TSS

ASM Thermal Spray Society

An Affiliate Society of ASM International ®

SM

November 2007

Volume 2 • Issue 4

Your Thermal Spray

Information Partner

I N T E R N A T I O N A L

Thermal Spray &

Surface Engineering

TM

T H E O F F I C I A L N E W S L E T T E R O F T H E A S M T H E R M A L S P R AY S O C I E T Y

Basics of

Thermal Barrier

Coatings

Metallizing Steel

Structures for

Corrosion

Resistance

Industry News

Thermal Spray

Tips

www.asminternational.org/tss

NOVEMBER 2007 • Volume 2 • Issue 4

TM

8 Thermal Spray Tip: Metallography

Editor Christopher C. Berndt

Managing Editor Ed Kubel

Art Director Barbara L. Brody

12 Thermal Spray Tip: DE

Production Manager Joanne Miller

Publisher Joe Zion

13 Thermal Barrier Coatings:

The Basics

Coating samples from

high velocity oxygen

fuel processes.

Sales

Mike Sellaroli

Columbus, Ohio

tel: 614/268-5260;

email: mike.sellaroli@asminternational.org

Erik Klingerman

North Royalton, Ohio

440-338-5151, ext. 5574

Erik.klingerman@asminternational.org

16 Thermal Spray Coatings

Protect Steel Structures

from Corrosion

Air bridges docked to aircraft;

bridges are given a thermal

spray coating to protect the

steel structure from corrosion.

Thermal Spray Society

Executive Committee

Peter Hanneforth, President

Richard Knight, Past President

Mitchell Dorfman, Vice President

Charles Kay, Secretary/Treasurer

Thomas S. Passek, Executive Director

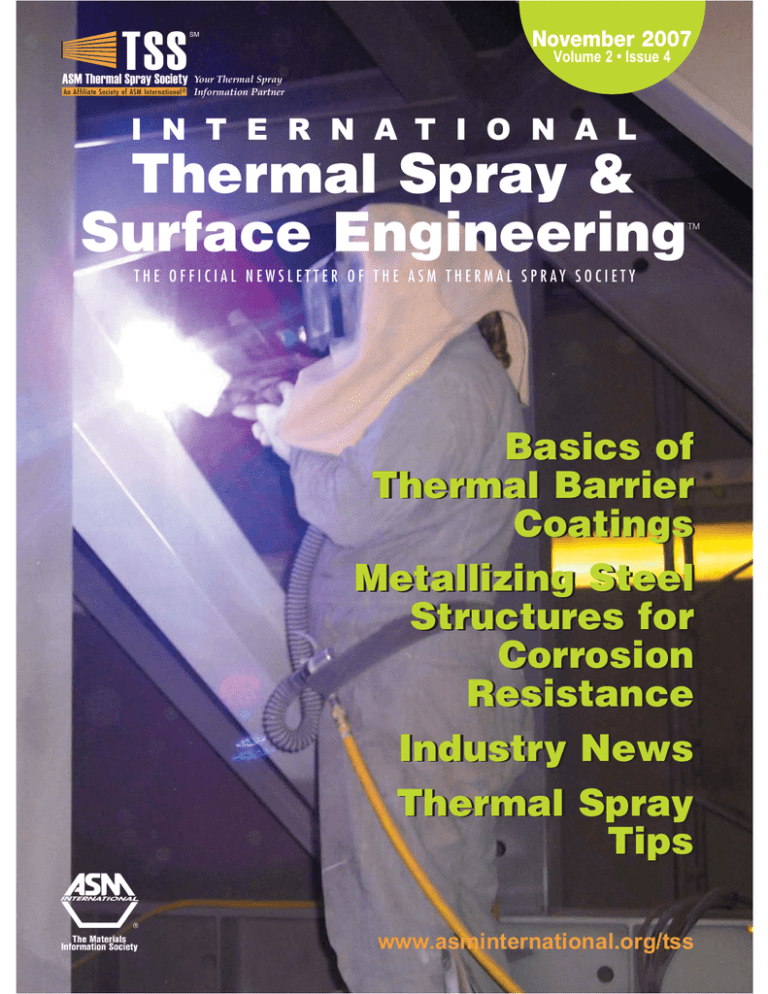

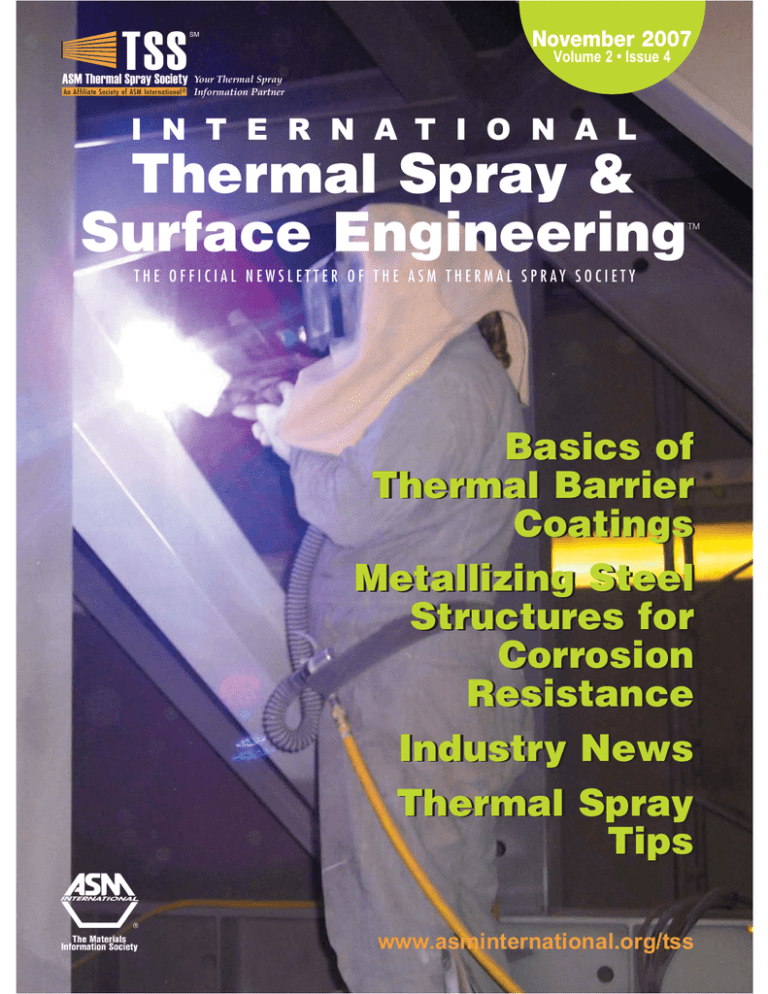

About the cover

Thermal spray coatings are used to protect

the Emsworth Lock and Dam on the Ohio

River in the U.S. from corrosion. Courtesy

of Metallisation Ltd., West Midlands, UK.

International Thermal Spray & Surface EngineeringTM is

published quarterly by ASM International®, 9639

Kinsman Road, Materials Park, OH 44073; tel:

440/338-5151; www.asminternational.org. Vol. 2, No.

3. Copyright© 2007 by ASM International®. All rights

reserved.

Departments

2

3

16

18

From the Editor

Industry News

ASM Thermal Spray Society News

JTST Highlights

20

Calendar

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

The acceptance and publication of manuscripts in

International Thermal Spray & Surface Engineering

does not imply that the editors or ASM International®

accept, approve, or endorse the data, opinions, and

conclusions of the authors. Although manuscripts

published in International Thermal Spray & Surface

Engineering are intended to have archival significance,

author’s data and interpretations are frequently

insufficient to be directly translatable to specific design,

production, testing, or performance applications

without independent examination and verification

of their applicability and suitability by professionally

qualified personnel.

99

iTSSe

1

FROM THE

EDITOR

Thermal Spray:

The Best Thing Since Sliced Bread?

H

ow many times have you been placed in the position of (a) having to describe what thermal

spray (TS) is all about, (b) defending the physical attributes of a thermal spray coating with respect to another product or process, or (c) arguing the attributes of thermal spray on the

basis of life cycle costs? And sometimes all of these topics might be discussed within a single

business exchange.

There are many pragmatic answers to these questions. There are many resources that discuss

the TS process including conferences, web sites, peer-reviewed literature, patents, private databases,

and professional societies.

In some cases, the honest answer is “Yes, I fully understand where you are coming from. Thermal

spray may not be the specific solution that your company needs for this particular application.” In such

instances, your expertise in understanding the entire array of surfacing solutions can be brought to

bear. The outcome is that the customer may very well be satisfied with the alternative solution and your

own credibility as an expert will be reinforced. Thus, this person will feel comfortable in coming back

to you, even though TS was not the solution for that particular application.

