Testing Connections - Stockers Starters!

advertisement

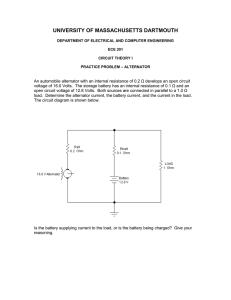

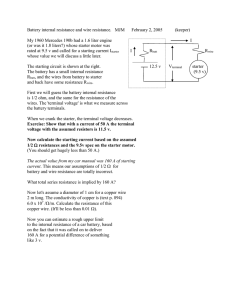

Testing Connections Simple Things Can Cause Big Problems Some of the most common problems in vehicles today are poor electrical connections. Poor connections can be caused by corrosion so slight that it cannot be seen (even by a well-trained eye) or a connection that has become loose from age and vibration. Among the symptoms are: Low or even no charging Dim or erratic lighting Erratic operation of gauges System failure indications on the dash or in the diagnostic codes Voltage regulator functioning erratically Add-on devices operating intermittently or improperly o St c ar ke te r' rs s These problems can easily be found by using a simple test for voltage drop. All you need is a digital voltmeter, and this test will help you find the corroded or loose connections. Every electrical connection drops a small amount of voltage in its normal operation, but as the drop in voltage increases there is an increasingly greater risk of a serious problem. St The following will allow you to solve electrical system problems, by locating and repairing the poor connections that can prevent normal operation and potentially cause damage to vehicle electronics. Rusted Connections Temporary Fix 1 Voltage-drop Testing Common problems can be detected: Every now and then, you will encounter an engine that cranks slowly, if at all, or an alternator that will not keep the battery charged. Yet, when the individual components are tested, they all check out fine. What’s going on? An often-overlooked problem is high-resistance in the high-amperage circuits that are part of the starting and charging systems. o St c ar ke te r' rs s High-resistance in a circuit is usually caused by a poor connection where wires or cables attach. Many times you can spot the problem just by using your eyes. We have all seen battery cable connections that are sprouting corrosion, but sometimes corrosion can form inside a connection that looks like new on the outside. A voltage-drop test will quickly find these hidden problems. Undersized wiring is another common cause of high-resistance. If the wiring is not properly sized to carry the load, it will be a bottleneck in the circuit and keep the required amperage from flowing. One of the most common causes of 6-volt vehicles not starting is that the original 6-volt battery cables have been replaced with lower-capacity 12-volt cables. Always check to see if additional accessories have been added that may require upgraded wiring. Voltage-drop testing will find all of the above problems, and more. It’s fast, it’s easy and it does not require any disassembly. How it works: Voltage-drop testing can be done only when current is flowing in the circuit. This means that the starter must be cranking to test the starting circuit, and the alternator must be producing output to test the charging circuit. More detailed instructions are provided in the Battery System Testing, Starting System Testing and Charging System Testing sections. (See Index) The important thing to remember is - voltage-drop tests will not return valid results unless the current flowing through the circuit is near the maximum amperage required for that circuit. To perform the test, you must use a digital voltmeter. Many voltmeters are auto-ranging, but some require you to manually select the scale. If you can manually set your voltmeter, select the range closest to 2 volts. St Caution: Performing the tests in the following sections requires working close to hot and moving engine parts. We strongly recommend using test leads with alligator clips to hold the leads in place and allow you to keep your hands safely out of the engine compartment. The illustration to the right shows a typical voltagedrop test. In this case, the alternator output circuit is being tested. Place the meter’s test leads on either end of the circuit that you are testing. While the current is flowing, note the reading on the meter. This is the total voltage drop across the two points that you are testing. You want a reading as close to zero as possible. The higher the reading, the more resistance is in the circuit. The maximum voltage drop varies, depending on the type of circuit being tested. The maximum allowable readings are listed in the charts in the following sections. 2 Voltage-drop Test Point List Refer to diagram on following page for test lead locations. How to Load Circuit Readings A and B 12.66v Component or leads being tested Battery voltage with engine off o St c ar ke te r' rs s No load required Test-lead Positions A and B 13.6v to 15.1v Charging voltage no load A and B 13.6v to 15.1v Charging voltage under load Use starter motor to crank engine B and D 0.1v max Drop between battery post and cable end Use starter motor to crank engine A and E 0.1v max Drop between negative battery post and chassis Use starter motor to crank engine A and F 0.1v max Drop between negative battery post and engine Use starter motor to crank engine B and J 0.2v max Drop between positive battery post and battery stud on solenoid Use starter motor to crank engine A and L 0.1v max Drop between negative battery post and starter ground Use starter motor to crank engine A and K 10v min Voltage at switch terminal while cranking Use starter motor to crank engine A and I 9.6v to 10.5v Use starter motor to crank engine J and I 0.3v max Voltage drop across solenoid while cranking Engine running Headlights on Heater fan on high Engine RPM at 2000 B and G 0.3v max Drop between positive battery post and alternator Engine running Headlights on Heater fan on high Engine RPM at 2000 A and H 0.2v max Voltage drop on ground side of alternator while charging No load required Engine running St Headlights on Heater fan on high Engine RPM at 2000 Voltage at starter while cranking Take care when using jumper wires. Avoid causing accidental arcs and sparks because they can damage onboard electronics. 3 St o St c ar ke te r' rs s Voltage-drop Test Point List 4 Never disconnect the battery while the engine is running. Alternators are designed to maintain batteries, not recharge them from dead. Keep hands and test-leads away from belts, fans and other moving parts. Be sure belts are not worn and are adjusted properly. Start all tests with a fully charged battery. Clean and inspect all wires and connections. Be sure that all grounding surfaces are cleaned to bare metal. Verify that alternator amperage is adequate for the vehicle loads. Be sure all mounting fasteners are tight. Do not over tighten alternator or battery cable connections. Ensure automatic tensioners operate properly. The tension spring should not bind, and the pulley bearing should operate smoothly without excessive free play. Ensure the transmission is in park or neutral during all tests, and the parking brake is set. Disconnect the battery before removing the starter or alternator. When removing the alternator, always disconnect the voltage-regulator plug first and reconnect it last. Always disconnect battery negative before battery positive and install in reverse order. Never use a battery charger as a power supply to test a starter motor. When replacing a starter motor, always inspect the ring gear for worn or damaged teeth. Always clean the starter mounting-surface to ensure the starter mounts properly. Always ensure all starter or alternator mounting bolts are properly torqued. Clean and inspect all connections to the starter, solenoid, alternator and battery when removing and replacing cables. Use dielectric gel in all plug connections to avoid future corrosion and water penetration. Be sure to replace all original brackets, air ducts, etc to ensure proper support and cooling. Some applications require the electronic control module codes to be cleared and reset before a replacement alternator will operate properly. If the proper scan-tool is not available, this will require a trip to either the dealer or a well-equipped electrical shop. Always test and charge batteries in a well ventilated area. The gasses emitted by batteries are highly explosive. Always wear eye protection when working with a battery, and avoid getting the electrolyte on skin and clothing. The electrolyte is sulfuric acid and is highly corrosive. When working with active circuits, be careful to avoid accidentally grounding circuits or contacting wires and terminals with rings, watches or other jewelry. For example, contact from the battery terminal to a wrench and a ring on the hand could cause a short if the ring came into contact with the frame or fender. o St c ar ke te r' rs s Testing Safety and Warnings St Special Note The electronic control module may need to be reset using a scan-tool if the “Check Engine” light remains on after any repair. Be sure to supply the Vehicle Identification Number (VIN) and Accessory Number before replacing a starter or alternator.