MIDLAND COLLEGE SYLLABUS DEMR 1305 ELECTRICAL

advertisement

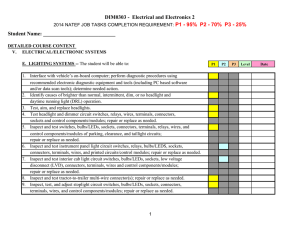

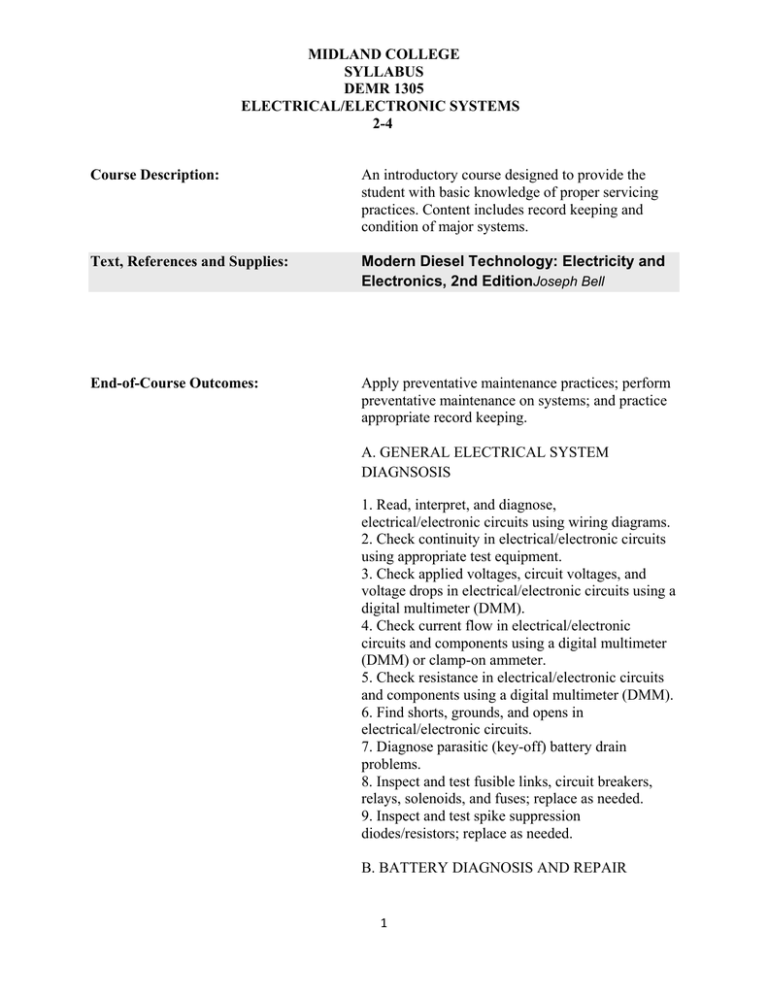

MIDLAND COLLEGE SYLLABUS DEMR 1305 ELECTRICAL/ELECTRONIC SYSTEMS 2-4 Course Description: An introductory course designed to provide the student with basic knowledge of proper servicing practices. Content includes record keeping and condition of major systems. Text, References and Supplies: Modern Diesel Technology: Electricity and Electronics, 2nd EditionJoseph Bell End-of-Course Outcomes: Apply preventative maintenance practices; perform preventative maintenance on systems; and practice appropriate record keeping. A. GENERAL ELECTRICAL SYSTEM DIAGNSOSIS 1. Read, interpret, and diagnose, electrical/electronic circuits using wiring diagrams. 2. Check continuity in electrical/electronic circuits using appropriate test equipment. 3. Check applied voltages, circuit voltages, and voltage drops in electrical/electronic circuits using a digital multimeter (DMM). 4. Check current flow in electrical/electronic circuits and components using a digital multimeter (DMM) or clamp-on ammeter. 5. Check resistance in electrical/electronic circuits and components using a digital multimeter (DMM). 6. Find shorts, grounds, and opens in electrical/electronic circuits. 7. Diagnose parasitic (key-off) battery drain problems. 8. Inspect and test fusible links, circuit breakers, relays, solenoids, and fuses; replace as needed. 9. Inspect and test spike suppression diodes/resistors; replace as needed. B. BATTERY DIAGNOSIS AND REPAIR 1 MIDLAND COLLEGE SYLLABUS DEMR 1305 ELECTRICAL/ELECTRONIC SYSTEMS 2-4 1. Perform battery load test; determine needed action. 2. Determine battery state of charge using an open circuit voltage test. 3. Inspect, clean, and service battery; replace as needed. 4. Inspect and clean battery boxes, mounts, and hold downs; repair or replace as needed. 5. Charge battery using slow or fast charge method as appropriate. 6. Inspect, test, and clean battery cables and connectors; repair or replace as needed. 7. Jump start a vehicle using jumper cables and a booster battery or auxiliary power supply using proper safety procedures. C. STARTING SYSTEM DIAGNOSIS AND REPAIR 1. Perform starter current draw test; determine needed action. 2. Perform starter circuit cranking voltage and voltage drop tests; determine needed action. 3. Inspect, test, and replace components (key switch, push button and/or magnetic switch) and wires in the starter control circuit. 4. Inspect, test, and replace starter relays and solenoids/switches. 5. Remove and replace starter; inspect flywheel ring gear or flex plate. D. CHARGING SYSTEM DIAGNOSIS AND REPAIR 1. Diagnose instrument panel mounted volt meters and/or indicator lamps that show a no charge, low charge, or overcharge condition; determine needed action. 2. Diagnose the charge of a no charge, low charge, or over-charge condition; determine needed action. 2 MIDLAND COLLEGE SYLLABUS DEMR 1305 ELECTRICAL/ELECTRONIC SYSTEMS 2-4 3. Inspect, test, and replace alternator drive belts, pulleys, fans, tensioners, and mounting brackets. 4. Perform charging system voltage and amperage output test; determine needed action. 5. Perform charging circuit voltage drop tests; determine needed action. 6. Remove and replace alternator. 7. Inspect, repair, or replace connectors and wires in the charging circuit. 