A more difficult circumstance is where you are placed in the position of defending the microstructure of TS coatings. Remember viewing your own coating under the microscope where the eyes focused on a structure of pores, inclusions, and cracks. It is not hard to see then that persons trained

as engineers, scientists, and technologists would find it difficult to understand how such structures

can function as coatings under actual engineering conditions. It’s easy to foresee the many questions

that might arise about coating strength vs. fully dense materials, the effects of surface roughness, and

mechanical properties including yield and ultimate tensile strengths, fatigue strength, and modulus.

As practitioners, we know that TS coatings do in fact perform more than satisfactorily in many adverse mechanical and corrosive environments. So we are able to defend the microstructure largely

through the many successful case histories and extensive industrial practices that are available.

Finally, the cost of TS coatings apparently is favorable since a global market of several billion dollars

exists for thermal spray. The high capital equipment cost can be amortized over 5 to 10 years, so the

major cost is people — engineers who can specify coatings and skilled operators who can program

manufacturing cells and/or hand spray complex geometries.

Is thermal spray the best thing since sliced bread? I have had experiences where thermal spray has

been over-sold, leaving the client cautious about repeating a negative experience. However, in the past

decade, the database of successful examples of thermal spray and other coating technologies has

increased significantly to build a high confidence level that the coatings will perform in accordance to

the required specification.

Thermal spray is a competitive technology for many applications. Whether TS is better than sliced

bread should not be based on what we are told to believe, but on the basis of solid engineering results

and hard data. There is a strong need for unbiased results and data, and many people are striving to

fill this need. I urge you to praise the success of all coating technologies so that we can, to paraphrase

local jargon, “not only make our bread, but serve it to our customers as well.”

Chris Berndt, FASM, Editor

Editor Emeritus: The Journal of Thermal

Spray Technology

Tel: +61 (07) 4781 6489

Fax: +61 (07) 4775 1184

Mobile: 0428 237 638

christopher.berndt@jcu.edu.au

cberndt@notes.cc.sunysb.edu

iTSSe

2

100

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

Xiom Corp., West Babylon, N.Y., a manufacturer of polymer

powder spray systems and polymer-based coatings, has developed a technology that is said to significantly reduce both the

risk of bridge deterioration and the costs involved in maintaining

bridges.

There is growing concern over the safety of bridges in the U.S.

Of the nation’s 600,000 bridges, it is estimated that more than

100,000 are structurally deficient. Corrosion is a major cause of

bridge failure, and Xiom’s polymer powder coatings offer good

corrosion-fighting ability.

After testing various coating formulations, the company determined that an 85%zinc-15% aluminum coating provides good

corrosion protection, and a hard polymer top coat provides a

more durable, weather-resistant coating than paint or other competitive coatings.

The coatings, which also can be used to coat concrete and the

rebar embedded in concrete, don’t drip and there are no overspray problems and no VOCs (volatile organic chemicals). The

coatings cure instantly; no oven-curing is required, thus enabling

bridges to reopen more quickly. www.xiom-corp.com.

Ceramic-Coated Bearings Prevent Fan-Motor Failings

SKF Ltd., Bedfordshire, UK, offers ceramic-coated bearings

to prevent fan motors from failing due to stray electric currents.

Many motors in manufacturing plants can be affected by stray

currents that leak through generators and associated equipment.

The stray currents can damage the rolling elements and raceways of steel bearings and rapidly degrade the lubricant, resulting in unplanned downtime and increased costs related to

bearing replacement and lost productivity. Alleviating the

problem by insulating the housing or shaft can be expensive and

time consuming, and may not yield optimum results. SKF’s Insocoat bearings are said to solve these problems.

The bearings are standard, all-steel bearings plasma sprayed

with a ceramic coating. The coating is applied to the outside surface of the inner or outer ring, depending on the application, and

sealed to protect against the conductive effects of water and

moisture. As well as being environmentally friendly, the coating

provides a consistent insulation layer that is virtually insensitive to high operating temperatures and chemicals.

Well-suited to medium and large sized motors, the bearings

have the same boundary dimensions as standard

bearings so do not require special installation procedures or expensive modifications. They also offer a number of advantages over other methods used

to prevent stray currents including:

• Extended bearing service life

• Increased machine uptime

• Reduced maintenance and

repair costs

• Cost effective compared

with other insulating methods

• Drop-in replacement for easy

installation

• No degradation of the lubricant

caused by current discharges

• Virtual elimination of bearing damage

from stray electric currents

To illustrate, an integrated pulp and carton-board

mill was losing productivity due to bearing problems in the pulp

boiler flue gas recirculation fan motors. The 400 kW ac motors

with frequency converters were running at 950 rpm with an operating temperature in excess of 100°C (212°F). The motors were

equipped with standard bearings, which lasted only six months

on average due to damage caused by stray electric currents.

The company installed Insocoat bearings to improve reliability and reduce fan maintenance and repair costs. Since installing the bearings, there have been no failures. The mill realized dramatic savings in maintenance and repair costs, along

with additional benefits in reduced downtime and increased productivity. www.skf.com.

INDUSTRY NEWS

Xiom Corp. Develops Coating Technology for Bridge Repairs

BTU International,

DEK International Partner

for Solar-Cell Metallization

Solutions

BTU International Inc., Billerica, Mass., a supplier of advanced

thermal processing equipment for the electronics manufacturing and alternative energy markets, entered a

strategic partnership with DEK International, a

business of Dover Corp., New York, N.Y., a

provider of printing equipment and processes

for the high-accuracy mass imaging of

electronic materials. The partnership will

provide complete in-line metallization

process solutions to photovoltaic (PV)

manufacturers.

The alliance combines DEK International’s next-generation printing technologies and handling solutions with BTU International’s high-performance drying and firing

technologies to form a complete turn-key metallization line for solar cells. This broadens BTU’s

product offerings to the solar industry, which also

includes integrated in-line diffusion and anti-reflective

coating systems. BTU’s goal is to offer customers the lowest

cost per watt process. www.btu.com; www.dek.com.

International Thermal Spray Conference & Exposition (ITSC 2008)

June 2-4, 2008 • Maastricht, Netherlands

Organized by the German Welding Society (DVS), the ASM Thermal Spray Society (TSS) and the International Institute of Welding (IIW).

For more information, visit www.dvs-ev.de/itsc2008; or contact Cust. Srvc. Ctr., ASM Intl., Matls. Park, Ohio; tel: 800/336-5152 (ext. 0) or

440/338-5151 (ext. 0); fax: 440/338-4634; e-mail: customerservice@asminternational.org; Web: www.asminternational.org.

iTSSe

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

101

3

INDUSTRY NEWS

Rolls Royce Links with Universities

to Advance Jet-Engine Technologies

Rolls-Royce plc, Derby, UK, opened a new University Technology Centre (UTC) at Karlsruhe University in Germany to research cooling in gas turbine combustors and turbines and related technologies required to improve the fuel efficiency and

environmental performance of future aero engines. The latest

UTC is the fourth to be established in Germany.

The economic and environmental demands on the aviation

industry call for aero engines to operate at higher fuel efficiencies, which means running at higher temperatures. Efficient

cooling systems are vital to prevent combustion and turbine components—even those made of the most advanced alloys—from

melting, and the UTC will take a holistic approach to maximize

the use of air for cooling. Using less air for cooling and more

in the combustion process will help to further reduce engine

emissions.

The University has proven academic capability in the research

areas of combustion cooling in very hot environments, film

cooling, and two-phase-flow; plus a range of rigs and sophisticated hardware, innovative methods, and measurement techniques. It is expected that Karlsruhe will work closely with a

number of existing Rolls-Royce UTCs in the UK—notably those

based in Surrey, Loughborough, and Nottingham Universities,

and the Osney Laboratory in Oxford—that collectively focus on

research into heat transfer, combustion, computational fluid dynamics (CFD), aerothermal techniques, and component interactions; and provide highly specialized modeling, validation,

and testing capabilities. www.rolls-royce.com.

In another area, Rolls-Royce Corp. acquired exclusive rights

to use a coating invented by Iowa State University (Ames, Iowa)

researchers that helps turbines stand up to the heat in jet engines.

The unique bond coating will be applied to engine turbine

blades made of nickel-base superalloys. The superalloys are designed for strength, but need help withstanding metal temperatures approaching 2100°F (1150°C) inside the hot section of a

jet engine, says Brian Gleeson, Iowa State’s Alan and Julie

Praxair and FMC

Technologies Sign

Agreement for Thermal

Spray Coatings Service

Praxair Surface Technologies, Indianapolis, Ind., a wholly owned

subsidiary of Praxair Inc., reached an agreement with FMC

Technologies, Houston, Tex., a global provider of technology

solutions for the energy industry and other industrial markets,

to supply thermal spray coatings for gate-valve components

used in oil and natural gas production. The agreement includes

plans for Praxair to establish a facility at Coimbatore in southern

India that is expected to be in full production by mid-2008. The

facility will include a manufacturing plant for coating oil-field

gate-valve components manufactured in India. Praxair’s thermal

spray coating provides wear and corrosion protection for

gate valves in critical service applications. Praxair also

provides FMC with thermal spray coating from its operations

in Houston and St. Etienne, France. www.praxair.com, or

www.praxairsurfacetechnologies.com.

