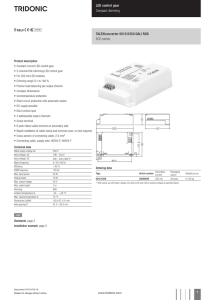

OPTOTRONIC Technical Guide.

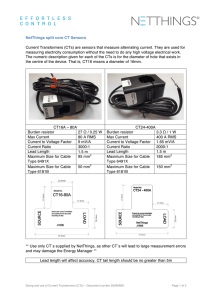

advertisement