Application Engineering Basics I 1 ____

Application Engineering Basics

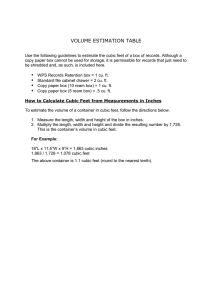

5ISPVHIPVUPVSDBUBMPHZPVXJMMöOEUFSNJOPMPHZVTFEGPSBJSNPWJOHTFMFDUJPOBOEQSPEVDUTJ[JOH#FMPXBSFBGFXPGUIFLFZUFSNT

Flow Specific Gravity t7PMVNF3BUF5JNF t30530/DIBSUTBSFJO4$'.NNJOPS-4 t4$'.4UBOEBSE$VCJD'FFU1FS.JOVUF "NFSJDBOXIFSF

UFNQFSBUVSF¡'

BJSEFOTJUZMCDVCJDGPPU

BOEBMUJUVEFGFFUBCPWFTFBMFWFM t.NJO$VCJD.FUFST1FS.JOVUF .FUSJD

t-TFD-JUFST1FS4FDPOE .FUSJD

tNNJO4$'.

t-TFD4$'.

t4FF4UBOEBSE&OHJOFFSJOH$POWFSTJPOTGPSPUIFSøPXTPO

QH*

Pressure t'PSDF"SFB t30530/DIBSUTBSFJO*8(14*(..PG8BUFS*)(PSNCBS t*8(*ODIFTPG8BUFS(BVHF "NFSJDBO t14*(1PVOET1FS4RVBSF*ODI(BVHF "NFSJDBO t..PG8BUFS.JMMJNFUFSPG8BUFS(BVHF .FUSJD

t*)(*ODIFTPG.FSDVSZ(BVHF "NFSJDBO tNCBS.JMMJCBS(BVHF .FUSJD

t14*"1PVOET1FS4RVBSF*ODI"CTPMVUF "NFSJDBO t*8(14*( t..PG8BUFS14*( t*)(14*( t#BSTNCBS14*( t4UBOEBSE"UNPTQIFSF14*(14*" t4FF#BTJD'BO-BXT$IBSUGPSDPSSFDUJOHQSFTTVSFEVFUPTQFFE

PSEFOTJUZDIBOHFTPOQHT*BOE*

Density t8FJHIU7PMVNF t4UBOEBSE"JSMCDVCJDGPPU t4FF%FOTJUZ$IBSUGPSPUIFSHBTFTPOQH* t4FF%FOTJUZ$PSSFDUJPO$IBSUEVFUPBMUJUVEFBOEUFNQFSBUVSF

DIBOHFTPOQH* t%FOTJUZ3BUJP3FMBUJWFUP"JS t4UBOEBSE"JS4( t.FUIBOF4( t4FF4QFDJöD(SBWJUZ$IBSUGPSPUIFSHBTFTPOQH*

Velocity t%JTUBODF5JNFPS'MPX"SFB t'1.'FFU1FS.JOVUF "NFSJDBO t.1).JMFT1FS)PVS "NFSJDBO t.NJO.FUFST1FS.JOVUF .FUSJD

t,NI,JMPNFUFST1FS)PVS .FUSJD

t'1..1) t.NJO.1) t,NI.1) t4FF4UBOEBSE&OHJOFFSJOH$POWFSTJPO$IBSUGPSPUIFS

WFMPDJUJFTPOQH* t4FF0SJöDF'MPX$BMDVMBUJPO$IBSUGPSBJSøPXFRVBUJPOTPO

QH*

Pressure Drop / Back Pressure / Impedance t'SJDUJPODBVTFTBJSUPTMPXEPXOBOEMPTUFOFSHZJTNFBTVSFE

JOQSFTTVSFESPQUFSNT t5ZQJDBMQSFTTVSFESPQBSFBTJODMVEFQJQJOHFMCPXT

BDDFTTPSJFTBOETZTUFN t&BDIöYFETZTUFNIBTBöYFETZTUFNJNQFEBODFDBVTFECZB

TJOHMFPSNVMUJQMFQSFTTVSFESPQQPJOUT t$IBOHJOHUIFTZTUFNJNQFEBODFXJMMDBVTFCMPXFSTXPSL

QPJOUUPDIBOHF t$IBOHJOHUIFCMPXFSXJUIöYFETZTUFNJNQFEBODFXJMM

DIBOHFUIFXPSLJOHCBDLQSFTTVSF t4FF'SJDUJPO-PTT1FS'PPUPG5VCJOHBOE'JUUJOH$IBSUTPO

QH*

This document is for informational purposes only and should not be considered as a binding description of the products or their performance in all applications. The performance data on this page depicts typical performance under controlled laboratory conditions. AMETEK is not responsible for blowers driven beyond factory specified speed, temperature, pressure, flow or without proper alignment. Actual performance will vary depending on the operating environment and application.

AMETEK products are not designed for and should not be used in medical life support applications. AMETEK reserves the right to revise its products without notification. The above characteristics represent standard products. For product designed to meet specific applications, contact AMETEK Technical & Industrial Products Sales department.

