Superconducting Magnetic Energy Storage Concepts and

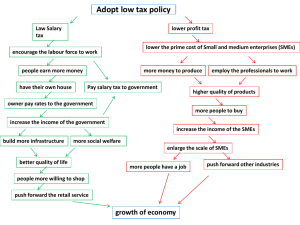

advertisement

Superconducting Magnetic Energy Storage Concepts and applications Antonio Morandi DEI − Guglielmo Marconi Dep. of Electrical, Electronic and Information Engineering University of Bologna, Italy ESAS Summer School on High Temperature Superconductors Technology for Sustainable Energy and Transport Systems Outline • SMES technology SC material and Conductor Coil Power conditioning system A case study - 1 MW / 5 s SMES • Applications Energy storage SMES applications Grid Customer / Industry • SMES actvities at the University of Bologna 2 SMES – Superconducting Magnetic Energy Storage PCS grid Current leads vacuum vessel Control and protection system Superconducting coil Cooling system 2 2 B B 1 2 E=∫ dτ ≈ ∫ dτ = L I 2 τ ∞ 2µ0 τ coil 2 µ 0 3 Advantages • High deliverable power • Infinite number of charge discharge cycles • High efficiency of the charge and discharge phase (round trip) • Fast response time from stand-by to full power • No safety hazard Critical aspects • Low storage capacity • Need for high auxiliary power (cooling) • Idling losses 4 Conductor and cable YBCO 16 K 20 K 24 K YBCO, B perpendicular 16 K MgB2 20 K 24 K MgB2 Main characteristics of a typical MgB2 Conductor Manufacturer Columbus Nominal radius 1.13 mm Number of filaments 36 Filling factor 0.14 Matrix Ni 70%, Copper 20 % Critical tensile strength 300 MPa Critical current, 22 K, self field 550 A Main charact. of a typical YBCO Coated Conductor Manufacturer Superpower Nominal Width 12 mm Nominal thickness 0.1 mm YBCO 1 µm Stabilizer, copper 2×20 µm Substrate, Hastelloy 100 µm Critical tensile strength 550 MPa Critical current, 77 K, self field 330 A 5 • Typical current for the SMES operating in the MW range is in the order of several kA • Several conductors have to be put in parallel for reaching the required transport current High current conductor made of 2G HTS tapes Continuously transposed (Roebel) cable • • Scraps are produced Je cable = 0.8 – 0.9 Je tape Slotted cable made of Roebels • Je cable << Je tape 6 Twisted stacked-tapes Cable made of twisted stacks • Je cable << Je tape Conductor on Round Core (CORC) cable Institute of Electrical Engineering Slovak Academy of Science 7 CCRP Cable Centre de Recherches en Physique des Plasmas ENEA Cable 10 kA – class cable: 150 2G-wires (5 stacks x 30 wires) 8 High current conductor made of MgB2 wires Flat Rutherford cable example 2 × 6 wires Stranded MgB2/Cu rope Copper MgB2 Example of Base Cable Unit: 12 MgB2 strands + 7 copper strands 1× 3× 7× 9 Layout of the winding – Arrangement of multiple pancake 5 MJ coil - 4T Solenoid • Simpler and more cost effective • Easier handling of the electromagnetic stress • Smaller foot-print Torus • Low stray field • Reduced component of magnetic field perpendicular to the conductor 10 Length of conductor versus the perpendicular field at the maximum current 5 MJ coil - 4T A large portion of conductor experiences a large perpendicular field in the toroid as well 11 Coil design – electromagnetic R′1 = p R1 L′= p L ∆ R′1 = ∆ R1 R′1 R1 L′ L ∆R H = Je ∆ R1 H = Je ∆ R′1 ∆R′ H2 E' = π R'12 L' = p 3 E 2µ0 ( ) VSC ' = π ( R'1 + ∆R ' ) 2 − R'12 L' ≈ p 2VSC The volume of the superconductor scales less than linearly with the energy of the coil VSC = k E 2 3 12 Coil design – mechanic V ≥k 1 σ E Virial’s theorem limit V, volume of structural material [m3] E, total energy of the coil [J] σ, allowable stress [N/m2] k, numerical coefficient ( ≥ 1 ) At high energy the structural constraint is stricter than the electromagnetic one Additional structural (and stabilizing ) material is required volume For solenoid k ranges from 1 if D/L tends to zero to 3 if D/L tends to infinite. ∝E ∝ E2/3 energy 13 Field dependence of the total conductor’s length • The required stored energy E is assigned • The operating field B of a the SC coil is a design choice By increasing the field • A reduced overall size of the coil is obtained which requires less conductor • More ampere-turns at reduced Jc are needed which require more conductor Which of the two effects is dominant? 