Air conditioners are estimated to be by far the largest consumer of

advertisement

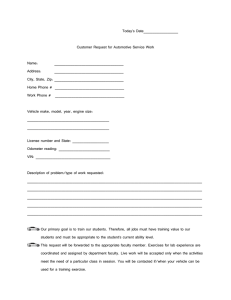

1 Presented at the 2008 ACEEE Summer Study on Energy Efficiency in Buildings, Pacific Grove CA. Appliance Energy Use in America’s Second Home – The Automobile Valerie M. Thomas, Georgia Institute of Technology Alan K. Meier, Thomas P. Wenzel, Lawrence Berkeley National Laboratory Siva G. Gunda, University of California, Davis ABSTRACT The average American spends nearly 500 hours per year in motor vehicles. This exceeds the time they spend in all buildings except for their primary residence. The fuel consumption of motor vehicles while moving is reasonably well captured in the fuel economy tests; however, most of the “domestic” appliances—the lights, heater, air conditioning, entertainment, etc. - are switched off during the test and are poorly documented. The vehicle versions of some appliances – notably the air conditioning and audio equipment—are comparable in size and usage of their counterparts in stationary homes. Building-like energy use in vehicles parallels that found in homes, but with some notable differences. The electricity use from appliances such as DVD players, laptops, and vehicle refrigerators remains modest, although stand-by power use is a growing issue. Vehicle air conditioners are much less efficient than residential air conditioners, with the result that vehicle air conditioners in the U.S. consume a total of about 0.9 Quads, comparable to the 2.3 Quads used by air conditioners in residences. Vehicle heating, in contrast, is a model of efficiency, running as a combined-heat and power system using waste heat from the motor. The efficiency and cost of vehicle-generated power depends on the appliance and how and when it is used, but even in the best case the efficiency is lower and the cost is higher than for typical residential electricity services. Generation efficiency ranges from 10 to 25%, and for gasoline costs of $3.20 per gallon, the cost of power ranges from 37¢/kWh to $1/kWh. Vehicles as a Type of Building Americans spend an increasing number of hours each day in automobiles. To be sure, the principal reason is to move from one location to another but the driver and other occupants also accomplish other tasks while in their vehicles. Many of these activities are familiar to buildings researchers: drink, eat, listen to audio entertainment, shave, communicate with friends on the telephone, and watch videos. All of these activities traditionally occurred inside buildings and have either shifted or expanded to mobile use. Furthermore, appliances that once resided solely in buildings are now becoming common in vehicles or being moved from one to the other. These trends suggest that the automobile has become an extension of the residence and office. It is therefore important to understand the energy implications of the 2 buildings-like activities within cars and their relationship to other buildings. Are there energy-saving opportunities in motor vehicles related to these new loads? Alternatively, can energy-saving strategies in vehicles be transferred to “stationary” buildings? The goal of this paper is introduce and describe a new building type and describe buildingsrelated energy use in motor vehicles. This paper is limited to an analysis of building-like energy use in light-duty vehicles. However, a similar situation exists with heavy-duty long-haul tractor-trailer trucks. Truck drivers often pull off the side of the road or into truck stops to sleep after their driving shift, and many run their engines through the night to provide heating, cooling, and electricity for other uses such as lighting or entertainment. This practice has lead EPA and several states to provide incentives for truck stops to provide electricity “hookups” to power these end-uses when the truck is not moving. Vehicle Occupancy Levels Estimates for the amount of time the average person spends in a vehicle range from 41 (Fischer and Sand 1997) to 95 minutes (Klepeis et al. 2001) per day. All respondents to the 2001 National Household Travel Survey (NHTS) spent an average of 66 minutes per day in a vehicle, whether it was moving or not. The national Human Activity Pattern Survey (HAPS) indicates that the average American