Address Korenbree 16

Zip code NL-7271 LH

City

Borculo

Tel.

+31(0)545 272434

Fax.

+31(0)545 271932

Mail.

info@ctstwente.com

Web.

www.ctstwente.com

Fabricated basket strainers.

FBS-SISOT...

DN50 – DN150 (ANSI 2” – 24”)

PN10 – PN16

Range of Applications

The CTST Fabricated basket strainer is a versatile filter

liquid media or pasty media. Its main features are its high

level of output, its compact design and that it is very

quick and easy to clean. On special versions the inlet and

outlet flange can be positioned anywhere.

In the standard model the filter consist of a welded steel

housing with a cover fixed with nuts and bolts. The filter

can be fitted with the alternative options of a basket or

ring insert.

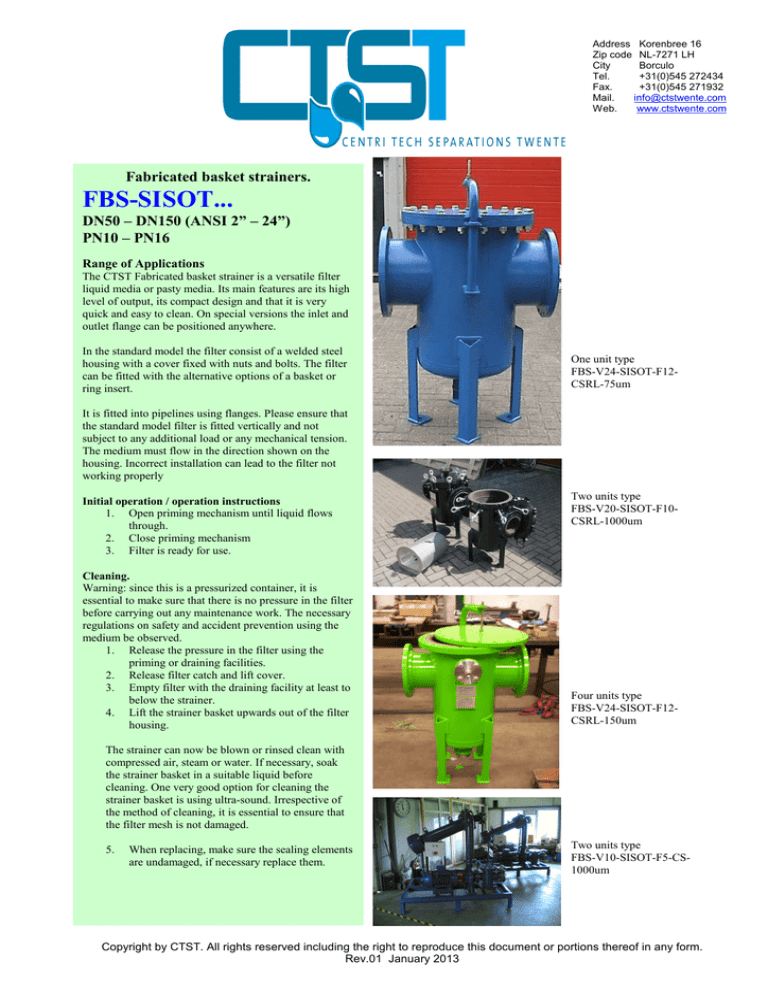

One unit type

FBS-V24-SISOT-F12CSRL-75um

It is fitted into pipelines using flanges. Please ensure that

the standard model filter is fitted vertically and not

subject to any additional load or any mechanical tension.

The medium must flow in the direction shown on the

housing. Incorrect installation can lead to the filter not

working properly

Initial operation / operation instructions

1. Open priming mechanism until liquid flows

through.

2. Close priming mechanism

3. Filter is ready for use.

Cleaning.

Warning: since this is a pressurized container, it is

essential to make sure that there is no pressure in the filter

before carrying out any maintenance work. The necessary

regulations on safety and accident prevention using the

medium be observed.