14 E B p Stape Je k • slim solenoid • given aspect ratio • Isotropic conductor Volume of the solenoid Stored Energy Nominal Field aspect ratio ( L / D ) of the solenoid cross section of the tape Eng. current dens. of the tape at field B I / Ic ratio Vsolenoid ≈ 2µ 0 E / B 2 1 3 8µ 0 − 23 D =π L ⇒ D = E B π 4 p 2 Diameter of the solenoid Vsolenoid Height of the solenoid 8µ0 p − 23 L = p D = E B π Superconducting cross section 2 1 3 k J e ( B ) S SC = H L ⇒ S SC Total length of tape N tape 1 3 8p 13 S SC 1 = = E B Stape Stape k J e ( B ) π µ 20 2 Number of turns 1 3 13 1 8p = E B k J e ( B ) π µ 20 2 LSC π 1 3 − 1 3 64 p 2 B 2 = π N tape D = E Stape k π µ 0 J e ( B) 15 LSC ( B ) ≤ LSC ( B' ) ⇔ B' J e ( B) ≥ J e ( B' ) B 1 3 YBCO, 16 K, B perpendicular J e (4) * (4 B ) 13 MgB2 , 16 K J e (2) * (2 B ) 13 For practical superconductors (YBCO and MgB2) the required length of conductor needed for a solenoid with given Energy E increases with the operating field 16 Outline • SMES technology SC material and Conductor Coil Power conditioning system • Applications Energy storage SMES applications Grid Customer / Industry 17 PCS – the magic box P I 0 AC Grid PCS SMES I0, current of SMES at time t0 I1, current of SMES at time t1 1 1 2 2 L I − LI 0 = − P (t − t0 ) 2 2 I = I 02 − 2 P (t − t0 ) L 1 2 1 2 L I − L I1 = P (t − t1 ) 2 2 I = I12 + 2 P (t − t1 ) L During discharge During charge I0 I1 t0 t1 18 PCS - Power Conditioning System Voltage source converter (VSC) Vdc L C ISMES • A controlled power is transferred from the DC bus to the grid by means of the inverter • The voltage of the DC bus is kept constant by the SMES by means of the two quadrant chopper 19 Idc P = V I cosϕ Vdc C The inverter regulates the power transfer between the grid and the capacitor An average positive current is established on the DC bus during power transfer to grid P ≈ Vdc < Idc > Vdc The voltage of DC bus decreases if the capacitor is not recharged time 20 The chopper controls the voltage of the DC bus Idc Discharge P = V I cosϕ I′dc Vdc L C i′dc ISMES ISMES < I ′dc > = < Idc > ⇓ Vdc ≈ constant The current of the SMES decreases during the ON phase TON < I ′dc > TOFF Tcycle time If the power P is delivered to the grid during the interval ∆t final current of the SMES is 1 2 1 2 L I 2 − L I1 = P ∆t 2 2 I2, current of he SMES at the end of the delivery I1, current of he SMES at the start of the delivery 21 Charge Idc P = V I cosϕ I′dc Vdc L C i′dc TOFF − ISMES time < I ′dc > TON Tcycle ISMES < I ′dc > = < Idc > ⇓ Vdc ≈ constant The current of the SMES increase during the ON phase If the power P is absorbed from the grid during the interval ∆t final current of the SMES is 1 2 1 2 L I 2 − L I1 = P ∆t 2 2 I2, current of he SMES at the end of the delivery I1, current of he SMES at the start of the delivery 22 Implementation - control algorithm Grid Load SW vg Ls iL is inverter PWM vs* vg is R2 Vdc* + − Vdc ic* R3 PWM chopper − is* iL ig* + R1 vg Qg* ( = 0) Pg* • The inverter is controlled in order to provide the required service to the grid • The SMES is controlled independently in order to stabilize the 23 voltage of the DC bus Idling Loss If no power is delivered/absorbed the SMES current of the free-wheels P=0 Vdc L C Losses are produced during the idling phase ISMES Von IGBT = 0.5 − 1 V Von DIODE = 0.5 − 1 V PIGBT = ISMES Von IGBT PDIODE = ISMES Von DIODE Pidling = 1 − 10 kW / kA • Time constants of RL circuit of typical SMES (1-5 MJ) during the standby phases are in the order of hundreds of seconds at most 24 SMES • The whole energy of the SMES is lost in the power electronics within a few minutes • Continuous recharge/compensation is needed The use of a thermal actuated SC switch for avoiding the losses during the standby is possible in principle but it is unfeasible in practice since it lowers the response time of the SMES P=0 Vdc C ISMES L 26 Outline • SMES technology SC material and Conductor Coil Power conditioning system A case study - 1 MW / 5 s SMES • Applications Energy storage SMES applications Grid Customer / Industry • SMES actvities at the University of Bologna 27 Main characteristics of the 1 MW - 5s SMES Systems 28 Grid performance of the 1 MW - 5s SMES System 29 Estimated AC losses of the 1 MW - 5s SMES System during one discharge/charge cycle. Round trip efficiency of the 1 MW - 5 s SMES System during one discharge/charge cycle. 