AMETEK TECHNICAL & INDUSTRIAL PRODUCTS

75 North Street, Saugerties, NY 12477

USA: +1 215-256-6601 - Europe: +44 (0) 845 366 9664 - Asia: +86 21 5763 1258

Customer Service Fax: +1 215.256.1338

www.ametektip.com

I 1

____

Application Engineering Basics

Standard Engineering Conversion

MULTIPLY

Atmospheres

Atmospheres

Atmospheres

Atmospheres

Atmospheres

Atmospheres

Atmospheres

Bars

Bars

Bars

Bars

British Thermal Units

British Thermal Units

British Thermal Units

British Thermal Units

British Thermal Units

British Thermal Units

Centimeters of Mercury

Centimeters of Mercury

Centimeters of Mercury

Centimeters of Mercury

Centimeters/Second

Centimeters/Second

Cubic Centimeters

Cubic Centimeters

Cubic Centimeters

Cubic Centimeters

Cubic Feet

Cubic Feet

Cubic Feet

Cubic Feet

Cibic Feet

Cubic Feet

Cu. Ft. of Water (60°F)

Cubic Feet/Minute

Cubic Feet/Minute

Cubic Feet/Minute

Cubic Inches

Cubic Inches

Cubic Inches

Cubic Inches

Cubic Meters

Cubic Meters

Cubic Meters

Cubic Meters

Cubic Yards

Cubic Yards

Cubic Yards

Cubic Yards

Feet

Feet

Feet

Feet

Feet of Air

(1 atmosphere 60°F)

Feet/Minute

Feet/Minute

Feet/Minute

Feet/Minute

Feet/Minute

Grams/Cu. Cm.

Horsepower

Horsepower

Horsepower

Horsepower

Horsepower-Hours

Inches

Inches

Inches of Mercury

Inches of Mercury

Inches of Mercury

Inches of Mercury

Inches of Mercury

Inches of Water

Inches of Water

Inches of Water

Inches of Water

Inches of Water

TO OBTAIN

Cms. of Mercury

Inches of Mercury

Feet of Water

Kgs./Sq. Inch

Pascals

Pounds/Sq. Inch

Torrs

Atmospheres

Dynes/Sq. Cm.

Kgs./Square Meter

Pounds/Sq. Inch

Kilogram-Calories

Foot-Pounds

Horsepower-Hours

Joules

Kilogram-Meters

Kilowatt-Hours

Atmospheres

Feet of Water

Kgs./Square Meter

Pounds/Sq. Inch

Feet/Minute

Meters/Minute

Cubic Feet

Cubic Inches

Cubic Meters

Liters

Cubic Cms.

Cubic Inches

Cubic Meters

Cubic Yards

Gallons

Liters

Pounds

Cubic Cms./Sec.

Liters/Second

Lbs. of Water/Min.

Cubic Centimeters

Cubic Feet

Cubic Meters

Cubic Yards

Cubic Centimeters

Cubic Feet

Cubic Inches

Cubic Yards

Cubic Centimeters

Cubic Feet

Cubic Inches

Cubic Meters

Centimeters

Inches

Meters

Yards

Pounds/Square Inch

Centimeters/Sec.

Feet/Second

Kilometers/Hour

Meters/Minute

Miles/Hour

Pounds/Cubic Foot

British Thermal Units/Min.

Foot-Pounds/Min.

Kg.-Calories/Min.

Watts

British Thermal Units

Centimeters

Mils

Atmospheres

Inches of Water

Kgs./Square Meter

Mms. of Mercury

Pounds/Square In.

Atmospheres

Inches of Mercury

Kgs./Square Meter

Pounds/Square Ft.

Pounds/Square In.

BY

76.0

29.92

33.90

10,333

1.013 x 10 5

14.70

760

0.9869

1. x 10 6

1.020 x 10 4

14.50

0.2520

777.5

3.927 x 10 -4

1054

107.5

2.928 x 10 -4

0.01316

0.4461

136.0

0.1934

1.969

0.6

3.531 x 10 -5

6.102 x 10 -2

10 -6

10 -3

2.832 x 10 4

1728

0.02832

0.03704

7.481

28.32

62.37

472.0

0.4720

62.4

16.39

5.787 x 10 -4

1.639 x 10 -5

2.143 x 10 -5

10 6

35.31

61,023

1.308

7.646 x 10 5

27

46,656

0.7646

30.48

12

0.3048

1/3

5.30 x 10 -4

0.5080

0.01667

0.01829

0.3048

0.01136

62.43

42.44

33,000

10.70

745.7

2547

2.540

10 3

0.03342

13.60

345.3

25.40

0.4912

0.002458

0.07355

25.40

5.204

0.03613

BY

0.06243

3281

56.92

737.6

1.341

14.34

3415

10 3

61.02

10 -3

2.303

0.4343

100

3.2808

39.37

10 -3

1.667

3.281

0.06

0.03728

5280

1.6093

1760

44.70

88

1,467

1.6093

26.82

0.0394

1.3595

-3

0.01934

28.87

473,179

16

444,823

453.6

16

14,544

27.68

0.1198

970.3

16.02

4,882

0.06804

27.7

2.036

703.1

6.895 x 10 3

51.715

1.973 x 10 5

1.076 x 10 -3

0.1550

929.0

0.09290

1.273 x 10 6

6.452

6.944 x 10 -3

10 6

645.2

10.76 x 10 6

10 6

1.196 x 10 6

10.764

1.196

1

1.8

1

5/9

0.05692

10 7

44.26

1.341 x 10 -3

0.01434

10 -3

3.415

1.341 x 10-

10 -3

MULTIPLY

KGS./Cubic Meter

Kilometers

Kilowatts

Kilowatts

Kilowatts

Kilowatts

Kilowatt-Hours

Liters

Liters

Liters

Log 10 N

Log N or Ln N

Meters

Meters

Meters

Meters

Meters/Minute

Meters/Minute

Meters/Minute

Meters/Minute

Miles

Miles

Miles

Miles/Hour

Miles/Hour

Miles/Hour

Miles/Hour

Miles/Hour

Mms. of Mercury

Mms. of Mercury

Mms. of Mercury

Pints (Liq.)

