GUARDRAIL - Florida Department of Transportation

advertisement

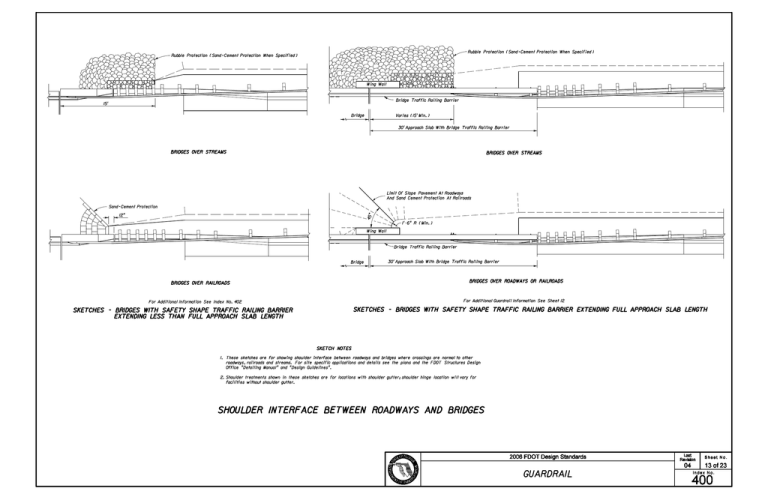

Rubble Protection (Sand-Cement Protection When Specified) Rubble Protection (Sand-Cement Protection When Specified) Wing Wall Bridge Traffic Railing Barrier 15’ Bridge Varies (15’ Min.) 30’ Approach Slab With Bridge Traffic Railing Barrier BRIDGES OVER STREAMS BRIDGES OVER STREAMS Limit Of Slope Pavement At Roadways And Sand Cement Protection At Railroads ^ Sand-Cement Protection 45 12" 1’-6" R (Min.) Wing Wall Bridge Traffic Railing Barrier Bridge 30’ Approach Slab With Bridge Traffic Railing Barrier BRIDGES OVER ROADWAYS OR RAILROADS BRIDGES OVER RAILROADS For Additional Guardrail Information See Sheet 12 For Additional Information See Index No. 402 SKETCHES - BRIDGES WITH SAFETY SHAPE TRAFFIC RAILING BARRIER EXTENDING FULL APPROACH SLAB LENGTH SKETCHES - BRIDGES WITH SAFETY SHAPE TRAFFIC RAILING BARRIER EXTENDING LESS THAN FULL APPROACH SLAB LENGTH SKETCH NOTES 1. These sketches are for showing shoulder interface between roadways and bridges where crossings are normal to other roadways, railroads and streams. For site specific applications and details see the plans and the FDOT Structures Design Office "Detailing Manual" and "Design Guidelines". 2. Shoulder treatments shown in these sketches are for locations with shoulder gutter; shoulder hinge location will vary for facilities without shoulder gutter. SHOULDER INTERFACE BETWEEN ROADWAYS AND BRIDGES 2006 FDOT Design Standards GUARDRAIL Last Revision Sheet No. 04 13 of 23 Index No. 400 20’ 6" 4’ Normal Face Varies 3’ Normal Face Of Guardrail 4’-6" (Min.) Shoulder Pavt. Shoulder Pavt. 8’ Normal Face Of Guardrail 6’-6" 2" Misc. Asphalt Pavt. 3’ 2" Misc. Asphalt Pavt. 2" Misc. Asphalt Pavt. 6" Of Guardrail See Plan Below (See Detail K) 6" Normal Face Varies Varies Varies Varies 6" Of Guardrail (See Detail K) Shoulder Gutter 4’ 2" Misc. Asphalt Pavt. 1: 6 For 20’ Not Steeper Than 1: 10 Clear Zone SHOULDER WITH OR WITHOUT 5’ PAVEMENT PAVED SHOULDERS SHOULDER GUTTER DOUBLE FACE RAIL 1: 3 (Max.) For 20’ Clear Zone 3’ MISCELLANEOUS PAVING FOR STANDARD GUARDRAIL SECTIONS 1: 3 (Max.) For 2" Misc. Asphalt Pavt. 14’ Clear Zone SECTION AA (EXAMPLE FOR 20’ CLEAR ZONE) 30’ 30’ 30’ 8’ 8’ 8’ Normal Face Normal Face Of Guardrail Of Guardrail 6’-6" 4’ 6" 6’-6" Normal Face 4’ 4’ Of Guardrail Not Steeper Than 1: 10 Not Steeper Than 1: 10 Shoulder Pavt. 3’ Shoulder Pavt. Varies Shoulder Gutter 2" Misc. Asphalt Pavt. 2" Misc. Asphalt Pavt. 1: 6 Reference Line SECTION CC (EXAMPLE FOR 30’ CLEAR ZONE) SECTION BB (EXAMPLE FOR 30’ CLEAR ZONE) A C B 3’ 3’ Shoulder Line avt. alt P Extended Shoulder Not Steeper Than 1: 10 10’ Shoulder Line 1 : 15 To No rmal Shoulde r Break Point 10’ Not Steeper Than 1 : 10 Varies** 10’ For 8’ Shoulders 12’ For 10’ And 12’ Shoulders Applies To Left And Right Side Shoulders. (See Index No. 525 For Shoulder Widths And Shoulder Gutter Locations On Ramps And Auxiliary Lanes) Edge Of Traffic Lane A **8’ For 6’ Shoulders Varies Varies See Detail K Varies Shoulder Gutter Normal Shoulder Varies See Detail K When Called For In The Plans Normal Face Of Guardrail 2’ Std. Misc. Asphalt Pavt. With Paved Or Unpaved Shoulders 6" Misc. Asphalt Pavt. Normal Face Of Guardrail Normal Face Of Guardrail Extended Shoulder On 0.06 Rise 10’ Extended Shoulder Misc. Asphalt Pavt. 1 : 15 To No rmal Shoulde r Break Point 3’ 1 : 15 To No rmal Shoulde r Break Point h . Asp 1: 6 Reference Line 1: 6 Reference Line SECTION AA (EXAMPLE FOR 30’ CLEAR ZONE) Shoulder Line 1: 3 (Max.) 7’ 1: 3 (Max.) 1: 3 (Max.) 2" Misc. Asphalt Pavt. Misc Transition Slope Transition Slope Transition Slope Edge Of Traffic Lane Edge Of Traffic Lane C B SHOULDER GUTTER PAVED SHOULDERS SHOULDER WITH OR WITHOUT 5’ PAVEMENT SHOULDERS, SLOPES AND MISCELLANEOUS PAVING FOR FLARED END ANCHORAGE ASSEMBLIES Rubrail (C6!8.2, Plates And Fastners or Bent Plate And Fastners In Accordance With Standards RLR01 And RER01 Normal Face 2’-0" * Of Guardrail Front Slope (1 : 4 Or Flatter) 12" Of AASHTO-AGC-ARTBA "A Guide To Standardized Highway Traffic Lane LATERAL PLACEMENT ON FRONT SLOPES (FROM EDGE OF TRAFFIC LANE) Barrier Hardware") ACCEPTABLE SLOPE Shoulder Width Plus 2’ For All Others Shoulders. STANDARD LOCATIONS For shoulders less than 12’ in width 28’ to 45’ the tabulated values will be reduced 4:1 14’ to 27’ Connect Beginning Of Rubrail 5:1 15’ to 25’ 26’ to 45’ 6:1 17’ to 22’ 23’ to 45’ With Post Bolt Flared End Anchorage Notes: WITH RUBRAIL To Back Side Of No. 3 Post * 12’ For Shoulders 10’ And Wider; 8’ For Median Shoulders 8’ Or Less In Width; and, NOT RECOMMENDED by the difference between 12’ and the shoulder width. 7:1 21’ to 24’ 25’ to 45’ Placement of guardrail on frontslopes 8:1 Acceptable to 25’ 26’ to 45’ steeper than 4:1 not recommended. 9:1 Acceptable to 26’ 27’ to 45’ Cost of rubrail to be included in the 10:1 Acceptable to 27’ 28’ to 45’ contract unit price for guardrail. LOCATIONS ON FRONT SLOPES GUARDRAIL LOCATION-DETAIL K 2006 FDOT Design Standards GUARDRAIL Last Revision Sheet No. 07/01/05 14 of 23 Index No. 400 16d Galvanized Nail (Timber And POSTS REFLECTOR NOTES Non-Form Fit Plastic Blocks Only) Post bolt hole in timber and plastic blocks to be centered (‘ 1/4 "). Timber 6"!8"!14" (Nominal) For 1. Reflectors shall conform to Section 993 of the Standard Specifications. Reflector Reflector 2. Reflector color (white or yellow) shall conform to the color of the near Timber lane edgeline. Cutaway View REMARKS OFFSET BLOCKS W-Beam And 6"!8"!22" All timber offset blocks shall be dressed on all four sides (S4S). (Nominal) For Thrie-Beam One 16d galvanized nail per block is to be used to prevent rotation Recycled Plastic (See Notes) of block (see detail left). Timber 6"!8"!14" (Nominal) For Same as above for timber and plastic blocks except that form fit W-Beam And 6"!8"!22" plastic block holes align with holes in steel posts and do not (Nominal) For Thrie-Beam require nails. 