Chapter 8 – DC Machinery Fundamentals

advertisement

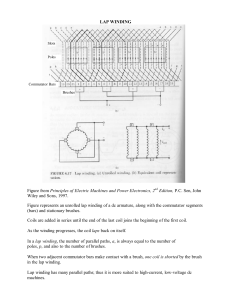

2/15/2013 EEE 118: Energy Conversion Dr. Mongkol Konghirun Department of Electrical Engineering King Mongkut’s University of Technology Thonburi Chapter 8 DC Machinery Fundamentals 1 2/15/2013 8.1 A Simple Rotating Loop between Curved Pole Faces A Simple Rotating Loop Between Curved Pole Faces The simplest possible rotating dc machine with a single rotating loop is shown - Rotating part : rotor - Stationary part : stator - To minimize the reluctance of the flux path, the air gap width should be shortest possible and uniform. - The magnetic flux is perpendicular to the rotor surface everywhere under pole faces. 4 2 2/15/2013 A Simple Rotating Loop Between Curved Pole Faces 5 A Simple Rotating Loop Between Curved Pole Faces 6 3 2/15/2013 The Voltage Induced in a Rotating Loop If the rotor of this machine is rotated, a voltage will be induced in the wire loop. 7 The Voltage Induced in a Rotating Loop To determine the total induced voltage on the loop, examine each segment of the loop separately and sum all the resulting voltages. 8 4 2/15/2013 The Voltage Induced in a Rotating Loop To determine the total induced voltage on the loop, examine each segment of the loop separately and sum all the resulting voltages. 9 The Voltage Induced in a Rotating Loop The total induced voltage on the loop eind is given by When the loop rotates through 180o , segment ab is under the north pole face instead of the source pole face. At this time, the direction of the voltage on the segment reverses, but its magnitude remains constant. 10 5 2/15/2013 The Voltage Induced in a Rotating Loop The waveform of total induced voltage on the loop eind is shown 11 The Voltage Induced in a Rotating Loop Alternative way to express the voltage induced in a rotating loop. The tangential velocity v of the edges of the loop can be expressed as 12 6 2/15/2013 The Voltage Induced in a Rotating Loop Substituting this velocity expression into equation (8-5) gives The area of the rotor under each pole (ignoring the small gaps between poles), Ap = πrl (= a half of area of rotor surface). Therefore, 13 The Voltage Induced in a Rotating Loop Since the flux density B is constant everywhere in the air gap under the pole faces, the total flux under each pole is Therefore, the final form of the voltage equation is 14 7 2/15/2013 The Voltage Induced in a Rotating Loop Thus, the induced voltage in any real machine will depend on the same three factors : 1. The flux in the machine. 2. The speed of rotation 3. A constant representing the construction of the machine. 15 Getting DC Voltage out of the Rotating Loop The induced voltage etot in Figure 8-3 is alternatively a constant positive and negative values. How can this machine be made to produce a dc voltage instead of the ac voltage it now has ? See following Figure 8-5(a) for a solution. Two key elements are commutator and brushes. Commutator : two semicircular conducting segments are added to the end of the rotating loop. So, both commutator and wire loop rotate together. Brushes : two fixed contacts are set up at an angle such that at the instant when the voltage in the loop is zero (wire loop is on the vertical position), the contacts short-circuit the two conducting segments. There is no current flowing to the wire loop at this time. 16 8 2/15/2013 Getting DC Voltage out of the Rotating Loop 17 The Induced Torque in the Rotating Loop Suppose a battery is now connected to the machine as shown in Figure 8-6. How much torque will be produced in the loop ? How much current is allowed to flow into the loop ? 18 9 2/15/2013 The Induced Torque in the Rotating Loop Consider the force on each segment of the loop separately 19 The Induced Torque in the Rotating Loop While the loop is under the pole faces, the torque is 20 10 2/15/2013 The Induced Torque in the Rotating Loop While the loop is under the pole faces, the torque is 21 The Induced Torque in the Rotating Loop While the loop is under the pole faces, the torque is 22 11 2/15/2013 The Induced Torque in the Rotating Loop While the loop is under the pole faces, the torque is 23 The Induced Torque in the Rotating Loop The resulting total induced torque on the loop is given by 24 12 2/15/2013 The Induced Torque in the Rotating Loop Thus, the torque produced in any real machine will depend on the same three factors : 1. The flux in the machine. 2. The current in the machine 3. A constant representing the construction of the machine. 25 8.2 Commutation in a Simple Four-Loop DC Machine 13 2/15/2013 A Simple Four-Loop, Two-Pole dc Machine - Four loops are buried in the slots carved in the laminated steel of its rotor. - The pole faces are curved to provide a uniform air-gap width to give a uniform flux density everywhere under the faces. - The “unprimed” end of each loop is the outermost wire in each slot (eg, 1, 2, 3, and 4). - The “primed” end of each loop is the innermost wire in the slot directly opposite (eg, 1’, 2’, 3’, and 4’). 