spent 79 minutes per day in an enclosed vehicle in 1992-94. Both of these estimates are per survey respondent, including people that were not in a vehicle at all during the day in question (Klepeis et al. 2001). The HAPS also recorded what other environments respondents occupied during the survey days. Table 1 summarizes the results of the HAPS, for all respondents and for those respondents that actually occupied the environment in question (called “doers”). For example, the average time all respondents occupied a vehicle was 79 minutes per day (481 hours per year). However, only 83% of respondents actually occupied a vehicle during the survey; this subset of respondents was in a vehicle an average of 95 minutes per day (578 hours per year). (The average American spent only 78 minutes per day in an office/factory, because only 21% of those surveyed visited an office/factory during the survey; those that did visit an office/factory spent an average of 388 minutes (6.5 hours) per day there.) Leech et al. (2002) report that Americans spend 5.7% of their time in vehicles and 3.9% in public schools. Table 1. Estimates of Time Spent in Specific Environments Mean time (min/day) overall Percent of average day spent in each environment overall Residence 990 69% Mean time (min/day) for “doers” 996 Office/factory 78 5% 388 Bar/restaurant 27 2% 112 Other indoor 158 11% 267 Enclosed vehicle 79 5% 95 Outdoors 109 8% 184 1,441 100% N/A Environment Total 3 Source: Klepeis et al. 2001. From Table 1, the total number of hours spent in vehicles can be calculated as either 79 minutes/day times total population (296.4 million in 2005), or 95 minutes/day times vehicle population (238.7 million light-duty vehicles in 2005). These figures give a range of 138 to 142 billion total hours spent in vehicles in 2005; we use an estimate of 140 billion person-hours per year. According to national transportation surveys, the amount of time the average American spends traveling each day has increased nearly 2 minutes every year, from 46 minutes a day in the 1983 survey to 79 minutes a day in the 2001 survey (Polzin et al. 2004). What Buildings-Related Energy Consumption Occurs in Vehicles? The car has a building envelope, with walls, windows—lots of them— doors, and air infiltration. These elements have R-values, transparencies, and air leakage which, if not controlled will create thermally uncomfortable conditions. Like a building, a car is heated, cooled, and ventilated. The modern car offers its occupants illumination, a range of consumer electronics, and food-related services. 1 These are all familiar end uses in buildings. The energy devoted to propelling the car is not considered buildings-related (and still represents the overwhelming majority of energy consumption of vehicles). It is relatively easy to distinguish between the motion-related and buildings-related. In our compilation, only headlights could be reasonably assigned to either category. 2 There are also increasing electric loads from vehicle-related equipment including anti-theft equipment, tele de-lock, and electronic engine controllers which are kept in wake mode for some time after stand-still to provide quick re-start (Meissner & Richter 2003). Non-Electrical Building Services in Vehicles: Heating and Cooling Automotive heating systems use waste heat from the engine and, except for the fans, are not electrically powered. Cooling systems in light-duty vehicles run about 80% on shaft power and 20% on electricity produced from the alternator. Air conditioning in light-duty vehicles consumes roughly 5.5% of all vehicle fuel (Rugh et al. 2007), corresponding to 0.94 Quads of primary energy per year (Davis & Diegel 2007). For comparison, air conditioning in the residential sector is responsible for 2.3 Quads (DOE 2006). Air conditioners in cars have unusual design constraints. They must be sized in order to quickly lower the temperature of a dangerously hot (over 150 degrees F) vehicle that has sat in the sun for a long period down to a comfortable temperature (Rugh et al. 2007). The cooling capacity is typically around 6 kW (20 kBtu/hour), which is similar to that needed to cool a house. Thus, for most situations, the air conditioner is drastically 1 These services are provided by both combustion and electrical devices though, like buildings, a continuing trend towards electrification is occurring. Renewable energy technologies—in the form of small PV arrays—are now appearing. 