Division 4-Miscellaneous

advertisement

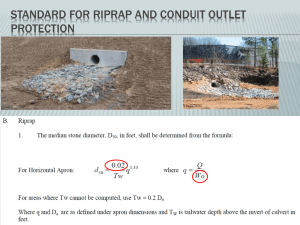

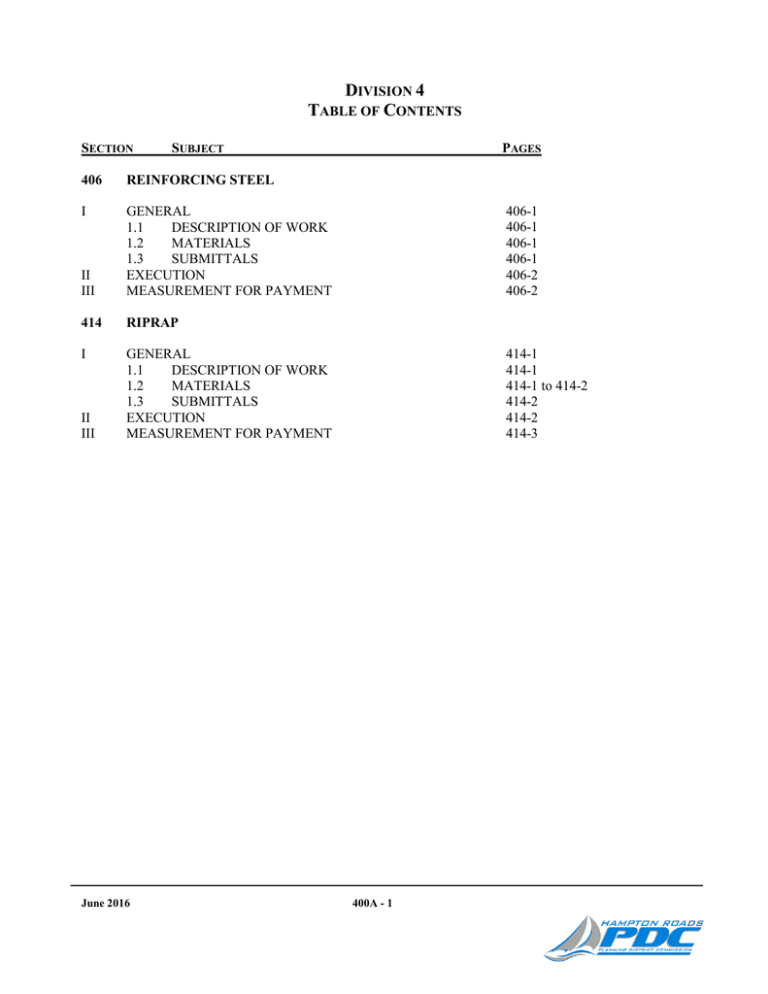

DIVISION 4 TABLE OF CONTENTS SECTION SUBJECT 406 REINFORCING STEEL I II III GENERAL 1.1 DESCRIPTION OF WORK 1.2 MATERIALS 1.3 SUBMITTALS EXECUTION MEASUREMENT FOR PAYMENT 414 RIPRAP I GENERAL 1.1 DESCRIPTION OF WORK 1.2 MATERIALS 1.3 SUBMITTALS EXECUTION MEASUREMENT FOR PAYMENT II III June 2016 PAGES 406-1 406-1 406-1 406-1 406-2 406-2 414-1 414-1 414-1 to 414-2 414-2 414-2 414-3 400A - 1 SECTION 406 REINFORCING STEEL I. GENERAL 1.1 DESCRIPTION OF WORK The Contractor shall furnish, fabricate, place and protect all reinforcing steel or wire mesh (including all wires, ties, clips, supports, chairs, spacers, and other accessories), used in concrete operations and masonry construction, all in accordance with the Contract Documents. 1.2 MATERIALS Materials shall be furnished by the Contractor in accordance with Section 200. 1.3 SUBMITTALS A. Submittals shall be made by the Contractor in accordance with the procedures set forth in Section 105 and as described below: The Contractor shall submit complete shop drawings of all material proposed to be furnished and installed under this Section. These drawings shall include: 1. Bar schedules, stirrup spacing, diagrams of bent bars, reinforcement arrangement and assemblies, bar splices and laps. 2. The drawings shall provide sufficient detail to permit placement of reinforcement without use of design drawings. 3. Shop drawings shall satisfy the requirements of ACI Standard 315. B. Accompanying the shop drawings, the Contractor shall submit the steel producer’s certificates of mill analysis, tensile, and bend tests for reinforcing steel. C. Where mechanical couplers are required or permitted to be used to splice reinforcing steel, the Contractor shall submit manufacturer’s literature which contains instructions and recommendations for installation for each type of coupler used; certified test reports which verify the load capacity of each type and size of coupler used; and shop drawings which show the location of each coupler with details of how they are to be installed in the formwork. D. If reinforcing steel is spliced by welding at any location, the Contractor shall submit mill test reports that shall contain the information necessary for the determination of the carbon equivalent as specified in AWS D1.4. The Contractor shall submit a written welding procedure for each type of weld for each size of bar which is to be spliced by welding. E. Welders shall be qualified per AWS and Contractor shall submit welder qualifications prior to beginning work. June 2016 406 - 1 II. EXECUTION The Contractor shall execute the Work in accordance with the latest edition of the VDOT Road and Bridge Specifications, Section 406.03, Procedures. Any references to “Engineer” or VDOT personnel shall mean the “Owner”. III. MEASUREMENT FOR PAYMENT A. Reinforcement steel, when a pay item, will be measured in pounds of steel placed in the structure as shown in the Contract Documents or Standard Details. The weight of welded wire mesh will be computed from the theoretical weight per square yard placed, including allowance for laps not to exceed 8 percent of the net area. Reinforcing steel or welded wire mesh will be paid for at the contract unit price per pound. B. Epoxy-coated reinforcement steel, when a pay item, will be measured in pounds of uncoated steel and will be paid for at the contract unit price per pound. The weight will be computed from the theoretical weights of the nominal sizes of steel specified and