Pints (U.S. liquid)

Pints (U.S. liquid)

Pounds

Pounds

Pounds

Pounds of Carbon to CO 2

Pounds of Water

Pounds of Water

Pounds of Water

Evaporated at 212°F

Pounds/Cubic Foot

Pounds/Square Foot

Pounds/Square Inch

Pounds/Square Inch

Pounds/Square Inch

Pounds/Square Inch

Pounds/Square Inch

Pounds/Square Inch

Square Centimeters

Square Centimeters

Square Centimeters

Square Feet

Square Feet

Square Inches

Square Inches

Square Inches

Square Inches

Square Inches

Square Kilometers

Square Kilometers

Square Kilometers

Square Meters

Square Meters

Temp. (Degs. C.) + 273

Temp. (Degs. C.) + 17.8

Temp. (Degs. F.) + 460

Temp. (Degs. F.) -32

Watts

Watts

Watts

Watts

Watts

Watts

Watts-Hour

Watts-Hour

Watts-Hour

TO OBTAIN

Pounds/Cubic Foot

Feet

British Thermal Units/Min.

Foot-Pounds/Sec.

Horsepower

Kg.-Calories/Min.

British Thermal Units

Cubic Centimeters

Cubic Inches

Cubic Meters

Log

E

N or Ln N

Log

10

N

Centimeters

Feet

Inches

Kilometers

Centimeters/Sec.

Feet/Minute

Kilometers/Hour

Miles/Hour

Feet

Kilometers

Yards

Centimeters/Sec.

Feet/Minute

Feet/Second

Kilometers/Hour

Meters/Minute

Inches of Mercury

Kgs./Square Cm.

Pounds/Square Inch

Cubic Inches

Cubic Centimeters

Ounces (U.S. fluid)

Dynes

Grams

Ounces

British Thermal Units (mean)

Cubic Inches

Gallons

British Thermal Units

Kgs./Cubic Meter

Kgs./Square Meter

Atmospheres

Inches of Water

Inches of Mercury

Kgs./Square Meter

Pascals

Millimeters of Mercury at 0°C

Circular Mils

Square Feet

Square Inches

Square Centimeters

Square Meters

Circular Mils

Square Centimeters

Square Feet

Square Mils

Square Millimeters

Square Feet

Square Meters

Square Yards

Square Feet

Square Yards

Abs. Temp. (Degs. C.)

Temp. (Degs. Fahr.)

Abs. Temp. (Degs. F.)

Temp. (Degs. Cent.)

British Thermal Units/Min.

Ergs/Second

Foot-Pounds/Min.

Horsepower

Kg.-Calories/Min.

Kilowatts

British Thermal Units

Horsepower/Hours

Kilowatt-Hours

This document is for informational purposes only and should not be considered as a binding description of the products or their performance in all applications. The performance data on this page depicts typical performance under controlled laboratory conditions. AMETEK is not responsible for blowers driven beyond factory specified speed, temperature, pressure, flow or without proper alignment. Actual performance will vary depending on the operating environment and application.

AMETEK products are not designed for and should not be used in medical life support applications. AMETEK reserves the right to revise its products without notification. The above characteristics represent standard products. For product designed to meet specific applications, contact AMETEK Technical & Industrial Products Sales department.

AMETEK TECHNICAL & INDUSTRIAL PRODUCTS

75 North Street, Saugerties, NY 12477

USA: +1 215-256-6601 - Europe: +44 (0) 845 366 9664 - Asia: +86 21 5763 1258

Customer Service Fax: +1 215.256.1338

www.ametektip.com

I 2

____

Application Engineering Basics

Density Correction Chart

This document is for informational purposes only and should not be considered as a binding description of the products or their performance in all applications. The performance data on this page depicts typical performance under controlled laboratory conditions. AMETEK is not responsible for blowers driven beyond factory specified speed, temperature, pressure, flow or without proper alignment. Actual performance will vary depending on the operating environment and application.

AMETEK products are not designed for and should not be used in medical life support applications. AMETEK reserves the right to revise its products without notification. The above characteristics represent standard products. For product designed to meet specific applications, contact AMETEK Technical & Industrial Products Sales department.

