1

Superconducting Magnetic Energy Storage (SMES)

in Power Systems with Renewable Energy Sources

Knut Erik Nielsen, Marta Molinas

Department of Electric Power Engineering

NTNU

Trondheim, Norway

Email: knutern@stud.ntnu.no

Abstract—A power conditioning system consisting of a Superconducting Magnetic Energy Storage (SMES) which can be used

to smooth out differences between output power of a generator

and power loads is analyzed in this paper. The SMES is connected

in shunt with the distribution lines through a converter. The

converter is a voltage source converter type with a DC-chopper.

The system is controlled by three regulators; they are working

on the DC-link voltage, the power to and from the SMES and

the AC-currents in the inverter. The regulators controlling the

power flow and the AC-currents are cascaded and the DC-link

voltage controller is situated in an independent loop with its

voltage kept constant using the SMES. Simulations have been

carried out using the software PSCAD/EMTDC.

Index Terms—Energy storage, SMES, AC-DC/DC-DC converter, PSCAD.

I. I NTRODUCTION

R

ENEWABLE energy sources will have a key role in

supplying energy in the future. More exactly wind power

and other types of new renewables. There are several issues

regarding large scale integration of new renewables into the

power system. One of the problems is the security of supply.

It is not possible to control the power output from a wind

park, or the output from a wave energy power plant as it is

for hydropower. These energy sources will provide energy, or

not provide, independent of the demand. The output power can

also have relatively large variations within a short time span.

