Glenair CB Series “PogoPin” Connectors

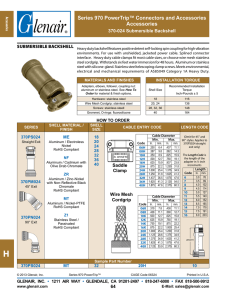

advertisement