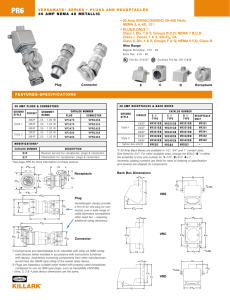

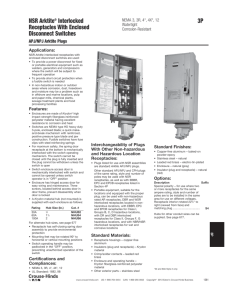

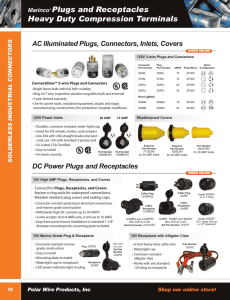

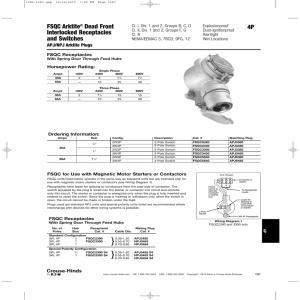

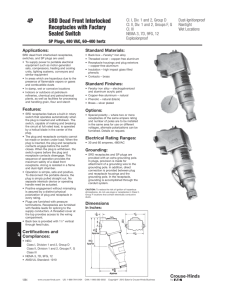

Arktite® Plugs and Receptacles Industrial Heavy Duty Hazardous 2P

advertisement