27 A Simple Four-Loop, Two-Pole dc Machine Connections of wire loop ends Loop 1 : 1 => commutator segment a 1’ => commutator segment b Loop 2 : 2 => commutator segment b 2’ => commutator segment c Loop 3 : 3 => commutator segment c 3’ => commutator segment d Loop 4 : 4 => commutator segment d 4’ => commutator segment a 28 14 2/15/2013 A Simple Four-Loop, Two-Pole dc Machine At the instant shown in Figure 8-7(a), the voltage in each of the 1, 2, 3’ and 4’ ends of the loop under north pole face is given by the voltage in each of the 1’, 2’, 3 and 4 ends of the loop under south pole face is given by The overall result is shown in Figure 87(b). 29 A Simple Four-Loop, Two-Pole dc Machine In this Figure 8-7(b), each coil represents one side (or conductor) of a loop. If the induced voltage on any one side of a loop is called e = vBl, then the total voltages at the brushes is There are two parallel paths for current through the machine. 30 15 2/15/2013 A Simple Four-Loop, Two-Pole dc Machine What happens to the terminal voltages E as the rotor continues to rotate ? Figure 8-8 shows the machine at time ωt=45o. Segments ab and cd are shorted circuit but no problem due to zero voltages across them. 31 A Simple Four-Loop, Two-Pole dc Machine What happens to the terminal voltages E as the rotor continues to rotate ? Figure 8-9 shows the machine at time ωt=90o. 32 16 2/15/2013 A Simple Four-Loop, Two-Pole dc Machine Compare Figure 8-7 to Figure 8-9 (ωt= 0o, 45o and 90o). Notice that the voltage on wire loops 1 and 3 have reversed between the two pictures, but since their connections have also reversed, the total voltage is still being built up in the same direction as before. Commutation : the process of switching the loop connections on the rotor of a dc machine just as the voltage in the loop switches polarity, in order to maintain an essentially constant dc output voltage. 33 8.3 Commutation and Armature Construction in Real DC Machines 17 2/15/2013 The Rotor Coils Most of rotor windings themselves consist of diamond-shaped preformed coils which are inserted into the armature slots as a unit. Each coil consists of a number of turns (loops) of wire, each turn taped and insulated from the other turns and from the rotor slot. 35 The Rotor Coils The number of conductors (i.e., each side of a turn) on a machine’s armature is given by Normally, a coil spans 180 electrical degrees. Then, the voltages in the conductors on either side of the coil will be exactly the same in magnitude and opposite in direction at all time. Such a coil is called a full-pitch coil. 36 18 2/15/2013 The Rotor Coils The relationship between the electrical angle and mechanical angle is given by Sometimes a coil is built that spans less than 180 electrical degrees. Such a coil is called a fractional-pitch coil. A rotor winding would with fractional pitch coils is called a chorded winding. A amount of chording is described by a pitch factor p 37 The Rotor Coils Most rotor windings are two-layer windings, meaning that sides from two different coils are inserted into each slot. The winding installation is very elaborate procedure. 38 19 2/15/2013 Connections to the Commutator Segments Once the windings are installed in the rotor slots, they must be connected to the commutator segments. There are a number of ways for connections with different winding arrangements, resulting different advantages and disadvantages. The distance (in number of segments) between commutator segments to which the two ends of a coil are connected is called the commutator pitch yc. For wave construction, Yc=-1 Yc=1 Progressive winding Retrogressive winding Progressive winding VS retrogressive winding => different rotational direction 39 Connections to the Commutator Segments Rotor (armature) windings are further classified according to the plex of their windings. - A simplex rotor winding is single, complete closed winding wound on a rotor - A duplex rotor winding is a rotor with two complete and independent sets of rotor windings. Each of the windings will be associated with every other commutator segment: One winding will be connected to segments 1,3,5, etc., and the other winding will be connected to segments 2,4,6, etc. - A triplex rotor winding will have three complete and independent sets of windings, each winding connected to every third commutator segment. - A multiplex windings: more than one set of windings. 40 20 2/15/2013 The Lap Winding Armature windings are also classified according to the sequence of their connections to the commutator segments. Two basic sequences: lap windings and wave windings. The simplest winding construction used in modern dc machines is the simplex series or lap winding. A simplex lap winding is a rotor winding consisting of coils containing one or more turns of wire with the two ends of each coil coming out at adjacent commutator segment (Figure 8-13). Figure 8-14 shows a simple two-pole machine with lap windings. 