)

in

in

Mrayl

dB/m

SLG Map

Map

–150

us

150

Echo from

8½-in

borehole wall

Echo from

7-in casing

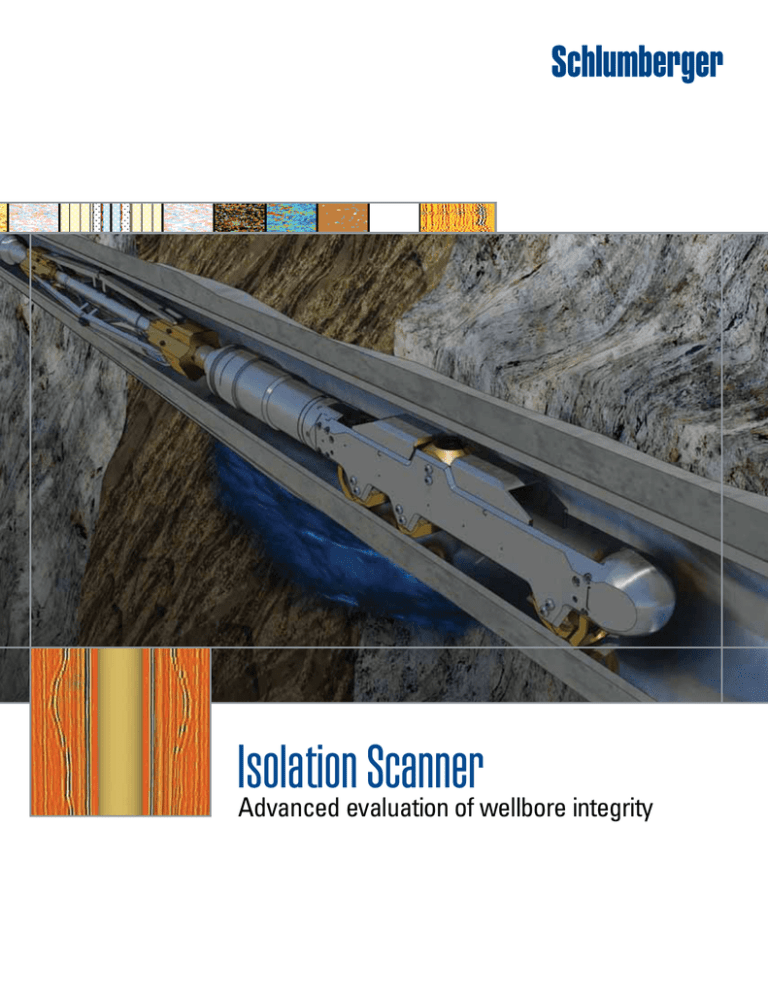

Isolation

Scanner

Advanced evaluation of wellbore integrity

Isolation Scanner* cement evaluation service integrates the conventional

pulse-echo technique with flexural wave propagation to fully characterize

the cased hole annular environment while evaluating casing condition.

Applications

Differentiate highperformance lightweight

cements from liquids

■

Map annulus material as

solid, liquid, or gas

■

Assess hydraulic isolation

■

Identify channels and defects

in annular isolating material

■

Determine casing internal

diameter and thickness

■

Assess annulus beyond the

casing/cement interface

■

C

ement placement is a critical component of a well’s architecture

for ensuring mechanical support of the casing, providing protection

from fluid corrosion, and, most importantly, isolating permeable zones

with different pressure regimes to prevent hydraulic communication.

Conventional cement bond log (CBL) and ultrasonic pulse-echo techniques are sometimes used together to diagnose zonal isolation but

encounter difficulties when attempting to evaluate cements with low

acoustic impedance or cements contaminated with mud. Ambiguity can

result because these tools rely on a significant contrast in acoustic

impedance between the cement and displaced fluid to identify solids.