30 Outline • SMES technology SC material and Conductor Coil Power conditioning system • Applications Energy storage SMES applications Grid Customer / Industry 31 National electric balance - Italy Production (grid immission) Thermal Rinnovabili Importazioni Loss 310 TWh, 2014 47.5% 37.9% 14.0% 19.5 TWh (6 %) Average power demand • Night average (2011) • Day average(2011) • Absolute minimum (2009) • Absolute maximum ( 2015) 39.1 GW 22.0 GW 52.0 GW 21.5 GW 53.3 GW, 21 July Installed power (2012 ) Installed power (2010 ) Average available power (2012) 124.0 GW 106.0 GW 69.3 GW Usage rate 57.3 % 32 Electric power system ICT storage storage Non progr. power. Non progr. power Non progr. power Active load Active load 33 Grid energy management • Generation / load imbalance is inherent in the power grid due to random fluctuation of loads induced by customers variation of generation from renewables • Sudden and Large generation / load imbalance can also occur due to contingency • Continuous and fast regulation of the generated power and/or loads is required for controlling the frequency and stability of the grid. Technology for grid energy management • Improved controllability of conventional generation • Responsive load • Supergrid (multi-terminal DC links ) • Energy storage 34 Energy storage T&D system only allows to move energy in space Total power produced must instantaneously balance the total load (including the losses). Energy storage system allows to shift electric energy in time so as to decouple production and consumption 35 Energy intensive storage Performance of Storage Technologies Power intensive storage 1 MWh = 3600 MJ 1 MW × 6h NAS module 1 MW × 10 s SMES 38 6 MWh NAS system 6 MWh SMES system Efficiency of an Energy Storage System P, deliverable power ∆t , duration of delivery ∆ tcycle , duration of the cycle ∆ tidle, duration of idling phase ηs , intrinsic efficiency of the storage device ηc , efficiency of the converters Paux , power required for auxiliary services Pidle , power loss (if any) during idling energy idle power cycle PPP∆∆∆ttt η= η= η= P ∆t P ∆t P ∆t + Pidle ∆+tP + Pidle ∆tcycle idle idle ∆ taux η s ηc η s ηc η η s c 40 By summarizing … • Energy capacity of SMES is ridiculous compared to batteries • Idling losses in power converters do not allow long term storage • Cooling losses further complicate losses Is the SMES useless and hopeless? 41 Parameters of the energy storage • Power that can be absorbed or supplied, P • Duration of the power delivery, ∆t • Number of cycles, N • Response time, tr 42 Grid and Customer Applications of Energy Storage Bulk energy management market / less need for inefficient (low load) operation of power plants ∼ 10 - 100 MW × 1 h , 1 cycle per day grid Transient Stability Increased transmission limit ∼ 10 - 100 MW × 1-10 s, occasional Frequency regulation less need inefficient (low load) operation of power plant ∼ 1 - 50 MW × 1-15 min, 10-1000 cycles per day Other applications with more limited cost/benefit trade-off • damping of sub-synchronous resonance • black start • deferral of new transmission and distribution 43 Customer Power quality and UPS compensation of voltage sag + Power Quality services to the customer ∼ 1 - 10 MW × 0.1-100 s, occasional deep cycle + continuous minor cycles Leveling of impulsive power constant power absorption from grid 1 - 10 MW × 0.1-1 s, continuous cycles 44 Parmeters of Storage for Grid and CustomerApplications • lev. imp. power • Voltage quality • UPS • Trans. stability • lev. imp. power • Voltage quality • UPS • Trans. stability • Freq. regulation • Freq. regulation • Bulk en. man. • Bulk en. man. • lev. imp. power • Freq. regulation • Voltage quality • Bulk en. man. • UPS • Trans. stability 1. Power intensive systems Cost of battery scales with power and is roughly independent on the energy Example: battery system made of 1 MW × 1 h module, 1M€ cost each Case 1 Rated power Duration of delivery Rated energy Num. of modules Total Cost Specific cost 30 MW 1h 30 MWh 30 30 M€ 1 M€ / MWh Case 2 Rated power Duration of delivery Rated energy Total Cost Specific cost 30 MW 6 min 3 MWh 30 M€ 10 M€ / MWh 46 Cost of SMES scales with energy and is roughly independent on the power For example SMES is competitive in case 2 if the cost of 3 MWh storage is lower than 10 M€ Case 1 Rated power Duration of delivery Rated energy Num. of modules Total Cost Specific cost 30 MW 1h 30 MWh 30 30 M€ 1 M€ / MWh Case 2 Rated power Duration of delivery Rated energy Total Cost Specific cost 30 MW 6 min 3 MWh 30 M€ 10 M€ / MWh If a large power is required for a more limited time SMES can represent a cost effective storage technology 47 2. Hybrid SMES - Battery systems load battery Low pass control PCS High pass control SMES SMES can be conveniently used in combination with battery due to the complementary characteristics • • Battery provides long term base power – hence energy SMES provides peak power and fast cycling 48 • Reduced power rating of batteries • Reduced wear and tear of batteries (no minor cycling) • Reduced energy rating of SMES SMES Advantages: battery total Power vs time 49 3. Increasy peak power of industry scale batteries 1 MW × 6h NaS battery system with double peak power capacity • The power rating of the system is to be doubled for short times ( < 10 s ) due to power quality requirement • No impact is obtained on the total storage requirement due to the increased peak power capacity Solution 1 the battery pack is doubled • Cost is doubled • Energy capacity is also doubled but the system is greatly underexploited 50 Solution 2 SMES is added to the battery to provide short term peak power To scale (roughly) 1 MW – 6 h + 1 MW – 10 s Size and cost of the system can be greatly reduced !! 51 4. Protection of sensitive equipment Sensitive customer Voltage sags may occur in power grid due to faults Sensitive customers can only tolerate a voltage reduction f 30 &% for 200 ms 1 MW – 5 s SMES system The Kameyama SMES 10 MW – 1 s SMES system 54 5. Leveling of impulsive loads by SMES Pgrid Pload Ismes Pload Pload • • Pgrid Iload Igrid No battery can be used for this application due to the prohibitive number of cycles Advantages brought by SMES can be significant also for moderate size systems 55 Auxiliary network services by SMES Iload Igrid Ifilter ISMES • • Harmonic compensation Power factor correction 56 6. Hybrid SMES - Liquid Hydrogen system • Liquid Hydrogen is used as energy intensive storage • Free cooling power is available for SMES due to the presence of LH2 at 20 K • SMES is used as power intensive storage 57 Shintomi et al. 58 Outline • SMES technology SC material and Conductor Coil Power conditioning system A case study - 1 MW / 5 s SMES • Applications Energy storage SMES applications Grid Customer / Industry • SMES actvities at the University of Bologna 59 1. A 200 kJ Nb-Ti µSMES ( 2004 – 2007 ) Cold test in 2014 (and 2013) 60 2. Conduction cooled MgB2 SMES demonstrator (2014 – 2016) • 3 kJ MgB2 Magnet • 40 KW Mosfet Based PCS Cold test in porgress Full test at 1-10 kW to come shortly 61 3. Conduction cooled MgB2 SMES Prototype (2016 – 2019) MISE - Italian Ministry of Economic Development Competitive call: research project for electric power grid Project funded Budget: 2.7 M€ Duration: 2016-2019 300 kJ – 100 kW prototype full system To resume on SMES ….. • SMES is feasible, but AC loss need to be investigated SMES is an option if • Continuous deep charge/discharge cycling is required (leveling of impulsive loads) • Short term increase of peak power of energy intensive systems is required • Fast delivery of large power is required for short time 63 Thank you for your kind attention … … antonio.morandi@unibo.it