41 The Lap Winding C=8, P = 2 42 21 2/15/2013 The Lap Winding Interesting feature of simplex lap windings: there are as many parallel current paths through the machine as there are poles on the machine. A number of coils in each parallel current paths = C/P where C = number of coils = commutator segments P = parallel current paths = number of poles = number of brushes Figure 8-15 shows a simple four-pole motor having four parallel current paths, each having an equal voltage. More parallel current paths (multi-pole machine) => low-voltage, high current machine. 43 The Lap Winding C=16, P = 4 Simple four-pole motor 44 22 2/15/2013 The Lap Winding Serious problem with multi-pole lap-wound machine. Figure 8-16 shows six-pole machine as an example. In the long usage, there has been slight wear on the bearings of machine, and the lower wires are closer to their pole faces than the upper wires are. As a result, there is a larger voltage in the current paths involving wires under the lower pole faces than in the paths involving wires under the upper pole faces. Since all the paths are in parallel => this cause the large circulating current flowing out some brushes as shown in Figure 8-17. Potentially serious heating problems. 45 The Lap Winding 46 23 2/15/2013 The Lap Winding The circulating currents in four or more poles can be reduced somewhat by equalizers or equalizing windings. Equalizers are bars located on the rotor of a lap-wound dc machine that short together points at the same voltage level in the different parallel paths. Using equalizers, the circulating current would flow inside the small sections of windings shorted together and to prevent this circulating current from flowing through the brushes. These circulating currents even partially correct the flux imbalance due to non-uniform air-gap. Figure 8-18 shows an equalizer for four-pole machine in Figure 8-15. Figure 8-19 shows an equalizer for a large lap-wound dc machine. 47 The Lap Winding 48 24 2/15/2013 The Lap Winding 49 The Lap Winding In case of duplex lap winding, therefore, the commutator pitch yc = ± 2 (depending on whether the winding is progressive or retrogressive). Since each set of windings has as many current paths as the machine has poles, there are twice as many current paths as the machine has poles in a duplex lap winding. In general, for an m-plex lap winding, the commutation pitch yc is 50 25 2/15/2013 The Wave Winding The series or wave winding is an alternative way to connect the rotor coils to the commutation segments. Figure 8-20 shows a simple four-pole machine with a simplex wave winding. There are two coils in series between the adjacent commutator segments, having a side under each pole face. All output voltages are the sum of the effects of every pole, and there can be no voltage imbalance. Progressive winding : second coil is connected to the segment ahead of the first coil. Retrogressive winding : second coil is connected to segment behind the first coil. 51 The Wave Winding For P pole machines, then there are P/2 coils in series between adjacent commutator segments. In a simplex wave winding, - There are only two current paths (ie., two brushes needed). - There are C/2 or one-half of the windings in each current path. - The brushes will be located a full pole pitch apart from each other. What is the commutator pitch yc for a wave winding ? Figure 8-20 shows a progressive non-coil winding, and the end of coil occurs five segments down from its starting point. In a retrogressive wave winding, the end of the coil occurs four segments down from its starting point. 52 26 2/15/2013 The Wave Winding In general, the commutator pitch in any simplex wave winding is where C is number of coils on the rotor and P is number of poles. The sign in the equation (8-27) indicates Plus sign => progressive winding Minus sign => retrogressive winding Figure 8-21 shows a simplex wave winding. Wave windings are well suited to building higher-voltage dc machines, since the number of coils in series between commutator segments permits a high voltage to be built up more easily than with lap windings. 53 The Wave Winding Simplex wave winding for four-pole machine For a multiplex wave winding => multiple independent sets of wave windings. => number of current paths, a (m=plex of winding) 54 27 2/15/2013 The Frog-Leg Winding The frog-leg winding or self-equalizing winding consists of a lap winding and a wave winding combined. Equalizers in lap winding are connected at point of equal voltage on the winding. Wave windings reach between points of equal voltage under successive pole faces of the same polarity, which are same locations that equalizers tie together. ⇒ Wave windings can function as equalizers for the lap winding. The number of current paths is as (P= number of poles, mlap = plex of lap winding) 55 8.4 Problems with Commutation in Real Machines 28 2/15/2013 Problems with Commutation in Real Machines Two major effects occur in the real dc machine to disturb the commutation process. 1. Armature reaction 2. L.di/dt voltages 57 Armature Reaction (Neutral-Plane Shift) There are two serious problems caused by armature reaction in real dc machines. 