Manual - Randolph Austin

advertisement

www.RandolphAustin.com

Operations Manual

Pump Series: 610

Model #610-200

610 Pump Head

Belt Driven, Explosion Proof

Motor Assembly

Class 1, Group D, 1/3 Hp,

1ph, 115/208-230VAC

Randolph Austin Company

2119 FM 1626

Manchaca, Texas 78652

(512) 282-1590

Revision 03/09/2012

14 1/2"

00-0420: Qty 1

Connector

05-0170: Qty 1

Junction Box, X-Proof

02-0503: Qty 1

Base

USED ON

APPLICATION

NEXT ASSY

03-0205: Qty 1

Motor, 1/3 Hp, X-Proof

62-0221: Qty 1

Belt Guard Assy

610-PHO: Qty 1

610 Pump Head

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

Randolph Austin Company. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

Randolph Austin Company IS

PROHIBITED.

8 1/4"

MATERIAL

--

--

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL 1/64

ANGULAR: MACH 1

TWO PLACE DECIMAL

.010

THREE PLACE DECIMAL

.005

FINISH

DO NOT SCALE DRAWING

DRAWN

CHECKED

ENG APPR.

MFG APPR.

COMMENTS:

Q.A.

200

180

160

140

120

100

80

60

40

20

0

0

NAME

SIZE

610 Flow Chart

200 RPM 300

400

3/8" Tubing

1/2" Tubing

500

SHEET 1 OF 1

REV.

Randolph Austin Company

610-200 Assembly

610-200

WEIGHT:

DWG. NO.

SCALE:1:10

A

20 1/2"

100

DATE

Flow: Gallons per Hour

61-0032: Qty 1

Tube Clamp

61-0440: Qty 1

Clamp Screw

61-0441: Qty 1

Nut, Adjusting

00-0295: Qty 1

Washer, Clamp

61-0140: Qty 2

Impeller Roller Assy

62-0020: Qty 1

Side, Cover

01-0186: Qty 1

E Clip - Tube Clamp

61-0080: Qty 1

Plate and Shaft

PROPRIETARY AND CONFIDENTIAL

USED ON

APPLICATION

NEXT ASSY

--

NAME

DATE

01-0133: Qty 1

Snap Ring

61-0010: Qty 1

Pump Head

00-0601: Qty 1

Helicoil 1/4-20

SIZE

REV.

Randolph Austin Company

SHEET 1 OF 1

610 Pump Head

Exploded Assembly View

Pumps after Aug-2008

610-PHO-XP

WEIGHT:

DWG. NO.

SCALE:1:5

A

61-0050: Qty 1

Serial Number Plate

01-0113: Qty 2

Bearing

COMMENTS:

Q.A.

MFG APPR.

ENG APPR.

CHECKED

DRAWN

00-0532: Qty 1

Bearing Shim

MATERIAL

-DO NOT SCALE DRAWING

FINISH

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL 1/64

ANGULAR: MACH 1

TWO PLACE DECIMAL

.010

THREE PLACE DECIMAL

.005

01-0185: Qty 1

E Clip - Hinge pin

00-0600: Qty 1

Clevis Pin

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

Randolph Austin Company. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

Randolph Austin Company IS

PROHIBITED.

>

-u

Ln

N)

CJ)

070

rn

Z

rn 0

0

T2A

40° C

B

rn E7 FT1

zu > *

o

0

cn 1—

cA

co

I

1—

>

,...----. 10

nn

I

Al

--""-----

p

0

c

I

i

>

I

C:

—1

[II

0

cn

[

1

7

lib.. ■II

ul < 0

rn

1—

1-unL==

-,•

z

0.6250

0 6245

op

co

o

cn

(...n

1-7

-<

0

W>

L)

0 1—

7.411111114

i

Z7

0

z

z

0 Ez

i

c0

u' 0

XY cP

J-

0

REF : 112974:

MOTOR ROTATION

DATA

AUTOMATIC

SWIVE L (180° ) CONE

ELBOW 1/2-14 N .P.i0 0 I

-N

4, - CO

e

i

daakA

war

*

'.

S

0

ON

\

A. A& ■d

4

.

ND

4

el

on

e

Co

►

o

yp

6

mw.mw

cp.