16d Galvanized Nail 3. Face of rail bolt, screw, rivet or bracket mounted reflectors shall not be Steel W6x8.5, used in lieu of adhesive mounted reflectors. Direction Of Traffic SECTIONAL W6!9 Or 6" C 4. Post mounted reflectors approved on the ’Qualified Products List’ may be FACE VIEW used by FDOT Maintenance to replace damaged or missing reflector in VIEW Timber Or Recycled Plastic Block Recycled Plastic (See Notes) a continuous run of existing post mounted reflectors. Adhesive and post Reflectors shall be centered in the channel of mounted reflectors shall not be intermixed in a continuous run of guardrail. W-beam and in the top channel of thrie-beam. 5/8 "\!1 1/2 " long hex head bolts with full length thread and nuts Steel W6x8.5, W6!9 Or 6" C TIMBER POST STEEL POST (2 Reqd.) and 5/8 " plain round washers (4 Reqd.) for mounting (Steel Modified Thrie-Beam) steel block to post. Bolts are to be installed in opposite holes, top and bottom. 5. The cost for reflectors shall be included in the contract unit price for REFLECTOR MOUNTING 16d Galvanized Nail Driven After Post Bolt Pull-Up, Single W14!22!17" (M14!18!17") Guardrail. And Double Face Guardrail, Single Face Guardrail Shown Notes: 1. Timber and recycled plastic offset blocks of identical size and shape can be intermixed within (16d Nail Between Blocks For Multiple Offset Blocks). 200’** 100’ 50’ 75’ a run of rail. 25’ 16d NAIL FOR PREVENTION OF OFFSET BLOCK ROTATION 2. Recycled plastic offset blocks shall meet the passing evaluation criteria for Test Level 3 of NCHRP 350. The blocks shall be tested as a component in a semi-rigid guardrail test article under full scale crash test conditions. The blocks shall be in conformance with Sections 536 Install Pipe Rail Over Pipe Rail End Fixture And Thru-bolt and 972 of the Specifications and be included on the Qualified Products List. W-Beam blocks With 1/2 "!3 1/2 " Long Hex Bolts And Nuts With 1/2 " Plain Note: Adjustment in spacing may be required to fit exact guardrail lengths as directed by the Engineer. Round Washers Under Heads And Nuts (2 Reqd.) shall be 14" in height and thrie-beam blocks shall be 22" in height. The blocks shall be capable For minimum installations (length 62.5’) provide one reflector at each end and at approximate center. of providing a 7 1/2 " (Min.) offset. (Upset Threads After Tightening) Pipe Rail Pipe Rail **For curves greater than 2^ the spacing shall be reduced to 100’ through the curve. End Fixture PERMISSIBLE POST AND OFFSET BLOCK COMBINATIONS REFLECTOR SPACING Steel Post Offset Block ADHESIVE REFLECTORS-DETAIL M Timber Post Steel Modified Thrie-Beam Offset Blocks (See Detail Left And Table Above) Guardrail Beam | Post Bolt M14x18 or W14x22 1’-9" 20"‘ R W-BEAM 2" 6" 1" Steel Guardrail Post 1" 3" Steel Guardrail Post Or Bike Path 2’ 4’ Std. 1’-9" 1’-9" Std. 3’-10" Std. Varies (3’ Min.) THRIE-BEAM W-BEAM THRIE-BEAM Restrictions Prohibit Normal Shoulder Extension Pedestrian Way Travel Way * *Front Slope When Right Of Way, Environmental Or Other Tightening) 3" MODIFIED THRIE-BEAM | Post Bolts | Post Bolt 4’-2" 1" 5/8 " Plain Round Washers 6" STEEL MODIFIED THRIE-BEAM OFFSET BLOCK Hex Bolt And Nut With (Upset Threads After 2" All Holes Are 13/16 "\ With 5/8 "!2" Long See Right) 75^ 1" SIDE VIEW Galv. Pipe Rail 3/4 "\ Bracket Hole (For Mounting 1/4 " Steel Pipe 2" Nom. \ Sch. 40 1 1/4 " Pipe Rail 3’-10" (Upset Threads After Tightening) ELEVATION 1 1/2 "\ Sch. 40 TRAFFIC FACE With 1/2 " Plain Round Washer Pipe Rail End Fixture Gutter 6" POST FACE With 1/2 "!3 1/2 " Long Hex Bolt And Nut 1’-9" Lip Of Gutter W-BEAM WITH RUBRAIL | Post Bolts 40^ 5/8 "\ Bracket And Pipe Holes Std. Pipe Rail Top Of Curb PICTORIAL Std. As Specified, See Sheet 14 For Additional Information) Varies (3’ Min.) 10" Guardrail Beam 1/4 (On One Or Both Sides * 17" 7" Steel Post 5 7/8 " Be Timber Only 12" By Location In The Plans This Post Can (Upset Threads After Tightening) Rubrail When Called For 1 1/8 " 4’-2" 1 1/8 " Round Washers Under Heads And Nuts (2 Reqd.) 2’ 1/2 "!7" Long Hex Bolts And Nuts With 1/2 " Plain 2 1/4 " | Panel Bolt | Post Bolt 1’-9" Structural Shape 2 1/4 " Std. Attach Pipe Rail End Fixture To Post With 3’-11" PLAN 2 1/2 "!2"! 1/4 "!4" Long 1 1/4 " 1 1/8 " Offset From | Of Guardrail Post Angle Bracket (Galvanized) VIEW A All Holes Shall Be 5/8 " \ MOUNTING HEIGHTS ON SHOULDERS AND IN MEDIANS 4" Edge Of Traffic Lane VIEW B Galvanize After Drilling And Welding STEEL POST PIPE RAIL END FIXTURE DOUBLE FACED GUARDRAIL SINGLE FACED GUARDRAIL 1 1/4 " 6’ Or Greater PIPE RAIL MOUNTING Edge Of Shoulder Pavement Desirable SECTION Edge Of Traffic Lane Shoulder Line 4’ Varies NOTES 1. Pipe Rail required on steel guardrail posts when pedestrian ways and bikeways are located 4’ or less from 1’-9" Y 1’-9" 2. When guardrails with timber posts are located with the back of posts 4’ or less from the near edge of the pedestrian 1’-9" back of the posts. Begin and end the pipe rail in accordance with this detail. 