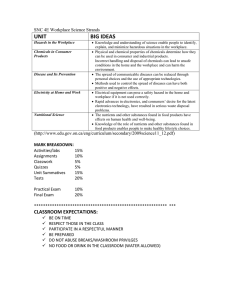

Working in the Science Industry: Procedures, Safety, and Lab Design

advertisement