You Must Know About the

New RIA Automation Standard

AMT

RIA Safety R15.06:2012

Decoding the essentials of RIA R15.06:2012

The new Robotics Industry Association (RIA) standard for robots and robot

systems (RIA R15.06:2012) will have a significant impact on all businesses

using robotic automation.

Here is your guide to what you need to know about the most important parts of

the new safety requirements within the standard. These are the game changers

that promise to have the most relevance and effect on your robotics design,

construction, installation, operation, and maintenance.

What’s Inside:

The new RIA R15.06:2012 defined

The “3 Game Changers” revealed that will have the greatest impact

on business

How they can affect your business.

“Putting it all together” Solutions for compliance that you can

implement

At AMT, we are committed to providing our clients the information they need.

We are conversant with the new RIA standard and relevant U.S. and global

industrial automation safety standards. Whether you are an integrator or end

user, this guide is designed to help you begin navigating your way through the

new RIA standard in order to become compliant.

© 2013 Applied Manufacturing Technologies All rights reserved

Fourteen years after the previous RIA Safety Standard, a new set of guidelines has

recently been adopted. It will make automation systems even safer for workers. It

also addresses the technical advancement in robotic systems that have occurred

since RIA R15.06:1999, the previous version. A standard such as this is not a law;

however, we recommend full compliance with it. R15.06:2012 does not take full

effect until January 1, 2015. However, we recommend that starting now when

modifying or implementing new systems there is little advantage to use the previous

version.

A complete revision

According to the RIA document, the new R15.06:2012 Safety Standard is a “complete

revision” of the previous R15.06:1999 (r2009) Safety Standard.

Some of the most significant changes in the new standard include the following:

1. A total reorganization of the text presenting the ISO 10218-1 and ISO 10218-2

in their entirety. Both parts of the ISO documents are presented in one volume

R15.06.

2. Changes of selected terminology (e.g. reduced speed for slow speed, protective

stop for safety stop), but not changes to functional requirements

3. Additional requirements regarding new features offered on robots and the safe

integration of the features

4. Requirements for detachable and wireless pendants

5. Change in clearance requirements

6. The “Operator” applies to ALL persons performing tasks including maintenance

and repair

7. Requirements for collaborative robot operation (new feature)

8. Functional Safety– A change in requirements to define and quantify safety

control circuitry

9. Safety Rated Soft Limits (SRSL) - A change in the approved control of robot

motion to include newly developed safety-rated soft axis and space limiting

10. Mandatory Risk Assessment- A Risk Assessment SHALL be performed and is no

longer optional

The “game changers”

We have highlighted the last three of the changes noted above as true “game

changers”: we contend that these will have the most impact on your business in the

coming months in terms of cost impact, allocation of in-house resources, and required

personnel skill sets to execute the work.

Key Takeaway: Beginning January 1st 2015, new RIA safety standards take full effect,

including several changes that will significantly affect business by changing how robotic safety is

implemented in the U.S.

Robotic Industries Association

(RIA) is North America’s trade

group serving the robotics

industry. RIA now represents

more than 280 robot

manufacturers, system

integrators, component

suppliers, end user, consulting

firms, research groups, and

educational institutions. It hosts

the ANSI/RIA National Robot

Safety Standard and annual

National Robot Safety

Conference. www.robotics.org

As a RIA Certified

integrator AMT has

been identified as a

specialist in safety and

risk assessment saving

our clients valuable

time and costs from

the implementation of

the new standard

RIA Safety R15.06:2012

When adopting the new RIA standard, or any consensus standard, it is important to

understand the content of the standard as well as how the standard could affect you.

The industry leaders of the R15.06 Subcommittee worked diligently to identify

specific guidelines and responsibilities for safety of industrial robots and robotic

systems. Due to the complexity of the task and the language necessary to detail the

standard, it is helpful to have a guide to understand the intent of the standard. Our

goal in this eBook is to provide that guide and highlight the three areas that may have

the greatest impact.

These “3 Game Changers” are highlighted because of the potential impact that they

may have on your business. These are:

1. Functional Safety – A change in requirements to define and quantify safety

control circuitry

2. Safety Rated Soft Limits (SRSL) - A change in the approved control of robot

motion to include newly developed safety-rated soft axis and space limiting.

3. Mandatory Risk Assessment - A Risk Assessment SHALL be performed and

is no longer optional.

*This is a big shift for our industry, especially for system suppliers who are

already feeling the squeeze of tight budgets and timelines. It is paramount to

your business that you have a full understanding of how these game changers can

affect you.

New Robotic

Safety Standard

How they can affect your business

Require a change in the allocation of valuable time – Potentially taking time away

from other important tasks (size of change is process dependent)

Additional Resources required – Safety experts, operators, programming, controls,

maintenance etc.

