Temperature Pressure Fluidhandling Heating, refrigeration, solar

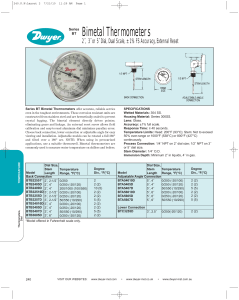

advertisement

-1- I N H A LT PRODUCT CATALOGUE NO. 03 Temperature measuring, displaying, adjusting, controlling Pressure measuring, displaying, adjusting, controlling Fluidhandling metering, transferring, sucking, determining Heating, refrigeration, solar plants Pressure gauges, Manifolds, Handpumps ISO 9001:2008 Reg.no. 12 100 24343 TMS WWW.LEITENBERGER.DE The LEITENBERGER Company was founded in 1969 in Reutlingen, an industrial town to the south of Stuttgart in the Federal German State of Baden-Württemberg. Since then the company logo is unchanged: LEITENBERGER REUTLINGEN ENGINEERED AND MADE IN GERMANY QUALITY MADE IN GERMANY Schwaben(swabian)power since 1969 From the outset, our employees‘ development capabilities and innovative ideas, characteristic qualities of the people of the area, rapidly led to an extensive range of measuring, testing and recording instruments, designed to record physical variables. In addition, the range now includes mechanical, electronic and optical testers. Of medium size, the Company has undergone considerable expansion as a result of further developments in every product group. In turn, we have SCHWABEN been able to optimise our services and to introduce the latest technologies jointly with our customers and, in this way, to establish long-term business relationships. Thanks to our uncomplicated, direct contact with the customer, we are able to satisfy the most wide ranging of functional and other requirements in the minimum of time, with reliable, thorough solutions. To this end, we also collaborate with efficient associates (SWABIAN) worldwide, guaranteeing exceptional value for money and high standards of quality. Customer satisfaction throughout the world confirms our success on a global scale. Thanks to user satisfaction and a loyal customer base, LEITENBERGER MESS- UND REGELTECHNIK GMBH can look forward to a successful, innovative future. POWER SINCE 1969 Our company is part of the LEITENBERGER-group with plants in Germany and Greece. Following companies also belong to the group: Autotestgeräte LEITENBERGER GmbH Druck & Temperatur LEITENBERGER GmbH - - - - Pressure Gauges - Pressure Calibration -Thermometer - Temperature Calibration - Data Logging and Recorders Garage tools Innovative test and measuring instruments for the engine and automotive industry solutions for customer-specific requirements, from the construction of prototypes up to serial production T H E L E I T E N B E R G E R C O M PA N Y Factory I: Bahnhofstraße 32 - - - - - - - Quality check Production, installation Lab / Development CAD office, 3D printer Electronics system Circuit board configuration Repair shop Factory II: Alexandroupolis, Greece Factory III: Commercial park Factory IV: Wannweiler Straße 3 -Pre-installation - Partial installation -Warehouse - Cardboard warehouse - Packaging material warehouse -Depot - Employee parking spaces - Visitor parking spaces - - - The Company‘s headquarter: Bahnhofstraße 33 - - - Offices, administration, purchasing, sales, QA, exhibition room, training room Lab for development electronics/ software, Development, Mechanics Production parts, Shipping CNC foam rotary cutter Case production, empty case and foam material, blank warehouse Lab for sensory devices (software/ hardware) software development -6- CONTENT Mechanical temperature measurement • Thermometer • Dial contact thermometer • Automotive thermometer and pressure gauges with lighting • Telethermostats Seite 8 - 17 15 18 19 - 21 •Capillaries 23 • Capillaries protection 23 • Probes 24 - 25 •Pockets 26 • Room thermostats with/without LCD 27 CONTENT -7- Digital measurement • Digital thermometers • Digital pressure gauge 28 - 29 29 Pressure measurement and control • Pressure gauges 30 - 33 • Manifolds for a/c and refrigeration systems 34 • SmartPressureGate - SPG 35 • Capsule Pressure Gauge 36 - 39 Hand pumps 40 -45 Refractometer 46 - 47 General Informations Products of our sister companys Contact 48 49 - 50 52 All errors and misprints reserved. Subject to technical alterations. -8- THERMOMETER Thermometer Thermometers and thermostats according to the principle of liquid extension which means no additional energy is needed. They are available in different measuring ranges between -80° C and +360° C, different length of capillary and various types of probes. Ranges from -80° C to +120° C are regularly produced with a plastic covered capillary. All ranges over 120° C are produced with a single copper covered capillary. Other models are available on request. Spezial versions and forms on request. Features: chooseable: - length and kind of the test lead - measurement range - type and lenght of the probe - mounting options - accuracy Customer options: chooseable: - scale color - customized dial -9- THERMOMETER R E C TA N G L E / O VA L / S Q U A R E W I T H I N T E G R AT E D S P R I N G C L I P S 02.00 - 25x58 - Without bimetal compensation accuracy ± 3 % - case: - window: ABS, black or white plexiglass options: - coloured scale - available case colours blew, red, yellow, green - frontframe ABS chromed or in case colour - bimetal compensation - mounting adapter 74 x 32, black, or white -u-clamp Type a b c d A B 1025x58 58 25 4 65 65 32 02.00 - 11x64 und 11x70 - Without bimetal compensation accuracy ± 3 % - case: - window: ABS, black or white plexiglass options: - coloured scale - front in rectangle shape Type a b c d A B 1011x64 - oval 62 12 2 44 64 14 1011x64 - rectangle 62 12 2 44 64 14 1011x70 - oval 62 12 2 44 70 14 1011x70 - rectangle 62 12 2 44 70 14 02.72 Without bimetal compensation accuracy ± 3 % - case: - window: ABS, black plexiglass options: - coloured scale -u-clamp - bimetal compensation Type a c d D 1048x48 20 10 45 48 1052x52 20 10 45 52 - 10 - THERMOMETER IN ABS-CASE, ROUND F O R F R O N T PA N E L - O R W A L L M O U N T I N G 02.12 Frontpanelmounting with integrated spring clips without bimetal compensation accuracy ± 3 % - case: - window: ABS, black or white plexiglass options: - coloured scale - front ring ABS chromed -u-clamp - bimetal compensation Type a b c d D 1052 K 20 35 5 52 57,5 65,5 1060 K 20 35 5 60 1080 K 23 33 3 80 84 1100 K 23 33 3 98 103 02.22 K3 3 possibilities to mount 1. frontpanelmounting with integrated springclips 2. frontpanelmounting with 3-hole front flange 3. surface mounting with back flange without bimetal compensation accuracy ± 3 % - case: - window: ABS, black or white plexiglass options: - coloured scale - available case colours blew, red, yellow, green - frontframe and case ABS chromed -u-clamp - bimetal compensation Type a c d D l L 1052 K3 25 3 55 80 4,5 74 1060 K3 25 3 63 80 4,5 74 1080 K3 25 3 83 105 4,5 96 1100 K3 25 3 103 132 4,5 116 LEGEND HBR F KB ABS (THERMOMETER) = back flange = front flange = u-clamp = Acrylnitril-Butadien-Styrol-Copolymerisat - 11 - THERMOMETER IN STEEL SHEET CASE F O R F R O N T PA N E L M O U N T I N G W I T H U - C L A M P 02.01 With bimetal compensation accuracy ± 2 % - case: - window: - front ring: steel sheet corrosion protected glass (type 1100 KB made of MAKROLON) chromed options: - back