1. neutral-plane shift. - Flux is distributed uniformly under the pole faces as shown in Figure 823(b). - As rotor rotates with ω, the rotor windings have voltage built up as shown in Figure 8-23(a). - The magnetic neutral plane is exactly vertical. 58 29 2/15/2013 Armature Reaction (Neutral-Plane Shift) There are two serious problems caused by armature reaction in real dc machines. - Now this generator is loaded. - The flow of load current produces a 1. neutral-plane shift. magnetic field from the rotor windings as shown in Figure 8-23(c). - As a combination of rotor magnetic field and magnetic field from poles, the magnetic flux in the air-gap of the machine is skewed. See Figure 823(d) 59 Armature Reaction (Neutral-Plane Shift) There are two serious problems caused by armature reaction in real dc machines. 1. neutral-plane shift. - The neutral plane is now shifted in the direction of rotation as shown in Figure 823(e). - For motor, the current in its rotor would be reversed. The rotor magnetic field is in the opposite. The neutral plane is shifted the other way, opposite with the direction of rotation. - Amount of shift depends on the amount of load current. 60 30 2/15/2013 Armature Reaction (Neutral-Plane Shift) So, what is the big deal about neutral-plane shift ? If the brushes are set to short out conductors in the vertical plane, then the voltage between commutator segments is indeed zero. When the machine is loaded, the neutral plane shifts and the brushes short out commutator segments with a finite voltage across them. The result is a current flow circulating between shorted commutator segments and large sparks at the brushes when the current path is interrupted as the brush leaves a commutator segment. The end result is arcing and sparking (even flashover near segments) at the brushes : ⇒ reducing brush life ⇒ pitting of the commutator segments ⇒ greatly increased maintenance costs 61 Armature Reaction (Flux Weakening) There are two serious problems caused by armature reaction in real dc machines. 2. Flux weakening. - In most machines, the operating flux density near saturation point (@pole mmf). - At the locations on the pole surfaces where the rotor magnetomotive force adds to the pole magnetomotive force => smaller increase in flux (smaller ∆φi) - At the locations on the pole surfaces where the rotor magnetomotive force subtracts from the pole magnetomotive force => larger decrease in flux (larger ∆φd) - The net result: total average flux under entire pole face is decreased. 62 31 2/15/2013 Armature Reaction (Flux Weakening) Effects of flux weakening Generator : lower induced voltage Motor : - lower produced torque - runaway condition 63 L.di/dt Voltages Sometimes this problem related to L.di/dt is called inductive kick. When a commutator segment is shorted out, the current flow through that commutator segment must reverse. Assuming that the total current in the brush is 400 A. Assuming that the machine is turning at 800 rpm, there are 50 commutator segments, each commutator segment moves under a brush and clear it again in t= 0.0015 sec = 60/(800*50) sec Therefore, the rate of change in current with respect to time in the shorted loop must average Even tiny inductance (L) in the loop, a very significant inductive voltage kick v = L.di/dt induced in the shorted commutator segment. 64 32 2/15/2013 L.di/dt Voltages This high inductive voltage causes sparking at the brushes. 65 Solutions to the Problems with Commutation Three approaches partially or completely correct the problems of armature reaction and L.di/dt voltages : 1. Brush shifting 2. Commutating poles and interpoles 3. Compensating windings 66 33 2/15/2013 Brush Shifting Today, the brush shifting approach was already obsolete. The idea of the brush shifting is to adjust the brushes every time the load on the machine changed. As the neutral plane moves with every change in load, and the shift direction reverses when the machine goes from motor to generator. Another slightly different approach was to fix the brushes in a compromise position causing no sparks at a specific load. As for different loads from this specific load, the sparks occur. However, the brush shifting actually aggravates the flux-weakening effect of the armature reaction because of two effects: 67 Brush Shifting However, the brush shifting actually aggravates the flux-weakening effect of the armature reaction because of two effects: 1. Rotor magnetomotive force now has a vector component that opposes the magnetomotive force from the poles (see Figure 827). 2. The change in armature current distribution causes the flux to bunch up even more at the saturated parts of the pole faces. 68 34 2/15/2013 Brush Shifting Rotor magnetomotive force now has a vector component that opposes the magnetomotive force from the poles (see Figure 8-27). 