AMETEK TECHNICAL & INDUSTRIAL PRODUCTS

75 North Street, Saugerties, NY 12477

USA: +1 215-256-6601 - Europe: +44 (0) 845 366 9664 - Asia: +86 21 5763 1258

Customer Service Fax: +1 215.256.1338

www.ametektip.com

I 3

____

Application Engineering Basics

Specific Gravity and Density of Various Gases at 60°F (1 ATM)

Gas or Vapor

Acetylene

Air

Ammonia

Argon

Benzene

Carbon Dioxide

Chlorine

Ethane

Ethylene

Helium

Hydrogen

Hydrogen Sulfide

Methane

Methyl Chloride

Nitrogen

Oxygen

Propane

Sulfer Oxide

Water Vapor

Chemical

Formula

C

2

H

2

-

NH

3

A

C

6

H

6

CO

2

CI

2

C

2

H

6

C

2

H

4

He

H

2

H

2

S

CH

4

CH

3

CI

N

2

O

2

C

3

H

8

SO

2

H

2

O

Specific Gravity

Explosive Atmosphere Classification

0.899

1.00

0.587

1.377

2.70

1.539

2.448

1.038

0.969

0.138

0.0695

1.19

0.555

1.785

0.967

1.105

1.55

2.26

0.622

Density

(lbs./cu ft.)

.0686

.0763

.0454

.1053

.205

.1166

.0738

.0799

.0739

.01054

.00531

.0897

.0424

.1356

.0738

.0843

.1180

.1720

.0373

North American European

Class I

Group A

Group B

Group C

Group D

Zone 1

Group II C

Group II C

Group II B

Group II A

Acetylene

Hydrogen or equivalent hazard

Ethyle ether vapors, ethylene or cyclopropane

Gasoline, hexane, naptha, benzene, butane, alcohol, acetone, benzol, lacquer vapors or natural gas

Class II

Group E

Group F

Group G

—

—

—

Metal dust

Carbon black, coal or coke dust

Flour, starch or grain

Temperature Conversion Chart

*In the center column, find the temperature to be converted.

The equivalent temperature is in the left column, if converting to Celsius, and in the right column, if converting to Fahrenheit.

Temp °F °C

26

27

28

29

30

31

32

33

34

20

21

22

23

24

25

14

15

16

17

18

19

10

11

12

13

7

8

9

4

5

6

1

2

3

-50

-40

-30

-20

-10

0

-110

-100

-166

-148

-90 -130

-80

-70

-60

-112

-94

-76

-58

-40

-22

-4

14

32

33.8

35.6

37.4

8.3

8.9

9.4

39.2

10.0

41.0

10.6

42.8

11.1

44.6

11.7

46.4

12.2

48.2

12.8

50.0

13.3

51.8

13.9

53.6

14.4

55.4

15.0

5.0

5.6

6.1

6.7

7.2

7.8

1.7

2.2

2.8

3.3

3.9

4.4

57.2

15.6

59.0

16.1

60.8

16.7

62.6

17.2

64.4

17.8

66.2

18.3

68.0

18.9

69.8

19.4

71.6

20.0

73.4

20.6

75.2

21.1

77.0

21.7

78.8

22.2

80.6

22.8

82.4

23.3

84.2

23.9

86.0

24.4

87.8

25.0

89.6

25.6

91.4

26.1

93.2

26.7

°C

-3.3

-2.8

-2.2

-1.7

-1.1

-0.6

0

0.6

1.1

-10.0

-9.4

-8.9

-8.3

-7.8

-7.2

-6.7

-6.1

-5.6

-5.0

-4.4

-3.9

-17.2

-16.7

-16.1

-15.6

-15.0

-14.4

-13.9

-13.3

-12.8

-12.2

-11.7

-11.1

-10.6

-78.9

-73.3

-67.8

-62.2

-56.7

-51.1

-45.6

-40.0

-34.4

-28.9

-23.3

-17.8

°F °C

140.0

141.8

143.6

145.4

147.2

149.0

150.8

100

152.6

104

154.4

110

156.2

158.0

159.8

116

121

127

71

77

82

88

93

99

161.6

163.4

165.2

132

138

143

167.0

149

168.8

154

170.6

160

172.4

166

174.2

171

176.0

177

95.0

27.2

96.8

27.8

98.6

28.3

100.4

28.9

102.2

29.4

104.0

30.0

105.8

30.6

107.6

31.1

109.4

31.7

111.2

32.2

113.0

32.8

114.8

33.3

116.6

33.9

118.4

34.4

120.2

35.0

122.0

35.6

123.8

36.1

125.6

36.7

127.4

37.2

129.2

37.8

131.0

43

132.8

134.6

136.4

138.2

49

54

60

66

Temp

72

73

74

75

76

77

78

79

80

66

67

68

69

70

71

60

61

62

63

64

65

56

57

58

59

53

54

55

47

48

49

50

51

52

41

42

43

44

45

46

35

36

37

38

39

40

°F °C

320 321

338 327

356 332

374 338

392 343

410 349

413 354

428 360

446 366

464 371

482 377

500 382

518 388

536 393

554 399

572 404

590 410

608 416

626 421

644 427

662 432

177.8

182

179.6

188

181.4

193

183.2

199

185.0

204

186.8

210

188.6

216

190.4

221

192.2

227

194.0

232

195.8

238

197.6

243

199.4

249

201.2

254

203.0

260

204.8

266

206.6

271

208.4

277

210.2

282

212.0

288

230 293

248 299

266 304

284 310

302 316

Temp

270

280

290

300

310

320

330

340

350

212

220

230

240

250

260

160

170

180

190

200

210

99

100

110

120

130

140

150

93

94

95

96

97

98

87

88

89

90

91

92

81

82

83

84

85

86

Temp °F

610

620

630

1130

1148

1166

640 1184

650 1202

660 1220

670 1238

680 1256

690 1274

700 1292

710 1310

720 1328

730 1346

740 1364

750 1382

760 1400

770 1418

780 1436

790 1454

800 1472

810 1490

420

430

440

450

460

470

360

370

380

390

400

410

480

490

500

510

520

530

540 1004

550 1022

560 1040

570 1058

580 1076

590 1094

600 1112

896

914

932

950

968

986

788

806

824

842

860

878

680

698

716

734

752

770

°F = 9/5C + 32

°C = 5/9 (F - 32)