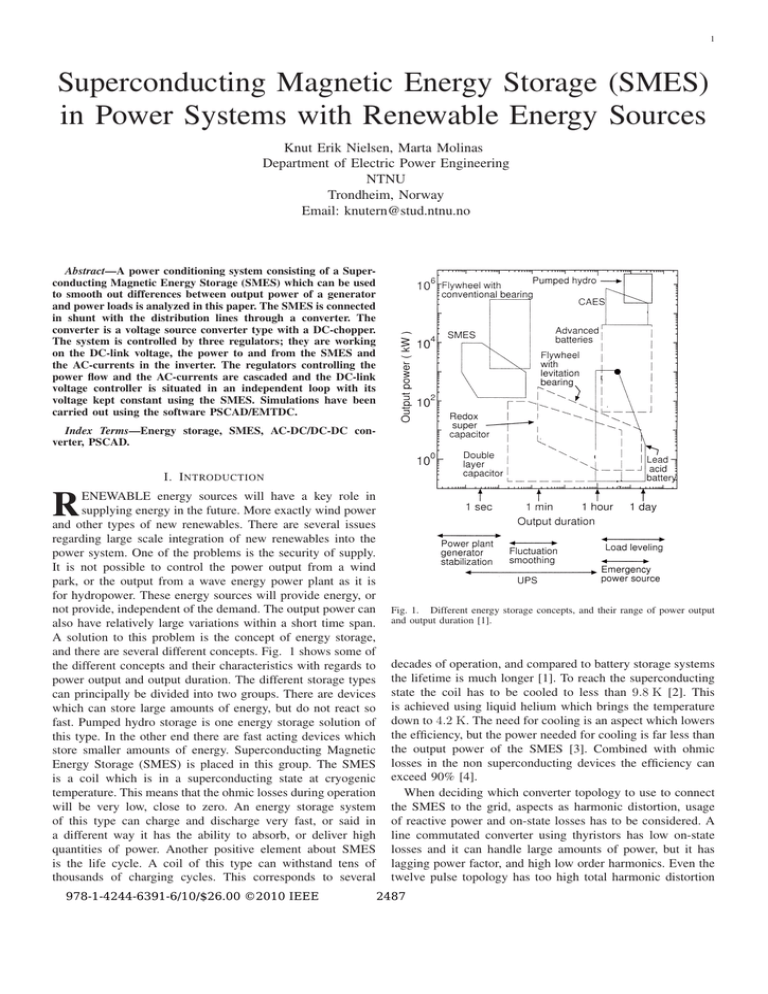

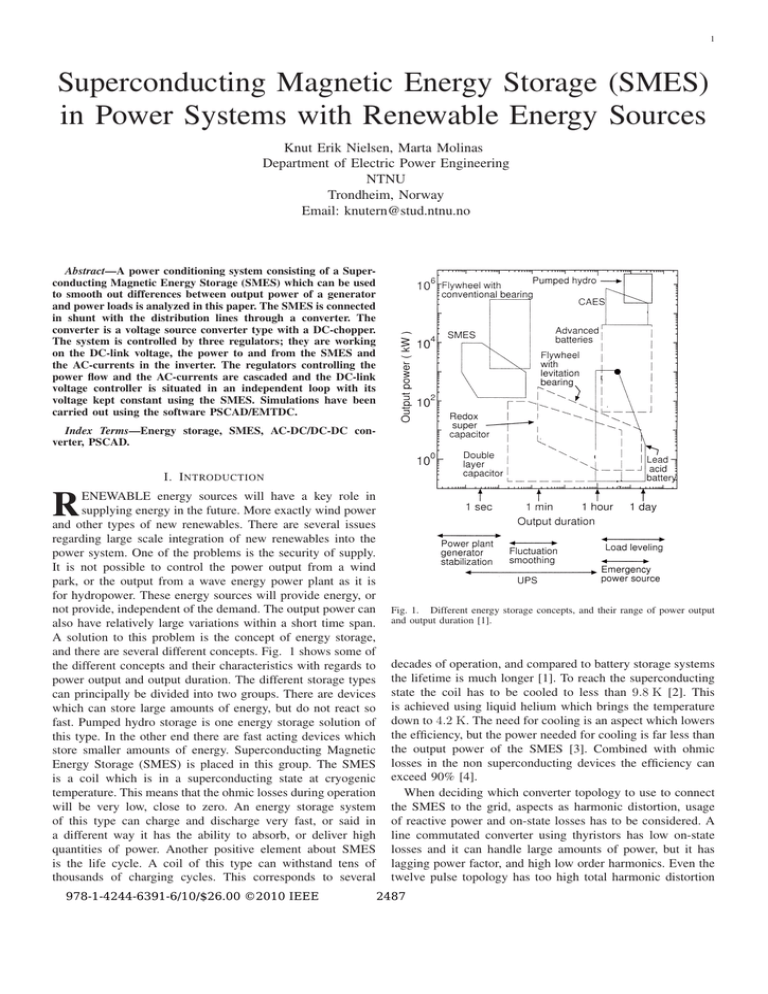

A solution to this problem is the concept of energy storage,

and there are several different concepts. Fig. 1 shows some of

the different concepts and their characteristics with regards to

power output and output duration. The different storage types

can principally be divided into two groups. There are devices

which can store large amounts of energy, but do not react so

fast. Pumped hydro storage is one energy storage solution of

this type. In the other end there are fast acting devices which

store smaller amounts of energy. Superconducting Magnetic

Energy Storage (SMES) is placed in this group. The SMES

is a coil which is in a superconducting state at cryogenic

temperature. This means that the ohmic losses during operation

will be very low, close to zero. An energy storage system

of this type can charge and discharge very fast, or said in

a different way it has the ability to absorb, or deliver high

quantities of power. Another positive element about SMES

is the life cycle. A coil of this type can withstand tens of

thousands of charging cycles. This corresponds to several

978-1-4244-6391-6/10/$26.00 ©2010 IEEE

Fig. 1. Different energy storage concepts, and their range of power output

and output duration [1].

decades of operation, and compared to battery storage systems

the lifetime is much longer [1]. To reach the superconducting

state the coil has to be cooled to less than 9.8 K [2]. This

is achieved using liquid helium which brings the temperature

down to 4.2 K. The need for cooling is an aspect which lowers

the efficiency, but the power needed for cooling is far less than

the output power of the SMES [3]. Combined with ohmic

losses in the non superconducting devices the efficiency can

exceed 90% [4].