adjustment - accuracy ±1 %, ±1,5 % - drag pointer - customized dial, coloured scale -plexiglass - front ring black or stainless steel Type a b c d D e 1052 KB 30 50 4 52 56 16 1060 KB 30 50 4 60 64 16 1080 KB 30 50 4 80 84 16 1100 KB 30 50 4 100 105 16 1160 KB 30 50 4 160 168 16 02.08 Without bimetal compensation with back adjustment accuracy ± 2 % - case: - window: - front ring: steel sheet corrosion protected glass (type 1100 KB/f made of MAKROLON) chromed options: - drag pointer - customized dial, coloured scale -plexiglass - front ring black or stainless steel Type a b c d D e 1052 KB/f 20 35 4 52 56 16 1060 KB/f 20 35 4 60 64 16 1080 KB/f 20 35 4 80 84 16 1100 KB/f 30 45 8 100 105 16 02.89 Without bimetal compensation with back adjustment accuracy ± 3 % - case: - window: - front ring: steel sheet corrosion protected glass (type 1100 KB/fs MAKROLON) chromed options: - customized dial, coloured scale -plexiglass - front ring black or stainless steel Type a b c d D e 1052 KB/fs 20 35 4 52 56 16 1060 KB/fs 20 35 4 60 64 16 1080 KB/fs 20 35 4 80 84 16 1100 KB/fs 30 45 8 100 105 16 - 12 - THERMOMETER IN ABS-CASE, SQUARE SHAPE F O R F R O N T PA N E L M O U N T I N G W I T H U - C L A M P 02.07 With bimetal compensation accuracy ± 2 % - - - - 1072x72/60 KB case: 1096x96/80 KB case: window: front ring: ABS, black steel sheet corrosion protected plexiglass / glass chromed options: - back adjustment - accuracy ±1 %, ±1,5 % - drag pointer - customized dial, coloured scale Type a b c d D e 1072x72/60 KB 30 45 8 60 72 16 1096x96/80 KB 30 45 6 80 96 16 02.78 Without bimetal compensation with back adjustment accuracy ± 2 % - 1072x72/60 KB/f case: ABS, black - 1096x96/80 KB/f case: steel sheet, corrosion protected - window: plexiglass / glass options: - drag pointer - customized dial / coloured scale Type a b c d D e 1072x72/60 KB/f 20 35 8 60 72 16 1096x96/80 KB/f 20 35 6 80 96 16 CAPILLARIES P. 2 3 PROBES P. 2 4 - 2 5 POCKETS S. 26 - 13 - THERMOMETER I N S T E E L - C A S E F O R F R O N T PA N E L M O U N T I N G WITH 3-HOLE FRONT FLANGE 02.03 With bimetal compensation accuracy ± 2 % - case: - window: - front flange: steel sheet corrosion protected glass (type 1100 F made of MAKROLON) INOX polished or chromed options: - back adjustment - accuracy ±1 %, ±1,5 % - drag pointer - customized dial, coloured scale -plexiglass Type a b c d D l L 1052 F 25 9 0,5 52 80 4,2 74 1060 F 25 9 0,5 60 80 4,2 74 1080 F 22 12 0,5 80 105 4,2 96 1100 F 30 8 0,75 102 132 4,5 116 1160 F 45 3,5 3 160 192 5,8 178 02.38 Without bimetal compensation with back adjustment accuracy ± 2 % - case: - window: - front flange: steel sheet corrosion protected glass (type 1100 F/f made of MAKROLON) INOX polished or chromed options: - drag pointer - customized dial, coloured scale -plexiglass Type a b c d D l L 1052 F/f 24 3,5 3 55 80 4,2 74 1060 F/f 15 9 0,5 60 80 4,2 74 1080 F/f 13 12 0,5 80 105 4,2 96 1100 F/f 30 8 0,75 102 132 4,5 116 02.39 Without bimetal compensation with back adjustment accuracy ± 3 % - case: - window: - front flange: steel sheet corrosion protected glass (type 1100 F/fs made of MAKROLON) INOX polished or chromed options: - customized dial, coloured scale -plexiglass Type a b c d D l L 1052 F/fs 24 3,5 3 55 80 4,2 74 1060 F/fs 15 9 0,5 60 80 4,2 74 1080 F/fs 13 12 0,5 80 105 4,2 96 1100 F/fs 30 8 0,75 102 132 4,5 116 - 14 - THERMOMETER IN STEEL SHEET CASE F O R S U R FA C E M O U N T I N G W I T H B A C K F L A N G E 02.04 With bimetal compensation accuracy ± 2 % - case: - window: - front ring: steel sheet plastic coated, light grey glass (type 1100 HBR made of