69 Commutating Poles or Interpoles Basic idea is that if the voltage in the wires undergoing commutation can be made zero, then there will be no sparking at the brushes. To accomplish this, small poles called commutating poles or interpoles are placed midway between the main poles. These interpoles are located directly over the conductors being commutated. By providing a flux from the interpoles, the voltage in the coils undergoing commutation can be exactly canceled. If the cancellation is exact, then there will be no sparking at the brushes. Interpoles do not affect both machine operation and armature reaction. 70 35 2/15/2013 Commutating Poles or Interpoles How it work ? This is done by simply connecting the interpole windings in series with the windings on the rotor (armature winding). See Figure 8-28. 71 Commutating Poles or Interpoles As the load increases, and the rotor current increases, both neutral-plane shift and L.di/dt effects increase the voltage in the conductor undergoing commutation. The interpole flux increases too, producing a large voltage in the conductors that opposes the voltage due to the neutral-plane shift. Interpoles work for both motor and generator operation. The interpoles must induce a voltage in the conductors undergoing commutation that is opposite to the voltage caused by neutral-plane shift and L.di/dt effects. The use of interpole is very common due to its fairly low cost. Almost found in dc machines of 1 hp or higher. Interpoles do nothing for the flux distribution under the pole faces. 72 36 2/15/2013 Commutating Poles or Interpoles Opposite polarity of voltages 73 Compensating Windings To completely cancel armature reaction, the compensating windings in slots carved in the faces of the poles parallel to the rotor conductors, to cancel the distorting the effect of armature reaction. These compensating windings are connected in series with the rotor windings, so that the load changes in the rotor, the current in the compensating winding changes too. See Figure 8-30(a) for the pole flux by itself. In Figure 8-30(b), the rotor flux and the compensating winding flux are shown. Figure 8-30(c) represents the sum of these three fluxes, which is just equal to the original pole flux by itself. 74 37 2/15/2013 Compensating Windings 75 Compensating Windings Figure 8-31 shows the development of the effect of compensating windings on a dc machine. The magnetomotive force due to compensating windings is equal and opposite to the magnetomotive force due to the rotor at every point under the pole faces. The resulting net magnetomotive force is just the magnetomotive force due to the poles, so the flux in the machine is unchanged regardless of the load on the machine. The main disadvantage of compensating windings is that they are expensive. Any motor that used them must also have interpoles. Compensating windings do not cancel L.di/dt effect while interpoles do. Compensating windings do correct the neutral-plane shifting only. 76 38 2/15/2013 Compensating Windings 77 8.5 The Internal Generated Voltage and Induced Torque Equations of Real DC Machines 39 2/15/2013 The Internal Generated Voltage of Real DC Machines The induced voltage in any given machine depends on three factors: The voltage in any single conductor under the pole faces is 79 The Internal Generated Voltage of Real DC Machines 80 40 2/15/2013 The Internal Generated Voltage of Real DC Machines 81 The Internal Generated Voltage of Real DC Machines It is common to express the speed of a machine in revolutions per minute (rpm, unit of n) instead of radians per second (unit of ω). So, the voltage equation with speed in rpm is 82 41 2/15/2013 The Internal Generated Torque of Real DC Machines The induced torque in any given machine depends on three factors: The torque in any single conductor under the pole faces is 83 The Internal Generated Torque of Real DC Machines 84 42 2/15/2013 The Internal Generated Voltage and Torque of Real DC Machines Both internal generated voltage and the induced torque equations just given are only approximations. Reasons: - Not all conductors in the machine are under the pole faces at any given time. - The surfaces of each pole do not cover an entire 1/P of the rotor surface. To achieve greater accuracy, the number of conductors under the pole faces could be used instead of the total number of conductor on the rotor. 85 Example Problem Example 8-4 on page 517 86 43 2/15/2013 8.6 The Construction of DC Machines Simplified Sketch of a dc Machine The physical structure of the machine consists of two parts: stator and rotor. 88 44 2/15/2013 Pole and Frame Construction The main poles of newer machines are made entirely of laminated material. The laminated main poles reduce the eddy current losses in the much higher ac content in the power supplied to dc motor driven by solid-state drive packages. 89 Pole and Frame Construction Pole faces: chamfered or eccentric type. The outer tips of a pole face have higher air-gap than the rotor surface at the center of the pole face. This increases reluctance at the tips and thus reduces the flux-bunching effects of armature reaction. 