-5PVC

STG-6PVC

STA-7

STA-B

STA-9

STCHG-3

STCHG-5

STCHG-6

1fz"

3/4"

1"

Applications: Ideal for pharmaaceutical, chemical and food

processing, pulp/paper and nuclear industries. Resistant to a variety

of chemicals, including acetic, citric and salt water. The 0-ring is a

special "Viton (75)" and has excellent chemical resistance. Hub is

provided with a stainless steel ground nut.

8

1114''

11fz"

2"

STA-10

STA-11

STA-12

®®·

SSTG-1

SSTG-2

SSTG-3

16

16

STA-4

STA-5

STA-6

25

10

10

STAINLESS STEEL HUB- NEMA 2, 3, 3R, 4, 4X, 11 and 12

STAINLESS STEEL- Type 316

UL File No. E-59509

Weight

Unit

Standard

Lbs. Per

Cat.#

Size

Quantity

Package

100

40

50

70

t Zinc products are available with optional Nickel-Chrome Plate Finish, add suffix "·CP". See

price list.

STG-10

STG-11

STG-12

GROUND HUB- NEMA 2, 3, 3R, 4, 4X, 11 and 12

ALUMINUM

STAG-1

1/z"

25

375

STAG-2

3f4''

25

250

STAG-3

1"

25

250

®

@·

STAG-4

STAG-5

STAG-6

11f4"

11fz"

2"

STAG-7

STAG-S

STAG-9

21fz"

3"

3112"

50

30

12

90

125

138

#2

1/0

2/0

#6

#6

#6

4"

5"

6"

12

8

8

150

325

350

2/0

3/0

3/0

#4

#2

#1

STAG-10

STAG-11

STAG-12

Copyright" 1999 Cooper Industries, Inc.

10

10

10

April1999

(2nd Proof 4-19-99)

9F-36 Hubs

'

1

(

CROUSE-HINDS"

r*

lP

PL.ANVIEW

PLAN VIEW

SIDE VIEW

"D" dimension indicated

maximum panel thickness

which hub will accommodate.

Minimum space from center of pipe or conduit to nearest obstruction.

1. Dimensions in black squares are centers for conduits of same size. Example: How close may 3" conduits be spaced?

Answer 41fz".

2. Dimensons in grey squares are for centers of conduits NOT of the same size. Example: What is the minimum spacing for 2" and 314''

conduit?

Read down column marked 314'' to figure opposite 2" and find dimensions is 211/Ji'.

3. Minimum spacing dimensions as shown will give approximately 1fa'' clearance between locking nuts.

April1999

(4-19-99 2nd Proof)

Copyright0 1999 Cooper Industries, Inc.

A-21

FM9TM Aluminum Unilet® Conduit Outlet Bodies,

Covers and Gaskets

For use with Rigid Steel, Rigid Aluminum and IMC.

Applications

• Serve as pulling fittings.

• Make bends in conduit system.

• Provide openings for splicing.

• Connect and change direction of

conduit runs.

• Allow connections for branch runs.

• Permit access to conductors for

maintenance.

Features: FM9 Unilet® conduit outlet

bodies

• Roomy interiors: deep body cavity

provides increased volume allowing

higher wiring capacity.

• Smooth, rounded integral bushings in

hubs protect conductor insulation.

• Accurately tapped, tapered threads

for tight, rigid joints and excellent

ground continuity.

• Completely interchangeable with

Crouse-Hinds Mark9™ bodies, gaskets

and covers. Equivalent FM9 and Mark

grM units have identical applications and

installation dimensions.

• Seven body styles available in 1/2"

to 4" sizes, TB's in 1/2" to 2" ans X's in

1/2" to1".

Features:

• Aluminum Unilets: produced from a

high-strength copper-free (4/1 0 of 1%

max.) alloy, for light weight and high

corrosion resistance.

• FM9TM FormtiteTM 9 covers with integral gasket are approved for use in wet

locations.

• Covers are domed for extra wiring

space.

• Smooth hub bushings and cover

openings protect conductor insulation.

Smooth hub openings allow easy conduit joining.

• Stainless steel pan-head cover

screws secure cover to body and provide superior screwdriver seating and

torque. Cover screws are captive to

prevent loss in sizes 1/2" to 2".

• Hub size, body style, and compliance data molded into body in large,

easy-to-read form. Also maximum wire

number/size and cubic capacity.

Effective June, 2006

Copyright 2006

LL Body with

Formtite™ 9 Integral Gasket Cover

Captive Stainless Steel

Pan-Head Cover Screws

Standard Materials

• Conduit bodies: copper-free aluminum.

• Covers: stamped copper-free aluminum

• Cover screws: stainless steel.