Isolation Scanner cement evaluation service provides more certainty by

combining the pulse-echo technique with a new ultrasonic technique that

induces a flexural wave in the casing with a transmitter and measures the

resulting signals at two receivers. The attenuation calculated between the

two receivers provides an independent response that is paired with the

pulse-echo measurement and compared with a laboratory-measured

database to produce an image of the material immediately behind the

casing. By measuring radially beyond traditional cement evaluation boundaries,

Isolation Scanner service confirms zonal isolation, pinpoints any channels in

the cement, and ensures confident squeeze or no-squeeze decisions.

The signals following the casing arrivals arising from the interface

between the annulus and the borehole or outer casing can be detected

and measured. These third-interface echoes (TIEs) provide the position

f the casing within the borehole, and if the borehole size is known, the

velocity of the annulus material can be determined. This additional

information, available only through the flexural measurements, can

provide useful information for remedial applications and serve to confirm

or determine the correct interpretation for complex evaluations.

8

6

Gas

Liquid

Cement

Contaminated cement

Acoustic impedance, 4

Mrayl

Difficult to diagnose with

acoustic impedance or

CBL measurements alone

2

Isolation Scanner cement evaluation

service fully characterizes the cased

hole environment, including casing

position in the borehole, borehole and

outer string imaging, and material

identification from velocity analysis.

Neat

Increasing

contamination

Light

0

Identifying and distinguishing various well fluids from cement with low acoustic

impedance is difficult for CBL and ultrasonic pulse-echo techniques.

x250

R

Flexural wave imaging

Pulse-echo tool

x300

Annulus

Formation

Pulse

echo

Pitch-catch propagation

The Isolation Scanner pulse-echo acoustic impedance measurement

is made with a rotating subassembly containing four transducers.

The normal-incidence transducer is oriented 180° from the other

three transducers. The three obliquely aligned transducers transmit

and receive high-frequency pulsed beams (on the order of 250 kHz)

to excite the casing in a flexural mode. Once excited in the casing,

the flexural wave propagates while radiating acoustic energy into

the annulus and back toward the receiving transducers, resulting

in a circumferential scan of the casing, annulus, cement, and nearwellbore formation. The annulus-propagating energy is reflected at

interfaces that present an acoustic contrast, such as the cement/

formation interface, and propagates back through the casing predominantly as a flexural wave that reradiates energy into the casing fluid.

The Isolation Scanner sub implements the

pulse-echo (normal-incidence) technique

with four transducers: a transreceiver and

the flexural wave imager comprising one

transmitter and two receivers obliquely

aligned to excite the casing flexural mode.

Flexural wave (TIE)

Flexural wave (casing arrival)

Ultrasonic wave

Borehole

T

x350

Casing

80 90 100 110 120 130 140 150 160 170

Time, us

Geometrical interpretation of signal propagation for the pulse-echo

(blue paths) and flexural wave imaging (green paths) techniques shows

that the pitch-catch flexural wave signal separates into an early-arriving

(or casing) signal and a later-arriving (TIE) signal in reference to the first

interface encountered in the annulus (the inner and outer walls of the casing

are the first and second interfaces, respectively). The attenuation of the

casing arrival amplitude complements the pulse-echo measurement to

determine whether the material behind the casing is a fluid or a solid. If

TIEs are present in the acquired data, they are used to further enhance

the characterization of the cased hole environment in terms of the state and

acoustic properties (wave speed) of the material filling the annulus, the position of the casing within the hole, and the geometrical shape of the hole.

Insight through attenuation

Solid-liquid-gas mapping

The rate of energy radiation into the annulus depends on the acoustic

properties of the annular fill. The attenuation is estimated by capturing the reflected signals at two of the receivers, which are a known

distance apart, and calculating the decay rate of the received signal.

Attenuation is expressed in decibels per centimeter.

The first goal of Isolation Scanner processing is to provide a robust

interpreted image of the material immediately behind the casing. The

inputs are cement impedance determined by the pulse-echo measurement and flexural wave attenuation computed from the amplitude of

the casing arrivals on the near and far receivers. These two independent

measurements are linked to the properties of both the fluid inside

the casing and the outside medium through an invertible relation.