ABSOLUTE RANKIN (R) R = °F + 460

ABSOLUTE KELVIN (K) K = °C + 273

NEMA Classifications

NEMA Type 1 – General Purpose – Indoor

Type 2 – Dripproof – Indoor

Type 3 – Dusttight, Raintight and Sleet (Ice)

Resistant – Outdoor

3R – Rainproof and Sleet (Ice) Resistant

– Outdoor

3S – Dusttight, Raintight and Sleet (Ice)

Proof – Outdoor

Type 4 – W atertight and Dusttight – Indoor

4X – W atertight, Dusttight and Corrosion

Resistant – Outdoor

Type 5 – Superseded by Type 12 for Control

Apparatus

Ref: NEMA Standards Publication, Pub. No. 1CS–1970

Type 6 – Submersible, Watertight, Dusttight and

Sleet Resistant – Indoor and Outdoor

Type 7 – Class I, Group A, B, C or D Hazardous

Locations; Air Break Equipment – Indoor

Type 8 – Class I, Group A, B, C or D Hazardous

Locations; Oil-immersed Equipment – Indoor

Type 9 – Class II, Group E, F or G Hazardous

Locations; Air-break Equipment – Indoor

Type 10 – Bureau of Mines

Type 11 – Corrosion Resistant and Dripproof;

Oil-immersed – Indoor

Type 12 – Industrial Use, Dusttight and Driptight

– Indoor

Type 13 – Oiltight and Dusttight – Indoor

This document is for informational purposes only and should not be considered as a binding description of the products or their performance in all applications. The performance data on this page depicts typical performance under controlled laboratory conditions. AMETEK is not responsible for blowers driven beyond factory specified speed, temperature, pressure, flow or without proper alignment. Actual performance will vary depending on the operating environment and application.

AMETEK products are not designed for and should not be used in medical life support applications. AMETEK reserves the right to revise its products without notification. The above characteristics represent standard products. For product designed to meet specific applications, contact AMETEK Technical & Industrial Products Sales department.

AMETEK TECHNICAL & INDUSTRIAL PRODUCTS

75 North Street, Saugerties, NY 12477

USA: +1 215-256-6601 - Europe: +44 (0) 845 366 9664 - Asia: +86 21 5763 1258

Customer Service Fax: +1 215.256.1338

www.ametektip.com

I 4

____

Application Engineering Basics

Physical Laws for Blower Applications

In the following formulae these symbols are used:

P – Pressure in pounds per square inch (PSI) or inches of

mercury column (inches Hg)

CFM – Volume in cubic feet per minute

RPM – Speed in revolutions per minute

D – Density in pounds per cubic foot (lbs./cu. ft.)

H – Height of air or gas column (ft.)

SG – Specific Gravity (ratio of density of gas to the density

of air)

“Standard Air” – Air at 68°F (absolute temperature 528°) and

29.92” Hg. (barometric pressure at sea level). The density of such air is 0.075 lbs./cu. ft. and the specific volume is 13.29 cu. ft./lb. The specific gravity is 1.0.

The outlet pressure of a blower depends on the condition of the air or gas at the inlet. The inlet condition is influenced by: a – Specific gravity (The ratio of density of the gas to density of

standard air) b – Altitude (location of blower) c – Temperature of inlet air

Basic Fan Laws Chart

V A R I A B L E

WHEN SPEED CHANGES

WHEN DENSITY CHANGES

V O L U M E

Varies DIRECT with Speed Ratio

CFM

2

= CFM

1

( RPM

2

)

RPM

1

Does Not Change

P R E S S U R E

Varies with SQUARE of Speed Ratio

P

2

= P

1

( RPM

2

) 2

RPM

1

Varies DIRECT with Density Ratio

P

2

= P

1

( D

2

)

D

1

H O R S E P O W E R

Varies with CUBE of Speed Ratio

HP

2

= HP

1

( RPM

2

) 3

RPM

1

Varies DIRECT with Density Ratio

HP

2

= HP

1

( D

2

)

D

1

Volume

The Volume changes in direct ratio to the speed.

Example – A blower is operating at 3500 RPM and delivering

1000 cfm. If the speed is reduced to 3000 RPM, what is the new volume?

V

1

= Original Volume (1000 CFM)

V

2

= New Volume

RPM

1

= Original Speed (3500 RPM)

RPM

2

= New Speed (3000 RPM)

V

2

= V

1

( RPM

2

)

RPM

1

1

= 1000 x

( 3000 )

3500

1

= 1000 x .857 = 857 CFM

Pressure

Pressure (barometric) varies in direct proportion to altitude.

Example – A blower is to operate at an elevation of 6000 feet and is to deliver 3 PSI pressure. What pressure (standard air) blower is required?