The Rolls-Royce LiftSystem for the F-35B Joint Strike Fighter

consists of the Rolls-Royce LiftFan, the 3 Bearing Swivel Module

(3BSM), and the roll posts. Courtesyof Rolls Royce plc, Derby, UK.

Renken Professor in Materials Science and Engineering and a

co-inventor of the coating. The bond coating improves the durability and reliability of a ceramic thermal barrier applied over

the bond coat, and offers significant advantages over existing

coating technologies.

The coating is based on a composition consisting of platinum,

nickel, aluminum, and hafnium. A key advantage to this technology is that it is mechanically compatible with the superalloys it covers and protects. It reacts to the heat and stress of an

engine about the same way the superalloy does, which gives the

coating composition—and therefore the engine parts—better

performance and a longer life.

The Iowa State researchers continue to work on the coating

composition project, with the intent to develop a better, less expensive way to produce the coating, and are looking for new

coating compositions and new ways to deposit them on materials.

Rolls-Royce will have an exclusive license to commercialize

the inventions. Patents are pending for the inventions, and the

term of the license agreement is for the life of any patents. Also,

the license has the potential to be an important source of revenue for the research foundation. www.iastate.edu.

Optomec Develops

Deposition System for

Solar-Cell Production

Optomec, Albuquerque, N. Mex., a provider of additive manufacturing systems for high-performance applications in the

iTSSe

4

102

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

Linde Gas Cools Off Spray

Coating Technology

Linde Gas, Murray Hill, N.J., a North American subsidiary

and affiliate of The Linde Group, a global engineering

and industrial gases company, designed a turnkey,

high-pressure gas delivery system capable of delivering

pressures above the 50 bar required to use nitrogen in

the cold-spray process. Cold spray enables manufacturers

to achieve coatings that are compatible with traditional

thermal spray technologies, such as plasma and flame

spraying. However, cold spray has relied on scarce,

expensive helium to propel the powder coating material on

to surfaces.

Linde’s high pressure delivery system has been optimized

to support cold spray gun technology called Kinetiks 4000,

manufactured by CGT GmbH, based in Ampfing, Germany.

Cold spray converts the kinetic energy of solid particles to

thermal energy as they hit the surface to be coated, forming

a nearly impermeable bond. Cold spray is being used in industries such as aerospace, oil and gas, and power; where

coated materials are subject to extreme mechanical and

physical demands.

Cold spray’s lower thermal load results in lower porosity

and oxygen content. The coated surface has deposition

rates that can exceed 95%, and is durable with respect to

surfaces coated using other technologies. Having fewer oxides implies that the surface will have electrical and thermal

conductivity. www.linde.com.

INDUSTRY NEWS

electronics, biomedical, and aerospace & defense markets, introduced its M3D Aerosol Jet Deposition system, which is said to improve photovoltaic cell efficiencies. The M3D system is a printing

platform used in the development of next-generation devices such

as high density circuitry for photovoltaic cells, fuel cells, and printable electronics.

The system, used in conjunction with a light-induced plating

process, significantly increases overall photovoltaic wafer efficiencies. In preproduction trials, M3D technology produced printed

collector lines as small as 45 Pm by using new and modified versions of screen-printing material.

The M3D Aerosol Jet is a Direct Write™ process that first

aerosolizes conductive photovoltaic inks or pastes and then forms

an aerodynamically focused droplet stream of the material. This

Direct Write capability eliminates the need for screens or stencils required by traditional contact deposition processes while also

enabling much finer feature sizes.

In addition to the wide variety of materials and substrates

supported and the finer feature sizes, the additive process used

by M3D reduces environmental impact by minimizing the waste

and chemicals that are part of more traditional manufacturing

processes.

An additional benefit of the process is that the non-contact aerosol

jet feature enables the deposition of photovoltaic materials onto

extremely thin, non-planar substrates. New silicon wafer manufacturing technologies generate very thin, non-planar wafers that

can be produced far less expensively than traditional, ingot-based

silicon-wafer technology. www.optomec.com.

iTSSe

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

103

5

INDUSTRY NEWS

Cold Spray at TWI Yorkshire

Cold spray, or more precisely cold gas dynamic spray (CGDS),

is a high-rate material deposition process in which powder particles (typically 1 to 50 Pm) are accelerated to velocities in the

range of 200 to 1000 m/s in a supersonic jet of compressed gas

at a temperature far below the melting point of the feedstock

powder (ambient temperature to 700°C, or 1290°F). Upon impact with a target surface, the solid particles experience plastic

deformation that disrupts thin surface films (such as metal oxides) and provides intimate conformal contact between the clean

metal surfaces under high local pressure. This permits bonding

to occur and rapid layer build-up of deposited material.

With CGDS, various materials can be sprayed without exposing them (or the substrate) to high thermal loads. Compared

with other thermal spray processes (e.g. plasma spray and flame

spray), CGDS allows coatings to be made having extremely low

porosity and oxygen content.

TWI uses the latest, highest specification commercial system

(CGT GmbH Kinetiks 4000, 47 kW) that can achieve process

gas temperatures up to 800°C (1470°F) and process gas pressures up to 40 bar. The feed-stock powder can be heated to temperatures over 500°C (930°F), resulting in improved adhesion

for some specific coating systems. The Active Jet Cold Spray

Gun can be operated with or without preheating the gas. This

enables the system to be configured for the application of tailored coatings.

Several materials have proven to be suitable for cold spray

including:

• Metals (Al, Cu, Ni, Ti, Ag, Zn, Ta, Nb)

• Refractory metals (Zr, W, Ta)

• Alloys (steels, Ni alloys, MCrAlYs)

• Composites (Cu-W, Al-SiC, Al-Al2O3)

With these materials in mind, a wide range of applications can

be explored, with possible end uses in a number of industry sectors, such as aerospace, automotive, oil and gas, power generation, motorsport, medical, petrochemical, and electronics.

www.twi.co.uk.

Sulzer Reports

Higher Sales and Earnings

for First Half of 2007

Sulzer, Winterthur, Switzerland, achieved strong growth and

substantially higher results in the first half of 2007, with divisions

increasing operating income by 46%. Orders, sales, operating

income, and net income were well above the previous year’s results.

All key markets and regions remained in a positive condition. The

outlook for the full year is encouraging, with strong gains expected in

orders and sales. In 2007, results are anticipated to be above those

of the previous year due to operating improvements and volume

leverage.

For Sulzer Metco, the first six months of 2007 depicted considerable impact from the operational improvement measures that were

started some years ago. Orders increased by 18.8% and sales improved by 23.1% to US $311 million. The operating income was up

64.8% to US $31 million. Return on sales reached 9.8%, compared

with 7.3% in the previous year’s first half. The key segments were in

a good condition. Although the positive trend is likely to continue over

the next few years, Sulzer Metco does not expect to develop at the

same pace as in this reporting period. www.sulzer.com

iTSSe

6

104

Entegris Acquires

High-Purity Semiconductor

Coatings Business

Entegris, Chaska, Minn., acquired the assets of the high-purity semiconductor coatings business of Surmet Corp.,

Burlington, Mass. The acquisition is said to help strengthen

the company’s ability to deliver solutions that purify, protect,

and transport critical materials in semiconductor applications,

and gives Surmet customers access to a wider range of global

resources.

Surmet is a pioneer in high-performance, high-purity coatings that protect wafer handling and equipment components,

such as electrostatic clamps, in the semiconductor manufacturing process, and reduce contamination of wafers from the

components themselves. These microparticle-free and corrosion-resistant, high-performance coatings use an innovative low-temperature plasma process that can be applied on

a wide range of substrates.

Entegris sees the potential to extend the application of

Surmet’s technologies beyond the semiconductor industry.

The terms of the transaction were not disclosed. www.

entegris.com; www.surmet.com.

Nanowire Coating

for Bone Implants, Stents

Researchers at University of Arkansas, Fayetteville, Ark., discovered a simple, inexpensive way to create a nanowire coating

on the surface of biocompatible titanium, which can be used to

create more effective surfaces for hip replacement, dental reconstruction, and vascular stenting. Further, the material can

easily be sterilized using ultraviolet light and water or using

ethanol, making it useful in hospital settings.