1. Release the pressure in the filter using the

priming or draining facilities.

2. Release filter catch and lift cover.

3. Empty filter with the draining facility at least to

below the strainer.

4. Lift the strainer basket upwards out of the filter

housing.

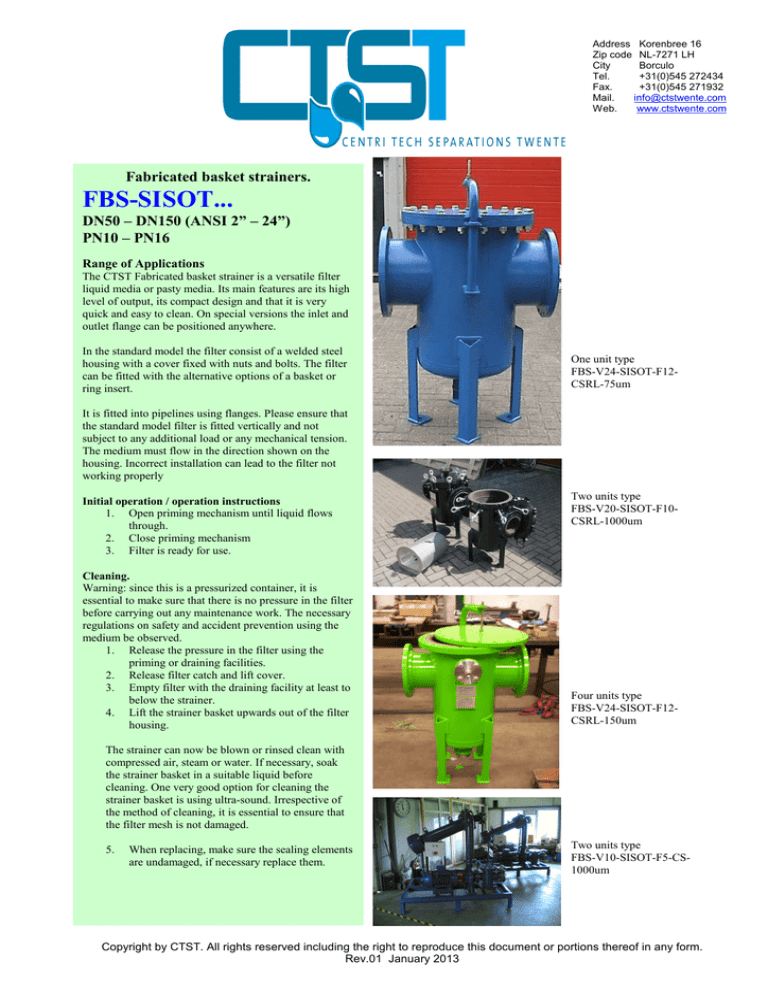

Two units type

FBS-V20-SISOT-F10CSRL-1000um

Four units type

FBS-V24-SISOT-F12CSRL-150um

The strainer can now be blown or rinsed clean with

compressed air, steam or water. If necessary, soak

the strainer basket in a suitable liquid before

cleaning. One very good option for cleaning the

strainer basket is using ultra-sound. Irrespective of

the method of cleaning, it is essential to ensure that

the filter mesh is not damaged.

5.

When replacing, make sure the sealing elements

are undamaged, if necessary replace them.

Two units type

FBS-V10-SISOT-F5-CS1000um

Copyright by CTST. All rights reserved including the right to reproduce this document or portions thereof in any form.

Rev.01 January 2013

Address Korenbree 16

Zip code NL-7271 LH

City

Borculo

Tel.

+31(0)545 272434

Fax.

+31(0)545 271932

Mail.

info@ctstwente.com

Web.

www.ctstwente.com

Applications

Water

The most popular application. From waste and water

treatment, boiler feed pumps, condensate service,

irrigation and general and intermediate water service.

Steel Mills

Cooling water for furnaces, rolling mills, lubricating oil,

fuel oil, etc.