When deciding which converter topology to use to connect

the SMES to the grid, aspects as harmonic distortion, usage

of reactive power and on-state losses has to be considered. A

line commutated converter using thyristors has low on-state

losses and it can handle large amounts of power, but it has

lagging power factor, and high low order harmonics. Even the

twelve pulse topology has too high total harmonic distortion

2487

2

Fig. 3.

VSC.

The DC-DC converter connecting the SMES to the DC-link of the

Fig. 2.

Single line diagram of the system investigated.

to meet the standards regarding harmonics [5]. Because of

these drawbacks, a self commutating converter is selected in

this paper. Even though the on-state losses are higher than

for thyristors, these have better characteristics when it comes

to harmonics and their reactive power flow can be controlled.

Among the self commutated converters there are mainly two

different to choose from: Current source converter (CSC) and

voltage source (VSC) converter. The CSC may seem as the

most suitable solution as the SMES can be viewed upon as a

current source. This converter has also proved to be the more

suitable for delivering active and reactive power quickly into

the network [5]. A CSC is also more efficient when operated

in square-wave mode than a PWM VSI [6]. On the other hand

a CSC is more complicated to control than a VSC [7], it has a

high level of low order harmonics and the inductance in the DC

side makes the response slower [6]. Therefore a VSC has been

chosen here. This topology is better known than the CSC, and

literature regarding this converter type is more comprehensive.

II. T HE SYSTEM TOPOLOGY

The topology of the system which is being studied is shown

in Fig. 2. It consists of an induction generator with a rated

power of 2 MW. This is connected to a grid through a stepup transformer (T1) with ratio 0.69/22 kV. The system has

a constant pure active load of 0.5 MW per phase. In order

to magnetize the induction generator a main grid is also

connected. The SMES coil is connected in shunt with the

lines through a transformer (T2), which is equal to T1. The

converter is a VSC and a DC chopper connected via a DClink. The SMES is connected at the output terminals of the

DC chopper. The inductance of the coil is 1.8 H. The base

frequency in the system is 50 Hz.

A. The DC-DC converter

The DC-DC converter which has been used is the chopper

shown in Fig. 3 [8]. This converter has been studied using

the software PSIM and PSCAD/EMTDC. The two switches

TA and TB are modeled as fairly ideal IGBTs having a

ON-resistance of 0.001 Ω, OFF-resistance of 106 Ω. These

switches are controlled using PWM switching technique. The

two switches are controlled by the same function, and are

both ON or OFF at the same time. The control of the IGBTs

is achieved by comparison of a DC control voltage, Vcon and

a triangular voltage Vtri . Vtri has a minimum value of -1.0

and a maximum value of +1.0. The following describes the

relationship between Vcon and Vtri :

ma =

Vcon

V̂tri

(1)

ma can attain values between -1 and +1. The following

explains the behaviour of TA and TB :

Vtri < Vcon → TA and TB are ON

Vtri > Vcon → TA and TB are OFF

As can be seen from Fig. 3 the voltage across the coil VL

will switch between ±Vdc . The relation:

di

(2)

dt

shows that when the IGTBs are ON, and the voltage across the

inductor is +Vdc the current in the coil will increase. When

the IGBTs are OFF, VL will be equal to −Vdc and the current

in the coil will decrease. There is also a third state, which is

steady state, or stand by. This state is when the current in the

coil is constant. These three states can be described using ma :

ma > 0 : The coil will be in the charge state.

ma < 0 : The coil will be in the discharge state.

ma = 0 : The coil will be in steady state.

During the different states the current will not have a completely constant increase or decrease. But on average it will

increase when ma is greater than zero and decrease when it is

less than zero. In steady state mode the charge period of the

coil will be equal to the discharge period, and the current will

fluctuate around a certain value. Fig. 4 shows how the current

increase and decrease, but increase on average during several

switching periods. For comparison and exemplification ma has

VL = L

2488

3

0.12

ma = 0.4

ma = 0.8

0.1

Current (A)

0.08

0.06

0.04

0.02

0

0

Fig. 4.

0.2

0.4

0.6

0.8

1

Time (s)

1.2

1.4

1.6

1.8

2

The current in the SMES coil during charge.