The researchers use an alkali and heat to create titanium

oxide-based ceramic nanowires that coat the surface of a titanium medical device. They can control the length, height,

pore openings, and pore volumes within the nanowire scaffolds by varying the time, temperature, and alkali concentration in the reaction, says Z. Ryan Tian, assistant professor of

chemistry and biochemistry in the J. William Fulbright College of Arts and Sciences. The process is extremely sustainable, requiring only that the device be rinsed in reusable water

after the heating process.

Reconstructive bone surgeries such as hip replacements use

titanium implants. However, muscle tissue may not adhere well

to titanium’s smooth surface, causing the implant to fail after

a decade or so and requiring the patient to undergo a second

surgery.

A nanowire-coated joint placed in mice had tissue adhering

to the joint after four weeks. Because the researchers can control the size and shape of the pores in the nanowire scaffold, the

material also could be coated onto stents used in patients with

coronary artery disease and in potential stroke victims. Conventional stents sometimes become reclogged with fat after implantation.

The researchers have applied for a provisional patent for the

multifunctional nanowire bioscaffolds on titanium or titaniumcontaining alloys such as Nitinol. www.uark.edu.

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

Reactive NanoTechnologies Inc. (RNT), Hunt Valley, Md.,

developer and manufacturer of its patented NanoFoil, partnered with the Kurt J. Lesker Co., (Clairton, Pa.;

www.lesker.com) to expand worldwide sales and distribution of NanoFoil and its accompanying NanoBond process.

Key markets to benefit from this partnership include semiconductor manufacturing, LCD and flat panel displays, advanced

displays, glass coatings, film coatings, and other vacuum industries using sputtering targets. Nanofoil precisely controls

the instantaneous release of heat energy for joining and reaction initiation applications. NanoBond produces a virtually

void-free solder bond having low residual stress and higher

melting temperatures; resulting in potentially higher sputter

powers, and greater film deposition rates.

Kurt J. Lesker Co. will serve as RNT’s exclusive distributor

in North America and Europe, offering NanoBond bonding

service for customer supplied materials, as well as full target assemblies incorporating NanoBond. www.rntfoil.com.

nCoat Involved in Various Activities

nCoat Inc.,Whitsett, N.C., announced through its operating

subsidiary High Performance Coatings (HPC) the formation of

a customer relationship with SoCal Diesel (Valencia, Calif.;

www.socaldiesel.com), which specializes in Duramax diesel

performance components. HPC applies heat and corrosion management and friction reduction coatings to internal diesel engine

components.

HPC coats the skirts of SoCal Diesel pistons with improved

S Series fluoropolymer dry film coating containing PTFE (polytetrafluoroethylene) additives. HPC’s lubricating coatings reduce metal-to-metal surface friction, thereby reducing wear

on the piston, and helping seat the piston during the break in period on the engine. HPC also coats the combustion sides of the

diesel engine pistons with H Series heat-management coatings,

which distribute combustion cycle heat evenly across the entire

crown of the piston. This reduces any hot spots and thermal oxidation affecting piston top surfaces. H Series is an inorganic ceramic metallic coating that also provides excellent thermal shock

characteristics when tested at temperatures greater than 1000

down to 65°F (540 down to 18°C) in water quench tests.

nCoat acquired Metallic Ceramic Coatings Inc. (MCC), King

of Prussia, Pa., which conducts business under the brand of JetHot coatings. The business combination is said to strengthen the

market position of both companies. MCC offers thermal barrier,

lubricating, and corrosion resistance coatings applied on autos

and bikes ranging from street rods and dragsters to classics, exotics, snowmobiles, and over-the-road trucks.

MCC claims to be a market leader in header coatings appli-

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

INDUSTRY NEWS

RNT, Kurt J. Lesker Co. to Expand Market Reach

for Sputtering Targets

105

iTSSe

7

INDUSTRY NEWS

cations producing low emissivity and ceramic insulating characteristics, which create thermal barriers on both the interior and

exterior surface of headers. In accelerated salt-spray tests conducted in accordance with ASTM B117, Jet-Hot corrosion barrier coatings last over 14 times longer than chrome and more

than 140 times longer than high-temperature paint, enduring

more than 5,000 hours.

nCoat announced that its newly acquired Pennsylvania-based

operating subsidiary, Jet-Hot Inc., opened a new production plant

in Quakertown, Pa., a high-volume, automated automotive

aftermarket coating facility in the northeast United States. In

its current configuration, the plant increases capacity at Jet-Hot

by 30%.

Jet-Hot Inc. announced a new high-temperature, high-gloss

coating known as Extreme Sterling. The coating uses near-molecular (nano-scale) ceramic particulates in its binder formulation that provides the coating with an exceptional binding capability. Extreme Sterling coatings serve as a thermal barrier to

reduce pipe skin temperatures up to 400°F (220°C), reducing

the need for higher grade pipes and thermal wrap insulation materials under the hood.

nCoat announced it received the Frost and Sullivan 2007 North

American Product Innovation of the Year Award for nCoat’s

thermal barrier coatings (TBCs). The coatings, developed at

nCoat subsidiary nTech Inc., are nano-formulated surface treatments. The award recognized the high-temperature resistant

nanoslurry coatings, which have low porosity, high density, good

strength and flexibility at temperatures to 4200°F (2310°C). The

Metallography of NiCrAl/Bentonite

Abradable Coatings

Abradable coatings (such

as Ni-4Cr-4Al/Bentonite) entail a family of coatings that

are used throughout jet engines, primarily as sacrificial

coatings into which moving

components wear. The coatings generally consist of a

metallic phase and a nonmetallic phase, and contain

Typical microstructure for Ni-4Crrelatively high porosity levels

4Al/Bentonite.

(to 40%). Typical locations

for application of an abradable coating include the fan, and lowand high-pressure compressor sections.

The composite nature of abradable coatings presents unique challenges from a metallography standpoint. Due to thickness and

porosity considerations, vacuum impregnation with a low-viscosity

cold mount epoxy is the recommended mounting method. To facilitate impregnation with fast-cure epoxies (which are typically

more viscous than slow-cure epoxies), the resin can be heated to

approximately 150°F (150°C) prior to mixing with the hardener.

Holding the epoxy at elevated temperature for 15 to 20 minutes

should result in a significant improvement in the viscosity of the

epoxy.

Thermal Spray Accepted Practices Committee

www.asminternational.org/tss.

8

106

NanoSteel Redefines

Hardfacing

NanoSteel Co., Providence, R.I., a producer of nano-structured steel alloys for industrial applications, announced the commercial availability of its latest alloy line using the company’s

patented super hard steel (SHS) technology. SHS 9700 features

an ultrarefined crystalline microstructure, up to a thousand times

finer than existing compositions, and extreme hardness up to 69

HRC without the use of nickel, molybdenum, or tungsten. SHS

9700, produced in a range of cored-wire diameters suitable for

metal inert gas (MIG)/open-arc/submerged-arc welding applications and as an atomized powder for plasma-transferred arc

(PTA) welding applications, provides exceptional wear resistance in severe abrasion environments up to five times that of traditional chrome carbide and complex carbide materials.

The improved hardness/wear performance and cost-effective

pricing of SHS 9700 makes it an attractive hardfacing and wearplate welding material for commercial end users needing to extend the service life of mission-critical parts and components on

ground engaging tools and materials processing equipment used

in industries such as mining, construction, and oil and gas.

www.nanosteelco.com.

Purdue Makes Precision Parts

Via Laser and Machining

THERMAL SPRAY TIP

iTSSe

nanoscale particulates in the slurry efficiently bind with the

substrate materials, which minimizes the risk of delamination

problems. www.ncoat.com.

Researchers at Purdue University, West Lafayette, Ind., are

perfecting a technique to manufacture parts that have complex

shapes and precision internal features by depositing layers of

powder materials, melting the powder with a laser, and immediately machining each layer. The method can be used to create

parts made of advanced materials such as ceramics, which are

difficult to manufacture and cannot be machined without first

using a laser to soften the material, according to Yung Shin, professor of mechanical engineering and director of Purdue’s Center

for Laser-Based Manufacturing.

Because the technique enables parts to be formed one layer

at a time, it promises new industrial applications for manufacturing parts containing myriad internal features. Although the

basic laser deposition technique is not new, the researchers have

increased its precision by adding the machining step. The method

is about 20 times more accurate by adding the ability to machine

the part while it is being formed. They have developed a facility

that can actually deposit the powder, heat it with the laser, and

machine it at the same time.

The new technique could be ideal for manufacturing certain

kinds of ceramic components that are not produced in large

enough quantities to justify the expense of designing costly dies.

Components made in small lot sizes might be produced far more

economically by machining instead of using dies. But there

has been no practical way to machine the brittle ceramic

materials economically with the high precision needed for many

applications.