6" 0.06 Std. way or bikeway, the bolt ends will require one of the following treatments: (a) Trimming back flush with the face of nut and metalizing or (b) Use of post bolts 15" in length with the washers and nuts counter sunk into sinks 1" to 1 1/2 " deep or (c) Use of post bolts 15" in length with sleeve nuts and washers. Y (Maximum Speed 50 mph) 3. The cost for Pipe Rail, mounting components and installation shall be included in the contract unit price for Y=6" Or Greater Y=Less Than 6" Shoulder Gutter guardrail. Bolt end treatment for timber post shall be included in the contract unit price for guardrail. FOR LOCATIONS USED BY PEDESTRIANS OR CYCLISTS LOCATION AT CURB & GUTTER SECTIONS-DETAIL L PEDESTRIAN SAFETY TREATMENTS 2006 FDOT Design Standards GUARDRAIL Last Revision Sheet No. 07/01/05 15 of 23 Index No. 400 A B C Std.; s - 5’ in.) 4’ M arie idth V alk (W 6’-6" Sidew Sidewalk Without Utility Strip 6’ * This Standard Post Must 21’-6" (Curb And Gutter Flare) 37’-6" Guardrail Flare Used In Guardrail Ahead 10’ 13’ 3’ Be Timber When Steel Post Curb Transition 3’ 10’ Curb And Gutter Type F (MELT Shown) 45’ B A PLAN 0’-9" (MELT) guardrail posts are 4’ or less from the near edge of 3’ Transition 35’-4" Drop Curb C a pedestrian way or bikeway and post bolt treatment 6’-8" Flared End Anchorage Assembly See Detail L *Safety pipe rail is required when the back of steel 20’ R 2" Misc. Asphalt 1’-3 1/2 " (SRT-350 & REGENT) 2’-3 1/2 "(FLEAT-350) 2’-3 1/2 " SRT/HBA-6 POST Sidewalk (Varies) is required when the back of timber posts are 4’ or less from the near edge of a pedestrian way or 2" Misc. Asphalt 1’-9" bikeway; see ’PEDESTRIAN SAFETY TREATMENTS’. 0.02 (Std.) Curb flare shall follow guardrail flare, see elsewhere in this Index for additional guardrail flare information. Note: For Proprietary End Treatments See the Qualified Products List. SECTION CC 1’-1" (MELT) 1’-8 1/2 " (SRT-350 & REGENT) Sidewalk (Varies) 2" Misc. Asphalt 0.02 (Std.) SECTION BB 4’ Sidewalk (Varies) 1’-9" 1’-7" SRT/HBA-6 POST 1’-9" 1’-7" (FLEAT-350) 0.02 (Std.) 2" Misc. Asphalt SECTION AA APPROACH TREATMENT FOR CURB AND GUTTER DETAIL Q 2006 FDOT Design Standards GUARDRAIL Last Revision Sheet No. 07/01/05 16 of 23 Index No. 400 25 1 2 3" Min. 2’-3 1/2 " ^ ‘ For End 2’-6" Anchorage Type Neutral Axis Contour To Fit 1’-3" R Standard (10 1/2 " R When Used 30^ For End Anchorage 3 3/8 " Lap 4 1/4 " "R 10" 3 3/8 " Metalizing Permitted Direction Of Traffic /4 61 Over Beam 1’-9" or 2’-6" 3" MELT and CRT. Field Bend With Type MELT) 4 1/4 " Trailing Beam, 8 1/2 " 2" Terminal Section Or End Shoe 7 1/2 " Varies 3/4 "\ Hole For Use 2" With End Anchorage 4" 4 1/4 " 4" 4 1/4 " Contour To Fit 3" Over Beam 3/4 "!2 1/2 " Slot Type MELT 4 1/4 " 4 1/4 " 2" End Section Or End Shoe 15/16 "\ Hole (Typ.) 29/32 "!1 1/8 " Slots (4 Reqd.) 30^ | 1’-4 1/8 " Approach Beam, Under Nut 12 1/4 " With 5/8 " Steel Washer | 12 1/4 " With Post Bolt And Nut 1’-4 1/8 " Approx. 12 1/4 " 3 1/2 " 3 1/2 " 3/4 "!2 1/2 " Slot 3/4 "!2 1/2 " Slots 8 1/2 " 2" 7 1/2 " Varies (Typ.) (8 Reqd.) 12 1/4 " (Typ.) (4 Reqd.) (Typ.) (8 Reqd.) Note: 5/8 "\ Steel washer required with splice bolts W-BEAM RAIL SPLICE SPECIAL END SHOE ROUNDED END SECTION FLARED END SECTION 12" 3" 29/32 "!1 1/8 " Slots (Typ.) (4 Reqd.) 6" 3/16 " Base Metal 1 1/2 " 1’-4 1/8 " 29/32 "!1 1/8 " Slots 29/32 "!1 1/8 " Slots 1"\! 1/16 " Deep Thickness BUFFER END SECTION Recess (Both Sides) 1 1/4 " 11/16 " 12 1/4 " 1 3/4 " 3/4 "!2 1/2 " Slot 5/16 " 1 3/8 " 5/8 " Note: For beam washer requirements on end terminals, see individual end anchorage assembly details. Washers are to be used where necessary to accomplish alignment or where the posts bolt head 15/16 " 7/8 " 1 3/32 " 11/16 "!1" Slot L 7/32 " 5/8 " MODIFIED HEAVY 15/16 " R Note: For application information see individual HEX NUT (RECESSED NUT) 1 3/8 " R end anchorage assembly details. shows tendency to pull through the rail slot. Washers installed on guardrail, between end anchorages, prior to July 1, 1990 may remain W-BEAM BACK-UP PLATE 29/32 "!1 1/8 " Slots ^ 55 in place until the guardrail is relocated or until repairs require removal and reinstallment of a post bolt. LENGTH (In.) 1 1/8 " THREAD L (RECTANGULAR PLATE WASHER) APPLICATION | Of Beam (Min.) (In.) BEAM WASHER 15/16 " R requirements of ASTM A449 (Type 1) with heavy hex nuts and washers. All other hex bolts shall conform to the requirements of ASTM A563. Bolts, nuts and washers Post Bolt - Timber Or Recycled Plastic Offset 9 10" 1 21/32 " 2 1/4 " nuts used for jam nuts. 2 5/16 " 1 3/4 " shall be hot dip galvanized. Heavy hex nut may be used in lieu of hex nuts and hex Block(s) On Steel Post 4" 55 " Base 64 As An Option, A Single 25"* ^ Metal Thickness Long Post Bolt May Be Used 18" 4" 25"* 4" 3/8 " R HEX BOLTS AND NUTS 1 1/16 " Post Bolt - Single Faced Guardrail Timber Posts ^ Single Or Double Faced Guardrail 55 ^ Rail Splice Bolt 25 Full Length 3 1/4 " HS Hex bolts for THRIE-BEAM TERMINAL CONNECTORS shall conform to the 1 1/4 " 11/16 " 12 1/4 " 3/4 "!2 1/2 " Slot 10^ (‘1^) Sheet Thickness Post Bolt - Double Faced Guardrail Timber Posts Tolerance (-0,+ 1/16 ") OFFSETS (Ft.) Double Faced Guardrail Steel Posts Measured From Face Of Guardrail To Special bolts having lengths of 10" or greater shall have a Note: The round washer is not intended for use under the recess nut for the beam to beam rail splice. The washer is required under the recess For applications where special bolts having lengths greater bolt nut for connecting the beam to the timber post and offset blocks; rod (field cut to length). A hex nut and beam washer shall for connecting the beam to steel posts with timber offset blocks; under be used at the guardrail face with no more than 3/4 " of the the hex bolt head for securing the beam anchor plate to the beam; and, threaded rod projecting beyond the top of the nut. The for general guardrail connections by 5/8 "\ hex bolts and nuts. For projecting thread on both ends shall be distorted to secure supplemental information see BEAM ANCHOR PLATE, PERMISSIBLE POST the nuts, and both ends of the threaded rod metalized with AND OFFSET BLOCK COMBINATIONS, individual end anchorage assembly organic zinc-rich coating. SINGLE BEAM NESTED BEAMS SPACING (Ft.) W-Beam Thrie-Beam W-Beam W-BEAM Thrie-Beam 6’-3" 4’ 3’-3" N/A N/A 3’-1 1/2 " 3’ 2’-8" 2’-8" 2’-4" 1’-6 3/4 " N/A N/A 2’-4" 2’ Note: The values shown should be utilized unless changes are supported by imperical validation. Those desiring details, SPECIAL STEEL GUARDRAIL POSTS, SPECIAL END SHOE, W-BEAM 5/8 " STEEL WASHER Front Of Above Ground Rigid Hazard POST than 25" are required, the Contractor may use a 5/8 "\ threaded CONNECTOR details. 