90 45 2/15/2013 Rotor and Armature Construction Core is composed of many laminations stamped from the steel plate, with notches along its outer surface to hold the armature windings. Commutator is built onto the shaft of the rotor at one end of the core. Armature coils are laid into the slots on the core, as described in Section 8.4, and their ends are connected to the commutator segments. 91 Commutator and Brushes Commutator is typically made of copper bars insulated by a mica-type material. The copper bars are made sufficiently thick to permit normal wear over the lifetime of the motor. Mica insulation between segments is harder than the commutator material itself. Brushes made of carbon, graphite, metal graphite or a mixture of carbon and graphite. (high conductivity reducing electrical losses & low coefficient of friction, reducing excessive wear) 92 46 2/15/2013 Commutator and Brushes Brushes are too soft => replaced too often Brushes are too hard => commutator surface will wear excessively over the life of the machine. Brush pressure is too great => Both brushes and commutator bars wear excessively. Brush pressure is too low => brushes tend to jump slightly and a great deal of sparking occurs at the brushcommutator segment interface. Another factor which affects the wear on the brushes and segments : amount of current flowing in the machine. If the current is too small, thin oxide layer (which lubricates the motion the brushes over segments) will break down, increasing frictions between brushes and commutator (rapid wear). 93 Winding Insulation To prevent the winding insulation from breaking down, it is necessary to limit the temperature of the windings. This can be partially done by ⇒ Cooling air circulation ⇒ Limit power that can be supplied continuously by machine. Increase in temperature => gradual degradation of the insulation. Rule of thump: motor life expectancy is halved for each 10% rise in winding temperature. National Electrical Manufacturers Association (NEMA) in USA has defined a series of insulation system classes in NEMA standard MG11993, Motors and Generators. International Electrotechnical Commision (IEC) or various national standards in other counties has also defined the insulation classes. 94 47 2/15/2013 Winding Insulation National Electrical Manufacturers Association (NEMA) in USA has defined a series of insulation system classes in NEMA standard MG11993, Motors and Generators. There are four standard NEMA insulation classes for integral-horsepower dc motors. Each class represents the highest permissible winding temperature. Class Class Class Class A .. is limited to 70oC B .. is limited to 100oC F .. is limited to 130oC H .. is limited to 155oC 95 8.7 Power Flow and Losses in DC Machines 48 2/15/2013 Efficiency in DC Machines The efficiency of a dc machine is defined by the equation The difference between input power and the output power of a machine is the losses that occur inside it. Therefore, 97 The Losses in DC Machines The losses that occur in dc machines can be divided into five categories: 1.Electrical or copper losses (I2R losses) 2.Brush losses 3.Core losses 4.Mechanical losses 5.Stray load losses 98 49 2/15/2013 Electrical or Copper Losses Copper losses are losses that occur in the armature and field windings of the machine. Resistance used in these calculations is usually winding resistance at normal operating temperature. 99 Brush Losses Brush loss is the power lost across the contact potential at the brushes of the machine. Voltage drop across a set of brushes is approximately constant over a large range of armature currents. The brush voltage drop is usually assumed to be about 2 V. 100 50 2/15/2013 Core Losses Core losses are the hysteresis losses and eddy current losses occurring in the metal of the machine. These losses are described in Chapter 1. These losses vary as the square of the flux density (B2) and, for the rotor, as the 1.5th power of the speed of rotation (n1.5). 101 Mechanical Losses Mechanical losses in a dc machine are losses associated with mechanical effects. There are two basic types: 1. Friction losses : losses caused by the friction of the bearings in the machine. 2. Windage losses : losses caused by the friction between moving parts of the machine and air inside the motor’s casing. These losses vary as the cube of the speed of rotation 102 (n3). 51 2/15/2013 Stray Losses (or Miscellaneous Losses) Stray losses are losses that cannot be placed in one of the previous categories. Some losses always escape inclusion in one of the above categories. All such losses are lumped into stray losses. For most machine, stray losses are taken by convention to be 1 percent of full load. 103 The Power-Flow Diagram One of the most convention techniques for accounting for power losses in a machine is the power-flow diagram. The mechanical power that is converted is given by The resulting electric power produced is given by 104 52 2/15/2013 The Power-Flow Diagram generator 105 The Power-Flow Diagram motor 106 53 2/15/2013 EEE 118: Energy Conversion Dr. Mongkol Konghirun Department of Electrical Engineering King Mongkut’s University of Technology Thonburi 54