• Gaskets. Neoprene

~Appleton·

Standard Finishes

• Conduit bodies, covers and screws:

natural

Compliances

• UL Standard 514A.

800-621-1506

www.appletonelec.com

PAGE 21

A-22

FM9™ Aluminum Unilet® Conduit Bodies, Covers

and Gaskets

For use with Rigid Steel, Rigid Aluminum and IMC Conduit.

A leton FM9 Conduit Bodies NOTE: Refer to a e A- 23 for Wirin

c

LB

LL

LR

Hub Size

in.

1/2

C19

LB19

LL19

LR19

3/4

C29

LB29

LL29

LR29

C39

LB39

LL39

LR39

1-1/4

C49

LB49

LL49

LR49

1-1/2

C59

LB59

LL59

LR59

2

C69

LB69

LL69

LR69

2-1/2

C789

LB789

LL789

LR789

LR889

3

C889

LB889

LL889

3-1/2

C989

LB989

LL989

LR989

4

C1089

LB1089

LL1089

LR1089

T

TB

X

Hub Size

in.

1/2

T19

TB19

X19

3/4

T29

TB29

X29

1

T39

TB39

X39

1-1/4

T49

TB49

1-1/2

T59

TB59

2

T69

TB69

2-1/2

T789

3

3-1/2

T889

4

T1089

T989

Appleton FM9 Blank Covers and Gaskets and Formtite™ 9 Stamped Aluminum Cover with Integral Gasket

Covers furnished with Stainless Steel Screws

Stamped Aluminum Cover

Solid Gasket Neoprene

Formtite™ 9

FM9 Body

Size in.

1/2

190

GASK1941

190G

3/4

290

GASK1942

290G

390

GASK1943

390G

1-1/4

490

GASK1944

490G

1-1/2

590

GASK1945

590G

2

690

GASK1946

690G

2-1/2

889

GASK808N

889G

3

3-1/2

889

989

GASK808N

GASK809N

889G

989G

4

989

GASK809N

989G

Effective June, 2006

Copyright 2006

PAGE 22

~Appleton·

800-621-1506

www.appletonelec.com

A-23

FM9TM Conduit Body Dimensions

t-----M----1

'

l__~_j

r

. ! _ __ _ _ _ _ _

Type C, T, TB & X

Type LB, LL & LR

Dimensions in Inches

Hub Size

A

1/2

4.97

5.69

3/4

6.59

1

1-1/4

7.63

C, LB,

1-1/2

8.25

T, LL,

10.69

2

& LR

2-1/2

15.63

15.63

3

3-1/2

18.75

18.75

4

1/2

3/4

1

1-1/4

1-1/2

2

TB

&X

5.94

6.56

7.50

8.50

8.25

10.69

B

1.56

1.81

2.06

2.69

3.03

3.75

4.94

5.31

6.19

6.44

1.94

2.22

2.44

2.69

3.03

3.75

c

1.38

1.56

1.75

2.19

2.53

3.19

5.00

5.00

6.25

6.25

1.38

1.56

1.75

2.19

2.53

3.19

D

1.06

1.22

1.41

1.88

2.19

2.81

4.25

4.25

5.44

5.44

1.03

1.22

1.38

1.75

2.19

2.75

E

3.28

3.94

4.56

5.25

5.94

8.06

10.88

10.88

13.44

13.44

3.28

3.94

4.56

5.25

5.94

8.06

F

4.22

4.81

5.59

6.56

7.25

9.56

12.25

12.25

15.00

15.00

4.22

4.81

5.59

6.56

7.25

9.56

G

0.63

0.75

0.88

1.09

1.25

1.50

2.50

2.50

3.13

3.13

0.63

0.75

0.88

1.09

1.25

1.50

Wiring Capacity in Cubic Inches

Hub Size

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

3-1/2

4

Effective June, 2006

Copyright 2006

c

4.8

7.8

12.3

25.3

37.5

77.5

230.0

250.0

450.0

470.0

LB

5.0

8.3

12.8

26.5

39.0

81.3

230.0

250.0

450.0

470.0

LL/ LR

T

5.3

5.0

8.5

13.3

27.3

39.8

82.8

230.0

250.0

450.0

470.0

8.3

12.5

26.3

38.5

79.5

230.0

250.0

450.0

470.0

TB

6.8

11.0

16.5

25.8

36.5

77.0

X

7.3

11.3

17.0

Cover

0.5

0.8

1.0

1.5

2.5

6.5

12.3

12.3

24.0

24.0

H

2.31

2.59

3.03

3.75

4.03

4.88

6.63

7.00

8.06

8.31

2.75

3.03

3.38

3.75

4.03

4.88

J

3.59

4.09

4.84

5.38

6.00

7.88

11.44

11.44

13.75

13.75

-

-

-

K

1.44

1.59

1.84

2.16

2.25

2.66

4.19

4.19

5.00

5.00

1.56

1.66

1.84

-

-

L

2.13

2.38

2.72

3.25

3.53

4.25

6.69

6.69

8.13

8.13

2.25

2.44

2.72

-

-

M

-

-

-

3.13

3.31

3.69

-

Fraction/Decimal Equivalents (Inches)