Increased Liabilities – Without the proper implementation of the new standard,

there could be an increased liability.

Next, we will examine each of the highlighted RIA R15.06:2012 “3 game changers”

and explore a path to compliance.

Key Takeaway: The “3 Game changers” from the RIA safety standard demand

your attention because they can have a direct impact on your business operations.

RIA Safety R15.06:2012

The goal of implementing functional safety is to define, as well as quantify,

engineering solutions (safety measures, techniques and procedures) that need to be

implemented to achieve an acceptable safety hazard level in compliance with the

safety standard.

What RIA R15.06:2012 says:

Safety related parts of control systems shall be designed so that they comply with

PL=d with structure category 3 as described in ISO 13849-1:2006, or so that they

comply with SIL 2 with a hardware fault tolerance of 1 with a proof test interval of not

less than 20 years, as described in IEC 62061:2005.

– (Part 1), 5.4.2, Performance Requirements

In Other Words:

Supplied components and their integration into the safety-related control system

must meet the required safety performance level and have the life expectancy

needed to meet the system’s overall functional safety. Performance Level (PL, ISO

13849) or Safety Integrity Level (SIL, IEC 62061) are calculated metrics that result

from the analysis of the entire safety-related control system.

What it means to you:

First a risk assessment of the automation system is performed. The risk assessment

identifies potential system hazards. Then, with the findings of the risk assessment, a

Functional Safety Design (further engineering analysis) is conducted to identify the

methods to reduce risk to a level acceptable to the end user. These methods may

include system and/or operational changes. Some examples are physical guards,

safeguarding devices, awareness devices, safeguarding methods, control

components, operating practices.

To conduct a Functional Safety Analysis, engineers must identify or calculate each

independent component’s Functional Safety value. They must then coordinate the

accumulated value(s) of the safety system to meet an acceptable level of hazard

exposure. Some calculations to consider are:

1.

2.

3.

4.

5.

6.

PFHd = probability of dangerous failure per hour (IEC/EN 62061)

SIL CL = SIL claim limit (IEC/EN 62061)

MTTFd = Mean time to dangerous failure (ISO 13849)

DC = Diagnostic coverage (ISO 13839)

Category = resistance to fault (ISO 13849)

= Measure against common cause failure (ISO 13849)

The result of the analysis is a documented for many valuable future uses, such as

certification of a reliable safety system, system validation tool, and even a scope of

work document to be used through the implementation of the Functional Safety

System.

Key Takeaway: The new functional safety standard is highly technical and may

require special expertise in assessing the efficacy of safety control systems

“Functional Safety provides

validation of your risk

assessment

countermeasures to risk

reduction. Finally, we have

a tangible and quantifiable

way to determine if the

control system meets our

designed acceptable risk

levels as well as current

safety standards.”

Jean-Yves Chretien,

Certified TUV Functional

Safety Engineer

RIA Safety R15.06:2012

Historically, robotic safety and safeguarding was all about hardware-controlled limits

to a robot’s movements, combined with access restrictions to the potential motion

space. These limits took the form of physical hard stops on robot joints, structured

walls, and columns, limit switches mounted to the robot, and non-contact safety

devices. In order to keep hazards at a safe distance from operators, safeguarded

areas were much larger than was required for the productive functioning of the cell .

With the proper safety system design, the new standard will now allow us to

use less floor space!

What RIA R15.06:2012 says:

Soft limits are software-defined limits to robot motion. Space limiting is used to define

any geometric shape that may be used as an inclusionary or exclusionary zone, either

limiting robot motion within the design space, or preventing the robot from entering

the defined space.

– (Part 1) 5.12.3, Safety-rated Soft Axis and Space Limiting

Robot installations SHALL be designed and integrated so as to reduce the potential

exposure of personnel hazards.” “To reduce the safeguarded space, the maximum

space can be limited by the provision of integral or external devices that restrict the

movement of the robot system.

– (Part 2) 5.4.1, Limiting Robot Motion (General)

What it means to you:

The development of Safety Rated Soft Limits (SRSL) was a

major innovation by robot manufacturers. They are

programmable software-defined limits to robot motion

within the robot’s operating system.

SRSL’s deliver immense

flexibility compared to

traditional safety

limiting and can help

dramatically optimize

floor space while

adhering to the new

RIA standard

When ordering a “new” robot with the proper Safety Rated

Soft Limit and/or manufacturer hard stop options the system

can be programmed to use a smaller portion of the robot’s

maximum reach area. By doing so the restricted space can be reduced to closer

match the shape of the required work envelope. Thus, less perimeter safeguarding

can be used and the guarding will enclose less floor space.