Combining them accounts for the effect of the inside fluid, which

eliminates the need for logging specific fluid-property measurements.

For a fluid filling the annulus, the attenuation is approximately proportional to the acoustic impedance. For cement bonded to the casing, the

attenuation exhibits a more complex behavior as a function of the

velocities at which the compressional and shear waves propagate in

the cement. As shown in the plot of flexural attenuation versus acoustic

impedance for a well-bonded cement, below a critical impedance (Zc)

of approximately 3.9 Mrayl, the attenuation increases linearly with the

impedance of the annular fill, whether the fill is liquid or solid. Beyond

3.9-Mrayl Zc, only the shear waves can propagate in the cement, and

the attenuation drops sharply to small values. A high-impedance cement,

such as Class G, has an attenuation similar to that of a liquid. This

ambiguity in identifying cement is resolved by determining the acoustic

impedance of the cement with the pulse-echo technique. However, the

distinct attenuation of low-impedance cements, such as lightweight or

contaminated cements, is used to differentiate them from fluids.

1

Solid

Liquid

Water

Gas

0.9

0.8

The processing output is a solid-liquid-gas (SLG) map displaying the

most likely material behind the casing. The map is computed during

an initialization step before logging by using a priori knowledge of the

possible materials:

■

■

■

■

Gas is defined as a very low impedance material, independent of

any input.

Liquid is defined as a liquid with the expected acoustic impedance

of the mud displaced by the cement, with provisions for possible

deviations from this value.

Solid is defined through the expected type of cement. A laboratorymeasured database is used to convert the material selection into

acoustic properties, again with provisions made for some contamination or incompletely set cement.

Areas corresponding to inconsistencies between the measurements (for example, at collars) are shown in white.

The mapped states are obtained for each azimuth by locating the

pulse-echo and flexural attenuation measurements, corrected for the

effect of the inside fluid, on the map with the areas encompassed by

each state.

0.7

0.6

Flexural attenuation,

0.5

dB/cm

0.4

1.8

0.3

1.6

1.4

0.2

1.2

Zc

0.1

0

Gas

Liquid

Solid

0

1

2

3

4

5

Acoustic impedance, Mrayl

Flexural wave attenuation of a well-bonded cement is plotted as a function

of acoustic impedance for various materials. The value of Zc corresponds to

the critical compressional wave speed of the cement.

6

1

Attenuation,

0.8

dB/cm

0.6

0.4

Nominal uncontaminated

Class G cement

0.2

0

–0.2

-2

0

2

4

6

Zusit, Mrayl

8

Three clouds of points are generated in SLG mapping of the measurement

plane for a Class G cement. Zusit is the impedance determined by the pulseecho technique; the attenuation is for the flexural wave technique.

10

x300

By measuring radially and beyond traditional cement evaluation boundaries,

Isolation Scanner service confirms zonal isolation, pinpoints any channels

in the cement, and ensures confident squeeze or no-squeeze decisions.

x350

Casing

Collar

Locator

–10

30

Depth, m

–500.0000

–6.0000

–5.6000

–5.2000

–4.8000

–4.4000

–3.6000

–3.2000

–2.6000

–2.4000

–2.0000

–1.6000

–1.2000

–0.6000

–0.4000

0.5000

–500.0000

–0.0780

–0.0680

–0.0520

–0.0440

–0.0380

–0.0280

–0.0200

–0.0120

–0.0040

0.0120

0.0280

0.0360

0.0440

0.0520

0.0600

0.0880

0.0760

Maximum

Internal

Radius

4.5 in

3.0 3.0 in

External

Radius

Average

(ERAV)

4.5 in

4.5

External

Radius

Average

(ERAV)

