STAUFF One - Hydraulic Accessories

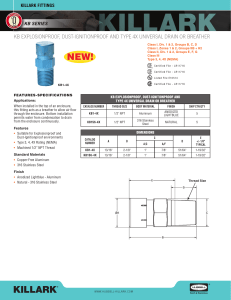

advertisement