•

-

4,

•

-[=•

cu -<

1- ,-1

00

2.085

2.065

c,

J

o

-

0

OFF

CD'

0 (u'

. °

AR'

6'

0

!

11

CD

l) _1

_

3.50

3.47

7

O

---- ,..,-,

cp

CA

-i-

6.63

62

WITHOUT TOLERANCES ARE REFERENCE ONLY

46

NOTES

1 MOTOR LISTED FOR HAZARDOUS

LOCATION — CLASS I , GROUP D.

350 40

LEADS

31

SEE LEAD NOTE

EXTERNAL CONNECTIONS

z

210 26

0

1—

1

. > 0

0 0 0

0 Z

0

0C

_1 z

z

I

-o

Z>

-7

T7

,

„I_ • ,

0

0

<-

0

4,

C...1

-fl S>

—1 7

m

nu

-

Oz

-0 >0

-0

Om

V) 7

co

-1,D cy,

TO

17

CC 1

I

> co

0 Z Z

z

0 C)

J

[

r

0

z

>

z

3

6 14

1--

F,,'

1

z

rn

i

0

7 n Z 0

-

n -1

rffn

> -n

Do

0

CD

I

. __ _,

C) PC 1

0 Z_.

>

i

-7

.

'i

66

FranIcH n M ce=.t rro' c

Bl ufft on , I ndi ana 46714

MODEL OUTLINE

"21007434

DIST:

1—

1—

REV

REV

LOW

.

-1,

-1,•

z_A\

FE STANDARD

51009

LKW 12/31/97

12/31/97

w

GE1

ASSEMBLY ROTATION

(,)

-.mcr)

,,,

PROTECTED.

0

-1

co

I

Z

0

7

0

CI U") >

- C 7 +

1— 1—

0

- > 0 =

0 DR

VOTOR

o

3>

z

CU

m

N

TENV X-PROOF

E

GI

0

7

U)

rn

GI -C• >

-C• GI

0 0 (i)

-0 U)

11- -1 -1

-< 7: 0

7: F7

F7 -, -0 F7

(..c) IE -0 >1

— -< — —I

cf-)1- z m

-1 rn 0 Z

> 0 - 0

Z7

—1

-1,1— Co

77 F7 =

(.7)

o

ASSEMBLY VOLTAGE

CUSTOMER NAME

z

N

7

N

ENCLOSURE

NORMAL

CUSTOMER PART NO .

DRAWN

APPROVED

RELEASED

N

0-,

F .E . BLUE

71

m

HORIZONTAL THERMALLY

Z

—1*—

Z 1— — Z

Fn — —1 Fn

Z 11_

>

Z 7 - 7

4,

..

PAINT

z

o

0

>

Z

0 U) U)

-

MOUNTING POSITION

ENVIRONMENTAL CONDITION

COLD ROLL STEEL

SHAFT MATERIAL

co

--- (f)

C,,i —

0-1

0 .34 0 .34

0

---I

N

CD >

-D CD(..0

IE C)

CONNECTION

LABEL

c),,

0000

> C) CO CD CO X

0

AS

TEMP CODE

INS . CLASS

MAX .AMB.

(7)

115/208-230

.

C>

Z

^0

U) 0 7

—Z 0

(y)

CT

56

CD

>

-13

7 7 7

- 7 7 ,

K

-0

co

INFORMATION DISCLOSED THERE IN SHALL BE REPRODUCED OR TRANSFERRED TO OTHER DOCUMENTS OR USED OR DISCLOSED TO

OTHERS FOR MANUFACTURING PURPOSES OR FOR ANY OTHER PURPOSES , EXCEPT AS SPECIFICALLY AUTHORIZED IN

m

C,,,i

m

■

—

WRITING BY FRANKLIN ELECTRIC.

)3

>

_1

N

m

HOLTS

FRAME

HVA CODE M

co

3 25/32"

Crouse Hines

EABC 16 - 1/2" NPT

5 9/16"

3 3/32"

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

Randolph Austin Company. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

Randolph Austin Company IS

PROHIBITED.

NEXT ASSY

MATERIAL

--

--

DO NOT SCALE DRAWING

FINISH

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL 1/64

ANGULAR: MACH 1

TWO PLACE DECIMAL

.01

THREE PLACE DECIMAL

.005

1 1/2"

TYP

USED ON

APPLICATION

ZONE

REV.

