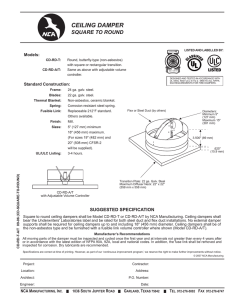

Heating, Ventilating and Air Conditioning

advertisement