Now that SRSL’s are safety-rated and accepted by national standards. This can be of

great benefit since it allows further optimization of floor space. Your overall robotic

system space requirements can be reduced by integrating the proper safeguard

devices into your safety control system.

Key Takeaway: The new RIA safety standard offers potential robotic system

implementation cost savings by reducing system components and reducing the amount of

floor space required

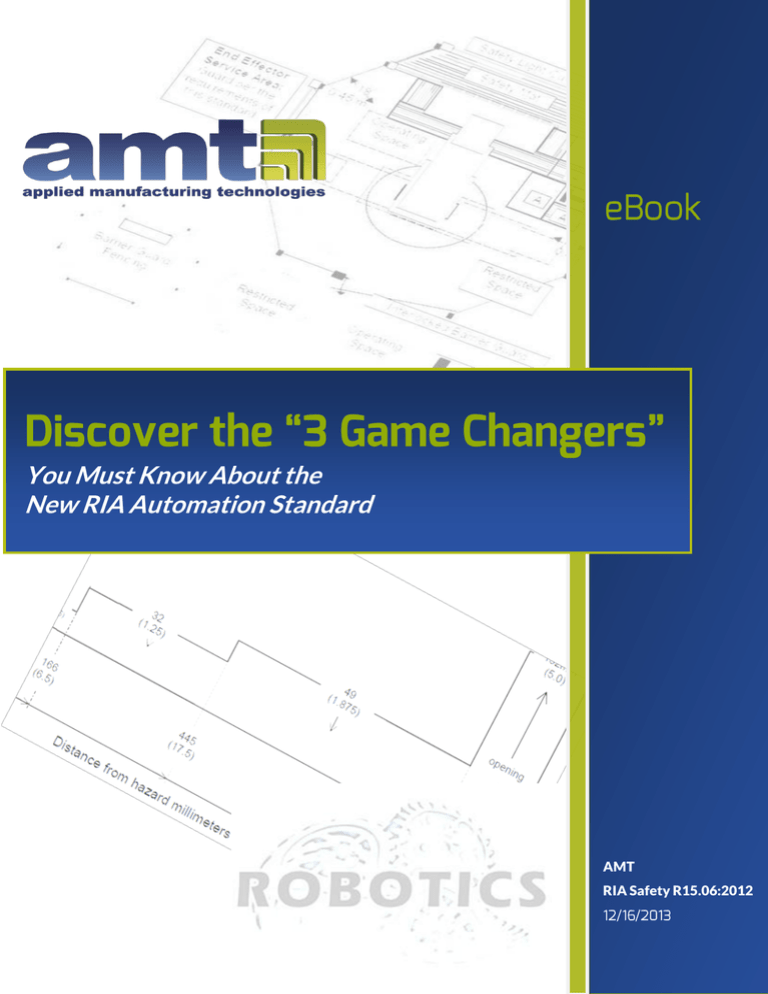

The figure above represents

a reduction in required floor

space using SRSL’s of a

system with the same work

envelope.

“With the new RIA safety

requirements and the ability

to purchase the

“SafeOperation” option on

our new robot, we were able

to save over 120 square foot

of productive floor space

within our cell. In granite

processing facilities, floor

space is at a premium and

this benefit will maximize

our material processing

area.” - Chuck Russo,

Owner Surface enCounters

RIA Safety R15.06:2012

A Risk Assessment is a comprehensive evaluation of the possible injury or damage to

health in a hazardous situation that is done in order to eliminate or reduce hazard or

to select appropriate safeguards.

The new standard now mandates that a Risk Assessment is the responsibility of all

involved in a robotic system’s build and use. It requires them to evaluate the hazards

associated with the robot system over its lifecycle. (i.e. commissioning set-up,

production, maintenance, repair, decommissioning.)

What RIA R15.06:2012 says:

Because a robot system is always integrated into a particular application, the

integrator SHALL perform a risk assessment to determine the risk reduction

measures required to adequately reduce the risk presented by the integrated

application.

– (Part 2), 4.3.1, Risk Assessment (General)

What it means to you:

Robotic systems must be assessed for risk. The assessment’s complexity varies with

the system’s application and use.

Previously, conducting a Risk Assessment was the end user’s responsibility. With RIA

R15.06:2012, a Risk Assessment must be done of all robotic systems by the system

supplier and the end user. Furthermore, a Risk Assessment is recommended on all

automation systems.

Ultimately, this process should be used to Identify, Assess, Reduce, and Verify that all

hazards are at an acceptable “Risk level” for operator interaction. To establish the

“risk level”, all hazards are required to be assessed according to their SEVERITY,

EXPOSURE, and AVOIDANCE. Based on these items, the following are BASIC steps

that should be used during a risk assessment.