placed in the structure. Measurement will not be made for epoxy-coating material. C. When not a pay item, the cost of reinforcing steel shall be included as an incidental item in the bid price for other specified pay items. D. Items considered incidental work will not be measured for payment or paid for as such. Incidental items are identified in Section 109.1.2 and also include the following: Furnishing, applying, and repairs of epoxy-coating material. E. No payment will be made for fastening devices that may be used by the Contractor for keeping reinforcing bars in their correct position. When the substitution of larger bars than those specified is allowed, payment will be made for only the amount of metal that would have been required if the specified size of bar had been used. When full-length bars are shown in the Contract Documents and the Contractor obtains approval to use short bars for convenience, the weight paid for will be based on the full-length dimensions with no allowance make for splices. End of Section June 2016 406 - 2 SECTION 414 RIPRAP I. GENERAL 1.1 DESCRIPTION OF WORK The Contractor shall furnish all labor, supervision, material (except as herein provided), tools, equipment, supplies, and services; and, shall perform all Work necessary for providing and placing the specified type of riprap in accordance with the requirements of these specifications and in reasonably close conformity to the dimensions, lines, and grades shown in the Contract Documents or as established by the Owner. 1.2 MATERIALS A. Riprap shall conform to the requirements of Section 200. B. Sand shall conform to the requirements of Section 200. Grading A, B, or C sand may be used in mortared or grouted riprap. C. Mortar and grout shall conform to the requirements of Section 200. D. Geotextile bedding shall conform to the requirements of Section 200. E. Welded wire fabric shall conform to the requirements of Section 200. F. The classes of dry riprap shall be as follows: G. June 2016 1. Class I: Stones shall weigh between 50 and 150 pounds each. At least 60 percent shall weigh more than 100 pounds, and approximately 10 percent may weigh 50 pounds or less. 2. Class II: Stones shall weigh between 150 pounds to 500 pounds each. At least 50 percent shall weigh more than 300 pounds, and approximately 10 percent may weigh 150 pounds or less. 3. Class III: Stones shall weigh from 500 pounds to 1,500 pounds each. At least 50 percent shall weigh more than 900 pounds, and approximately 10 percent may weigh less than 500 pounds. 4. Class AI: Stones shall weigh between 25 and 75 pounds each, except that approximately 10 percent may weigh 25 pounds or less and 10 percent may weigh 75 to 100 pounds. Dumped riprap is classified according to the following types: 1. Type I: Core riprap shall be composed of compact angular pieces of derrick stone weighing from 3/4 ton to 2 tons each with an average weight of approximately 1 ton. Approximately 10 percent by weight may weigh less than 3/4 ton. 2. Type II: Heavy riprap shall be composed of compact angular pieces of derrick stone weighing from 3 to 10 tons each with an average weight of approximately 4 tons. 414 - 1 Approximately 10 percent by weight may weigh less than 3 tons. H. Mortared Riprap stone shall be the same size as specified for Dry Riprap, Class II, and shall be selected to obtain fairly large, flat-surfaced stones that will produce a true and even surface with a minimum of voids. I. Grouted Riprap for Slopes: Stones shall be of the same sizes and placed in the same manner as specified for Dry Riprap, Class I. Grout shall