Petrochemical

Refining crude oil to gasoline. Protection of pumps,

meters, etc.

Utilities

Protection for heat exchangers, pumps, and condensers,

strain cooling water, screen transformer oil, etc.

Chemical Plants

Separation of solid impurities from liquids. Protection of

process equipment.

Pulp and Paper

An industry which utilizes extensive filtration of water,

coatings and pigments.

Marine

General filtration of seawater in cooling, sanitary, and

general cleaning of lines. Fuel, hydraulic fluid, lubricating

systems, etc.

One units type

FBS-V11-SISOT-F6SS316-500um

Process Equipment

Protection of vital equipment such as flow meters, spray

nozzles, heat exchangers, condensers, pumps, etc. Other

industrial applications include food processing, paint,

cement, ink, pharmaceutical, cosmetics, tank car and

trucks, ceramics and many more.

One units type

FBS-V10-SISOT-F5SS304-2000um

One units type

Duplex FBS-V8-SISOT-F3CS-500um

Copyright by CTST. All rights reserved including the right to reproduce this document or portions thereof in any form.

Rev.01 January 2013

Address Korenbree 16

Zip code NL-7271 LH

City

Borculo

Tel.

+31(0)545 272434

Fax.

+31(0)545 271932

Mail.

info@ctstwente.com

Web.

www.ctstwente.com

Standard Model

Special Version and Optional Features

Filter insert

Strainer basket

Filter mesh size

10 - 1000 micron >1mm perforated plate.

Filter closing method

Bolts with nuts (fig.1)

Klammerschauben / Bajonet quick closure

Connection

Depending on design pressure and

temperature of the filter, Inlet and outlet at

different height.

To customer’s specification.

St 35.8, P265GH, 1.4301, 1.4404, 1.4541,

1.4571Asbestos-free gasket, EPDM, NBR,

VITON

St., St./1.4401, 1.4301, 1.4301/1.4401

Various plastic’s PP, PE, PVDF

Materials:

Housing and cover

Cover seal

Perforated plate / mesh

1.4571/1.4401, MS/Bz, Hastelloy C4,

various plastics

Magnetic filter insert

Steam, hot water or electric heating.

Optical, electrical

Additional filter

Heating

Differential pressure

display

-

Surface Treatment

Interior:

Housing, steel

Housing, Stainless steel

Housing, Plastic

PP, PE, PVDF, GRP/FRP

Preservative oil

Anti-corrosion paint, epoxy resin, rubber

Etched and passivated, electro-polished

Surface Treatment

Exterior:

Housing, Steel

Epoxy paint, RAL 5010 Blue

Housing, Stainless Steel

Glass bead blasted

Rubberized, epoxy coated as well as

customer specific

Etched and passivated, electro-polished

This product can be produced and supplied with special features and materials.

This upon request.

Please contact us!

One units type: FBS-V8-SISOT-F3-CS-1000um

Copyright by CTST. All rights reserved including the right to reproduce this document or portions thereof in any form.

Rev.01 January 2013

Address Korenbree 16

Zip code NL-7271 LH

City

Borculo

Tel.

+31(0)545 272434

Fax.

+31(0)545 271932

Mail.

info@ctstwente.com

Web.

www.ctstwente.com

* Subject to be changed

Copyright by CTST. All rights reserved including the right to reproduce this document or portions thereof in any form.

Rev.01 January 2013

Address Korenbree 16

Zip code NL-7271 LH

City

Borculo

Tel.

+31(0)545 272434

Fax.

+31(0)545 271932

Mail.

info@ctstwente.com

Web.

www.ctstwente.com

Photo’s and references

Weir entropie SA

Profilter

Unipro

Waveney Pumps Ltd

Bouman Machinefabriek

JM Water systems

Emcor Engineering Services

Copyright by CTST. All rights reserved including the right to reproduce this document or portions thereof in any form.

Rev.01 January 2013