The technique is potentially practical for industry because it

does not require expensive clean room environments. Rolls-

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

Mechanical engineering doctoral student Kevin Schoeffel controls a laser-cladding system

developed as part of research led by Yung Shin, a professor of mechanical engineering and

director of Purdue’s Center for Laser-Based Manufacturing. A powdered material is deposited

and then melted by a direct-diode laser, producing coatings in a one-step process that is less

expensive and faster

Royce Corp. is evaluating the machining method for potential medium- and long-range

applications.

Purdue’s Office of Technology Commercialization has filed patents in connection with the

laser-deposition-machining technique, which is available for licensing. www.purdue.edu.

Raymor Industries Inc., Boisbriand, Quebec, Canada, a developer and producer of singlewalled carbon nanotubes,

nanomaterials, and advance

materials, announced that

its wholly-owned subsidiary,

Raymor Aerospace has signed

a conditional agreement for the

acquisition of a company specializing in manufacturing and

repairing precision parts the

aerospace and industrial sectors. The strategic acquisition

allows Raymor Aerospace to

rapidly implement a one-stop

shop for its specialized coating

services in these sectors.

www.raymor.com.

INDUSTRY NEWS

Raymor

Industries

Acquisition

Bolsters

Its Coating

Division

iTSSe

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

107

9

TSS News

Members of the TSS Board

Reelected to a Second Term

The TSS electorate, consisting of active TSS Board and Committee members, has re-elected the following people to the TSS Board for 2007-2010,

effective October 1, 2007:

Mr. Peter Heinrich, Manager, Thermal Spray, Linde Gas AG, Germany

Mr. William J. Lenling, Vice President and Materials Engineer, Thermal

Spray Technologies, Inc., Sun Prairie, Wis.

Dr. Roland D. Seals, FASM, Senior Staff Scientist, BWXT Y12

National Security Complex, Oak Ridge, Tenn.

Continuing in their leadership roles on the TSS Board are Mr. Peter Hanneforth, president; Mr. Mitchell Dorfman, vice president; Mr. Charles Kay,

secretary/treasurer; and Dr. Richard Knight, FASM, immediate past president.

Other TSS board members include:

Mr. Richard Bajan

Mr. Thomas S. Passek

Dr. Basil R. Marple

Executive Director

Dr. Christian Moreau, FASM

Mrs. Sarina Pastoric

Ms. Lysa Russo

Staff Liaison

Mr. Raymond J. Sinatra

Dr. Mark F. Smith, FASM

Board Liaison

Dorfman

Hanneforth

Heinrich

Knight

Lenling

Seals

Kay

International Thermal Spray

Conference & Exposition

(ITSC 2008)

June 2-4, 2008

Maastricht, Netherlands

Organized by the German Welding Society (DVS),

the ASM Thermal Spray Society (TSS)

and the International Institute of Welding (IIW).

For more information, visit www.dvs-ev.de/itsc2008;

or contact Cust. Srvc. Ctr., ASM Intl., Matls. Park, Ohio;

tel: 800/336-5152 (ext. 0) or 440/338-5151 (ext. 0);

fax: 440/338-4634;

e-mail: customerservice@asminternational.org;

Web: www.asminternational.org.

iTSSe

10

108

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

Register Today.

2008 Surface Engineering for Aerospace

and Defense Conference and Exposition

January 21-22, 2008

Coronado Springs Resort

Walt Disney World • Orlando, FL

This two day event will bring together surface engineering

professionals from a wide variety of disciplines – electroplating,

PVD, CVD, thermal spray, ion implantation – focused on problems

facing the aerospace and defense industries. Topics include:

•

•

•

•

Green Manufacturing and De-Manufacturing

Engineered Materials for Harsh Environments

Extending Service Life and Enhancing Performance

Surface Engineering and Global Climate Change

If your organization is involved in any aspect of surface finishing,

you won’t want to miss this unique opportunity! In addition to

the technical excellence of this conference, the networking

opportunities are invaluable.

To register for Surface Engineering for Aerospace and Defense visit

www.asminternational.org/surfaceengineering

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

109

iTSSe

11

THERMAL SPRAY TIP

Measuring Deposition Efficiency

Definition: Deposition efficiency (DE) is defined as an idealized measure of the percentage of particles introduced into

a spray jet that actually deposits onto a flat substrate without

overspray considerations.

Measurement: Deposition efficiency (DE) can be measured

according to the following procedure:

• Determine the mass (X ) of a clean, grit blasted 4 in. × 6 in.

× 0.125 in. (100 × 150 × 3 mm) flat steel plate

• Place powder into the powder feeder

• After stabilization of the spray parameters and powder feed,

spray material onto the steel plate for a known period of time

(e.g., 60 s) at a predetermined feed rate (e.g., 20 g/min) ensuring

that the spray pattern remains on the plate at all times. (The

plate may be cooled using air/gas jets directed at the rear face

of the plate.)

• Measure the mass (Y ) of the plate plus the coating.

• Determine the gain in mass due to the coating deposited (Z

= Y - X ).

• Divide the mass deposited in one minute (Z) by the powder

feed rate and multiply by 100 to give DE in %.

• Repeat the measurement a minimum of three times and take

the average.

Note: Deposition efficiency is only useful insofar as it provides

a measure for optimizing spray parameters.

Source: Handbook of Thermal Spray Technology, Ed. J.R.Davis,

ASM International, Materials Park, OH, 2004.

Thermal Spray Accepted Practices Committee

www.asminternational.org/tss.

iTSSe

12

110

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

Thermal Barrier

Coatings: The Basics

Andrea Scrivani and Gabriele Rizzi

Turbocoating S.p.A, Parma, Italy

hermal barrier coatings (TBCs) are widely used surface

treatments typically consisting of a top coat of Y2O3 air

plasma sprayed partially stabilized ZrO2, and a MCrAlY

bond coat (where M is Ni, Co, or NiCo), which can be

deposited using different thermal spray processes such as air plasma

spray (APS), vacuum plasma spray (VPS), and high-velocity oxyfuel (HVOF) [1-3]. Another example is a top coat of Y2O3 partially

stabilized ZrO2 deposited using electron-beam physical vapor deposition (EBPVD), and an aluminum alloy bond coat deposited using

chemical vapor deposition (CVD).

For many metallic components, adequate creep properties (creep

resistance, thermal efficiency, thermal shock resistance, etc.) can

only be achieved with the use of nickel and cobalt superalloy base

material plus adequate coatings and surface treatments to obtain resistance to oxidation and corrosion at high temperature. Repair of

components means restoring their original properties. Therefore,

these surface treatment processes are not only used during manufacture, but also during repair.

T

Mechanics of Thermal Spray

Thermal spray processes are widely used to coat components because they can deposit a range of materials and obtain thicknesses

from 80 to 2,000 Pm. The main stages of a thermal spray coating

deposition are:

• Feeding the coating material into the spray gun

• Heat transfer from plasma or combustion gas to melt coating

material

• Transport of melted particles on to the substrate surface

• Heat transfer from the melted particles to the substrate and solidification

• Coating formation by means of overlapping of several coating

material layers

The particles assume a splat configuration and solidify and transfer

the heat to the base material. The final coating consists of several

layers of coating materials. The bonding is generally mechanical,

created by local melting and diffusion.

Surface preparation is critical so that the spray particles can adhere and establish an integral coating. For thermal spray, the most

common surface preparation method is grit blasting the surface using

a suitable abrasive material such as corundum or silicon carbide.

The main parameters to be considered are the type of blasting machine, blasting media (type, grain size distribution, shape, and hardness), working pressure, and hardness of substrate materials. Tuning

of blasting parameters is crucial to obtain good surface preparation

without causing contamination from the blasting particles.

In the case of plasma spraying under a vacuum, the coating process

is carried out at reduced pressure (about 10 to 50 mbar). The jet velocity is higher because of the absence of air resistance, and the lack

of oxygen results in oxide-free coatings[3,4]. The higher jet velocity

and less cooling result in a higher-energy deposition, which creates

coatings that are denser and have higher chemical purity.

In turbine applications, air plasma spray is used to spray yttria

partially stabilized zirconia (functioning as the TBC) and also aluminum on the “fir-tree” section of blades to serve as a seal with

the rotor when the part is assembled. (The fir-tree section refers to

the bottom part of a blade that slots into the rotating assembly.)

Vacuum plasma spray is used to spray MCrAlY alloys as a bond

coat and a high-temperature corrosion- and oxidation-resistant

coating.

The HVOF process is used to deposit several anti-wear and anticorrosion coatings. The coatings are dense and the splat on the surface is ideal. The powder is injected into the flame by a suitable carrier gas (usually nitrogen), melted, and projected on to the substrate

surface. The most common materials sprayed using this technology

are metals, carbides, cermets, and some polymers[5-8].