3 1/4 " thread length of not less than 4". nut for connecting the beam to the special end shoe; under the post RAIL SPLICE, THRIE-BEAM RAIL SPLICE, and THRIE-BEAM TERMINAL 3 3/16 " * Use of the 25" AASHTO-AGC-ARTBA standard length post bolt to develop offset values from the simulated deflection on double faced guardrail that results in the bolt projecting more values shown in Table 5.4 of the AASHTO Roadside than 3/4 " beyond the face of the nut after pull-up shall be trimmed Design Guide are cautioned to proceed only if back- to 3/4 " reveal and metalized with organic zinc-rich coating. ground in the table development is understood. 5/8 " OVAL SHOULDER BUTTON HEAD BOLT MINIMUM OFFSET FOR SINGLE FACED GUARDRAIL (Ft.) 2006 FDOT Design Standards GUARDRAIL Last Revision Sheet No. 07/01/05 17 of 23 Index No. 400 5/8 " Steel P L 8" 2" Hex Nut 6" 4" 4" 4" 2" Hex (Jam) Nut 3/4 "\ Holes 1 5/8 " 1"\ Anchor Rod And 1 1/8 "\ Hole 15/16 " R Cable Assembly 3/4 "\ Galvanized Cable (6!19) 1 3/4 " 1 1/4 " 4" 3/8 " R BREAKAWAY TERMINAL POST SLEEVE 8" Anchor Plate 1 15/16 " Swage Fitting 3/8 " W-Beam (8 Reqd.) (2.067" ID, 2.375" OD) 5 1/4 " 3/8 " Round Washers Under Heads 16" 2" Nom. Dia. 5" 6’-6" 2 11/16 " Bolts And Nuts With Plain (Typ.) (8 Reqd.) Galvanized (Both Ends) 7" 5/8 "-11!1 1/2 " Long Hex Head 3/4 "\ Holes 1"\!7" Stud, Full Threads, 9 Washer (2" OD, 1 1/16 "ID, 64 1 5/8 " 3/8 "!2 3/4 "!3" Steel End Plate Swage Connected To Studs 35^ Thick) Shaped Steel Plate With 1 1/8 " Center Hole 3/4 "\ Holes 23 (16"!12 9/16 "! 3/16 ") BEARING PLATE /8 " Three Note: Cable assemblies shall be in accordance with the specifications of 1/4 5 1/2 33 /8 " Sides AASHTO-AGC-ARTBA ’A Guide To Standardized Highway Barrier Hardware’ Cable Anchor Assembly FCA01. An additional cable assembly 9’ in length with a 2 7/8 " 12" CABLE ASSEMBLY 4" 4" 2" BEAM ANCHOR PLATE 4" 2" 3/4 "\ 12" Hole 8" 3 13/16 " 2 3/8 " 3 1/2 " 7 5/8 " 12" 6" 2" 21" 3 13/16 " 9" 24" 3/4 "\ Holes 9" 4" 1 1/2 " 20" (‘ 1/4 ") 12" 3/4 "!2 1/2 " Slot 4" 3 1/2 " 7 5/8 " 2 3/8 " 3 13/16 " 6" 18" 3/4 "\ Holes SECTIONS BACK VIEW swaged fitting on one (1) end is required for each end anchorage assembly Type CRT. 8" 12" 9" 5/8 " Plate For Bridge Traffic Railing Barrier 24" 1 1/4 " Plate 1/4 " Plate For Barrier Walls 9" 1/4 " Plate For All Applications See Detail J For Application 9" 6" SPECIAL END SHOE THRIE-BEAM TERMINAL CONNECTOR 24" 1/4 " SteelLP, Galvanized Back-up plate required behind rail elements at intermediate (non-splice) posts when steel SOIL PLATES offset block used. FILLER PLATE All Holes 1"\ Except As Shown GALVANIZED STEEL BACK-UP PLATES FOR CONNECTING SPECIAL END SHOES AND TERMINAL WALLS CONNECTORS TO CONCRETE BRIDGE TRAFFIC RAILING BARRIERS AND CONCRETE BARRIER THRI-BEAM BACK-UP PLATE 6’-3" 3’-1 1/2 " 2" 4 1/4 " 4 1/4 " 3’-1 1/2 " 2" Min. 2" Min. 4 1/4 " 4 1/4 " 2" 2’-6" 3" 3 1/4 " 4 1/4 " 3/4 "\ Holes (2 Reqd.) Trailing Beam, W-Thrie Beam Transition Section ^ 55 15/16 "\ Holes (Typ.) | Post Bolt Slot (7 Reqd.) 4" 4 1/4 " 4 1/4 " 3" 3/4 "!2 1/2 " Post Bolt Slots (Typ.) 29/32 "!1 1/8 " Splice Bolt Slots (Typ.) 3/4 "!2 1/2 " Post Bolt Slots (2 Reqd.) W-THRIE BEAM TRANSITION SECTION 1 21/32 " 29/32 "!1 3/4 " Slots Rotated 50^ (Typ.) (12 Reqd.) 3 1/4 " 55 ^ 15/16 " R 3/4 "!2 1/2 " Slots (2 Per Beam) Note: 5/8 "\ steel washer required with splice bolts With Post Bolts And Nuts 2 1/4 " With 5/8 " Steel Washers THRIE-BEAM TERMINAL CONNECTOR ^ 55 2 3/8 " Under Nuts (2 Reqd.) 25 ^ 3/8 " R 1 1/16 " 10^ (‘1^) 3 3/16 " Tolerance (-0,+ 1/16 ") Sheet Thickness 4" Or Terminal Connector 1 1/8 " 29/32 "!1 1/8 " Slots 3 13/16 " 3 13/16 " 3 13/16 " 3 13/16 " 15/16 " R About | 4 1/4 " 20" (‘ 1/4 ") Symmetrical Lap 3/4 "!2 1/2 " Slots 20" (‘ 1/4 ") 2" 12 1/4 " Neutral Axis 20" 3 3/8 " Neutral Axis 3 1/4 " Approach Beam, W-Thrie Beam Transition Section Or Terminal Connector THRIE-BEAM 2006 FDOT Design Standards Direction Of Traffic THRIE-BEAM RAIL SPLICE GUARDRAIL Last Revision Sheet No. 07/01/05 18 of 23 Index No. 400 | W8!18 Post | W8!18 Post 6" 17" 7" 7" 7/8 "\!10" Galvanized 5 1/2 " (+0,- 1/4 ") 7 1/2 " (+0,- 5/16 ") 5 1/2 " Hex Nuts (8 Reqd.) & Standard Washers 7/8 "!14"!11" (4 Reqd.) Base Plate 7" 14" W8!18 Post 1’-9" Anchor Bolts (4 Reqd.), 3/4 "!1 1/2 " Slotted Hole 7" 7 5/8 "* Varies 3/4 "\ Hole 4" 3/4 "\ Holes 3" 3/4 "!2 3/4 " Slot TS 8"!6"! 3/16 " Galvanized In End Post Only) (See Note 3) TOP VIEW SIDE VIEW 3 1/2 "\ Hole (2 Holes Each Post) 7/8 "\ Hole 2 1/2 " FRONT VIEW Treated 3’-6 1/2 " Base Plate 6’ S4S And (Install Breakaway Terminal Post Sleeve Anchor Hole 5’ 2 3/8 "\ Hole 1’-4" 7" 2"\ Recess 18" | Slotted Hole Min. 1" Adjusting Nuts 1"\ Holes FOR REPLACEMENT OF EXISTING W8!18 GUARDRAIL POSTS ON APPROACH SLABS AND BRIDGES Open End * Additional slotted hole required when mounting thrie-beam guardrail SIDE VIEW FRONT VIEW SIDE VIEW FRONT VIEW For Use In Combination With Steel Tube | W6!9 Post SIDE VIEW Short Timber Breakaway Post STEEL TUBE Note: SPECIAL TIMBER GUARDRAIL POSTS 6" 6" 6" 3/4 "\!10" Galvanized Anchor Bolts (4 Reqd.), Hex Nuts (8 Reqd.) & Standard Washers 1/2 "!12"!12" 4" Base Plate 1 1/8 " (See Note 3) 1 1/8 " 7" 0.170" 0.75" 7" 7" Anchor Hole 0.25" R 8" 6" Nom. Nom. 12" 12" All Holes 13/16 "\ 13/16 "\ Hole When Rubrail Called For * 1. See Index No. 402 for special steel posts required for construction and repair of guardrail transitions 3/4 "\ Hole (When Thrie Beam Post) 6’-6" 6’-6" 7 5/8 " Flanges (Total 4 Holes) NOTES: (SPECIAL STEEL POST) 3/4 "\ Hole (Centered ‘ 1/4 ") 2 Holes Front And Back 6’-9" OR OTHER STRUCTURE PRECLUDES DRIVEN POST INSTALLATION 6’-6" 6’-6" FOR CONSTRUCTION OF GUARDRAIL WHERE CULVERT, PIER FOOTING 12" 7 5/8 " 10" VIEW 7" Existing Structure SIDE PROJECTION 1 1/8 " Min. 1" 2"\ Recess 7" Adjusting Nuts 4.340" 1 1/8 " 4" 4" 5 7/8 " (4 Reqd.) 5.875" See Notes Nos. 