DRAWN

ENG APPR.

CHECKED

MFG APPR.

COMMENTS:

Q.A.

DATE

2 29/32"

NAME

REVISIONS

DATE

1/2 " NPT

Typ 2X

05-0170

Conduit Box 610-201

DWG. NO.

WEIGHT:

APPROVED

SHEET 1 OF 1

REV.

Randolph Austin Co

DESCRIPTION

SIZE

A

SCALE:1:2

2:

5:

SYS19: BASE2

PDFINFO

50:

95:

98:

100:

JOB: CRMAIN06-1011-2 Name: 2P-1011

DATE: JAN 19 2006

Time: 6:08:36 PM Operator: RB

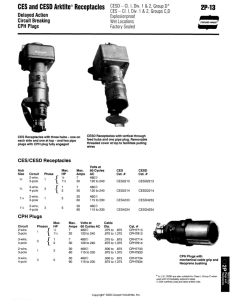

CES and CESD Arktite Receptacles

Delayed Action

Circuit Breaking

CPH Plugs

COLOR: CMYK

2P

Interchangeability of Plugs

with Non-Hazardous

Location Receptacles:

Features:

ɀ CES and CESD receptacles are equipped

with a delayed action rotating sleeve which

prevents complete withdrawal of the CPH

plug in one continuous movement

ɀ The delayed action feature permits the plug

to be used as an emergency push-pull switch

ɀ Details of operation are illustrated and

described below:

Fig. 3

Fig. 4

Figure 4 shows the plug completely

withdrawn. To accomplish this, the delayed

action sleeve must be rotated

counterclockwise. The time required to

actuate the mechanism permits dissipation of

the arc-generated heat before contacts and

arcing chambers are opened to the

atmosphere.

When inserting the plug, the reverse

procedure is followed.

ɀ Receptacles are factory sealed to simplify

installation and wiring. External seals are not

required

ɀ The 30 ampere receptacles are provided

with pressure terminals for field connection.

The 60 ampere receptacles have flexible

leads. Plugs are equipped with solder

terminals.

ɀ Two arrangements are provided for the 3⁄4⍯

and 11⁄4⍯ conduit hubs, as shown in the

listings and dimensions on page 1012.

Grounding:

Figure 1 above shows a CES receptacle

assembly with CPH plug fully engaged.

Figure 2 shows the plug withdrawn until it is

stopped by the delayed action sleeve. In this

position the circuit has been broken and the

arc has been snuffed in the contact

chambers.

Figure 3 shows the delayed action receptacle

sleeve rotated approximately 45° to allow

withdrawal of plug from receptacle.

csm no.: 100

ɀ CES and CESD receptacles and CPH plugs

are provided with an extra grounding pole for

attachment of the grounding wire. In the

plugs, provision is made for attachment of

the grounding wire to the grounding pole. In

addition, direct connection is provided

between plug and receptacle housings and

the ground pole. In the receptacles,

grounding is accomplished through the

conduit system.

CES and CESD receptacles with CPH plugs

are used:

ɀ with portable electrically operated devices

such as motor-generator sets, compressors,

conveyors, portable tools, lighting systems

and similar equipment

ɀ in locations which are hazardous due to the

presence of flammable vapors or gases

ɀ in damp or corrosive locations

ɀ at petroleum refineries, chemical and

petrochemical plants, and other process

industry facilities where similar hazards exist

Fig. 2

Typedriver Name: TS name

CESD – Cl. I, Div. 1 & 2, Group D*

CES – Cl. I, Div. 1 & 2, Groups C,D

Explosionproof

Wet Locations

Factory Sealed

Application:

Fig. 1

TCP: 15001

ɀ NEC article 501 and CEC Part 1 Section 18

require that metal frames or exposed noncurrent-carrying metal parts of portable

devices used in hazardous locations be

grounded through an extra conductor in the

portable cord.

