CMS Audit Tool Components for Ambulatory Surgical Facilities

advertisement

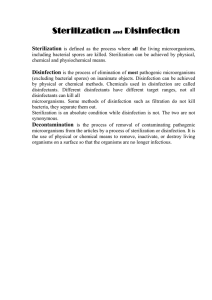

Centers for Medicare and Medicaid Services Audit Tool Components for Ambulatory Surgical Facilities Patient Safety in the Ambulatory Surgical Setting 2 Hand Hygiene—Centers for Medicare and Medicaid Services (CMS) Requirements • Staff to perform hand hygiene: – – – – 3 After removing gloves After direct patient contact Before performing invasive procedures After contact with blood, body fluids, or contaminated surfaces (even if gloves are worn) Hand Hygiene—CMS Requirements • Hand hygiene supplies in patient care areas include the following: – Availability of sinks with soap, water, and paper towels in all patient care areas – Installation and availability of alcohol-based handrub, according to Life Safety Code® requirements 4 Handwashing Policy When hands are visibly dirty or contaminated with blood or other body fluids, perform hand hygiene with soap and water. Procedure • Turn on water to a comfortable warm temperature. • Moisten hands with soap and water and make a heavy lather. • Wash well under running water for a minimum of 15 to 30 seconds, using friction. • Rinse hands well under running water. • Dry hands with a clean paper towel. • Use the paper towel to turn off the faucet, then discard the towel. 5 Hand Hygiene—Alcohol-Based Handrub • If hands are not visibly soiled, use an alcohol-based handrub for routinely decontaminating hands in all clinical situations other than those listed under “Handwashing.” • When decontaminating hands with an alcoholbased handrub, apply product to palm of one hand and rub hands together, covering all surfaces of hands and fingers until hands are dry. 6 Hand Hygiene—Alcohol-Based Handrub • Follow the manufacturer’s recommendations regarding the volume of product to use. • Alcohol-based handrubs are not sporicidal. • Consider washing hands with soap and water if contact with spores (e.g., Clostridium difficile) is likely to have occurred. The physical action of washing and rinsing hands, if done appropriately, will likely remove spores from the surface of the hands. 7 Hand Hygiene—Glove Usage CMS requires the following: • Wear gloves for procedures that might involve contact with blood and body fluids. • Wear gloves when handling potentially contaminated equipment. • Remove gloves when moving to the next task or patient. • Monitor hand hygiene by observing staff who are directly involved in patient care (e.g., physicians, nurses) (monitoring tool provided). 8 Safe Injection Practices—CMS Requirements • • • • • Needles are used for only one patient. Syringes are used for only one patient. Medication vials are always entered with a new needle. Medication vials are always entered with a new syringe. Medications that are predrawn are labeled with the time of draw, initials of the person drawing, medication name, strength, and expiration date or time. • Single-dose (single-use) medication vials are used for only one patient. 9 Safe Injection Practices—CMS Requirements • Manufactured prefilled syringes are used for only one patient. • Bags of intravenous solution are used for only one patient. • Medication administration tubing and connectors are used for only one patient. • Multidose injectable medications are used for only one patient. • The rubber septum on a multidose vial used for more than one patient is disinfected with alcohol prior to each entry. 10 Safe Injection Practices—CMS Requirements • Multidose medications used for more than one patient are dated when they are first opened and discarded within 28 days of opening or according to manufacturer’s recommendations, whichever comes first. • Multidose medications used for more than one patient, are not stored or accessed in the immediate areas where direct patient contact occurs. • All sharps are disposed of in a puncture-resistant sharps container. • Sharps containers are replaced when the fill line is reached. 11 Single-Use Devices, Sterilization, and HighLevel Disinfection—CMS Requirements • Precleaning must always be performed prior to sterilization and high-level disinfection. • Sterilization must be performed for critical equipment (i.e., instruments and equipment that enter normally sterile tissue or the vascular system, such as surgical instruments). • High-level disinfection must be performed for semicritical equipment (i.e., items that come into contact with nonintact skin or mucous membranes, such as reusable flexible endoscopes and laryngoscope blades). 12 Single-Use Devices—CMS Requirements • If single-use devices are reprocessed, they are devices that are: – Approved by the U.S Food and Drug Administration (FDA) for reprocessing – Reprocessed by an FDA-approved reprocessor 13 Sterilization—CMS Requirements • Critical equipment is sterilized. • Items are precleaned according to manufacturer’s instructions or evidence-based guidelines prior to sterilization. • Medical devices and instruments are visually inspected for residual soil and recleaned as needed before packaging and sterilization. • Method of sterilization is defined (e.g., steam autoclave, peracetic acid). • A chemical indicator is placed in each load. 14 Sterilization—CMS Requirements • A biologic indicator is performed at least weekly and with all implantable loads. • Each load is monitored with mechanical indicators (e.g., time, temperature, pressure). • Documentation for each piece of sterilization equipment is maintained and up to date and includes results from each load. • Items are appropriately contained and handled during the sterilization process to ensure that sterility is not compromised prior to use. 15 Sterilization—CMS Requirements • After sterilization, medical devices and instruments are stored in a designated clean area so that sterility is not compromised. • Sterile packages are inspected for integrity, and compromised packages are reprocessed. 