MAKROLON) chromed options: - back adjustment - accuracy ±1 %, ±1,5 % - drag pointer - customized dial, coloured scale -plexiglass - case in black Type a b c d D l L 1060 HBR 36 0,9 4 64 86 3,6 75 1080 HBR 38 0,9 4 84 110 3,6 95 1100 HBR 38 1,5 8 105 132 4,5 116 1160 HBR 47 6 – 160 196 5,8 178 02.48 Without bimetal compensation with back adjustment accuracy ± 2 % - case: - window: - front ring: steel sheet plastic coated, light grey glass (type 1100 HBR/f made of MAKROLON) chromed options: - drag pointer - customized dial, coloured scale -plexiglass - case in black Type a b c d D l L 1060 HBR/f 26 0,9 4 64 86 3,6 75 1080 HBR/f 26 0,9 4 84 110 3,6 95 1100 HBR/f 28 0,9 8 105 132 4,5 116 02.49 Without bimetal compensation with back adjustment accuracy ± 3 % - case: - window: - front ring: steel sheet plastic coated, light grey glass (type 1100 HBR/fs MAKROLON) chromed options: - customized dial, coloured scale -plexiglass - case in black Type a b c d D l L 1060 HBR/fs 26 0,9 4 64 86 3,6 75 1080 HBR/fs 26 0,9 4 84 110 3,6 95 1100 HBR/fs 28 0,9 8 105 132 4,5 116 - 15 - THERMOMETER IN STEEL-CASE FOR WALLMOUNTING WITH WALL HOLDER 02.06 With bimetal compensation accuracy ± 2 % - case: - window: - front ring: steel sheet plastic coated, light grey glass (type 1100 WK MAKROLON) chromed options: - back adjustment - accuracy ±1 %, ±1,5 % - drag pointer - customized dial, coloured scale -plexiglass - case in black Type a c d D L 1060 WK 30 4 60 64 60 1080 WK 30 4 80 84 60 1100 WK 30 4 100 105 60 D I A L C O N TA C T T H E R M O M E T E R Dial contact thermometer Thermometer Ø 100 mm (4“) and Ø 160 mm (6.3“) with limit signal switch made by Wiebrock with bimetal compensation accuracy ± 2% - Case: - types XX: INOX 13 = panel mounting with u-clamp 31 = panel mounting with 3-hole front flange 41 = wall mounting with back flange 61 = wall mounting with wall bracket Clear cover made of polycarbonate with PG cable fitting Photo: Wiebrock Mess- und Regeltechnik GmbH - switching: slow action contact nominal voltage: max. 250 V on / off curent: max. 0,7 A switching capacity: 10 W 18 VA magnet action-contact nominal voltage: max. 250 V on / off curent: max. 1,0 A switching capacity: 30 W 50 VA inductive contact nominal voltage: 8 V DC - types: single, break or make contact double common or double seperated as double break, double make or break/make Please send us your inquiry – we issue an offer especially for you! - 16 - THERMOMETER I N I N O X - C A S E F O R F R O N T PA N E L M O U N T I N G WITH U-CLAMP OR 3-HOLE FRONTFLANGE 02.13 U-clamp fixing With bimetal compensation Accuracy ± 2 % - case: - window: - front ring: INOX plexiglass INOX polished options: - back adjustment - accuracy ±1 %, ±1,5 % - drag pointer - customized dial, coloured scale -glass - glycerine filling Type a b c d D e 1063 KB/V 33 48 6 63 68 16 1080 KB/V 30 45 6 80 85 16 1100 KB/V 30 45 7 100 105 16 1160 KB/V 35 50 13 160 190 178 02.81 U-clamp fixing without bimetal compensation with back adjustment accuracy ± 2 % - case: - window: - front ring: INOX plexiglass INOX polished options: - customized dial, coloured scale - glycerine filling - front flange mounting Type a b c d D e 1060 KB/Vf 20 35 4 60 64 16 02.31 3-hole front flange with bimetal compensation accuracy ± 2 % - case: - window: - front ring: INOX plexiglass INOX polished options: - back adjustment - accuracy ±1 %, ±1,5 % - drag pointer - customized dial, coloured scale -glass - glycerine filling Type a b c d D d1 l L 1063 F/V 26 10,5 3 68 80 63 3,6 74 1080 F/V 28 6 0,75 85 105 80 4,2 96 1100 F/V 28 7 0,75 105 132 100 4,5 116 1160 F/V 35 