2 We assigned headlights to buildings because they represent a form of “outside lighting”, which is typically included in residential energy use. Turn signals, on the other hand, are a mobile use. 4 oversized. Conventional auto air conditioners cannot modulate output so the temperature is adjusted by mixing heated air from the engine, similar to terminal re-heat in commercial building HVAC systems. The typical system COP for an auto air conditioner is about 1.6 (EER = 5.5) (Gado 2006) but test conditions differ from residential units so these values are only indicative (Hendricks 2003). Strategies to reduce vehicle air conditioning fuel use include variable output compressors, reduced thermal loads using reflective paints and glazings, better controls, and consumer information (Rugh, Hovland, & Andersen 2004). There is also a trend towards electrically-powered air conditioners, especially in hybrid vehicles (Meissner & Richter 2005). This approach allows variable output and operation while the engine is switched off. Rooftop photovoltaic collectors have also been investigated as a means of cooling vehicle cabins while the car is parked (John Rugh et al. 2007). NREL has estimated that, on average, vehicle air conditioning is switched on 34% of the time, ranging from 6% of the time in Alaska to 69% of the time in Hawaii (NESCCAF 2004; Johnson 2002). A survey of 10 instrumented vehicles in Southern California found that vehicle air conditioners were used in 69% of trips, and that, when air conditioners were switched on, the compressor was on an average of 64% of the duration of the trip (Levine et al. 2000). A transition toward electric vehicles will increase the reliance of vehicles on electricity for heating and cooling. Electrically Powered Building-Like Services in Vehicles Lighting Lighting energy consists of interior and exterior lighting. We treat headlights as part of buildings-related energy consumption. The IEA estimated the electricity consumed by each external light function based on the power and number of hours of operations (IEA 2006). The data are summarized in Table 2. In 1995, the typical car had four interior lights. In 2001 the average had already climbed to 15 (Murphy 2001). Some are rated at above 10 W (though a shift to LEDs is underway). We assumed eight 3-watt bulbs in the average vehicle and that lights were operated for 3 minutes/day, which might occur as a result of door opening and closing (see Table 2). However, some lights may actually stay on while driving or occupants may deliberately keep some lights on while the car is stationary; including these activities could easily double energy consumption. There are also an increasing number of products which may either come with the car (GPS navigation systems) or may be purchased by consumers for use in the car (seat warmers, refrigerators for vehicles), or are home appliances that are also used in vehicles (laptop computers). Power inverters , offered as original equipment or as retrofits, can provide up to 150 or 350 watts of AC power and can be used to provide power to run a TV, DVD, video game system, or other products. Cigarette lighter power adapters are now being marketed for running computers, TVs, DVDs and other equipment for hours at a time when the car is off (SterlingTek 2008). Table 3 summarizes typical power requirements for energy-using products designed for vehicles. 5 Table 2. Lighting Use in Light-Duty Vehicles Light Headlamps (high beam) 24 65 1.6 Est. percent time in operation (based on 480580 hrs driving/year) 4-5% Headlamps (low beam) 115 55 6.3 20-24% Rear tail lamps 115 7 0.8 20-24% Daytime running lamps 141 40 5.6 24-29% Interior lights 146 20 2.9 25-30% 5 ? 