16 High-Level Disinfection—CMS Requirements • Semicritical equipment is high-level disinfected or sterilized. • Method of high-level disinfection is specified, such as manual, automated, or other processes. • Items are precleaned according to manufacturer’s instructions or evidence-based guidelines prior to high-level disinfection. • Medical devices and instruments are visually inspected for residual soil and recleaned as needed before high-level disinfection. 17 High-Level Disinfection —CMS Requirements • High-level disinfection equipment is maintained according to manufacturer instructions. • Chemicals used for high-level disinfection are: – Prepared according to manufacturer instructions – Tested for appropriate concentration according to manufacturer’s instructions – Replaced according to manufacturer’s instructions – Documented to have been prepared and replaced according to manufacturer’s instructions 18 High-Level Disinfection—CMS Requirements • Instruments requiring high-level disinfection are: – Disinfected for the appropriate length of time as specified by manufacturer’s instructions or evidence-based guidelines – Disinfected at the appropriate temperature as specified by manufacturer’s instructions or evidence-based guidelines • Items that undergo high-level disinfection are allowed to dry before use. • Following high-level disinfection, items are stored in a designated clean area in a manner to prevent contamination. 19 Point-of-Care Devices (e.g., blood glucose meter)— CMS Requirements • A new single-use, auto-disabling lancing device is used for each patient. • The glucose meter is not used on more than one patient unless the manufacturer’s instructions indicate this is permissible. • The glucose meter is cleaned and disinfected after every use. 20 Environmental Cleaning—CMS Requirements • Observations are to be made of staff who perform environmental cleaning (e.g., surgical technicians, cleaning staff). • Operating rooms (OR) are cleaned and disinfected after each surgical or invasive procedure with an Environmental Protection Agency (EPA)-registered disinfectant. • ORs are terminally cleaned daily. • High-touch surfaces in patient care areas are cleaned and disinfected with an EPA-registered disinfectant. • The ambulatory surgical facility has a procedure in place to decontaminate gross spills of blood. 21 References Centers for Disease Control and Prevention. Guideline for hand hygiene in health-care settings: recommendations of the Healthcare Infection Control Practices Advisory Committee and the HICPAC/SHEA/APIC/ IDSA Hand Hygiene Task Force [online]. MMWR Morbid Mortal Week Rep 2002 Oct 25 [cited 2011 Oct 26]. http://www.cdc.gov/mmwr/PDF/rr/rr5116.pdf. Centers for Disease Control and Prevention, Healthcare Infection Control Practices Advisory Committee. Guide to infection prevention for outpatient settings: minimum expectations for safe care [online]. 2011 May [cited 2011 Oct 26]. http://www.cdc.gov/HAI/pdfs/guidelines/standatds-of-ambulatorycare-7-2011.pdf. 22 References Centers for Medicare and Medicaid Services. State Operations Manual (SOM) appendix L, ambulatory surgical centers (ASC) comprehensive revision [memorandum online]. 2009 May 15. [cited 2011 Oct 26]. https://www.cms.gov/SurveyCertificationGeninfo/downloads/SCLetter09_37.pd f. Dolan SA, Felizardo G, Barnes S, et al. APIC position paper: Safe injection, infusion, and medication vial practices in health care [online]. Am J Infect Control 2010 Apr [cited 2011 Oct 26]. http://www.apic.org/Resource_/TinyMceFileManager/Position_Statements/AJIC _Safe_Injection0310.pdf. 23 Additional Resources Ambulatory Surgery Center Quality Collaboration. Sterilization audit checklist [online]. [cited 2011 Oct 26]. http://www.ascquality.org/Library/sterilizationhighleveldisinfectiontoolkit/Sterilization%20 Audit%20Checklist%20SPSmedical.pdf. ASGE Quality Assurance in Endoscopy Committee, Petersen BT, Chennat J, et al. Multisociety guideline on reprocessing flexible gastrointestinal endoscopes [online]. Gastrointest Endosc 2011 Jun [cited 2011 Oct 26]. http://www.asge.org/uploadedFiles/Publications_and_Products/Practice_Guidelines/Mult isociety%20guideline%20on%20reprocessing%20flexible%20gastrointestinal.pdf. Association for Professionals in Infection Control and Epidemiology. Instrument cleaning, wrapping/packaging, and sterilization: competency [competency checklist online]. 2005 May [cited 2011 Oct 26]. http://www.ascquality.org/Library/sterilizationhighleveldisinfectiontoolkit/APIC%20Steriliz ation%20Competency.doc. 24 Additional Resources Association for Professionals in Infection Control and Epidemiology, Greater Omaha Chapter. Sterile processing checklist [online]. 2009 Jul [cited 2001 Oct 26]. http://www.goapic.org/documents/2009/SterileProcessingChecklist.pdf. GOJO. Hand hygiene observation form [online]. [cited 2011 Oct 26]. http://www.gojo.com/~/media/GOJO/Countries/USA/Markets/Healthcare/AS C/Files/Resources/HH%20observation%20form%20v2.doc. GOJO. Sample environmental cleaning schedule—ambulatory surgery centers [online]. [cited 2011 Oct 26]. http://www.gojo.com/~/media/GOJO/Countries/USA/Markets/Healthcare/AS C/Files/Resources/sample%20environmental%20cleaning%20schedule.docx. 25 Additional Resources Lakeland Surgical and Diagnostic Center. Sample general area cleaning check list [online]. [cited 2011 Oct 26]. http://www.beckersasc.com/accreditation/Sample%20General%20Area%20Cle aning%20Checklist.doc. Lakeland Surgical and Diagnostic Center. Sterile processing department testing and load document [online]. [cited 2011 Oct 26]. http://www.beckersasc.com/accreditation/SPD%20Testing%20and%20Load%20 Document.doc. Lakeland Surgical and Diagnostic Center. Sterile processing department testing and QI load worksheet [online]. [cited 2011 Oct 26]. http://www.beckersasc.com/accreditation/SPD%20Testing%20and%20Load%20 QI%20Worksheet.xls. Lakeland Surgical and Diagnostic Center. Terminal cleaning checklist [online]. [cited 2011 Oct 26]. http://www.beckersasc.com/accreditation/Sample%20Terminal%20Cleaning%2 0Checklist.doc. 26 Questions and Answers 27