ɀ CPH plugs can also be used with standard

AR and NR receptacles of the same ampere

rating, style and number of poles, thus

permitting portable devices which are

suitable for use in hazardous locatioins to be

connected to receptacles in both hazardous

and non-hazardous areas

ɀ Portable devices for non-hazardous areas

equipped with APJ and NPJ Arktite plugs

cannot be used with CES and CESD

receptacles

Standard Materials:

ɀ Back boxes – Feraloy® iron alloy

ɀ Receptacle housings – 30 ampere –

copper-free aluminum; 60 ampere – Feraloy®

iron alloy

ɀ Plug bodies – copper-free aluminum

ɀ Insulation – Krydon® fiberglass – reinforced

polyester

ɀ Contacts – brass or hard-drawn copper

Standard Finishes:

ɀ Feraloy – electrogalvanized and aluminum

acrylic paint

ɀ Copper-free aluminum – natural

ɀ Krydon material – red

ɀ Brass and copper – natural

Electrical Rating Ranges:

ɀ 30 and 60 amperes

Certifications and

Compliances:

ɀ NEC/CEC:

CES – Class I, Division 1 and 2, Groups

C,D;

CESD – Class I, Division 1 and 2, Group D*

ɀ ANSI/UL Standard: 1010

ɀ CSA Standard C22.2 No. 182.1

* For U.S. CESD are also suitable for Class I, Group C when

used with immediately adjacent seals.

Options:

ɀ The following special options are available

from factory by adding suffix to Cat. No.:

Suffix to be

Added to

Cat. #

Description

Special polarity – for use where two or more receptacles of the same ampere

rating, style and number of poles are to be installed in the same area for

use on different voltages. Available as follows:

Receptacle interior rotated 221⁄2 degrees clockwise when viewed from face and plug

changed to match . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S4

US: 1-866-764-5454

STIBOINFO((CRH:66008com:2P:1011))

CH0 2 P - 1 1

CAN: 1-800-265-0502

Copyright© 2006 Cooper Crouse-Hinds

1011

Zoom: 100

2:

5:

SYS19: BASE2

PDFINFO

50:

95:

98:

100:

JOB: CRMAIN06-1012-1 Name: 2P-1012

DATE: JAN 19 2006

Time: 6:08:38 PM Operator: RB

CES and CESD Arktite Receptacles

2P

Circuit Breaking

Delayed Action, CPH Plugs

Dimensions

CES

Cat. #

CES2213

CES2214

CES4233

CES4234

COLOR: CMYK

TCP: 15001

Typedriver Name: TS name

CESD – Cl. I, Div. 1 and 2, Group D*

CES – Cl. I, Div. 1 and 2, Groups C,D

Explosionproof

Wet Locations

Factory Sealed

CESD

a

b

c

d

e

f

g

h

j

77⁄16

45⁄8

23⁄16

33⁄8

23⁄4

41⁄8

5⁄16

11⁄32

7⁄8

Cat. #

CESD2213

CESD2214

12

7

27⁄8

51⁄4

43⁄8

61⁄8

7⁄16

13⁄32

11⁄8

CESD4233

CESD4234

a

b

e

f

g

h

j

75⁄8

63⁄8

41⁄4

5

17⁄8

11⁄32

13⁄16

131⁄2

95⁄8

61⁄4

71⁄4

3

13⁄32

13⁄16

CPH

Cat. #

CPH7713

CPH7913

CPH7714

CPH7914

CPH7733

CPH7933

CPH7734

CPH7934

a

6

67⁄16

6

67⁄16

73⁄4

81⁄8

73⁄4

81⁄8

b

23⁄8

23⁄8

23⁄8

23⁄8

23⁄4

23⁄4

31⁄16

31⁄16

c

45⁄16

43⁄4

45⁄16

43⁄4

5

53⁄8

5

53⁄8

* In U.S. CESD are also suitable for Class I, Group C when

used with immediately adjacent seals.

1012

STIBOINFO((CRH:66008com:2P:1012))

CH0 2 P - 1 2

US: 1-866-764-5454

CAN: 1-800-265-0502

Copyright© 2006 Cooper Crouse-Hinds

csm no.: 100

Zoom: 100

2:

5:

SYS19: BASE2

PDFINFO

50:

95:

98:

100:

JOB: CRMAIN06-1013-5 Name: 2P-1013

DATE: JAN 19 2006

Time: 6:08:38 PM Operator: RB

CES and CESD Arktite® Receptacles

Delayed Action

Circuit Breaking

CPH Plugs

CES Receptacles with three hubs – one on

each side and one at top – and two pipe

plugs with CPH plug fully engaged

COLOR: CMYK

TCP: 15001

Typedriver Name: TS name

CESD – Cl. I, Div. 1 & 2, Group D*

CES – Cl. I, Div. 1 & 2, Groups C,D

Explosionproof

Wet Locations

Factory Sealed

csm no.: 100

2P

CESD Receptacles with vertical through

feed hubs and one pipe plug. Removable

threaded cover at top to facilitate pulling

wires

CES/CESD Receptacles

Hub

Size

3⁄4

Circuit

2-wire,

3-pole

3⁄4

3-wire,

4-pole

11⁄4

2-wire,

3-pole

11⁄4

3-wire,

4-pole

Phase

1

3

{

{

1

3

Max.