Pressure = 3 x

29.92

23.98

= 3.75 or 3 3/4 lb.

If it is desired to determine what pressure a 3 lb. (standard air) blower will deliver at 6000 feet –

Pressure = 3 x

23.98

29.92

= 2.4 or about 2 1/2 lb.

When a blower is to operate at a high altitude it is frequently specified that the blower be capable of handling a given volume of “standard air”. It is then necessary to determine the equivalent volume of air at the higher altitude.

Example – A blower is to operate 6000 feet altitude and is to handle 1000 CFM of standard air. What is the CFM of air the blower must handle at 6000 feet altitude?

Let: V

1

= Volume of standard air (1000 CFM)

V

2

= Volume of thinner air

Hg

1

= Barometric pressure sea level (29.92)

Hg

2

= Barometric pressure 6000’ (23.98)

V

2

= V

1

Hg x

Hg

1 = 1000 x

2

29.92

23.98

= 1248 CFM

The pressure changes as the square of the speed ratio.

Example – A blower is operating at a speed of 3500 RPM and delivering air at 5.0 pounds pressure. If the speed is reduced to

3000 RPM, what is the new pressure?

P

1

= Original Pressure (5 lbs.)

P

2

= New Pressure

RPM

1

= Original Speed (3500 RPM)

RPM

2

= New Speed (3000 RPM)

P

2

= P

1

( RPM

2

RPM

1

) 2

= 5 x

( 3000

3500

) 2

= 5 x .735 = 3.68 pounds

This document is for informational purposes only and should not be considered as a binding description of the products or their performance in all applications. The performance data on this page depicts typical performance under controlled laboratory conditions. AMETEK is not responsible for blowers driven beyond factory specified speed, temperature, pressure, flow or without proper alignment. Actual performance will vary depending on the operating environment and application.

AMETEK products are not designed for and should not be used in medical life support applications. AMETEK reserves the right to revise its products without notification. The above characteristics represent standard products. For product designed to meet specific applications, contact AMETEK Technical & Industrial Products Sales department.

AMETEK TECHNICAL & INDUSTRIAL PRODUCTS

75 North Street, Saugerties, NY 12477

USA: +1 215-256-6601 - Europe: +44 (0) 845 366 9664 - Asia: +86 21 5763 1258

Customer Service Fax: +1 215.256.1338

www.ametektip.com

I 5

____

Application Engineering Basics

Pressure (Cont’d)

The Air Density varies in inverse proportion to the absolute temperature.

Example – A blower is to handle 200°F air at 3 PSI pressure.

What pressure (standard air) blower is required?

Let: P

1

= Pressure hot air (3 PSI)

P

2

= Pressure standard air

AT

1

= Absolute temperature hot air (200+460=660°F)

AT

2

= Absolute temperature standard air (68+460=528°F)

P

2

= P

1

AT x

AT

1 = 3 x

2

660

528

= 3.75 or 3 3/4 lb.

A blower is capable of delivering 3 PSI pressure with standard air. What pressure will it develop handling 200°F inlet air?

P

1

= P

2

AT x

AT

2 = 3 x

1

528

660

= 2.4 or about 2 1/2 lb.

Pressure varies in direct proportion to the density.

Example – A 3 lb. (standard air) blower is to be used to handle gas having a specific gravity of 0.5. What pressure does the blower create when handling the gas?

Let: Pa = Air pressure (3 lb.)

Pg = Gas pressure

SG = Specific gravity of gas (0.5)

Pg = Pa x SG = 3 x .5 = 1.5 lb.

If we are required to handle a gas having a specific gravity of 0.5

at 1.5 lb. pressure, we can determine the standard air pressure blower as follows:

Let: Pa =

Pg 1.5

=

SG .5

= 3 lb.

The following table gives the barometric pressure of various altitudes:

Absolute Pressure At Altitudes Above Sea Level (Based on U.S. Standard Atmosphere)

Altitude

Feet

0

500

600

700

800

900

1,000

1,500

2,000

In. Hg.

Pressure

PSIA

29.92

29.38

29.28

29.18

29.07

28.97

28.86

28.33

27.82

14.70

14.43

14.38

14.33

14.28

14.23

14.18

13.90

13.67

Altitude

Feet

2,500

3,000

3,500

4,000

4,500

5,000

5,500

6,000

6,500

Pressure

In. Hg.

27.31

26.81

26.32

25.84

25.36

24.89

24.43

23.98

23.53

PSIA

13.41

13.19

12.92

12.70

12.45

12.23

12.00

11.77

11.56

Altitude

Feet

7,000

7,500

8,000

8,500

9,000

9,500

10,000

In. Hg.

Pressure

PSIA

23.09

22.65

22.22

21.80

21.38

20.98

20.58

11.34

11.12

10.90

10.70

10.50

10.90

10.10

Horsepower

The horsepower changes as the cube of the speed ratio.

Example – A blower is operating at a speed of 3500 RPM and requiring 50 horsepower. If the speed is reduced to 3000 RPM, what is the new required horsepower?

HP

1

= Original Horsepower (50)

HP

2

= New Horsepower

RPM

1

= Original Speed (3500 RPM)

RPM

2

= New Speed (3000 RPM)

HP

2

= HP

1 x

( RPM

2

)

RPM

1

3

= 50 x

( 3000 )

3500

3

= 50 x .630 = 31.5 horsepower

The above is known as the 1-2-3 rule of blowers.

