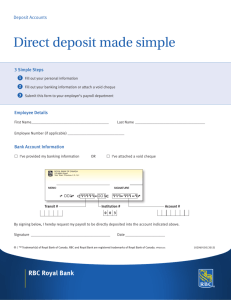

the entire catalog PDF

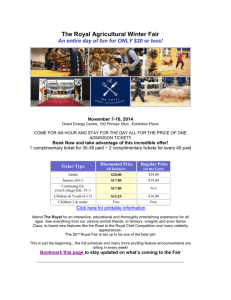

advertisement