Applying MCrAlY Coatings

Studies have been carried out to compare HVOF and LPPS-VPS

technologies by evaluating their MCrAlY bond coats[1, 3]. Commercial powder (AMDRY 995, a widely used coating) was used in tests

and deposited-film quality was assessed. Coatings from the two

processes were compared in terms of their microstructural (porosity,

oxide concentration, presence of unmelted particles ) and mechanical characteristics (hardness). The surface composition and morphology of the coatings were also determined, and specific efficiency tests were performed for the three technologies.

Vacuum plasma sprayed technologies are currently the state-ofthe-art for the production of MCrAlY alloy coatings, which serve

as oxidation-resistant material and the bond coat in TBC systems.

The quality of the coatings obtained by VPS is better than that obtained by means of HVOF (Fig. 1). Nevertheless, HVOF coatings

demonstrate a good porosity level due to the high flame velocity,

but the oxide content is slightly higher than in VPS coatings. Hardness is the same for both processes.

Prior to coating, serviced gas turbine components usually go

through repair processes. Factors that should be considered before

thermal spraying include:

• The extent of and quality of potential damage to the base material

Porosity, %

Oxides, %

Hardness, HV300

LPPS

Nearly zero

Nearly 0

370-450

HVOF

<1

<1

400-450

Fig. 1 — Coating samples from low pressure plasma spray (left) and

high velocity oxygen fuel processes (right).Scales at top right are 50Pm.

iTSSe

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

111

13

Set A

Set C

Parameter set

A

B

C

D

Porosity, %

11-14

17-19

21-23

26-28

Set B

Set D

Fig. 2 — Sets A, B, C, and D refer to increasing power level of the

plasma. The porosity varies; however, the pores are uniformly distributed for all the parameters.

• The presence of various kinds of materials that are carried over

from any repair processes. For example, the bulk material, and

welding and brazing materials having different thermal expansion

coefficients will influence the properties of the coating.

• The risk of cracks or damage from preheating by plasma spray

Possible solutions are HVOF technology, or using an improved

preheating procedure for LPPS coatings. The HVOF process is a

relatively cold process; i.e., preheating the components to high temperature is not needed, and the coatings have less oxides (similar to

LPPS). This process is also more economical.

Preheating to high temperature is needed for vacuum plasma spray

processes. The plasma jet generates a local overheating and the

inhomogeneous temperature sometimes reopens cracks or damage

in repaired areas. Therefore, an improved preheating procedure is

needed to minimize the contact between the plasma and the components. Turbocoating has designed an inert gas furnace for preheating.

Applying Top Coats

After deposition of metallic MCrAlY bond coats, a ceramic layer

could be deposited to reduce the life-service temperature of components. Usually yttria partially stabilized zirconia (YPSZ) is used

as a coating material and deposited by APS.

Typically, OEM specifications classify the ceramic top coat according to thickness. A thin TBC, usually applied to blades and

vanes, is defined as a 200 to 800Pm thick coating having from 5 to

20% porosity. A thick TBC, usually applied to stationary gas turbine components such as the combustion chamber or segments and

liner that cover turbine internal walls, is generally a 1.5 to 2.0mm

thick zirconia coating having up to 28% porosity.

Zirconium oxide (ZrO2) is selected due to its properties of low

heat conduction coefficient (making it useful as a thermal barrier)

and a higher coefficient of thermal expansion than that of most

oxides (such as alumina and chromia), which makes the deposition

of the ceramic coating on a metal alloy substrate easier. Furthermore, the relatively poor mechanical stability of ZrO2 caused by a

4% volume increase during transformation from tetragonal to monoclinic phase, has been substantially improved in recent years. This

is accomplished by partially stabilizing the tetragonal phase at room

temperature by adding suitable stabilizers such as calcium oxide

(CaO), magnesium oxide (MgO) and yttrium oxide (Y2O3). Yttria

is normally preferred since CaO and MgO tend to vaporize at high

temperatures[9, 10].

iTSSe

14

112

YPSZ is a multiphase material. At room temperature, the stable

cubic phase coexists with the tetragonal phase (metastable at room

temperature) and a small percentage of the monoclinic phase. This

structure produces better mechanical properties in terms of mechanical strength and fracture toughness[11].

The presence of monoclinic phase in the coating should be avoided

as much as possible to prevent the volume variation induced by

phase transformation, which could occur during the service of the

coating. Therefore, powders having low monoclinic content are preferred, and phase content in the coating after deposition has to be

checked carefully.

Comparing Porosity

Besides several applications of both thin and thick TBCs, Turbocoating studies have been carried out to develop a thick TBC to

resist to thermal cycling fatigue (TCF), paying attention to the microstructure and the coating porosity[12]. This development has been

engineered for application on gas turbine combustion chambers,

mainly on heat shields and liners.

Tests on APS sprayed yttria partially stabilized zirconia produced

using four different sets of parameters (with increasing level of

power) show that porosity varies from 11 to 28%. The coating structure is homogeneous (Fig. 2) with fine pores uniformly dispersed

in the coating matrix. In a TCF test, the coating samples passed 1,000

thermal cycles (from 1,000 to 20°C, or 1,830 to 68°F) with good

performance. This result shows that high coating cohesion coupled

with good structure is more important than absolute TBC porosity.

The presence of fine, uniformly distributed pores contributes to TCF

resistance, but the number of pores (the overall porosity) is of less

importance.

While thermal spray processes are versatile and widely used, they

cannot be used in some situations such as the coating of internal

cooling passages. In such cases, an aluminum coating is deposited

using the chemical vapor deposition process.

Conclusions

Thermal spray processes are widely used in gas turbine application thanks to their versatility. In particular, vacuum plasma spray

technologies currently remain the state of the art for the production

of MCrAlY alloy coatings to be used as oxidation-resistant material and bond coats in TBC systems. Nevertheless, HVOF coatings

demonstrate an acceptably low porosity level due to the high impact conditions during impingement and, additionally, the oxide

content is slightly higher with respect to VPS. On the other hand,

the HVOF process is less expensive than a VPS process.

The TBC developed and presented in this paper exhibited good

behavior with regard to thermal cycling tests. The process is robust

and produces a high-performance TBC coating having low sensitivity to variations in the process parameters.

iTSSe

References

1. A. Scrivani, et. al., A Comparative Study on HVOF, Vacuum Plasma

Spray and Axial Plasma Spray for CoNiCrAlY Alloy Deposition, Proc.

ITSC2001, Singapore, 28-30 May 2001.

2. A. Scrivani, et. al., On the Experimental Correlation Between The Properties of Yttria Partially Stabilized Zirconia Coatings And The Process Characteristics, Proc. ICCE/8, Tenerife, Spagna, 5 -11 August 2001.

3. A. Scrivani, et. al., A Comparative Study of High Velocity Oxygen Fuel,

Vacuum Plasma Spray (VPS) and Axial Plasma Spray (AxPS) for The Deposition of CoNiCrAlY Bond Coat Alloy, J. of Thermal Spray Tech., Vol.

12(3), Sept. 2003-1.

4. A. Scrivani, Thermal Spray Coatings: Introduction and Application to

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

the Power Generation Field,” Proc. of II course, Intl. Summer School on

Advanced Matl. Sci. & Tech., Advanced Coating Technologies, 28 Aug.1 Sept. 2000. Jesi-Ancona (Italy) p 124-133.

5. A. Scrivani, et. al., Resistance of Thermal Spray Coatings in Sour Environments: A Comparison of Tungsten Carbide, Chromium Carbide and

Inconel 625, Proc. EUROPM 99, Advances in Hard Materials Production,

Torino, Italia, 8-10 Nov. 1999.

6. A. Scrivani, et. al., A Contribution to the Surface Analysis and Characterization of HVOF Coatings for Petrochemical Application, Wear, Vol.

250/1-12, p 107-113, 2001.

7. A. Scrivani, et. al., A Comparative Study of the Deposition of Spray and

High Velocity Oxygen Fuel, Proc. ITSC2001, Singapore, 28-30 May 2001.

8. A. Scrivani, M. Rosso, and L. Salvarani, Performances and Reliability

of Thermal Spray Coatings WC Based Materials, Proc. 15th Plansee Seminar, Reutte, Austria, 28 May - 1 June 2001.

9. A. Scrivani, et. al., On The Experimental Correlation Between Plasma

Spray Process Conditions and Yttria Partially Stabilized Zirconia Coating

Properties, Thermal Spray, Surface Engineering via Applied Research,

Proc. ITSC2001, Ed. C. Berndt, ASM International, Materials Park, OH,

USA, p 1207-1210, 2001.

10. D.S. Suhr, T.E. Mitchell, and R.J. Keller, Microstructure and Durability

of Zirconia Thermal Barrier Coatings, Advances in Ceramics,” Vol. 3,

Ed. A. H. Hueur and L.W. Hobbs, American Ceramic Soc., USA, p 503517, 1982.