8. Diagnose AC voltage leakage (failed rectifier) at alternator output; determine needed action. E. LIGHTING SYSTEMS DIAGNOSIS AND REPAIR 1. HEADLIGHTS, DAYTIME RUNNING LIGHTS, PARKING, CLEARANCE, TAIL, CAB AND INSTRUMENT PANEL LIGHTS 1. Diagnose the cause of brighter than normal, intermittent, dim, or no headlight and daytime running light (DRL) operation. 2. Test, aim, and replace headlights. 3. Test headlight and dimmer circuit switches, relays, wires, terminals, connectors, sockets and control components; repair or replace as needed. 4. Inspect and test switches, bulbs/LEDs, sockets, connectors, terminals, relays and wires of parking, clearance, and taillight circuits; repair or replace as needed. 5. Inspect and test instrument panel light circuit switches, relays, bulbs, sockets, connectors, terminals, wires, and printed circuits/control modules; repair or replace as needed. 6. Inspect and test interior cab light circuit switches, bulbs, sockets, connectors, terminals, and wires; repair or replace as needed. 7. Inspect and test tractor-to-trailer multi-wire connector(s); repair or replace as needed. 2. STOPLIGHTS, TURN SIGNALS, HAZARD LIGHTS, AND BACK-UP LIGHTS 3 MIDLAND COLLEGE SYLLABUS DEMR 1305 ELECTRICAL/ELECTRONIC SYSTEMS 2-4 1. Inspect, test, and adjust stoplight circuit switches, bulbs/LEDs, sockets, connectors, terminals and wires; repair or replace as needed. 2. Inspect and test turn signal and hazard circuit flasher(s), switches, relays, bulbs/LEDs, sockets, connectors, terminals, and wires; repair or replace as needed. 3. Inspect, test, and adjust backup lights and warning device circuit switches, bulbs/LEDs, sockets, horns, buzzers, connectors, terminals, and wires; repair or replace as needed. 4. Inspect and test gauge circuit sending units, gauges, connectors, terminals, and wires; repair or replace as needed. 5. Inspect and test warning devices (lights and audible) circuit sending units, bulbs/LEDs, sockets, connectors, wires, and printed circuits/control modules; repair or replace as needed. 6. Inspect, test, replace, and calibrate (if applicable) electronic speedometer, odometer, and tachometer systems. G. RELATED ELECTRICAL SYSTEMS 1. Diagnose the cause of constant, intermittent, or no horn operation; determine needed action. 2. Inspect and test horn circuit relays, horns, switches, connectors, and wires; repair or replace as needed. 3. Diagnose the cause of constant, intermittent, or no wiperoperation; diagnose the cause of wiper speed control and/or park problems; determine needed action. 4. Inspect and test wiper motor, resistors, park switch, relays, switches, connectors, and wires; repair or replaceas needed. 5. Inspect wiper motor transmission linkage, arms, and blades; adjust or replace as needed. 6. Inspect and test windshield washer motor or pump/relay assembly, switches, connectors, terminals, and wires; repair or replace as needed. 4 MIDLAND COLLEGE SYLLABUS DEMR 1305 ELECTRICAL/ELECTRONIC SYSTEMS 2-4 7. Inspect and test sideview mirror motors, heater circuit grids, relays, switches, connectors, terminals, and wires; repair or replace as needed. 8. Inspect and test heater and A/C electrical components including: A/C clutches, motors, resistors, relays, switches, connectors, terminals, and wires; repair or replace as needed. 9. Inspect and test auxiliary power outlet, integral fuse, connectors, terminals, and wires; repair or replace as needed. 10. Diagnose the cause of slow, intermittent, or no power side window operation; determine needed action. 