Fig. 5.

been set equal to 0.4 and 0.8, and the carrier signal has been

given a frequency of 2 Hz and amplitude of ±0.5. The larger

the absolute value of ma , the smaller is the current derivative

in the opposite direction than the average current derivative as

can be seen from Fig. 4. The higher the switching frequency

is, the smaller is the current flow in the opposite direction than

the average current direction in each switching interval.

In a real case simulation the charging and the discharging

of the coil will have to be automatic. The control techniques

will be described later in this text.

B. AC-DC converter

The AC-DC converter is a conventional six switch full

bridge converter shown in Fig. 5. This means that the converter

can act as a rectifier and inverter. A capacitor is connected

in shunt between the two converters in the DC-link. The

capacitor is connected in order to keep the DC-voltage on

a constant level. The switching devices are IGBTs having the

same properties as those in the DC-DC converter. The DCside of the converter is connected to the terminals of the DCchopper. The switching is controlled using a PWM-switching

scheme, comparing a high frequency triangular signal and a

voltage reference signal. The reference signal is made using

d-q transformation. The d-q transformation secures simpler

calculation in the control loops because of the reduction from

three AC quantities to two DC quantities. It also enables the

possibility to control active and reactive power independent

from each other [9].

III. C ONTROL SYSTEM

The control system consists of three regulators. A DC-link

voltage controller, an active power controller and a current

controller. See appendix for block diagram and parameters

of the regulators. The parameters has been calculated using

the modulus optimum tuning criterion for the inner current

controller, and the symmetric optimum tuning criterion for

the other two regulators. The DC-link voltage regulator is

aimed at keeping the DC-link voltage on a constant reference.

This regulator is a PI-regulator (proportional-integral). The

reference voltage is set to be equal to 1.0pu, which equals

1.1 kV. The output of the regulator gives the voltage reference

for the DC-chopper, which is compared with a triangular

The VSC converter used between AC-grid and DC-link.

voltage. This means that the superconducting coil is being

charged or discharged to keep the voltage in the DC-link on a

constant level, or said in another way keep the current in the

DC-link capacitor near zero. This secures that the control of

the charging of the coil will be fast and accurate as the control

structure consists of only one block.

The control of the AC-DC converter is composed by two

cascaded regulators. The outer controller is the active power

controller. The reference for this regulator is the difference

between the generated power from the induction generator and

the active power demand by the load. The error is passed

through a PI-regulator and gives a reference current idref . This

reference goes into the inner current controller which output

is the voltage reference for the PWM. The output of the PWM

is the triggering signals for the IGBTs in the converter.

IV. S IMULATIONS

The power system in Fig. 2 has been simulated using the

software PSCAD/EMTDC. Simulations with different inductance values have been performed. The inductance values

are: 0.18 H, 1.8 H and 12 H. The sequence of events in the

simulation are given in Table I. This line of events takes

the SMES through all the three different states. The negative

sign before the torque reference indicates that it is driven as a

generator. -1.0pu corresponds to rated power, which is 2 MW.

This leaves 0.5 MW of extra power because the total load

is only 1.5 MW. The extra power is used to charge the coil.

When the torque reference is reduced to 0.75pu, the generated

power is equal to the load power, and the SMES is in steady

state, drawing no power nor supplying power to the network.

As the torque reference drops to 0.6pu the power from the

generator is not large enough to supply the loads. This takes

the SMES into the discharging state, which means that it

TABLE I

T HE SEQUENCE OF EVENTS IN THE SIMULATION STUDY

Time (sec)

0.0

2.0

4.0

6.0

2489

Event

System start up, generator control mode set to torque

control, and torque reference set to -1.0pu

Generator torque reference set to -0.75pu

Generator torque reference set to -0.6pu

Simulation stops

4

4.5

3

4

2.5

3.5

Charge

Steady state

Discharge

2

Current (kA)

Power (MW)

3

1.5

1

L=0.18 H

2.5

2

L=1.8 H

1.5

0.5

1

0

-0.5

0

Fig. 6.