HP

1⁄2

11⁄2

Max.

Amps

7

30

Volts at

60 Cycles

AC

4801

120 to 240

1

3

7

30

4801

120 to 240

3

30

60

4801

120 to 240

5

30

60

4801

120 to 240

Max.

HP

1⁄2

11⁄2

Max.

Amps

7

30

Volts at

60 Cycles AC

4801

120 to 240

1

3

7

30

4801

120 to 240

4801

120 to 240

4801

120 to 240

CES

Cat. #

CESD

Cat. #

CES2213

CESD2213

CES2214

CESD2214

CES4233

CESD4233

CES4234

CESD4234

CPH Plugs with

mechanical cable grip and

Neoprene bushing

CPH Plugs

Circuit

2-wire,

3-pole

3-wire,

4-pole

Phases

1

3

{

{

2-wire,

3-pole

1

3

30

60

3-wire,

4-pole

3

5

30

60

CABLE DIA.

.375 to .875

CPH7713

CPH7714

.500 to .875

CPH7733

CPH7734

.875 to 1.375

CPH7913

CPH7914

CPH7933

CPH7934

* In U.S. CESD are also suitable for Class I, Group C when used with immediately

adjacent seals.

1 CSA certified units are rated at 600 volts.

US: 1-866-764-5454

STIBOINFO((CRH:66008com:2P:1013))

CH0 2 P - 1 3

CAN: 1-800-265-0502

Copyright© 2006 Cooper Crouse-Hinds

1013

Zoom: 100

HOW TUBING IS INSERTED IN THE PUMP

1. Turn power off. Open the cover plate and tube clamp. Remove existing tubing by manually

turning rollers while gently tugging on the tubing.

2. Clean any debris from pump race way and tube clamp with a clean rag or paper towel. A light

detergent spray can be used as well. Avoid the use of solvents such as acetone as they will have

an adverse effect on the paint.

3. Thread tubing back into pump. Start at the top of the pump and manually move the rollers so

that they start occluding the tubing. Care should be taken to avoid pinching fingers with rollers.

Align the tubing so that is in the center of the raceway.

4. Add lubricant. Close pump cover. Tighten tubing clamp to ensure the tubing is not fed through

the pump.

Pump Series

250

250

300

400

500

500

610,615,620, & 630

610,615,620, & 630

750

750

780

880

880

Tubing Size

.062” (1/16”) ID X .187” (3/16”) OD

.125” (1/8”) ID X .250” (1/4”) OD

.250” (1/4”) ID X .437” (7/16”) OD

.250” (1/4”) ID X .437” (7/16”) OD

.187” (3/16”) ID X .375” (3/8”) OD

.250” (1/4”) ID X .437” (7/16”) OD

.375” (3/8”) ID X .625” (5/8”) OD

.500” (1/2”) ID x .750” (3/4”) OD

.625” (5/8”) ID X .937” (15/16”) OD

.750” (3/4”) ID X 1.062” ( 1 1/16”) OD

.750” (3/4”) ID X 1.062” ( 1 1/16”) OD

.750” (3/4”) ID X 1.25” ( 1 1/4”) OD

1.00” (1.00”) X 1.50” ( 1 ½”) OD

Randolph Austin Company

Tubing Chemical Resistance Chart

Code indicates the percentage weight gain or loss after 24 hours immersion in the fluid.

(B) Best = 1-4%, (G) Good = 5-10%, (F) Fair = 11- 15%, (P) Poor = 16%+

The data contained herein are based on tests conducted on representative samples and are considered

accurate. The results should indicate liquids that could be used with the tubing. However no guarantee is

given or implied regarding the application of this data to the safe use of the tubing. It is suggested that the

purchaser conduct tests to determine if this material is suited to this application.