1. Identify: All Risks, All Hazards, Who could be affected, probability of

occurrence and severity of the hazards)

2. Assess the risk: Use of the ANSI B11 TR:3 2000 chart is the best method to

describe the risk level

3. Reduce Risk to Acceptable: Create mitigation solutions that bring risks to a

level that are acceptable for the systems end user

4. Validation of the mitigation action taken: Validation that the implemented

hazard protection has appropriately reduced the potential harm, that all

safeguard solutions are properly working, and that all hazards will be

monitored and controlled through the lifecycle of the equipment

Key Takeaway: Mandatory risk assessments for robotic systems are now the

responsibility of the system supplier and the end user. This will require additional time and

resources from both the supplier and the end use.

RIA Safety R15.06:2012

Let’s recap;

The new RIA R15.06:2012 Safety Standard is now complete and this long awaited

set of revised guidelines has been adopted. This standard makes automation systems

safer for workers, and addresses the technical advancement in robotic systems.

An important question is, how does it affect you, your business and how are you going

to become compliant?

We identified what we consider the most impactful “3 Game Changers” in the new

standard:

1. Functional Safety

2. Safety Related Soft Limits (SRSL)

3. Mandatory Risk Assessment

To assure compliance with the new standard you will need to adhere to these

changes and possibly other changes and implement them into your future operations.

To do that there are a couple of solutions:

1. Implement from within – You can do it in-house with your current resources.

2. Outsource – Bring a company in to consult on solutions. This may include an

evaluation of your current operations, perform a Functional Safety design, or

to do a Risk Assessment.

When evaluating these options there are some factors you want to consider:

For new cells, if I change nothing, am I exposed to increased liability?

The short answer is…yes. OSHA is recommending that RIA R15.06:2012 be used as a

guideline. At a minimum, the RIA standard now requires a Risk Assessment.

Conducting a proper risk assessment will be crucial to your operation. If not properly

done, it can increase your liability

Will I have the time required?

Every process is different. Some assessments will require more time than others will.

Do you have the additional time? Can you afford the required time and resources to

complete the process?

Will I have the resources I need?

Do you have the in-house staff and knowledge needed to complete the compliance

process? Do you have a safety expert on staff?

RIA Safety R15.06:2012

If you have determined that you may not have the time, resources, or expertise to

fully comply with the new RIA standard, you may be considering outsourcing.

Consider this;

Some companies that provide consulting services also sell safety related hardware.

They may come with a product agenda that could include purchasing their products.

Make certain to verify credentials and seek out an RIA certified Robot integrator that

has the experience, expertise, and successful track record to partner with.

Introducing: The AMT Advantage

If you are interested in complying with the new RIA standard, AMT can consult with

you to find your best solution.

As an industry leader, AMT specializes in robotic challenges and solutions. We offer a

No Product Agenda approach to safety solution services. At AMT, we do not

manufacture safety related products. This allows us to take a product-neutral look at

your needs and design a solution tailored specifically for you. Whether it is a newly

installed or an existing system, we’ll recommend the hardware and software that best

suits your situation.

Among the benefits of using AMT for robotic system safety engineering:

AMT employs a certified Functional Safety Engineer and other consultants.

AMT has been assisting our customers with RIA specific risk assessments

for the past 6 years.

AMT is a RIA Certified Robot Integrator

By teaming up with AMT your company will benefit from our trained, certified

consultants who have the experience to identify possible hazards, determine risk

reduction requirements, and then propose and validate possible solutions.

Relying on AMT for advice and consultation during this period of change, you’re

assured of a minimum of disruption to your processes and in house resources.

Press Release:

The Robotic Industries

Association (RIA) today

announced that Applied

Manufacturing

Technologies (AMT) has

received the prestigious

RIA Certified Robot

Integrator designation. In

order to become certified,

AMT completed a rigorous

process that includes an onsite audit and testing of key

personnel among other

important criteria.

“We are delighted to

welcome AMT as

our eighteenth Certified

Robot Integrator,” said

Jeff Burnstein, President

of the RIA.

Learn how we can help you.

Timing is essential in the process and now is the time to get ahead of the competition.

Get your Personal Consultation Today!

Click Now To Get Started

(Ctrl + Click to open new window)

Our goal in this guide was to introduce you to the new RIA standards, shed some light

on what you can do to be compliant in 2014 and offer you the best possible solutions.

Proper implementation of the new RIA R15.06:2012 safety standard is crucial. With

knowledge, the right strategic partnership and careful implementation your business

can be safer and flourish in 2014 and many years beyond.

RIA Safety R15.06:2012

Applied Manufacturing Technologies

219 Kay Industrial Drive

Orion, MI 48359

248.409.2007

safety@appliedmfg.com

© 2013 Applied Manufacturing Technologies All rights reserved