5 ? Brake lamps, turn signals Dashboard lights Total Operating Time (hours/year) Typical Power for Incandescent Design (W) Annual Energy Use (kWh/year) 17.3 Source: IEA 2006 Neither the number of vehicles with these appliances, nor the usage of these appliances are known. To illustrate the potential energy use of these appliances, we illustrate the energy use of these appliances if they were used 100 hours per year. 100 hours corresponds to using these appliances about 20% of the time that an average vehicle is driven. It is plausible that some appliances in Table 3 might be used more than 100 hours per year – audio systems, perhaps – and some appliance might be used less – seat warmers perhaps. Table 3. Electric Appliances Used in Vehicles Appliance Illustrative Typical Power Illustrative Operating Time (W) Annual Energy (h/yr) Use (kWh/yr) Large speakers/stereo 100 200 20 TV/DVD combo 100 150 15 GPS Navigator 100 88 8.8 Seat warmers 100 40 4 Moderate speakers/stereo 100 60 6 Refrigerators 100 60 6 Laptop computer 100 50 5 DVD 100 50 5 13” color TV 100 50 5 Car stereo systems (simple) 100 40 4 Video Game Console 100 20 2 Charger for cell phone/PDA 100 15 1.5 Standard car radio 100 4 0.4 Sources: Audio: Crutchfield 2007; Z28 Forum 2007; Mikhaylova 2003. GPS: Al-eds, 2008; Refrigerators: PPL 2008; Seat warmers: Smarthome, 2008; Other: JC Whitney 2008. 6 Overall power used in vehicles is reported to have risen from less than 500 W in the 1960s to more than 2kW by the year 2000 (Meissner & Richter 2003). The net power use is much less than in typical homes; however (as noted below), the costs of operating these appliances is inflated by the high cost of vehicle-generated electricity. Energy Needed to Produce a kWh in a Vehicle The energy needed to produce a kWh in a vehicle varies depending on the appliance and how and when it is used. Figure 1 shows power generation modes in vehicles and their corresponding efficiencies. The conversion of the chemical energy of the gasoline into mechanical energy at the crankshaft is about 25-30% efficient (DOE and EPA 2007; Fenske et al. 2006). The belt that transfers power from the shaft to all mechanical loads is about 95% efficient (Gates 2008), which means that mechanical loads have an efficiency of about 26% (23.8-28.5%). Figure 1. Power generation pathways and efficiencies Net pathway efficiency Power generation and usage steps ~ 23.8-28.5% Engine efficiency to convert chemical energy in fuel to mechanical energy at the crankshaft ~ 2530 % When the engine is running, the battery acts as a stabilizer. DC-AC converter Therefore, there for plug loads are no have an significant efficiency of ~ charging75-90% discharging losses Belt efficiency Alternator that transfers efficiency that power from converts shaft to all Wiring mechanical mechanical connections loads, typically energy from the efficiencies are When engine is serpentine belt connecting belts ~ 100% to electrical turned off, all ~ 95% energy is ~ 50electrical 62% components run on the battery power and the DC-AC converter for plug loads associated have an chargingefficiency of ~ discharging 75-90% efficiencies are in the order of ~ 70-92% ~ 11.8-17.8% ~ 8.9-15.9% Load ~ 8.3-16.3% ~ 6.2-14.6% Mechanical energy is converted to electricity with an alternator; alternators have efficiencies in the range of 50-62% (Bosch 1996). The wiring has negligible losses. When the engine is running, the battery acts as a stabilizer, so there are not significant charging/discharging losses and electricity production therefore has an efficiency of about 15% (11.8-17.8). AC devices that are plugged in to the cigarette lighter or other plug will incur an additional loss from the conversion of DC to AC at an efficiency of 75 to 90% (All-battery.com 2008; Labkorea.com 2008), resulting in plug load efficiency of 7 about 12% (8.9-15.9%) when the vehicle is turned on. When the vehicle is turned off, all electrical components run on battery power; the charging/discharging efficiency is in the range of 70-92% (DOE 1995), so the efficiency of electricity production is only about 12% (8.3-16.3%) and only about 10% (6.2-14.6%) for plug loads. Table 4. Energy efficiency and power cost for vehicle appliances Power generation Costs ($3.2/gal) & (36.63 kWh(th)/ gal) = 8.74 cents/kWh(th) Average cost A/C unit, Roughly 80-20 Case 1: Part of compressors run shaft to direct the appliance directly from the alternator load shaft through a runs on shaft distribution, power and rest belt and blower equates to ~ and the controls on electrical 21.4-26.4% run of the power efficiency electricity. $0.33 - $0.41 /kWh $0.37 / kWh Case 2: Power generation cost at margin during vehicle travel Wiper, power steering etc ~ 