L=12 H

0.5

1

2

3

Time (s)

4

5

Power output from the induction generator in the system of Fig. 2.

1.5

0

0

6

1

2

3

Time (s)

4

6

Fig. 8. The current profile in the SMES coil during charge, standby and

discharge for different inductances.

Power in SMES

Power reference for SMES

L = 1.8 H

L = 0.18 H

L = 12 H

1

1.2

Charge

0.5

Steady state

Discharge

1

0

Energy (MJ)

Power (MW)

5

-0.5

-1

-1.5

0

L = 12 H

L = 1.8 H

0.8

L = 0.18 H

0.6

0.4

1

2

3

Time (s)

4

5

0.2

6

0

0

Fig. 7. The reference power in the SMES and the actual power in the SMES

with 1.8 H coil.

supplies power to the grid. For comparison the simulation has

also been carried out when the SMES is not connected to

the grid. Fig. 6 shows the power output from the induction

generator. The first 0.2 second is the generator start-up period,

this results in some transients, but these have not been given

any consideration. As can be seen the power output does not

change instantaneously due to inertia in the generator. It is also

clear that 75% torque reference does not completely comply

with 75% power output from the generator.

The power flow in the SMES (grey line) is shown in Fig. 7

together with the difference between the generated power and

the load (black line). This difference is the reference for the

SMES power. The plot shows that the power to and from the

SMES follows the reference very good for these operating

conditions. As aforesaid the first 0.2 second is the start-up

period of the generator. During this period the reference power

for the SMES is set to zero to avoid the controller from trying

to follow the difference between generated power and the load

under transitory conditions.

The current and the energy in the superconducting coil

during the same sequence of simulation is shown in Fig. 8 and

Fig. 9 for the three different inductance values. The relation

between current and energy is:

E=

1 2

LI

2

(3)

The different current values and energy levels can be found in

table II. The maximum current level in the coil with the

Fig. 9.

1

2

3

Time (s)

4

5

6

The energy in the SMES for different inductances.

TABLE II

T HE ENERGY AND CURRENT LEVELS IN SMES COIL WITH DIFFERENT

INDUCTANCES .

Max current

Current at end of steady state

Current at end of simulation

Max energy

Energy at end of steady state

Energy at end of simulation

0.18 H

3.265 kA

3.145 kA

1.733 kA

0.959 MJ

0.890 MJ

0.270 MJ

1.8 H

1.058 kA

1.048 kA

0.658 kA

1.01 MJ

0.988 MJ

0.390 MJ

12 H

0.4122 kA

0.4095 kA

0.270 kA

1.02 MJ

1.01 MJ

0.437 MJ

least inductance is much higher than the current levels of

the coils having larger inductance. But the energy level is as

seen lower. The low inductance coil does also lose more of

its stored energy during the steady state than the others. The

reason for the more varying current is given by Lenz’s law

[10] which says that there will be induced an emf to oppose

the change of current. This opposing emf is stronger in a

coil having more inductance, and thereby the coil having the

least inductance will experience more change in the current.

An advantage of the low inductance coil is that it can react

quicker on demands from the network. On the other side

is the large inductance coil which stores more energy, but

have a somewhat slower reaction time. Anyway the response

time is very short, so this is not a major issue. The low

current in the 12 H-coil can be an advantage when it comes to

equipment. It would mean less demand on the current handling

capabilities of non superconducting components in the system.

2490

5

0.6234

V. S IZING OF UNITS IN THE SYSTEM

0.6233

0.6233

Current (kA)

0.6232

0.6232

0.6231

0.6231

0.623

0.623

0.6229

1.904

Fig. 10.

1.9041 1.9042 1.9043 1.9044 1.9045 1.9046 1.9047 1.9048 1.9049

Time (s)

1.905

Zoom of the current in the coil during charge.

The maximum current in the low inductance coil is almost

seven times higher than for the high inductance coil. It is

also evident that the maximum energy in the 12 H-coil and

the 1.8 H-coil are quite similar. The decrease in the current

during the steady state period is very large for the 0.18 H-coil

and the current decrease is also present for the two others.