13 – – 192 160 5,8 178 - 17 - THERMOMETER I N I N O X - C A S E F O R S U R FA C E M O U N T I N G WITH BACKFLANGE OR WALL HOLDER 02.41 With bimetal compensation accuracy ± 2 % - case: - window: - back flange: INOX plexiglass INOX options: - back adjustment - accuracy ±1 %, ±1,5 % - drag pointer - customized dial, coloured scale -glass - glycerine filling Type a b c d D l L 1063 HBR/V 45 0,8 6 68 85 3,6 75 1080 HBR/V 45 0,8 6 85 110 3,6 95 1100 HBR/V 47 0,8 7 105 132 4,5 116 1160 HBR/V 37 13 7 190 190 5,8 178 02.43 With bimetal compensation accuracy ± 2 % - case: - window: - back flange: INOX plexiglass INOX options: - back adjustment - accuracy ±1 %, ±1,5 % - drag pointer - customized dial, coloured scale -glass - glycerine filling Type a b c d d1 e D l L 1100 HBR/V 14 50 7 105 102 16 128 4,2 116 02.61 With bimetal compensation accuracy ± 2 % - case: - window: - front ring: INOX plexiglass INOX options: - back adjustment - accuracy ±1 %, ±1,5 % - drag pointer - customized dial, coloured scale -glass - glycerine filling Type a c d D L 1063 WK/V 40 6 63 68 60 1080 WK/V 40 6 80 85 60 1100 WK/V 42 7 100 105 60 - 18 - A U T O M O T I V E T H E R M O M E T E R S AND PRESSURE GAUGES WITH LIGHTING 02.18 U-clamp fixing without bimetal compensation with back adjustment accuracy ± 2 % - - - - - Type a b c d D e h 1052 KB/LF 30 50 4 52 56 16 20 1060 KB/LF 30 50 4 60 64 16 20 02.09 case: window: front ring: dial: lamp socket: steel sheet corrosion protected glass chromed background white or black for bulb 12 / 24 V DC U-clamp fixing without bimetal compensation with back adjustment accuracy ± 2 % - - - - - Type a b c d D e h 1052 KB/ex 30 50 4 52 56 16 20 1060 KB/ex 30 50 4 60 64 16 20 MANO case: window: front ring: dial: lamp socket: steel sheet corrosion protected glass chromed background white or black for bulb 12 / 24 V DC Pressure gauge with lighting and u-clamp fixing - - - - - - - Type a b c d D e h 1052 KB-Mano 30 50 4 52 56 16 20 1060 KB-Mano 30 50 4 60 64 16 20 case: window: front ring: range: connection: dial: lamp socket: steel sheet corrosion protected glass chromed 0...6 / 10 / 16 / 25 kg/cm², class. 1.6 back center, M 12x1.5, brass standard black with white prints for bulb 12 / 24 V DC - 19 - TELETHERMOSTATS F O R F R O N T PA N E L M O U N T I N G WITH U-CLAMP 04.11 With bimetal compensation accuracy ± 2 % - case: steel sheet corrosion protected - window: glass - front ring: chromed - circuit type: snap-action microswitch, 1 single pole change-over - max. load: 5 Amps 250 VAC (non inductive) - electrical connection: AMP plug, 6.3 mm - setpoint: setting frontside by knob Type a b c d e f D 3060.1 KB 65 85 4 60 16 11 64 3080.1 KB 65 85 5 80 16 11 84 3100.1 KB 65 85 8 100 16 12 105 04.12 options: - customized dial / coloured scale -plexiglass - front ring black or INOX - plug protection by backwards cap, ABS black - various possibilities for setpoint setting Without bimetal compensation accuracy ± 2 % - 3060.1 KB/K case: ABS, black - 3060.1 KB/M case: steel sheet corrosion protected - window: plexiglass or glass - front ring: chromed - circuit type: snap-action microswitch, 1 single pole change-over - max. load: 5 Amps 250 VAC (non inductive) - electrical connection: AMP plug, 6.3 mm - setpoint: setting frontside by knob Type a b c d e f D 3060.1 KB/K(D) 50 70 2(4) 60 16 13 63 3060.1 KB/M 50 70 4 60 16 13 63 options: - customized dial / coloured scale - front ring black or INOX - plug protection by backwards cap, ABS black - various possibilities for setpoint setting - 20 - TELETHERMOSTATS F O R F R O N T PA N E L M O U N T I N G WITH 3-HOLE