2 thru 5 Below. FRONT VIEW For Use In Combination With CRT TIMBER POST SHORT TIMBER BREAKAWAY POST (6’-6" When Used As Part Of BEST System) Nom. 11" 5 1/2 " 6" 8" 8" Nom. 1" 1 3/8 " 3/4 "\ Hole (When Rubrail to bridge traffic railing barrier retrofits on existing bridges. See Structures Index Nos. 470 through 476 Required) for steel posts required to construct traffic railing barrier retrofits on existing bridges. S4S And Treated 2. Either anchor bolts, concrete wedge anchors or approved Adhesive-Bonded Anchors for Structural Applications may be used. Anchor bolts, wedge anchors and adhesive anchors shall have a minimum tensile strength of 60,000 psi and galvanized in accordance with ASTM A153 (stainless steel components may be substituted but components plated in accordance with ASTM B-633 are not acceptable). Adhesive anchor rods shall be equal in diameter to that detailed for anchor bolts. Wedge anchors are to be installed in accordance with the manufacturer’s SIDE VIEW W-BEAM * 13/16 "\ Hole When Rubrail Called For THRIE-BEAM THRIE-BEAM WITH WITH STANDARD STEEL MODIFIED OFFSET BLOCKS THRIE-BEAM SIDE VIEW Note: 6"-C steel posts are to face the OFFSET BLOCKS recommendations, assuming 3,000 psi compressive strength for concrete. Wedge anchors shall also meet the following requirements: (a) tensile load each anchor: approach slabs 14,000 lbs.; other structures 8,000 lbs. (b) shear load each anchor: approach slabs 15,000 lbs.; other structurers 7,800 lbs. 3. Posts are to be plumbed by adjusting nuts or mortar seating. Posts installed using anchor bolts and adhesive anchors are to be set with adjusting nuts as detailed, unless the Engineer approves the use of mortar seating in lieu of adjusting nuts. Posts installed using wedge anchors are to be set with mortar seating. Base plates shall be grouted with neat finish. FRONT VIEW FRONT VIEW FRONT VIEW FRONT VIEW same direction in any continuous run of guardrail. Posts to be galvanized in accordance with ASTM A123. SIDE VIEW FRONT VIEW All Holes Shall Be 13/16 "\ Identical Front And Back Flanges 6"-C STEEL POST Note: W6!8.5 or W6!9 steel posts may be either rolled or welded structural shapes TIMBER POST conforming to or exceeding the design properties of ASTM A6/A6M. Welding shall be in accordance with the requirements of ASTM A769/A769M. Posts shall be cut to length and the ends seal welded between web and flange before galvanizing. Posts to be galvanized in accordance with ASTM A123. 4. Adhesive-Bonded Anchors for Structural Applications shall comply with Section 937 and be installed in accordance with Section 416. Drilled hole diameter shall be in accordance with the manufacturer’s instructions. W6!8.5 OR W6!9 STEEL POST 5. Anchor holes and recesses shall be drilled; wedge anchor holes are to be drilled in accordance with the manufacturer’s specifications. Encountered reinforcing steel shall be drilled through. Holes shall be thoroughly cleaned when setting bolts and anchors and dry when setting wedge anchors. STANDARD TIMBER AND STEEL GUARDRAIL POSTS 6. Steel post and base units shall be galvanized in accordance with ASTM A123. Any damaged galvanized areas are to be metalized in accordance with Section 562 of the Standard Specifications. SPECIAL STEEL GUARDRAIL POSTS GUARDRAIL POSTS 2006 FDOT Design Standards GUARDRAIL Last Revision Sheet No. 07/01/05 19 of 23 Index No. 400 Only Single Special Post Shown One Of Two Special Posts Max. Variation In Location Of One Of Two Special Posts NUMBER OF SPECIAL POSTS NUMBER OF SPECIAL POSTS (Single Offset Block) (Double Offset Block) Min. 2 Min. 1 Min. 1 Max. 2 Max. 2 Max. 2 Basis Of Estimate For Payment 2 Basis Of Estimate For Payment 1 CURB INLET TYPE 2 CURB INLET TYPE 1 Timber Or 1’-9" Max. Variation In Location Of One Of Two Special Posts Steel Posts At Face Of Rail Max. Variation In Location Of One Of Two Special Posts 2" Max. Variation In Location On For Single Special Post (W6!9 Post Shown) Misc. Asphalt Varies (2’ Min.) Max. Variation In Location Varies (4’-3" Min. For W-Beam, 4’-7" Min. For Thrie-Beam) (Normal Location For Special Post) Foam Wrap Class ~ Conc. (Do Not Add Reinf. Steel) Only Single Special Post Shown (Normal Location For Offset Block) Max. Variation In Location Max. Variation In Location 3" For Single Special Post Of Special Post SECTION Max. Variation In Location Of Max. Variation In Location Of One Of Two Special Posts One Of Two Special Posts 15" For Steel Post Or 17" For Timber Post NUMBER OF SPECIAL POSTS (Single Offset Block) NUMBER OF SPECIAL POSTS Min. 1 Min. 1 Min. 1 (Double Offset Block) Max. 1 Max. 2 Basis Of Estimate For Payment 1 Max. 1 Basis Of Payment 1 To Facilitate Post Replacement Install With 3/16 " Plastic Foam Sheet On All Sides, Below The Surface Of The Miscellaneous Asphalt Pavement. Foam Or Timber Block-Out For W6!9 Or 6" C Posts PLAN (SQUARE OPTION) 15" For Steel Post Or 17" For Timber Post CURB INLET TYPE 4 CURB INLET TYPE 3 Foam Wrap And Foam Or Timber Max. Variation In Location Of Special Post Max. Variation In Location Of Max. Variation In Location Of One Of Two Special Posts One Of Two Special Posts NUMBER OF SPECIAL POSTS Block-Outs Same As For Square Option Above. NUMBER OF SPECIAL POSTS Min. 1 Min. 2 Max. 1 Max. 2 Basis Of Payment 1 Basis Of Payment 2 PLAN (ROUND OPTION) Note: For line post applications only, i.e., not to be used with breakaway post applications nor be used to modify End Anchorage Assemblies Type ~~. TO BE USED PRINCIPALLY OVER SHALLOW UTILITIES ENCASED GUARDRAIL POST CURB INLET TYPE 6 CURB INLET TYPE 5 Notes: LEGEND 1. The locations shown for special posts mounted on inlets are to be used as guidelines for positioning the posts and for estimating the number of required posts. 