Aqueous Solutions

Water

Sodium Chloride (Saturated)

Aluminum Sulfate

Acids & Bases

Sulphuric Acid (66° Be)

Acetic Acid, Glacial

Hydrochloric Acid (30° Be)

Nitric Acid (40° Be)

Sodium Hydroxide (50% sol.)

Ammonia Hydroxide

Aliphatic Hydrocarbons

Diesel Fuel

Naptha

Mineral Oil

Aromatic Hydrocarbons

Toluene

Xylene

Chlorinated Solvents

Trichloroethylene

Carbon Tetrachloride

Methylene Chloride

Ketones

Acetone

Methyl Ethyl Ketone (MEK)

Esters

Amyl Acetate

Butyl Acetate

Ethyl Acetate

Alcohol

Butyl Alcohol

Isoproply Alcohol

Methyl Alcohol

Ethyl Alcohol (90%)

Glycol

Ethylene Glycol

Glycerine

Vegetable Oil

Safflower Oil

ED-Plex

Povinal

B

B

B

B

B

B

P

F

P

B

B

B

B

B

B

B

B

B

B

B

B

B

P

B

B

B

B

P

P

P

P

P

P

G

P

P

P

B

B

B

F

G

G

B

B

P

P

P

P

P

P

B

B

B

G

G

G

G

G

B

P

P

P

P

B

B

P

P

P

G

P

P

P

P

P

P

B

B

B

P

P

P

P

P

P

B

G

B

G

F

F

P

P

P

P

P

P

P

B

B

F

F

F

F

P

P

P

P

P

P

G

G

B

B

G

B

B

B

P

F

F

G

G

B

G

G

B

B

B

G

B

B

B

B

G

G

B

B

B

B

B

B

B

B

G

Cilran

Prothane II

Vytex

8-Mar-01

(800)-531-5263 - (512)-282-1590 – Fax (512)-280-0678

General Characteristics of Randolph Austin Tubing Materials

Cilran is made from a thermoplastic elastomer that possesses exceptional chemical resistance

to acids and bases. Cilran has low gas permeability; good flex fatigue resistance and meets

USP Class VI specifications. Ideal for use in many laboratory applications, it may be used in

place of silicone for some applications. Cilran is translucent white in color.

Povinal is a polyvinyl alcohol based tubing which is excellent for use in applications with

aliphatic, aromatic and chlorinated hydrocarbon solvents. Povinal has good flex fatigue

resistance and is suitable for many industrial applications. It may be used as a substitute for

fluroelastomer polymers in some applications. Not recommended for use with water or solutions

containing concentrations of water. Pump tubing is teal in color. Transfer tubing is amber.

Vytex is a clear flexible polyvinyl tubing ideal for general-purpose usage in applications with

dilute aqueous solutions (both acids and alkali's), and for food and beverage usage. Strong acid

solutions may be used with Vytex for short intervals, but should be flushed with water after

use. The smooth surface allows for easy flushing and cleanup for food and beverage applications.

Vytex is a durable, high flex tubing with a Shore "A" durometer of 60 allowing a long life

expectancy for continuous flexing where peristaltic pumps are used.

Prothane II is transparent, aqua blue, polyester polyurethane tubing that exhibits excellent

abrasion resistance, has good low temperature properties and is resistant to ozone and oxidation.

Prothane II exhibits an excellent resilience to continuous flexing and impacting experienced in

peristaltic pumps. Along with these exceptional features Prothane II exhibits good hydrolic

stability, good oil and fuel resistance, and high tensile and tear strength.

Prothane II is

resistant to diesel fuel, kerosene, motor oil, mild solvents, aromatic hydrocarbons, gasoline, and

concentrated acid and alkaline solutions.

E-D Plex is multi-purpose tubing that is ideally suited for applications that range from

transferring paint, ink, acids, and bases. Some oil and hydrocarbons will work with E-D Plex,

but should be tested before use. Combining the environmental resistance of EPDM with the

chemical resistance of chloropreme, E-D Plex possesses similar elastomeric performance

found in more expensive vulcanized rubber, while still maintaining high flex fatigue resistance.

E-D Plex has been proven very successful in peristaltic pump applications where continuous

flexing is required.

Tel 512-282-1590 - Fax 512-280-0678

18 October 2005