CASE STUDY:

BRADY ToughWash™

HELPS COMPANIES TACKLE

CRITICAL BUSINESS ISSUES

bradyID.com.au/toughwash

FOOD SAFETY The #1 concern for

all food processors.

CRITICAL BUSINESS

ISSUES

■■

Food Safety - Regulation

■■

Food Safety - Sanitation

■■

Workplace Safety

■■

CI - Waste Reduction

■■

CI - Worker Education

FOOD SAFETY

STANDARDS

Safe Food Australia is the guide

to the mandatory standards. The

following standards are mandatory

for all food businesses.

■■

3.2.2 Food Safety Practices

and General Requirements

■■

3.2.3 Food Premises and

Equipment

Source: Australian Government Department of Industry

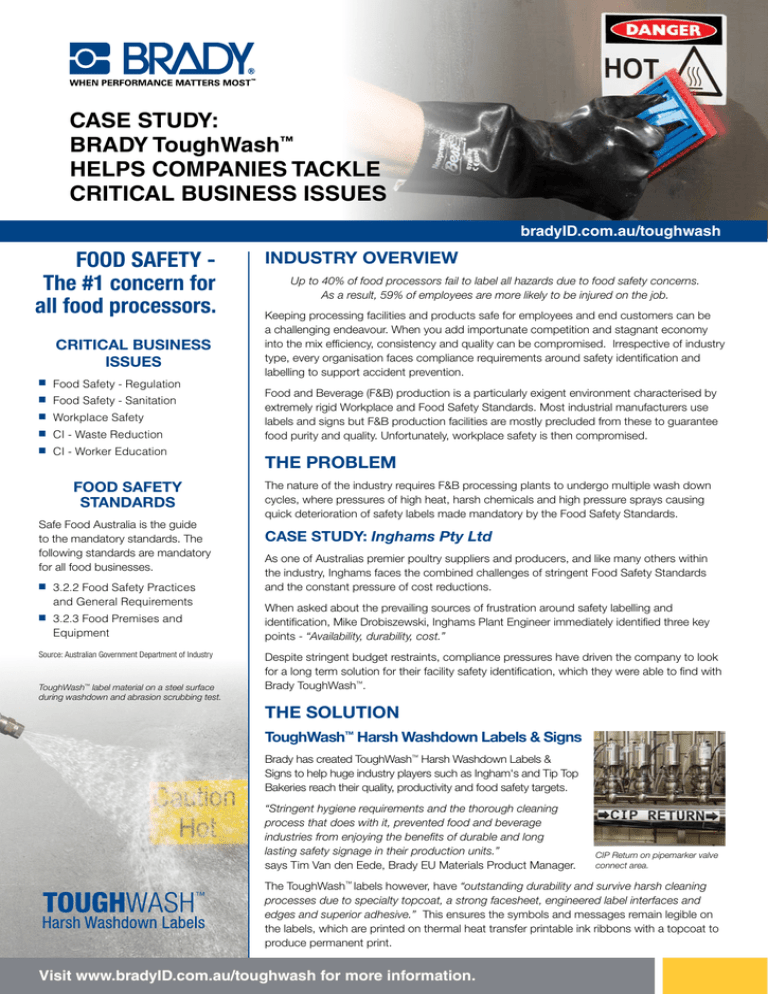

ToughWash™ label material on a steel surface

during washdown and abrasion scrubbing test.

INDUSTRY OVERVIEW

Up to 40% of food processors fail to label all hazards due to food safety concerns.

As a result, 59% of employees are more likely to be injured on the job.

Keeping processing facilities and products safe for employees and end customers can be

a challenging endeavour. When you add importunate competition and stagnant economy

into the mix efficiency, consistency and quality can be compromised. Irrespective of industry

type, every organisation faces compliance requirements around safety identification and

labelling to support accident prevention.

Food and Beverage (F&B) production is a particularly exigent environment characterised by

extremely rigid Workplace and Food Safety Standards. Most industrial manufacturers use

labels and signs but F&B production facilities are mostly precluded from these to guarantee

food purity and quality. Unfortunately, workplace safety is then compromised.

THE PROBLEM

The nature of the industry requires F&B processing plants to undergo multiple wash down

cycles, where pressures of high heat, harsh chemicals and high pressure sprays causing

quick deterioration of safety labels made mandatory by the Food Safety Standards.