These losses comes from the path the current will have to

flow during steady state, and the fact that it is difficult to tune

the output from the generator to be exactly similar to the load

power and thereby the power reference equal to zero.

Fig. 11 shows the power exchange with the interconnected

power grid. It is evident that in the case of no SMES the

interconnected network has to absorb or cover the power

fluctuations from the generator. The differences between the

different inductance cases consist of some fluctuations in the

beginning, and a decrease in power at the end of the simulation

time for the 12 H-coil. The reason for this power dip is that

the current in the coil goes under a certain threshold. In order

to deliver the requested power, the DC-link voltage will have

to increase beyond its limit. When this does not occur, the

power output from the SMES decreases. The DC-link voltage

can be increased in order to utilize more of the energy in the

coil. However this is outside the scope of this paper. The 12 Hsetting has the largest fluctuations in the power exchange. This

is due to the longer settling time of the DC-link voltage when

the inductance is large.

1.2

L = 0.18 H

L = 1.8 H

L = 12 H

No SMES

1

0.8

Power (MW)

0.6

0.4

0.2

0

-0.2

-0.4

0

Fig. 11.

0.5

1

1.5

2

2.5

3

3.5

Time (s)

4

4.5

5

5.5

The power exchange with the interconnected power grid.

6

The current in the SMES coil is the constraining factor on

the switching units. The simulations show that the maximum

current is around 1 kA. A current of this magnitude will not

make any difficulties regarding the availability of devices.

Semiconductors like the ones used in this system can handle

up to 2.4 kA [11] when it comes to IGBTs, and currents

much higher than this when it comes to diodes. The reference

value of the DC-link voltage is 1.1 kV. On the AC side

the peak of the line to line voltage is 976 V. Neither the

voltage magnitudes make any difficulties when it comes to

the availability of devices. An IGBT having a current rating

of 2400 A and voltage rating of 1700 V [12] will fulfil the

requirements in the operation. It will also introduce safety

margins. The constraining factor in the SMES coil is the current. The maximum current is called its critical current. Above

this current the coil will lose its superconductivity. Therefore

it is important to stay below this limit and include a safety

margin [2]. The coil inductance will influence the amount

of stored energy, and is a parameter which is determined by

the number of turns, the cross sectional area, and the length

of the wire [10]. The inductance of the coil in this system

has been chosen to be fairly low because the unit is used to

compensate power fluctuations and thus the stored energy level

is not the highest priority. An inductance of 1.8 H has through

simulations proved to be a good choice for this purpose.

VI. C ONCLUSION AND FURTHER WORK

In this paper a power conditioning system for a SMES coil

has been studied for load leveling in a power system with

renewable energy sources. The energy storage system has been

connected in shunt with the power grid. A comparison between

three different inductance values of the SMES-coil has also

been performed. From the comparison the 1.8 H-coil proved

to be the most suitable. The energy level in this coil was

slightly less than for the 12 H-coil, but the large inductance

coil was not able to deliver the requested power for the entire

simulation. The small inductance coil introduced too high

current in the DC-link. The control system of the converter has

been divided into two parts. One PI-regulator controlling the

DC-voltage with the DC chopper and two cascaded regulators

where the outer one is controlling the power flow in the SMES

and the inner regulator controls the current in the AC-DC

converter. This division ensures a faster reaction time from

the controllers than if all the regulators where connected in

series. The simulation results show that the SMES will relieve

the strain on the connection to the interconnected grid and

work as a supplementary power source when the power from

the induction generator fluctuates as when coming from wind

or wave sources. Further work which can be done involves

improving the steady state response of the SMES current. A

current source converter topology replacing the voltage source

converter topology and DC-chopper will also be investigated.

Different connection strategies of the SMES should also be

investigated. This includes series compensation instead of

shunt compensation and both shunt and series compensation

at the same time.

2491

6

A PPENDIX

B LOCK DIAGRAMS FOR THE REGULATORS

Vdc,ref,pu

−

Fig. 12.

vs

Kpv,pu 1+T

Tv s

P I−controller

1

1+Ta s

ωb Cpu

s

DC−chopper System

R EFERENCES

Vdc,pu

The DC-voltage controller.

