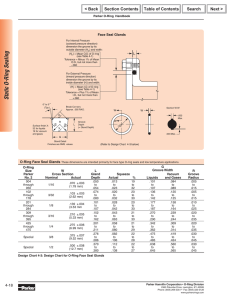

THE RIGHT SEAL

advertisement