3. Variations shown for the locations of special posts mounted on inlets are established from standard post spacing (6’-3"); clearance of standard posts from inlets (4" min.); use of single and double offset blocks on standard posts adjacent to the inlets; optional 2. Special posts and their anchorages mounted on curb inlets shall be in accordance with special steel guardrail posts Sheet 19, and paid for under the contract unit price for Special Guardrail Post, EA. Variation In Location Of Special Post: Single Offset Block (s) On Adjacent Standard Post (s) flange mountings; and, concrete anchor edge distances (2" for grouted and 3 3/4 " for expansion anchors). The number of posts and their locations may vary by reducing post spacing and adjusting the length of rail panel (s). Expanded Location By Using Double Offset Blocks On Adjacent Standard Post (s) 4. Encased guardrail posts shall conform in section to standard timber and steel posts, and be paid for under the contract unit price for Special Guardrail Post, EA. Payment shall include cost of foam wrap and concrete encasement. SPECIAL POST LOCATIONS ON CURB INLETS 2006 FDOT Design Standards GUARDRAIL Last Revision Sheet No. 00 20 of 23 Index No. 400 Misc. Asphalt Pavt. 10’ Approach End Guardrail Soil Plate Anchor Plate Hex Nut & Hex (Jam) Nut And Washer Each End Cable Assembly Misc. Asphalt Pavt. 5/8 "!25" Long Post Bolt And Nut With Beam Washer Under Head And Under Nut 10’ Approach End Guardrail Buffer End Section (Timber Post And Block) Misc. Asphalt Pavt. 6’ Trailing End Guardrail Short Timber Breakaway Post TOP VIEW - DOUBLE FACE Approach Rail (Position Varies) Buffer End Section For Approach End Anchorage Steel End Plate, Washer, Hex 5/8 "!18" Long Post Bolt And Nut With Beam Washer Under Head And 5/8 " Plain Round Washer Under Nut (Timber Post And Block) 5/8 "!10" Long Post Bolt And Nut Nut And Hex (Jam) Nut With Beam Washer Under Head And 5/8 " Plain Round Washer Under Nut Anchor Rod Cable Assembly Position Varies Turnbuckle (6") See Note Below (Rounded End Section When Guardrail 30" Flared End Section Anchor Plate Located Adjacent To Pedestrian Way Or Bikeway) Hex Nut & Hex (Jam) Nut Flared Or Rounded End Section Trailing Rail And Washer Each End Soil Plate On Trailing End Section Concrete Anchor Block 30" Short Timber Breakaway Post TOP VIEW - SINGLE FACE TOP VIEW Misc. Asphalt Pavt. End Measurement For Guardrail Payment (Block To Be Positioned To Suit Anchorage Alignment. Only One Anchorage Required. 6’ Trailing End Guardrail Anchorage To Be On Approach Rail When Both Approach End Measurement For Guardrail Payment And Trailing Guardrails Are 4’-9" 6’-3" 6’-3" 6’-3" To Next Post 12" Connected.) 16" Standard Post Anchor Plate 16" Short Timber End Section Anchor Plate Misc. Asphalt Pavt. Misc. Asphalt Pavt. Turnbuckle (6") See Note Below Timber Or Steel Post With Timber 3’-6" Std. Block May Be Used, Timber Post And Timber In Steel Post Run Of Rail Cable To Be Drawn Taut Adjacent To Pedestrian Way With Hand Wrench Prior Or Bikeway, To Provide Anchorage To Setting Jam Nuts Post Sleeve Two 8d Nails To Prevent Rotation 1’-9" Block Shown (This Post Must Be No Cover Required 30" Breakaway Post 1’-9" 12" 1"\ Galv. Anchor Rod Galvanized 4"!4"! 3/4 " Plate Beveled Washer And Hex Nut 1 1/2 " ID Pipe Sleeve Bearing Plate For Pipe Rails As Required) Misc. Asphalt Pavt. FRONT VIEW Turnbuckle to be used only for guardrail that is reset vertically. The existing anchor rod (1" or 1 1/4 " Dia.) shall be field cut, threaded 4" on each end, and, metalized in accordance with Sections 562 and 971 of the Standard Specifications. The cost 5/8 "!10" Long Bolt And Nut With 5/8 " Plain Round Washer Under Head And Nut 5/8 "!18" Long Bolt And for cutting, threading, metalizing and the turnbuckle shall be included in the contract unit price for Reset Guardrail, LF. Nuts With 5/8 " Plain Round Washer Under Head And Nut The payment for the items of End Anchorage Assembly Type ~~ shall be full compensation for furnishing and installing the (2 Req’d.) Beam Anchor Plate, Anchor Rod, Pipe Sleeve, Anchor Block, either Flared, Rounded or Buffer End Section, and the necessary hardware. Soil Plate 18"!24"! 1/4 " Note: Steel tubes and attached soil plate may be installed by: CONCRETE ANCHOR BLOCK OPTION Steel Tube (1) Excavating, backfilling and compacting to provide full passive soil resistance to TYPE ~~ NOTES all surfaces of the tube and soil plate. 1. Unless specified in the plans, the contractor can supply either the cable anchor option or the concrete anchor block option. (2) Driving steel tube and soil plate as a unit with a dummy timber post to prevent damage to breakaway post. 2. Type ~~ end anchorage assemblies are approved for all speeds and are intended for use as: (a) trailing end anchorages for single face free standing guardrail systems; (b) approach end anchorages for single face free standing guardrail systems when end anchorage is located outside of the clear zone; and, FRONT VIEW (c) both approach and trailing ends of double face guardrail systems. Crash cushions shall be constructed at or in lieu of approach Type ~~ end anchorages located The payment for the items of End Anchorage Assembly Type ~~ shall be full inside the clear zone. compensation for furnishing and installing either the Round or the Buffer End Section, the Beam Anchor Plate, Cable Assembly, Pipe Sleeve, SoilPlate, Steel Tube, Bearing Plate, Short Timber Breakaway Post, Offset Blocks and the necessary hardware. 3. These end anchors are to be paid for under the contract unit price for Guardrail, End Anchorage Assembly (Type ~~), EA as called for in the plans or by permit. CABLE ANCHOR OPTION END ANCHORAGE ASSEMBLY TYPE ~~ 2006 FDOT Design Standards GUARDRAIL Last Revision Sheet No. 07/01/05 21 of 23 Index No. 400 End Measurement For Guardrail Payment MODIFIED ECCENTRIC LOADER TERMINAL NOTES 2 1 1. The MELT is applicable for design speeds up to 45 mph. The MELT is intended for use as an approach end guardrail 1 : 15 To No rmal Shoulde r Break Point 10’ 4 anchorage for shoulder guardrail. Its alignment is a flare from the normal guardrail alignment with an effective length of 37.5’ including three standard W-beam panel outside of any standard guardrail, guardrail transitions or other special treatments. 