11.8-17.8% efficiency $0.49 - $0.74 /kWh $0.62 / kWh Case 3: Generation cost at plug load while the vehicle is running Laptops etc ~ 8.9-15.9% efficiency $0.55 - $0.98 /kWh $0.77 / kWh Starter motor etc ~ 8.3-16.3% efficiency $0.54 - $1.05 /kWh $0.80 / kWh Laptops etc ~ 6.2-14.6% efficiency $0.60 - $1.41 /kWh $1.01 / kWh Cases Case 4: Power usage through stored battery power Case 5: Power usage at plug loads through stored battery power Example Efficiency Table 4 shows generation efficiency and costs for five different cases. It shows that, for a gasoline cost of $3.20 per gallon, the cost of power in a vehicle ranges from about 37¢ per kWh (mechanical) to run the air conditioner, to about $1 per kWh (electrical) to run appliances while the vehicle is turned off. We estimate that the average 8 cost of generating electricity is at least 80 cents/kWh. This is about seven times the price of residential electricity in the United States. Conclusions Light-duty vehicles increasingly provide many of the services normally associated with buildings: heating, cooling, and ventilation, lights, entertainment systems, communication systems, and even some kitchen services. All of these services consume energy. Despite increasing emphasis on energy efficiency in buildings and in automobiles, these uses of energy have received little attention: they are not included in the calculations of automobile fuel economy as measured by the US EPA and used in the corporate average fuel economy (CAFE) standards, nor are they included in the US EPA Energy Star program. Air conditioners in vehicles use an estimated 0.94 quads of primary energy annually in the US, whereas air conditioners in residential US buildings use 2.3 quads, even though vehicles are much smaller than residential buildings and even though people spend only about an hour and a half per day in vehicles as opposed to 16 hours per day in residences. Turler et al. (2003) have shown that thermal insulation and window technologies can reduce heating and cooling loads, resulting in greater fuel efficiency for conventional and hybrid vehicles, increased range for electric vehicles, increased passenger comfort and reduced degradation of interior surface. Zhai (2001) suggests that improved compressors could significantly improve the efficiency of automotive air conditioning systems. In comparison with automotive air conditioners, other appliances used in vehicles have a relatively modest energy footprint, consuming about an order of magnitude less energy than automobile air conditioners. However, this is offset by the high cost of vehicle-generated electricity. Standby power for some of these appliances can have a far greater impact than in stationary buildings, because stand-by power can drain the battery. Moreover, there is a second kind of standby power associated with appliances in cars: all of the accessories add weight to the vehicle and result in increased fuel use according to their weight. For example, a DVD player and display, if kept in the vehicle continuously, will use about as much petroleum to be transported in the vehicle as it will use in electricity to operate. Automotive heating systems, in contrast, are a model of efficient building heating systems, in effect a mobile combined heat-and-power system References All-battery.com , 2008. www.allbattery.com/index.asp?PageAction=VIEWPROD&ProdID=451 Al-eds. 2008. http://www.al-eds.com/product.php?productid=16265&cat=280&page=1 Bosch, Robert. 1996. Automotive Handbook, 4th ed. Bentley Publishers, p. 813. 9 Crutchfield, 2007. Car Stereos Frequently Asked Questions. http://www.crutchfieldadvisor.com/ISEOrgbtcspd/learningcenter/car/car_stereo/faq.html#8 Davis, Stacy, and Susan Diegel. 2007. Transportation Energy Data Book. Washington: U.S. Department of Energy. [DOE] Department of Energy. 2006. 2006 Buildings Energy Data Book. Washington, D.C.: Building Technologies Program. [DOE and EPA] Department of Energy and Environmental Protection Agency. 2008. Advanced Technologies and Energy Efficiency. www.fueleconomy.gov/feg/atv.shtml [DOE] Department of Energy. 