3.0 3.0 in

Minimum

Internal

Radius

Amplitude

Internal

of Echo

Radii Minus

Minus Max. Average, 4.5 in

(Rugosity)

in

Minimum

Internal

Radius

4.5

Maximum

Internal

Radius

3.0 3.0 in

–500.0000

–0.0780

–0.0680

–0.0520

–0.0440

–0.0380

–0.0280

–0.0200

–0.0120

–0.0040

0.0040

0.0120

0.0200

0.0280

0.0360

0.0440

0.0520

0.0600

0.0680

0.0760

–500.0000

–0.03000

2.8000

2.9091

3.0182

3.1273

3.2364

3.3454

3.5638

3.6727

3.7818

3.8909

4.0000

0.0000

50.0000

57.0000

64.0000

71.0000

78.0000

85.0000

92.0000

99.0000

106.0000

113.0000

120.0000

127.0000

134.0000

141.0000

155.0000

Thickness

Flexural

Minus

4.5 Average, Impedance, Attenuation,

dB/m

Mrayl

in

Solid

Liquid

Gas

Seal

No seal

0º

SLG Map

Hydraulic

Communication

Map

Min.

VDL of Far Re

–150

x200

Echo from

8½-in

borehole wall

x250

x300

x350

In additional to pulse-echo information on the rugosity, radius, cross section, and thickness of the 7-in [17.8-cm] casing, Isolation Scanner service processed the

acoustic impedance and flexural attenuation data to produce an SLG map. Although the cement is heavy Class G, the flexural attenuation map clearly displays

low-density material from X,320 to X,270 m, revealing that the cement is contaminated in that interval. Regardless of the density difference, the material is correctly

indicated as solid on the SLG map.

New measurements from formation-wall echoes

In addition to the SLG map identifying the annular fill immediately

behind the casing, a further Isolation Scanner objective is to extract

relevant information from the annulus/formation reflection echo or

echoes for quantifying the state of the annulus between the casing

and formation. First, the echoes following the casing arrival are detected

and their time of arrival and amplitude measured. From the time differences between the reflection echoes and the casing arrival—provided

sufficient echo azimuthal presence is available in the data—the casing

centering within the borehole can be determined. This is conveniently

presented as a percentage, with 100% representing perfect centering

and 0% for fully eccentered casing, in contact with the formation wall.

If the borehole diameter is known, the time-difference processing can

be further converted into material wave velocity and is displayed as

an annulus velocity map.

Other new measurements possible with the Isolation Scanner TIE

reflected from the cement/formation interface are

■

estimated wave velocity, which can be used to confirm the

SLG map and better understand cement placement

■

imaged borehole shape

■

imaged outer string to reveal corrosion and damage.

Hole enlargement

Depth, m

X,673

X,674

X,675

X,676

Casing

arrival

X,677

X,678

Echo from

formation

wall

Hole enlargement

X,679

X,680

X,681

X,682

X,683

X,684

Isolation Scanner imaging of the formation wall through casing and cement reveals

hole enlargement (caving) in the reflection echo from the cement/formation interface at

two opposite azimuths in the intervals X,673–X,675 m and X,679–X,682 m. The left-side

image, displaying the raw data at all azimuths, shows that the formation-wall echo is

present at nearly all azimuths. Echo moveout appears sinusoidal because of casing

eccentering. Each cycle represents a tool azimuthal scan.

x300

Measurement Specifications

x350

Isolation Scanner Tool

Output†Solid-liquid-gas

map of annulus material, hydraulic

communication map, acoustic impedance, flexural

attenuation, rugosity image, casing thickness image,

internal radius image

Max. logging speed

Standard resolution (6 in, 10° sampling): 823 m/h [2,700 ft/h]

High resolution (0.6 in, 5° sampling): 172 m/h

[563 ft/h]

Range of measurement

Min. casing thickness: 0.38 cm [0.15 in]

Max. casing thickness: 2.01 cm [0.79 in]

Vertical resolution

High resolution: 1.52 cm [0.6 in]

High speed: 15.24 cm [6 in]