Horsepower vs. Specific Gravity & Ratio of density.

The horsepower varies in direct proportion to the specific gravity

(ratio of density of gas to density of air).

Example – A standard air blower requires a 10 HP motor. What horsepower is required when this blower is to handle a gas whose specific gravity is 0.5?

HP = 10 x 0.5 = 5 horsepower

It is possible that several of the above modifications may be required on one installation. Therefore, it may be necessary to use various combinations of these formulae.

This document is for informational purposes only and should not be considered as a binding description of the products or their performance in all applications. The performance data on this page depicts typical performance under controlled laboratory conditions. AMETEK is not responsible for blowers driven beyond factory specified speed, temperature, pressure, flow or without proper alignment. Actual performance will vary depending on the operating environment and application.

AMETEK products are not designed for and should not be used in medical life support applications. AMETEK reserves the right to revise its products without notification. The above characteristics represent standard products. For product designed to meet specific applications, contact AMETEK Technical & Industrial Products Sales department.

AMETEK TECHNICAL & INDUSTRIAL PRODUCTS

75 North Street, Saugerties, NY 12477

USA: +1 215-256-6601 - Europe: +44 (0) 845 366 9664 - Asia: +86 21 5763 1258

Customer Service Fax: +1 215.256.1338

www.ametektip.com

I 6

____

Application Engineering Basics

Orifice Flow

Orifice Flow Calculation

To determine air flow through an orifice:

V = CK

√

P Q = AV VP =

( V )

2

K

Where:

V = V elocity in feet per minute (fpm)

C = Orifice Coefficient

K = Constant = 14,786 when P is expressed in In. Hg

21,094 when P is expressed in PSIG

4,005 when P is expressed in In. of Water

(Above constants are based on an air density of 0.075 lbs/ft 3 )

P = Pressure differential across the orifice

Q = Flow rate in cubic feet per minute (CFM)

A = T otal orifice area expressed in square feet

VP = Velocity pressure (units are those of pressure)

Coefficient C for Orifices Under

Vacuum or Pressure Flow

ORIFICE PRESSURE DROP AS A FUNCTION

OF FLOW AND ORIFICE AREA (C=.65)

100

80

60

40

20 c-.98

c-.72

c-.92

c-.65

c-.80

c-.82

c-.80

c-.53

Area of Orifices

Orifice Diameter in Inches

Diameter in Inches Square Inches Square Feet

1/8

3/16

1/4

3/8

1/2

5/8

7/8

1.0

.01227

.02761

.04908

.11044

.19634

.30679

.60132

.78539

Orifice area (in sq. inches) = .25 X π X (orifice diameter in inches) 2

Orifice area (in sq. feet) = Area in sq. inches ÷ 144

.000085

.00019

.00034

.00076

.00136

.00213

.00417

.00545

200

180

160

140

120

100

80

60

40

20

0 100 200 300

Flow Rate SCFM

400 500

150

135

120

105

90

75

60

45

30

15

500 700 900 1100

Flow Rate SCFM

1300 1500

1500 1700 1900 2100

Flow Rate SCFM

2300 2500

This document is for informational purposes only and should not be considered as a binding description of the products or their performance in all applications. The performance data on this page depicts typical performance under controlled laboratory conditions. AMETEK is not responsible for blowers driven beyond factory specified speed, temperature, pressure, flow or without proper alignment. Actual performance will vary depending on the operating environment and application.

AMETEK products are not designed for and should not be used in medical life support applications. AMETEK reserves the right to revise its products without notification. The above characteristics represent standard products. For product designed to meet specific applications, contact AMETEK Technical & Industrial Products Sales department.

AMETEK TECHNICAL & INDUSTRIAL PRODUCTS

75 North Street, Saugerties, NY 12477

USA: +1 215-256-6601 - Europe: +44 (0) 845 366 9664 - Asia: +86 21 5763 1258

Customer Service Fax: +1 215.256.1338

www.ametektip.com

I 7

____

Application Engineering Basics

Friction Loss Per Foot of Tubing

Friction Loss in Fittings

To calculate friction loss in fittings use chart below. This chart will yield equivalent lengths (in feet) of tubing. Use this length with graph above to find friction loss in inches of water column.

NOMINAL PIPE SIZE (INCHES)

1 1/4

1 1/2

2

2 1/2

3

4

5

6

8

EQUIVALENT TUBING LENGTH (FEET)

90° EL 45° EL

7

1 0

1 2

1 5

2 0

5

6

3

4

4

5

6

7.5

10

1.5

2

2.5

3

This document is for informational purposes only and should not be considered as a binding description of the products or their performance in all applications. The performance data on this page depicts typical performance under controlled laboratory conditions. AMETEK is not responsible for blowers driven beyond factory specified speed, temperature, pressure, flow or without proper alignment. Actual performance will vary depending on the operating environment and application.

AMETEK products are not designed for and should not be used in medical life support applications. AMETEK reserves the right to revise its products without notification. The above characteristics represent standard products. For product designed to meet specific applications, contact AMETEK Technical & Industrial Products Sales department.