11. G.N. Heintze and R. McPherson, Structures of Plasma-Sprayed Zirconia Coatings, Advances in Ceramics, Vol. 24, Ed. S. Somiya, H. Yanagida,

and N. Yamamoto, American Ceramic Soc., USA, p 431-437, 1988.

12. A. Scrivani, H.K. Pugsley, and G. Rizzi, Development of Thick Thermal

Barrier Coating With Varying Porosities and Continually High Functional

Properties, Proc. ITSC2004, Osaka, Japan, 10-12 May 2004.

For more information: Andrea Scrivani is technical director, and Gabriele

Rizzi is R&D manager for long-term research projects (e-mail:

gabrielerizzi@turbocoating.it), Turbocoating S.p.A., Parma, Italy; Web

site: www.turbocoating.com.

CALENDAR

3–4 Dec. Surface Tech. & Functional Coatings, a European Exec. Seminar: Ermatingen, Switzerland. Contact Deutsche Gesellschaft für Materialkunde e.V., Frankfurt, Germany; tel: +49-(0)69-75306-757; fax: +49(0)69-75306-733; e-mail: np@dgm.de; Web site: www.dgm.de.

2008

21–22 Jan. Engrd. Surfaces for Aerospace & Defense: Lake Buena Vista,

Fla. Sponsored by ASM Intl. Contact Cust. Srvc. Ctr., ASM Intl., Matls.

Park, Ohio; tel: 800/336-5152 (ext. 5900) or 440/338-5151; fax: 440/3384634; e-mail: customerservice@asminternational.org; Web site: www.asminternational.org.

27–30 Jan. Paint & Coatings Expo (PACE 2008): Los Angeles, Calif.

Web site: www.pace2008.com.

28 Jan.–1 Feb. 32nd Intl. Conf. & Expo on Advanced Ceramics &

Composites: Daytona Beach, Fla. Contact Megan Mahan, mktg. dir., Amer.

Ceramic Soc., Westerville, Ohio; tel: 614/794-5894; e-mail:

mmahan@ceramics.org; Web site: www.ceramics.org/acc.

8-9 Feb. WTS 2008 (Workshop on Thermal Spray): New Delhi, India.

Organized by Metallizing Equipment Co. Pvt. Ltd., Jodhpur, India); Contact Mr. Girish Mathur; tel: +91 9351509835; or Mr. Noman M. Shaikh; tel:

+91-291-2747601; Web site: www.mecpl.com/wts-2008.

12–13 Feb. ShipTech: Biloxi, Miss. Contact Tricia Wright, event coord.,

Concurrent Technologies Corp., Johnstown, Pa.; tel: 814/269-2567; e-mail:

wright@ctc.com.

27–28 Feb. 48th Israel Ann. Conf. on Aerospace Sciences: Tel Aviv and

Haifa, Israel. Contact Dan Knassim Ltd., Ramat Gan, Israel; tel: 972-36133340, ext. 207; fax: 972-3-7604829; Web site: www.aeroconf.org.il.

iTSSe

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

113

15

Thermal Spray Coatings Protect

Steel Structures from Corrosion

etal spray, or thermal spray, is commonly used today

to protect steel structures from corrosion. In excess of

200 metric tons of zinc wire is sprayed annually in

New Zealand to protect steel structures in many different types of environments, from inland to submerged conditions.

This represents an area of 200,000 m2 (2.1 million square feet) with

a coating thickness of 75 Pm or 100,000 m2 (1.07 million square

feet) with a coating thickness of 150 Pm.

In one of those applications, Metallisation Ltd.’s, (Dudley, West

Midlands, UK) New Zealand distributor, Metal Spray Suppliers

(NZ) Ltd., supplied equipment and supplies to Edmonds Industrial

Coatings Ltd of Wanganui to apply a coating system for airport air

bridges in New Zealand. Typically, Pacific Rim airports are often

located on the coast and air bridges are exposed to the harsh marine

environment. Coating systems have to provide long-term, advanced

corrosion protection and be visually attractive. J & D McLennan

Ltd (ael.co.nz), responsible for maintenance of Airport equipment

for the whole of the South Pacific specified a finish and quality to

the same high standard as automotive bodywork. This meant creating a zinc anti-corrosion coating that was smooth enough to facilitate a functional, yet decorative, paint system, and protect the air

bridge against the elements.

Requirements for the job included an arc-spray system that would:

• Apply a smooth, high-quality zinc layer at the fastest rate possible without having to sand the surface smooth after spraying

• Be flexible enough to minimize equipment repositioning and

allow the operator good access to the air bridge

• Be reliable in a hostile blast and spray environment

• Be economical to use and easy to operate and maintain

Edmonds selected the Metallisation Arc 170 push/pull system,

which provided the required spray rates, as well as the necessary

10-m (33 ft) reach for convenient positioning. The Arc 170 is fast

and provides a high deposition rate and efficiency that doesn’t compromise the coating quality or integrity. The spray system’s fast

spray rate ensures that blast-prepared surfaces are coated as quickly

as possible, keeping oxidization and contamination of the interface

to a minimum. This is critical to achieve the strongest possible bond

to the surface. With the system, processing time for all anti-corrosion surface treatments has been cut by half to two days, and eliminated time consuming manual sanding.

Air bridges come in many forms to suit the diverse types of passenger aircraft. A complete air bridge can be up to 27 m (88 ft) long.

Using the Metallisation Arc 170 equipment, and the space available

at its extensive facility, Edmonds can complete the anti-corrosion

treatment of the air bridges in one process. The complete turnaround

time for an Apron drive air bridge is ten days. Resene Paints, working

in conjunction with McLennan, developed and specified the post

zinc arc spray paint system that would complement and work in synergy with the zinc layer. Resene proposed a low-build duplex paint

system that would incorporate all three methods of corrosion protection available; that is, sacrificial, inhibitive, and barrier. The

process sequence using the three-mode protection method was:

M

iTSSe

16

114

Air bridges docked to aircraft; bridges are given a thermal spray coating

to protect the steel structure from corrosion.

• Surface preparation to SA3 abrasive grit blast

• Apply a 100 Pm zinc arc spray with one pass

• Seal/build coat (2 applications) using Resene’s zinc-phosphate

inhibitive epoxy system

• Resene’s low sheen urethane top coat (2 applications) developed to suppress reflection from lights at the airport to aid the pilot’s

vision when taxiing the aircraft to the bridge

The Resene paint system is sprayed directly on to the as-sprayed

zinc. The smoothness of the zinc coating eliminated the need for

any dressing or prepaint preparation, which saved time, labor, and

expense. The competed air bridge with its attractive and functional

anti-corrosion coating system is then ready for a very long service

at any of New Zealand’s airports.

The first air bridge using this innovative system was installed at

Wellington Airport in October 1997, and since then air bridges have

been coated and supplied to Auckland, Melbourne and Sydney, with

many more proposed for the Australasian region. Nearly a decade

on, the first air bridge coating system is performing with ease in the

harsh conditions. J & D McLennan Ltd. guarantees the air bridge

coating system for 20 years. Edmonds has now provided anti-corrosion protection for more than 40 air bridges.

Arc-sprayed zinc provides a thicker, greener alternative to galvanizing, and furthermore, is not limited by tank size and does not

distort the work piece. Coating thickness may be varied from place

to place to provide extra protection in critical areas. The process is

not limited to zinc and the coating material may be selected specifically for the environment. The coating can be applied on site, without

creating any effluent disposal problems. The system requires a reduced stock of zinc, which means working capital is not tied up in

a molten zinc bath. Further savings are made, as fuel is not needed

to keep zinc molten when the process is not operational. Metal

spraying is also used to restore corrosion protection on damaged

areas of welded galvanized steel.

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

In another application, thermal spray coatings are used to protect

the Emsworth Lock and Dam on the Ohio River in the U.S. from

corrosion. Metallisation’s North American distributor, TMS Metalizing Systems Ltd., worked closely with its customer, Oregon Iron

Works (OIW) who has metal sprayed six dam gates with zincaluminum alloy.

The gates make up the bulkhead, which raise and lower the sluice

gate on the dam. This was part of an overhaul project to rehabilitate

the dam’s gate and mechanical electrical systems. OIW secured the

project with Pittsburgh’s District Office of the Corps.

The aim of the project was to metal spray the gates with zincaluminum coating to protect them from corrosion. Each of the six

gates measured 115 ft long and 12 to 14 ft high (35 m and 3.65 to

4.25 m). Consisting of steel T-bars and angle iron, they created

approximately 15,000 ft2 (1,400 m2) of surface area to be sprayed.

The job specifications required 85/15 zinc-aluminum material with

a minimum thickness of 16 mils (0.4 mm). The sheer size and shape

of the structure presented OIW with a number of challenges, especially having access to all surfaces.

TMS Metalizing Systems conferred with OIW to identify the

challenges and advise on the best possible approach to the project.