‡

Range: 0 to 10 Mrayl

Acoustic impedance Resolution: 0.2 Mrayl

Accuracy: 0 to 3.3 Mrayl = ±0.5 Mrayl,

>3.3 Mrayl = ±15%

Flexural attenuation

Range: 0 to 2 dB/cm§

Resolution: 0.05 dB/cm§

Accuracy: 0.01 dB/cm§

Min. quantifiable channel width 30 mm [1.2 in]

Casing and annulus up to 7.62 cm [3 in]

Depth of investigation†

Mud type or weight limitation†† Conditions simulated before logging

Combinability

Bottom only, combinable with most wireline tools

Telemetry: fast transfer bus (FTB) or enhanced FTB (EFTB)

Special applications

H2S service

†Investigation

of annulus width depends on the presence of third-interface echoes. Analysis and processing

beyond cement evaluation can yield additional answers through additional outputs, including the Variable

Density log (VDL) of the annulus waveform and polar movies in AVI format.

‡Differentiation

of materials by acoustic impedance alone requires a minimum gap of 0.5 MRayl between

the fluid behind the casing and a solid.

§For

8-mm [0.3-in] casing thickness.

††Max.

mud weight depends on the mud formulation, sub used, and casing size and weight, which are

simulated before logging.

Mechanical Specifications

Isolation Scanner Tool

Max. temperature

177 degC [350 degF]

Pressure range 1 to 138 MPa [145 to 20,000 psi]

Casing size—min.†4 1⁄2 in (min. pass-through restriction: 4 in)

Casing size—max.†9 5⁄8 in

Outside diameter

IBCS-A: 8.57 cm [3.375 in]

IBCS-B: 11.36 cm [4.472 in]

IBCS-C: 16.91 cm [6.657 in]

Length without sub

6.01 m [19.73 ft]

Weight without sub

151 kg [333 lbm]

Sub length, weight

IBCS-A: 61.22 cm [24.10 in], 7.59 kg [16.75 lbm]

IBCS-B: 60.32 cm [23.75 in], 9.36 kg [20.64 lbm]

IBCS-C: 60.32 cm [23.75 in], 10.73 kg [23.66 lbm]

10,000 N [2,250 lbf]

Sub max. tension

Sub max. compression

50,000 N [12,250 lbf]

†Limits

for casing size depend on the sub used. Data can be acquired in casing larger than 9 5⁄8 in with

low-attenuation mud (e.g., water, brine).

–3.2000

–2.6000

–2.4000

–2.0000

–1.6000

–1.2000

–0.6000

–0.4000

0.5000

–0.0280

–0.0200

–0.0120

–0.0040

0.0120

0.0280

0.0360

0.0440

0.0520

0.0600

0.0880

0.0760

4.5 in 3.0 3.0 in 4.5

External

Radius

Average

(ERAV)

External

Radius

Average

(ERAV)

Isolation Scanner

4.5 in 3.0 3.0 in 4.5

–0.0200

–0.0120

–0.0040

0.0040

0.0120

0.0200

0.0280

0.0360

0.0440

0.0520

0.0600

0.0680

0.0760

3.3454

3.5638

3.6727

3.7818

3.8909

4.0000

92.0000

99.0000

106.0000

113.0000

120.0000

127.0000

134.0000

141.0000

155.0000

Minimum Maximum

Internal

Internal

mplitude Internal

Radius

Radius Thickness

Flexural

of Echo Radii Minus

Minus

inus Max. Average, 4.5 in 3.0 3.0 in 4.5 Average, Impedance, Attenuation,

dB/m

Rugosity)

Mrayl

in

SLG Map

in

Depth, m

0º

•

7-in

casing

180º

x200

8½-in

borehole

x250

Min.

Amplitude

Max.

Hydraulic

x300

Communication VDL of Far Receiver at Two Opposing Azimuths,

Map

us

–150

150

x350

Echo from

8½-in

borehole wall

Echo from

7-in casing

www.slb.com/scanner

*Mark of Schlumberger

Copyright © 2011 Schlumberger. All rights reserved. 11-PR-0028

(Rugosity)