TABLE III

T HE PARAMETERS IN THE DC- VOLTAGE CONTROLLER

Parameter

Kpv,pu

Tv

Ta

ωb

Cpu

iref

−

Fig. 13.

Value

63.48

0.0016

1

T

= 0.0001

2 switch

100π

0.125358336

is

Kpi,pu 1+T

Ti s

1

1+Ta s

1

1

Rpu 1+τpu

P I−controller

V SC

System

i

The inner current controller.

TABLE IV

T HE PARAMETERS IN THE INNER CURRENT CONTROLLER

Parameter

Kpi,pu

Ti

Ta

Rpu

τpu

Pref

−

Fig. 14.

Kpp,pu

[1] J. Kondoh, I. Ishii, H. Yamaguchi, A. Murata, K. Otani, K. Sakuta,

N. Higuchi, S. Sekine, and M. Kamimoto, “Electrical energy storage

systems for energy networks,” Energy Conversion & Management,

vol. 41, pp. 1863–1874, February 2000.

[2] J. Bray, “Superconductors in applications; some practical aspects,” IEEE

Transactions on Applied Superconductivity, vol. 19, pp. 2533–2539, June

2009.

[3] T. Katagiri, H. Nakabayashi, Y. Nijo, T. Tamada, T. Noda, N. Hirano,

T. Nagata, S. Nagaya, M. Yamane, Y. Ishii, and T. Nitta, “Field test

result of 10mva/20mj smes for load fluctuation compensation,” IEEE

Transactions on Applied Superconductivity, vol. 19, pp. 1993–1998, June

2009.

[4] P. Tixador, “Superconducting magnetic energy storage: Status and perspective,” IEEE/CSC & ESAS European superconductivity news forum,

January 2008.

[5] D. Casadei, G. Grandi, U. Reggiani, and G. Serra, “Analysis of a

power conditioning system for superconducting magnetic energy storage

(smes),” in IEEE International Symposium on Industrial Electronics,

1998. Proceedings. ISIE ’98., vol. 2, pp. 546–551 vol.2, Jul 1998.

[6] C. Hawley and S. Gower, “Smes pcs topology design - a critical comparison of inverter technologies,” tech. rep., School of Electrical, Computer

and Telecommunications Engineering, University of Wollongong, 2002.

[7] J. ichi Itoh, I. Sato, A. Odaka, H. Ohguchi, H. Kodachi, and N. Eguchi,

“A novel approach to practical matrix converter motor drive system with

reverse blocking igbt,” IEEE Transactions on Power Electronics, vol. 20,

pp. 1356–1363, Nov. 2005.

[8] A. Esmaieli, S. Niaki, A. Tajfar, and H. Nademi, “Unified modeling of

upfc-smes in power system application,” in Industrial Electronics and

Applications, 2008. ICIEA 2008. 3rd IEEE Conference on, pp. 2051–

2056, June 2008.

[9] V. Blasko and V. Kaura, “A new mathematical model and control of

a three-phase ac-dc voltage source converter,” IEEE Transactions on

Power Electronics, vol. 12, pp. 116–123, Jan 1997.

[10] H. D. Young and R. A. Freedman, Sears and Zemansky’s University

Physics with Modern Physics. Pearson Addison Wesley, 11 ed., 2004.

[11] V. K. Khanna, IGBT Theory and Design. Wiley-Interscience, 2003.

[12] ABB, ABB HiPak IGBT Module datasheet.

Value

15.9156

0.0849

1

T

= 0.0001

2 switch

0.00375

0.08488

1+Tp s

Tp s

P I−controller

1

1+Teq s

vd

P

Inner

current

controller

The outer power controller.

TABLE V

T HE PARAMETERS IN THE OUTER POWER CONTROLLER

Parameter

Kpp,pu

Tp

Teq

Rpu

vd

Value

4

0.0032

2Ta = 0.0001

0.00375

≈1

2492