The outcome was to opt for two Metallisation Arc170 systems, a

700 A, high-production arc spray system with the required supplies

package reach of 33 ft (10 m).

TMS Metalizing Systems arranged on-site training to ensure the

metalizers were fully prepared prior to starting the project. To coincide with this training and preparation, OIW also enlisted the help

of SSPC ( the Society for Protective Coatings) to conduct the SSPC

Metallizing steel structures of the Emsworth locks on the Ohio River.

Thermal Spray Inspection Training Course, which supported OIW’s

ongoing commitment to quality and training of its staff.

The push/pull design of the arc spray system allows a 33 ft (10m)

supplies package, which enabled OIW to coat the top surfaces

without rotating the gate. The drum dispensers also resulted in

lower material costs, as spooling was not required. To protect

the gates from corrosion, they were metallized with 0.125 in. (3

mm) diameter, 85/15 zinc-aluminum alloy wire. The use of this

diameter wire also has the benefit of providing a good quality

coating at high throughputs with increased deposit efficiency.

www.metallisation.

Find the answers

you are looking for on the

Thermal Spray Society Forum.

Ask questions; bounce ideas; find the key solutions you and your business need!

The Thermal Spray Society Community

Website — It’s interactive, it’s easy, it’s

the place to be.

• Create your own Research Library.

• New search technology provides members

with the best in research tools. The more

you use and fine tune your personal search

agents, the more accurate they become.

Visit tss.asminternational.org now.

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

115

iTSSe

17

Calculated gas flow in a new powder port ring

holder designed and optimized to prevent

nozzle clogging and lump formation. Argon

flows through the circular ring channel and 16

convergent channels (in red) to form a gas

screen (in green) in front of the nozzle wall.

JTST

HIGHLIGHTS

The Journal of Thermal Spray

Technology (JTST), the official journal of

the ASM Thermal Spray Society,

publishes contributions on all aspects –

fundamental and practical – of thermal

spray science, including processes,

feedstock manufacture, testing, and

characterization. As the primary vehicle

for thermal spray information transfer, its

mission is to synergize the rapidly

advancing thermal spray industry and

related industries by presenting research

and development efforts leading to

advancements in implementable

engineering applications of the

technology.

JTST editor Christian Moreau has

announced that the December issue

16(4) is a special issue focusing on

thermal spray activities in the Nordic

countries of Europe. Guest editors for

this issue are Nicolaie Markocsan,

Per Nylén, Erja Turunen, Petri Vuoristo,

and Jan Wigren. Several articles are

highlighted here.

In addition to the print publication,

JTST is available online through

www.springerlink.com. For more

information, please visit

www.asminternational.org/tss.

iTSSe

18

116

“Clogging and Lump

Formation during

Atmospheric Plasma

Spraying with Powder

Injection Downstream the

Plasma Gun”

Isabelle Choquet,

Stefan Björklund,

Jimmy Johansson, and Jan Wigren

This study numerically and experimentally investigates lump formation during atmospheric

plasma spraying with powder injection downstream the plasma gun exit. A first set of investigations focused on the location and orientation

of the powder port injector. It turned out to be impossible to keep the coating quality while avoiding

lumps by simply moving the powder injector. A

new geometry of the powder port ring holder was

designed and optimized to prevent nozzle clogging, and lump formation using a gas screen. This

solution was successfully tested for applications

with Ni-5 wt.%Al and ZrO2-7 wt.%Y2O3 powders used in production. The possible secondary

effect of plasma jet shrouding by the gas screen

and its consequence on powder particles prior to

impact was also studied.

“Laser Shock Flier Impact

Simulation of ParticleSubstrate Interactions in

Cold Spray”

M. Jeandin, S. Barradas,

V. Guipont, R. Molins, M. Arrigoni,

M. Boustie, C. Bolis, L. Berthe,

and M. Ducos

Coating-substrate adhesion in cold spray is a

paramount property, the mechanisms of which

are not yet well elucidated. To go into these mechanisms, due to the intrinsic characteristics of the

cold spray process (particle low-temperature and

high velocity) direct observation and control of

in-flight particles and related phenomena cannot

be done easily. For this reason, an experimental

simulation of the particle-substrate reactions at

the particle impingement was developed. This

Simulation of Cu particle (ø 15Pm, v = 800 m.s1) impingement on Al.

simulation is based on original flier impact experiments from laser shock acceleration. Relevant interaction phenomena were featured and

studied as a function of shearing, plastic deformation, and phase transformation, primarily.

These phenomena were shown to be similar to

those involved in cold spray. This was ascertained

by the study of the Cu-Al metallurgically-reactive system using SEM, TEM, EPMA, and energy balance and diffusion calculations. This simulation could also be used to feed finite element

(FE) modeling of cold spray and laser shock flier

impact.

“Microstructural Studies of

Cold Sprayed Copper,

Nickel, and Nickel30%Copper Coatings”

Heli Koivuluoto, Juha Lagerbom,

and Petri Vuoristo

Cold spraying enables production of metallic

coatings with low porosity level and low oxygen

content. Several material properties such as electrical conductivity and corrosion resistance rely

on these properties. The aim of this study was

to characterize microstructural properties of cold

sprayed copper, nickel, and nickel-30%copper

coatings. Microstructures, denseness, and deformation of particles were investigated. SEM

analysis and corrosion tests were done to get information about through-porosity. Open porosity

has an important role on the protectiveness of anodically protective coatings, such as copper and

nickel. In this study cold sprayed Cu coating was

fully dense. However, cold sprayed Ni and Ni30%Cu coatings seemed to be microstructurally

dense, but some porosity in some areas of the coatings, especially in some parts of the particle

boundaries was noticed after corrosion tests. Furthermore, the effect of annealing on microstruc-

Morphology of Cu powder (BSA -22+5 Pm).

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

ture and corrosion test behavior was studied. Cold

sprayed Ni coating became denser during heat

treatment.

“A Method for

Characterizing the Degree

of Inter-particle Bond

Formation in Cold Sprayed

Coatings”

T.S. Price, P.H. Shipway,

D.G. McCartney, E. Calla,

and D. Zhang

The degree of bonding between particles within

cold sprayed deposits is of importance as it affects their mechanical and physical properties.

This paper describes a method for characterizing

the bonding between aluminium and copper particles following deposition by cold spraying. Aluminium and copper powders were blended in the

ratio 1:1 by volume, deposited onto a copper substrate, and subsequently heat treated at 400 °C for

15 minutes. An intermetallic layer formed along

some regions of the aluminium-copper boundaries, believed to be where true metal to metal

contact occurs. In other regions, metal to metal

contact was inhibited by the presence of oxide

films. Image analysis was employed to measure

the fraction of the aluminium–copper interface

covered with intermetallic phases and to estimate

intermetallic thicknesses. By increasing the primary gas pressure in the cold spray process an increase in the degree of inter-particle bond formation occurred.

BSE image of the heat treated Al-Cu deposit

sprayed at 29 bar at high magnification

showing Cu, bright, Al, dark, and three distinct

intermetallic layers at the interface. Spray direction top to bottom.

“Measuring Substrate

Temperature Variation

During Application of

Plasma Sprayed Zirconia

Coatings”

H.R. Salimijazi, L. Pershin,

T.W. Coyle, J. Mostaghimi,

S. Chandra, Y.C. Lau,

L. Rosenzweig, and E. Moran

Substrate temperature variation was measured

during plasma spraying of ZrO2 7%Y2O3 powder

using fast response thermocouples embedded

in the stainless steel surface. Coatings were deposited with both stationary and moving torches.

Particles velocity and temperature within the

plasma plume at 50 mm spray distance.

The substrate was either kept at room temperature at the start of coating deposition or pre-heated

to 270-300°C. Peak temperature during spraying

reached 450°C for a surface initially at room temperature, and 680°C for a surface preheated to

300°C before coating deposition. Preheating the

substrate reduced coating porosity by approximately 40%. The porosity at the center of the deposit was significantly lower than that at its periphery since particle temperature and velocity

were lower at the edges of the plasma plume than

along its axis. When a coating was applied with

a moving torch the substrate temperature did not

increase above 450°C, at which temperature heat

losses to the ambient equalled the heat supplied

by the plasma plume and particles. Coating

porosity decreased with distance from the substrate. As sequential layers of coating are applied

surface temperature increases and roughness decreases. Both of these factors suppress breakup of particles landing on the substrate and

thereby reduce coating porosity.

Hollis Joins

JTST Editorial Team

Dr. Christian Moreau, editor of the Journal of

Thermal Spray Technology, has announced that

Dr. Kendall Hollis, technical staff member, Los

Alamos National Laboratories (LANL), will join

Moreau

Hollis

ADVANCED MATERIALS & PROCESSES/NOVEMBER 2007

Kuroda

the JTST editorial team as associate editor.