11. Inspect and test motors, switches, relays, connectors, terminals, and wires of power side window circuits; repair or replace as needed. 12. Inspect block heaters; determine needed repairs. 13. Inspect and test cruise control electrical components; repair or replace as needed. 14. Inspect and test engine cooling fan electrical control components; repair or replace as needed. Student Contributions and Class Policies: Evaluation of Students: 1. Student/ Participant must sign, date and turn in (as intention of compliance a copy of DIESEL TECHNOLGY POLICIES AND PROCEDURES. 2. Student/ Participant must furnish a set of approved safety eye glasses. 3. Student/Participant must understand class attendance is critical; therefore, three consecutive absences or five total absences may be considered justification for failure or dismissal from class. 4. Punctuality, being prepared for class, being alert, participating pro-actively and exhibiting a respectful and appropriate attitude will be required. Chapter Questions Participation Lab Tasks & Final Exam Total 5 40% 10% 50% 100% MIDLAND COLLEGE SYLLABUS DEMR 1305 ELECTRICAL/ELECTRONIC SYSTEMS 2-4 90 and above 80-89 70-79 60-69 59 and below Course Schedule: SCANS Information: A B C D F This class meets for 2 lecture hours and 4 lab hours per week. SCANS skills are taught and/or reinforced in automotive courses. The student must locate, read,interpret and understand instruction information and direct materials. The participant must communicate thoughts, ideas and information through verbal and written mediums. Practical arithmetic and mathematics will apply continually throughout automotive technology training. Listening, interpreting, and responding to verbal communications and instructions as well as speaking in response to questioning will be a daily Involvement. Thinking, reasoning, visualizing and problem solving are required assets to the automotive technician. The student/participant must display responsibility, self-management and honesty. Instructor Information: Pete Avalos E-Mail: pavalos@midland.edu (432) 620-0246 (432)681-6344 Fax (432) 620-0297 James McCutcheon E-Mail: jmccutcheon@midland.edu (432) 620-0246 Fax (432) 620-0297 Administrative Information: Curt Pervier, Division Chair Applied Technology Lisa Tanner, Division Secretary 6 MIDLAND COLLEGE SYLLABUS DEMR 1305 ELECTRICAL/ELECTRONIC SYSTEMS 2-4 Applied Technology (432) 685-4676 Fax: (432) 685-6472 Helen Arrieta, Division Clerk Applied Technology (432) 685-4664 Fax: (432) 685-6472 Students should feel free to contact the instructor at any time. Appointments are encouraged for advising and planning the most appropriate or beneficial course work. Students with Disabilities Midland College provides services for students with disabilities through Student Services. In order to receive accommodations, students must place documentation on file with the Counselor/Disability Specialist. Students with disabilities should notify Midland College prior to the beginning of each semester. Student Services will provide each student with a letter outlining any reasonable accommodations. The student must present the letter to the instructor at the beginning of the semester. Federal Statement Students MUST actively participate by completing an academic assignment required by the instructor by the official census date. Students who do not actively participate in an academically‐related activity will be reported as never attended and dropped from the course. 7