consist of 1 part hydraulic cement and 3 parts sand, thoroughly mixed with water to produce grout having a thick, creamy consistency. J. Erosion Control Stone for Culvert Outlet Protection shall conform to the requirements for Dry Rip Rap Class AI, I, & II respectively of (a) herein for weight. K. Erosion Control Riprap Riprap shall consist of sound, nonerodible shot rock. Erosion control riprap rock shall be not more than 15 inches in its greatest dimension and shall contain a sufficient percentage of smaller rocks to provide a reasonably dense mass with a thickness of at least 8 inches. L. Concrete Riprap in Bags shall be either wet or dry mixtures as follows: 1. Wet mixture Riprap shall consist of Class A3 concrete in suitable burlap bags. Bags shall weigh approximately 100 pounds when 2/3 filled with concrete. 2. Dry mixture Riprap shall conform generally to the requirements for wet mixtures except that the mixture shall consist of the dry ingredients and the Owner will not enforce the requirements for water, consistency, and air. Dry riprap may be in burlap or paper bags. Riprap shall be a rectangular solid enclosure approximately 3 inches in thickness and shall weigh approximately 80 pounds per bag. Paper bags shall be perforated throughout on approximate 1-inch centers and shall be of adequate seal, thickness, and strength to maintain the integrity of the riprap until the concrete mixture sets. Bags shall be biodegradable. 1.3 SUBMITTALS When required by the Owner, the Contractor shall submit certifications in the form of affidavits from the material suppliers, together with supporting data, attesting that the riprap meets specification requirements. II. EXECUTION The Contractor shall execute the Work in accordance with the latest edition of the VDOT Road and Bridge Specifications, Section 406.03, Procedures. Any references to “Engineer” or VDOT personnel shall mean the “Owner”. June 2016 414 - 2 III. MEASUREMENT FOR PAYMENT The price for the various types of riprap shall include, as appropriate, furnishing and placing riprap, including mortar, grout, welded wire fabric or geotextile bedding material (when not included as a separate pay item) including overlaps when required, mortar or grout; excavation; and granular riprap bedding material. The price shall also include preparing the surface, repair work, and excavating and backfilling toe-ins. A. Riprap will be paid for at the contract unit price. 1. Dry riprap will be measured and paid in square yards of surface area or tons as specified in the Bid form. 2. Mortared riprap will be measured and paid in square yards of surface area for the type specified. 3. Grouted riprap will be measured and paid in square yards of surface area or tons as specified in the Bid form. 4. Dumped riprap will be measured and paid in square yards of surface area or tons as specified in the Bid form. 5. Concrete riprap in bags will be measured and paid in cubic yards as specified in the Bid form. B. Erosion control riprap will be measured and paid at the contract unit price in square yards of surface area or tons for the Class specified on the Bid form. C. Erosion Control Stone used for Culvert Outlet Protection will be measured in square yards of surface area or tons for the Class and Standard specified and will be paid for at the contract unit price per square yard or ton. D. Incidental items are identified in Section 109.1.2 and, unless otherwise indicated in the Bid form, also include the following: 1. Erosion and sediment control materials and effort necessary to perform the Work. End of Section June 2016 414 - 3