CASE STUDY: Inghams Pty Ltd

As one of Australias premier poultry suppliers and producers, and like many others within

the industry, Inghams faces the combined challenges of stringent Food Safety Standards

and the constant pressure of cost reductions.

When asked about the prevailing sources of frustration around safety labelling and

identification, Mike Drobiszewski, Inghams Plant Engineer immediately identified three key

points - “Availability, durability, cost.”

Despite stringent budget restraints, compliance pressures have driven the company to look

for a long term solution for their facility safety identification, which they were able to find with

Brady ToughWash™.

THE SOLUTION

ToughWash™ Harsh Washdown Labels & Signs

Brady has created ToughWash™ Harsh Washdown Labels &

Signs to help huge industry players such as Ingham's and Tip Top

Bakeries reach their quality, productivity and food safety targets.

“Stringent hygiene requirements and the thorough cleaning

process that does with it, prevented food and beverage

industries from enjoying the benefits of durable and long

lasting safety signage in their production units.”

says Tim Van den Eede, Brady EU Materials Product Manager.

CIP Return on pipemarker valve

connect area.

The ToughWash™ labels however, have “outstanding durability and survive harsh cleaning

processes due to specialty topcoat, a strong facesheet, engineered label interfaces and

edges and superior adhesive.” This ensures the symbols and messages remain legible on

the labels, which are printed on thermal heat transfer printable ink ribbons with a topcoat to

produce permanent print.

Visit www.bradyID.com.au/toughwash for more information.

ToughWash™ Metal Detectable Signs & Labels

“As an extra safeguard, Bradys Toughwash™ label also comes in a metal

detectable version that can be recognized by standard metal detection equipment

in the F&B industry.” says Mr. Van den Eede. The product uses steel instead of

aluminium and in-line detection equipment which will recognise the label without

fault due to steel's stronger alternating current field generation.

CASE STUDY: Tip Top Bakeries

Tip Top Bakeries, part of George Weston Foods and one of Australia's largest

bakeries with brand names such as Tip Top, Weston Milling, Don KRC and

Jasol have recently purchased a Brady BMP71 Printer with Toughwash™ metal

detectable stock to re-label their Dandenong production facility. During the initial

implementation phase, after weeks of testing the labels under their standard

washdown conditions and metal detectors, Tip Top Bakeries were very impressed

with the ToughWash™ metal detectable feature.

When asked what prompted their decision to choose Brady ToughWash™, over

other labelling materials currently saturating the market, both Tip Top Bakeries

and Inghams found the washdown resistant and metal detectable features equally

important, adding value to overall convenience and effectiveness.

Metalized ToughWash™ material going through a F&B metal

detector.

BRADY PRINTERS

RESULTS

Brady ToughWash™ materials are available in a variety of formats that can be

used with Brady's thermal transfer printers

■■

BMP™ 71 Portable Printer

■■

BBP® 31 Sign and Label Printer

■■

BBP® 33 Sign and Label Printer

As Brady ToughWash™ material was designed

to meet Food Safety Regulatory requirements

both of Inghams and Tip Top Bakeries made

significant strides towards meeting compliance

criteria and are expecting to see benefits in

several areas:

■■

GlobalMark®2 Industrial Label Maker

■■

Improved effectiveness in meeting Food

Safety Standards

■■

Increased quality and productivity

■■

Waste reduction and improved yield

■■

Reduced re-work and enhanced

employee training

■■

Decreased long-term consumption of

safety identification and labelling solutions

According to Mr. Drobiszewski, typically companies purchase pre-made signs

as required. However, to improve availability and decrease costs a Brady

printer is a must - BBP31 and BBP33 printers being the preferred options for

Inghams facilities.

“The purpose of the Brady printer in long term will be customising labels for

use in factory. It will supplement the purchase of standard signs and/or labels.”

says Mr. Drobiszewski.

MORE TO COME!

Since implementation, over the last few months

Tip Top Bakeries have managed to successfully

use Brady ToughWash™ materials to re-label

their Dandelong production facility. Stay tuned

for more information as we follow up with the

company for a more comprehensive overview

of their experience.

Hoses connected to switchboard in F&B facility.

Brady Australia Pty Ltd

Ph: 1800 620 816

bradyID.com.au

© 2014 Brady Worldwide Inc. ALL RIGHTS RESERVED

Visit www.bradyID.com.au/toughwash to view an online demo video.