Fraction

Decimal

Fraction

1/16

0.06

9/16

1/8

0.13

5/8

11/16

3/16

0.19

0.25

3/4

1/4

0.31

13/16

5/16

3/8

0.38

7/8

15/16

7/16

0.44

1/2

0.50

1

~Appleton'

N

4.59

2.52

6.09

7.09

7.81

10.13

13.94

13.94

16.88

16.88

5.06

5.69

6.53

7.53

7.81

10.13

Decimal

0.56

0.63

0.69

0.75

0.81

0.88

0.94

1.00

800-621-1506

www.appletonelec.com

PAGE 23

®

USUI ,

Price Group: J 1

TypeT

Type LL

Type LR

Type LB

TYPE C

TYPE E

TYPE X

23240 Chagrin Blvd Suite 405 • Cleveland, OH 44122 • 216-464-3400 • www.primeconduit.com

©Prime Conduit 2014

11

The ultimate in corrosion protection!

OCAL-BLUE Conduit

• Hot-dip galvanized steel or aluminum conduit

• Nominal .002" (2 mil) blue urethane coating on interior

• Hot-dipped galvanized threads (steel)

• Minimum .040" (40 mil) PVC coating on exterior- in your

choice of blue, white, gray or custom colors

• Color-coded thread protectors

• Couplings shipped with conduit are packaged separately

/

PIPE

SIZE

IN.

METRIC SIZE

DESIGNATOR*

OUTSIDE

DIAMETER

STEEL ONLY

IN.

MM

OUTSIDE

DIAMETER

WITH PVC

IN.

MM

NOMINAL

WALL

THICKNESS

STEEL ONLY

IN.

MM

155

NOTE -Inches and pounds are indicated in bold type. Metric measure is directly below bold type.

* Metric size designator (ANSI CBO. 1-1994).

NOMINAL

WALL

THICKNESS

WITH PVC

IN.

MM

NOMINAL

INSIDE

DIAMETER

IN.

MM

CROSS

SECTION

AREA IN

SQUARE

IN.

MM

MINIMUM

LENGTH

WEIGHT

WITHOUT

PER FOOT

COUPLINGS STEEL ONLY

FT.

LBS.

M

KG

Corrosion-protected connections for conduit sections.

OCAL-BLUE Couplings

• Nominal .002" (2 mil) blue urethane coating on interior and threads

• Minimum .040" (40 mil) PVC coating bonded to exteriorin your choice of blue, white, gray or custom colors

• Straight threads (NPS)

• Molded ribs on outer coating for easy installation

(up to and including 4" trade size)

• Pressure-sealing sleeves protect your connection

COUPLING

SIZE

IN.

METRIC SIZE DESIGNATOR*

TOTAL

MINIMUM LENGTH

WEIGHT

INCLUDING SLEEVE

STEEL ONLY

IN.

MM

LBS.

KG

Factory bent to save wasted time and materials!

~OCAL-BLUE

Standard-Radius Elbows

• Fabricated from Ocal PVC-coated conduit

• Standard radii in 30°, 45°, 60° and goo available for immediate shipment

• Color-coded thread protectors for easy identification of conduit size

~SIZE

.-----------.,

IN.

METRIC SIZE

DESIGNATOR*

STRAIGHT END

RADIUS "R"

OFFSET "C"

"D"

UNBENT

LENGTH

WEIGHT EACH

STEEL ONLY

1-39

Liquidtight Connectors and Hubs

for Liquidtight Flexible Metal Conduit

General Information and special features.

Applications

• Seal out oil, water, dirt, dust and

fumes wherever liquidtight flexible

metal conduit is used.

• Typical applications include food

processors, beverage plants, chemical

plants, dairies, machine shops, plastic

fabricators, petroleum machinery, and

gantry cranes.

ST and STB Series

For connections to threaded hubs.

Insulated throat on STB protects

conductors. Connectors are available

with grounding lugs. Straight sizes

3/8" thru 5"; 45° and goo, 3/8" thru

4". Straight and goo styles in sizes

3/8" thru 2" also available with certain

metric thread sizes. See page l-4g.

·451;> STJSTB

Straight ST!STB

Female ST