3’ 3 Shoulder Line 5 2. This standard drawing is produced by the Florida Department Of Transportation solely for use by the Department and its 6 assignees. This standard drawing provides the general graphics and information necessary to field identify component parts re Line Misc. Asphalt Pavt. To Suit Shoulder Treatment, See Sheet No. 14 3. This standard drawing is sufficient for plan details for the MELT when installed in connection with shoulder guardrail and precludes the requirement for shop drawing submittals unless the plans otherwise call for such submittals. The MELT shall be assembled in accordance with the distributor’s detailed drawings, procedures and specifications. 4. The first two post must be short timber breakaway posts with steel foundation tubes and soil plates, post Nos. 3 thru 6 must be CRT timber posts and post No. 7 must be a standard timber post. 1" Special Transition Or Other Special Treatment 2’-1" 1’-2" Standard Guardrail, 4’-0" Departu of the MELT and their incorporation into a whole system. 1: 10 Max. Max. Misc. Asphalt Pavt. 1: 10 7 Beginning Of Length Of Need 8" 4" 2 1/2 " 3 Spaces @ 4’-2" 2 Spaces @ 6’-3" 5. The MELT can not be used in medians where horizontal clearance requires the use of a backrail. 2 Spaces @ 6’-3" CRT Timber Posts And Offset Blocks Standard 6. See the General Notes for galvanizing requirements of metallic components. Timber Post No Bolts Through Rail To Posts And Offset Block ‘21’ R Fabricated 7. If the plans call for the MELT at a specific location, substitutions with other end anchorage assemblies will not be permitted Over Beg. 6’-3" (Bolt Back Up Plate To No. 4 Post To Provide Nested Support For Rail) unless approved by the Engineer. If the plans call for end anchorage assembly ’flared’ at a specific location, the contractor 37.5’ Flare (Lap Panels In Direction Of Near Traffic) has the option to construct any FDOT approved flared assembly that meet the applications for that location. Where a flared end anchorage is called for in the plans, any approved substitution with a parallel end anchorage will not be eligible for VECP PLAN consideration. 10 1 Head Bolts And Special End Shoe 3/4 "!1" Slot 8 1/2 " 3" To Nose Anchor Plate 7 1/2 " 6 1/8 " 4 7/8 " 4 7/8 " 1’-4" 12 1/4 " Retroreflective Cable Assembly Adhesive Sheeting Bolt & Nut With 25 3/4 " And Washer Each End Apply 8"!24" Amber Steel Tube 25 3/4 " 8 1/2 " PLAN Hex Nut, Hex (Jam) Nut Strut And Yoke Assembly 5/8 "!18" Long Post 6" Recess Nuts (6 Reqd.) Soil Plate Nut & Washer ^ Soil Plate 45 Steel Tube compensation for furnishing and installing all components in accordance with the plans; the distributor’s detailed drawings, procedures and specifications and this Index. 13^ 5/8 "!1 3/4 " Long Button 8. The MELT shall be paid for under the contract unit price for Guardrail, End Anchorage Assembly (Flared), EA and shall be full ^ 13^ Buffer End Section Diaphragm Plate 45 /2 " R MODIFIED ECCENTRIC LOADER TERMINAL (MELT) 5/8 "!10" Long Post Bolt And Nut With 5/8 " Plain Round Beam Washer Under Head And Washer Under Nut 8 1/2 " 2" 5/8 " Plain Round Washer Under Nut Shelf Angle 6 3/4 " 8 1/4 " 1 1/2 " 1/4 " Steel Plate 8 1/4 " Max. 5/8 "!1 3/4 " Long Button Head Bolt FLAT PLATE LAYOUT ELEVATION And Nut With Beam Washer 29 Under Head And Nut All Slots Shall Be 32 SHELF ANGLE 1 18 ! BUFFERED END SECTION TOP VIEW 4" 5/8 " 6 1/4 " Diaphram Plate 1 1/8 3 1/2 " Short Timber Breakaway Post 1’-8 3/4 " 1’-4" " 21 /4 " 1" R (Typ.) 1" 45 1’-0" 2" 6’-3" Short Timber Breakaway 5 1/2 " ^ Post And Offset Block Splice Bolts And Nuts 5’-7 1/4 " Amber Retroreflective A e R 3/16 " STRUT R 10 " 1/2 6" e Se N 5/1 ot Sheeting (See Above) Bearing Plate Strut And Yoke Assembly B | 21 /2 " B Post Sleeve 3/8 " R (Typ.) 6" \ Hole 6 1/2 " 2 3/8 "\ Hole Guardrail Pavement A 3/4 " Breakaway Terminal Two 8d Nails To Prevent Rotation 1’-9" Slots Cable To Be Drawn Taut With Hand Wrench Prior To Setting Jam Nuts 8 1/8 " 2- 3/4 "!4" Shelf Angle Yoke Yoke PLAN 1 11/16 " @ 10^ (2 Reqd. Per Steel Tube) 5/8 " Under Heads And Nuts 13^ 1 11/16 " 2" 10^ STEEL STRUT AND YOKE ASSEMBLY PLAN 1/4 " R or Steel Tube 5/16 " R 24"!24"! 1/4 " Steel Tube Note: Steel tubes and attached soil plate may be installed by: (1) Excavating, backfilling and compacting to provide full passive soil resistance guardrail and turned up for left side guardrail. 3/4 "!1 1/8 " Slot 1 1/8 " 24"!18"! 1/4 " 1 1/8 " 24"!24"! 1/4 " 1 7/16 " Soil Plate 6 3/4 " 2 1/4 " 4" With 5/8 " Plain Round Washer or Bending 3/4 " @ 35^ 2- 5/8 "!7 1/2 " Long Bolts And Nuts Note: Assembly installed with channel turned down for right side 1 1/8 " Round Wasner Under Head And Nut 24"!18"! 1/4 " YOKE (2 Reqd.) 10 1/2 " R Before 2" @ 35^ 5/8 "!10" Long Bolt And Nut With 5/8 " Plain Soil Plate 7/8 "!2" Slot C 6!8.2 3/4 " 35^ 2 1/4 " SECTION BB SECTION AA Note: Bolt holes are not required, but, diaphragms with either manufacturer produced two or three hole in line patterns are acceptable. to all surfaces of the tube and soil plate. DIAPHRAGM PLATE (2 Reqd.) (2) Driving steel tube and soil plate as a unit with a dummy timber post to prevent damage to breakaway post. FRONT VIEW END ANCHORAGE ASSEMBLY TYPE MELT 2006 FDOT Design Standards GUARDRAIL Last Revision Sheet No. 02 22 of 23 Index No. 400 3/4 " Dia. x 9’-0" Cable With One Swaged End (See Sheet 18) 1. Controlled release returns are intended for use (a) in openings in continuous Lower Cable Attachment Steel Tube CONTROLLED RELEASE RETURN NOTES Special End Shoe Buffer End Section Anchor Plate (See Left) guardrail for driveway and side road access when flares and transitions or standard radial returns can not be applied (Sheet 11); and, (b) for shielding the Soil Plate ends of bridge traffic rails and barrier walls where the driveway and side road Short Timber Breakaway Post 3/4 " Dia. x 9’-0" Cable access is in close proximity to the structure and space does not permit the proper With One Swaged End 3/8 "!4"!12" Steel Plate Structural Tube 2. Controlled release returns are not intended as a substitute or replacement 3/4 "\ Cable With Swaged Ends 10" OD Pipe (See Below) Soil Plate for the appropriate use of approved vehicle impact attenuators. Soil Plate (See Sheet 18). Cable To Be Drawn Taut Tack Weld 2 1/2 "!2 1/2 "! 