1995. Primer on Lead-Acid Storage Batteries, FSC-6910 hss.energy.gov/NuclearSafety/techstds/standard/hdbk1084/hdbk1084.pdf Feneske, George, Robert Erck, Layo Ajayi, Ali Erdemir, Osman Eryilmaz, 2006. Parasitic Energy Loss Mechanisms Impact on Vehicle System Efficiency, Project 15171, Argonne National Laboratory. Fischer, S.K., J.R. Sand. 2007. “Total Environmental Warming Impact (Tewi) Calculations for Alternative Automotive Air-Conditioning Systems.” SAE 970526. Gado, Amr El-Sayed Alaa El-Din. 2006. Development of a Dynamic Test Facility for Environmental Control Systems, Departmet of Mechanical Engineering, University of Maryland, College Park. Gates Corporation, Selecting the Right Drive System – costs and Performance. www.gates.com/brochure.cfm?brochure=5262&location_id=6196 Hendricks, Terry. 2003. Multi-Variable Optimization of Electrically-Driven Vehicle Air Conditioning Systems Using Transient Performance Analysis Paper read at SAE Vehicle Thermal Management Systems. [IEA] International Energy Agency, 2006. Light's Labour's Lost. Paris: International Energy Agency. www.iea.org/Textbase/npsum/Light2006SUM.pdf JC Whitney www.jcwhitney.com/media/jcwhitney/jcw/Documents/SZC01_11671G.html Johnson, Valerie, 2002. Fuel Used for Vehicle Air Conditioning: A State by State Thermal Comfort Approach. SAE 2002-01-1957. 10 Klepeis, N.E. et al. The National Human Activity Pattern Survey (NHAPS): a resource for assessing exposure to environmental pollutants. J. Exposure Analysis and Environmental Epidemiology 11,231-252, 2001. Labkorea.com, 2008. www.labkorea.com/inverter.html Leech, J., W.C. Nelson, R.T. Burnett, S. Aaron, M.E. Raizenne. 2002. “It’s about time: A comparison of Canadian and American time-activity patterns.” Journal of Exposure Analysis and Environmental Epidemiology, 12:427-432. Levine, C., T. Younglove, M. Barth. 2000. “Interaction of Temperature, Humidity, Driver Preferences, and Refrigerant Type on Air Conditioning Compressor Useage.” Journal of the Air & Waste Management Association, 50:10, October. Meissner, Eberhard and Gerolf Richter. 2003. Battery Monitoring and Electrical Energy Management: Precondition for Future Vehicle Electric Power Systems. J Power Systems 116, 79-98. Meissner, Eberhard, and Gerolf Richter. 2005. The challenge to the automotive battery industry: the battery has to become an increasingly integrated component within the vehicle electric power system. Journal of Power Sources 144 (2): 438-460. Mikhaylova, Zhanna, 2003. Power of a Car Stereo. The Physics Fact Book. http://hypertextbook.com/facts/2003/ZhannaMikhaylova.shtml Murphy, P. 2001. Spotlight on Automotive Interior Lighting. Machine Design. http://machinedesign.com/ContentItem/70928/Spotlightonautomotiveinteriorlighti ng.aspx [NESCCAF] Northeast States Center for a Clean Air Future. 2004. Reducing Greenhouse Gas Emissions from Light-Duty Motor Vehicles. Table D-2. September Polzin, S., X. Chu, L. Toole-Holt. 2004. “The Case for More Moderate Growth in VMT: a Critical Juncture in US Travel Behavior Trends.” Slide 22. Presentation for US Department of Transportation, November 3. PPL, 2008. Car Refrigerator. http://www.pplmotorhomes.com/parts/rv-refrigerators/carrefrigerator.htm Rugh, John, Lawrence Chaney, Jason Lustbader, John Meyer, Mukesh Rustagi, Kurt Olson, and Rupert Kogler. 2007. Reduction in Vehicle Temperatures and Fuel Use from Cabin Ventilation, Solar-Reflective Paint, and New Solar-Reflective Glazing. Paper read at 2007 SAE World Congress, April 16-19, at Detroit. 11 Rugh, John, Valerie Hovland, and Stephen O. Andersen. 2004. Significant Fuel Savings and Emission Reductions by Improving Vehicle Air Conditioners. 15th Annual Earth Technologies Forum and Mobile Air Conditioning Summit, April 15, at Washington. Smarthome, 2008. Comfortable 12-Volt Car Seat Cover Heats to Adjustable Levels http://www.smarthome.com/92901b.html?src=WG1003498 SterlingTek, 2008. 150 Watt Power Inverter Car Adapter http://sterlingtek.com/caradforalll.html Turler, Daniel, Hopkins, Deborah, and Goudey, Howdy. Reducing Vehicle Auxiliary Loads Using Advanced Thermal Insulation and Window Technologies. Advances in Automotive Climate Control Technologies, 2003. SAE World Congress. Z28 Forum, 2007. Car Audio-Wattage Explained. http://www.z28.com/forum/showthread.php?t=36069 Zhai, Kelvin. Could Automotive HVAC Become an EPA/DOE Energy Star? Future Transportation Technology Conference & Exposition, August 2001, Costa Mesa, CA, USA, Session: Energy, Environment and Economics.