AMETEK TECHNICAL & INDUSTRIAL PRODUCTS

75 North Street, Saugerties, NY 12477

USA: +1 215-256-6601 - Europe: +44 (0) 845 366 9664 - Asia: +86 21 5763 1258

Customer Service Fax: +1 215.256.1338

www.ametektip.com

I 8

____

Application Engineering Basics

Noise Facts t OSHA (Occupational Safety & Health Administration) regulates and monitors in-plant noise.

t Allowable noise is a function of dBA level at certain distance over an exposure time.

t OSHA regulations state 90 dBA for an 8 hour work period using slow responic setting on meter.

t Adding a second noise producer of equal dBA will add 3 dBA to the first dBA reading.

t Sound pressure level (SPL) decreases with distance (d)

(SPL)

2

= (SPL)

1

- 20LOG

( d2 d1

)

Therefore, each doubling of distance results in 6 dBA reduction.

Loudness Levels of Familiar Noises (Approximate Average Including Ear Nework)

10 13 130

Threshold of Painful Feeling

Airplane and Propeller at 10 Ft.

10 12 120

DEAFENING

10 11 110

Train Passing at High Speed

10 10 100

NOISY

AVERAGE

QUIET

VERY QUIET

10 9

10 8

10 7

10 6

10 5

10 4

10 3

90

80

70

60

50

40

30

Riveter at 30 Ft. Auto Horn at 20 Ft.

Pneumatic Drill at 10 Ft.

Subway Train

Fire Siren at 75 Ft. Noisy Street Railway

Noisy Street

Police Whistle at 15 Ft. Auto at 60 MPH

Very Noisy Restaurant. Auto at 40 MPH

Average Stenographic Room

Factories. Auto at 20 MPH

Noise in Pullman (Windows Shut)

Noisy Office

Average Restaurant

Dept. Store. Average Conversation at 3 Ft.

Average Office. Quiet Street

Noisy Residence

Quiet Restaurant

Quiet Office

Museum

Average School

Average Residence

Motion Picture Theater

Library Reading Rooms

Auditoriums

Average Whisper at 5 Ft.

Very Quiet Residence

10 2 20

SOUND PROOF

R OOMS

10

1

10

1

Broadcasting Studio

Zero of A.I.E.E. Scale 14 Db.

Zero of Original Scale 8.5 Db.

Threshold of Audibility

This document is for informational purposes only and should not be considered as a binding description of the products or their performance in all applications. The performance data on this page depicts typical performance under controlled laboratory conditions. AMETEK is not responsible for blowers driven beyond factory specified speed, temperature, pressure, flow or without proper alignment. Actual performance will vary depending on the operating environment and application.

AMETEK products are not designed for and should not be used in medical life support applications. AMETEK reserves the right to revise its products without notification. The above characteristics represent standard products. For product designed to meet specific applications, contact AMETEK Technical & Industrial Products Sales department.

AMETEK TECHNICAL & INDUSTRIAL PRODUCTS

75 North Street, Saugerties, NY 12477

USA: +1 215-256-6601 - Europe: +44 (0) 845 366 9664 - Asia: +86 21 5763 1258

Customer Service Fax: +1 215.256.1338

www.ametektip.com

I 9

____

Application Engineering Basics

Industrial Blower Noise Chart* in dBA

Model

SE

MF

RDC

SL2

SL4

SL5

Mode

Suction Pressure

60-62

64-65

76-78

69-72

72-78

76-79

60-62

64-65

76-78

69-72

72-78

76-79

101

202

303

353

404

454

Model

Mode

Suction Pressure

65-67

67-69

65-67

72-73

73-74

76-77

66-68

68-70

67-69

73-74

74-75

75-76

* Average at 1 meter, 4 places around the blower dBA at Distance Conversion Chart

To read, use straight edge to connect blower distance and dBA rating. A pivot point A will be developed.

Use straight edge again with new distance and pivot point A to read dBA at new distance.

Model

513

505

523

555

656

6

Mode

Suction Pressure

80-81

77-78

82-83

80-81

82-83

85-86

80-81

76-77

82-83

80-81

82-83

85-86

Model

757

808

633

S7

858

833

Mode

Suction Pressure

83-85

84-85

81-82

88-89

84-85

82-84

84-86

84-85

81-82

88-89

84-85

82-84

Model

S/P 9

909

1233

S/P 13

14

S/P 15

Mode

Suction Pressure

90-91

81-82

84-85

87-88

86-87

91-92

90-91

84-86

84-85

90-91

86-87

91-92

This document is for informational purposes only and should not be considered as a binding description of the products or their performance in all applications. The performance data on this page depicts typical performance under controlled laboratory conditions. AMETEK is not responsible for blowers driven beyond factory specified speed, temperature, pressure, flow or without proper alignment. Actual performance will vary depending on the operating environment and application.

AMETEK products are not designed for and should not be used in medical life support applications. AMETEK reserves the right to revise its products without notification. The above characteristics represent standard products. For product designed to meet specific applications, contact AMETEK Technical & Industrial Products Sales department.

AMETEK TECHNICAL & INDUSTRIAL PRODUCTS

75 North Street, Saugerties, NY 12477

USA: +1 215-256-6601 - Europe: +44 (0) 845 366 9664 - Asia: +86 21 5763 1258

Customer Service Fax: +1 215.256.1338

www.ametektip.com

I 10

____