1/4 " Special Guardrail Pipe With Hand Wrench Prior To Setting Jam Steel Plate With 1 1/16 " Dia. Attach W-beam To Steel Pipe With Hole To Tubular Steel use of approved flared and parallel types of Guardrail End Anchorage Assemblies. Misc. Asphalt Pavt. 4" 2 1/2 "!2 1/2 "! 1/4 "!8" Galvanized Nuts And Connecting Lower Cable Attachment (See Left) 3. Controlled release returns with either 8’, 16’ or 24’ radii are designed for TOP VIEW highway speeds of 60 mph or less; the 32’ radius return is to be used only 5/8 "!1 1/4 " Button Head Bolt With No Washer. No Connection To Post Is Required. Hex Nut, Hex (Jam) Nut & Washer Each End Timber Breakaway Post TOP VIEW for highway speeds of 45 mph or less. 6’-3" 6’-3" 10’ 4. The controlled release returns shown are designed as full returns based on To Next Post 5/8 "\!1 1/2 " Hex Bolt & Beam Washer Under Head TOP VIEW 12" 18" 12" 16" or as otherwise detailed in the plans. Attachment (See Left) Timber Breakaway Post Steel Plate (See Above) an intersection angle of 90^. The return can be terminated with the Guardrail End Anchorage Assembly Type CRT or connected to standard guardrail as shown Special Guardrail Pipe Buffer End Section 1/4 1/4 1/4 2 1/2 "!2 1/2 "! 1/4 "!8" Galvanized 10" OD Schedule 40 6" Structural Tube 1’-9" 7" Timber Breakaway Post Steel Tube controlled release returns with 8’, 16’, 24’ and 32’ radii as shown; the assembly Retroreflective Sheeting is not to be used in any tangent rail or flared rail applications. Other types of To Nose Bearing Plate 6- 3/4 " Cable Clamps 4 1/2 " Spacing Typ. Galvanized Steel Pipe 5. The Guardrail End Anchorage Assembly Type CRT is to be used only for the Apply 8"!24" Amber end anchorage assemblies are not to be used in the controlled release returns. 6. The area immediately behind the control release return shall have slopes not steeper than 1 : 2 and be maintained free of fixed objects in accordance with Cable (See Above) Timber Breakaway Post 3/4 " Dia Hole 7. The surface approaching the controlled release return shall have a transverse Under Head And Nut FRONT VIEW Soil Plate (24"!18"! 1/4 ") LOWER CABLE ATTACHMENT 2" Misc. Asphalt Pavt. With 5/8 " Plain Round Washers (See Left) FRONT VIEW the area limits tabulated in the plan below. 5/8 "!10" Long Bolts And Nuts Lower Cable Attachment 1/4 slope not exceeding 1 : 10. The effective width of the transverse surface is Soil Plate (24"!18"! 1/4 ") to be based on standard vehicle departure, return radii and preceding shielding; SPECIAL GUARDRAIL PIPE ATTACHMENT 5/8 "!8" Long Bolts And Nuts the width (beyond shoulder) shall be not greater than the corresponding 15’ and With 5/8 " Plain Round Washers 20’ ’W’ values tabulated below. Under Head And Nut (2 Reqd. Per Steel Tube) 8. The curved guardrail portion of the controlled release return shall be full section shop bent panels (12.5’ or 25’ panels). Steel Tubes FRONT VIEW 9. Washers are not to be used between the guardrail beam and the head of the button head post bolts at any controlled release terminal (CRT) post or at any GUARDRAIL END ANCHORAGE ASSEMBLY TYPE CRT Guardrail End Anchorage Assembly Type CRT breakaway timber post. 10. The guardrail beam of the 8’ radius return is not bolted to the center Standard Wood Or Steel Posts control release post. Guardrail Section (As Shown) Or Guardrail Transition To Bridge Principle Highway 11. See the General Notes for galvanizing requirements of metallic components. Rail (See Detail J and Index No. 402) Or To Barriers Wall (Index No. 410) 12. Controlled release return systems shall be paid for under the contract unit prices for Guardrail (Roadway), LF, Guardrail (Shop-bent Panels), LF, and S ’- R st s Be Maintained Free Of Fixed Object Hazards And Have Slopes Not Steeper Than 1:2 Po CRT 5/8 "!10" Long Post Bolt And Nut With 5/8 " Plain Round Washer Under Nut L Misc. Asphalt Pavt. See Sheet 14 1’-9" Slope=10:1 Or Flatter 2’-0" Min. 1’-4" Or Driveway Intersecting Roadway @ P os t s CRT R @ included in the cost for guardrail. Area Behind Guardrail To ’ CRT Posts components in accordance with the plans and with this index. CRT posts are 2 ’ or by permit and shall be full compensation for furnishing and installing all " 3 6 24 @ ’R Guardrail, End Anchorage Assembly (Type CRT), EA as called for in the plans g in c a p 3 CRT Post 16 6’ - R S 3" " 8’ in c g W c g S a n i p a p " ng ci @ RETURN NOTES’ No. 10) a 6’ -3 (See ’CONTROLLED RELEASE p 6’ -3 The Center Of The Nose. S Do NOT Bolt Rail To Post At End Measurement For Guardrail Payment 3 1/2 " Dia. Holes Nom. R 8’ Required Area Free Length Of Shop Bent Panels No. Of CRT L 12.5’ 5 W 25’ x 15’ 25’ 6 30’ x 15’ 37.5’ 8 40’ x 20’ 32’ 50’ 11 50’ x 20’ Guardrail End Anchorage Assembly Connecting Guardrail On Intersecting Roadway Or 24’ 16’ Centered In Post Of Hazards Posts 2’-4" Return 1:2 Max. Driveway Options Type CRT (In Absence Of Connecting Note: To be constructed when flares and transitions or standard radial returns can not be applied. See Sheet 11. Guardrail) 8" CRT TIMBER POST CONTROLLED RELEASE RETURN FOR SIDE ROAD AND DRIVEWAY ACCESS 2006 FDOT Design Standards GUARDRAIL Last Revision Sheet No. 04 23 of 23 Index No. 400