FRONT FLANGE 04.31 With bimetal compensation accuracy ± 2 % - case: - window: - front flange: - circuit type: - max. load: - electrical connection: - setpoint: Type a b c d f D l L g 3060.1 F 60 9 0,5 60 13 80 4,2 74 75 3080.1 F 58 12 0,5 80 13 105 5,2 96 75 3100.1 F 60 7,5 0,8 102 13 132 4,5 116 75 04.32 steel sheet corrosion protected glass chromed / INOX polished snap-action microswitch, 1 single pole change-over 5 Amps 250 VAC (non inductive) AMP plug, 6.3 mm setting frontside by knob options: - customized dial / coloured scale -plexiglass - plug protection by backwards cap, ABS black - various possibilities for setpoint setting Without bimetal compensation accuracy ± 2 % - 3060.1 F/K case: ABS, black - 3060.1 F/M case: steel sheet, corrosion protected - window: plexiglass or glass - front flange: INOX polished - circuit type: snap-action microswitch, 1 single pole change-over - max. load: 5 Amps 250 VAC (non inductive) - electrical connection: AMP plug, 6.3 mm - setpoint: setting frontside by knob options: - customized dial / coloured scale - plug protection by backwards cap, ABS black - various possibilities for setpoint setting Type a b c d f D l L g 3060.1 F/K 55 9 0,5 60 13 80 4,2 74 70 3060.1 F/M 55 9 0,5 60 13 80 4,2 74 70 CERTIFICATE The Certification Body of TÜV SÜD Management Service GmbH certifies that LEITENBERGER Meß- und Regeltechnik GmbH Bahnhofstraße 32/33, 72138 Kirchentellinsfurt, Germany Scope of application: development, manufacturing and sales of pressure and temperature, measurement, calibration and regulation devices DRUCK & TEMPERATUR Leitenberger GmbH Bahnhofstraße 32/33, 72138 Kirchentellinsfurt, Germany Scope of application: development and sales of pressure and temperature, measurement, calibration and regulation devices AUTOTESTGERÄTE Leitenberger GmbH Bahnhofstraße 32/33, 72138 Kirchentellinsfurt, Germany THE QUALITY MANAGEMENT SYSTEM OF THE LEITENBERGER-GROUP I S C E R T I F I C AT E D A C C O R D I N G T O : Scope of application: development, manufacturing and sales of test equipment for cars has established and applies a Quality Management System. An audit was performed, Report No. 70005540 Proof has been furnished that the requirements according to ISO 9001:2008 are fulfilled. The certificate is valid from 2014-02-08 until 2017-02-07. Certificate Registration No. 12 100 24343 TMS Product Compliance Management Munich, 2014-02-06 ISO 9001 : 2008 REGISTRIER-NR. 12 100 24343 TMS - 21 - TELETHERMOSTATS SQUARE FRONT F O R F R O N T PA N E L M O U N T I N G W I T H U - C L A M P 04.71 With bimetal compensation accuracy ± 2 % - case: - window: - circuit type: - max. load: - electrical connection: - setpoint: steel sheet corrosion protected plexiglass / glass snap-action microswitch, 1 single pole change-over 5 Amps 250 VAC (non inductive) AMP plug, 6.3 mm setting frontside by knob options: - customized dial / coloured scale - plug protection by backwards cap, ABS black - various possibilities for setpoint setting Type a b c d e f D 3072x72.1 KB 65 85 8 60 16 13 72 3096x96.1 KB 65 85 6 80 16 13 96 04.72 Without bimetal compensation accuracy ± 2 % - 3072x72/60 KB/K case: ABS, black - 3072x72/60 KB/M case: steel sheet, corrosion protected - window: plexiglass - circuit type: snap-action microswitch, 1 single pole change-over - max. load: 5 Amps 250 VAC (non inductive) - electrical connection: AMP plug, 6.3 mm - setpoint: setting frontside by knob Type a b c d e f D 3072x72/60.1 K 50 70 8 60 16 13 72 3072x72/60.1 M 50 70 8 60 16 13 72 options: - customized dial / coloured scale - plug protection by backwards cap, ABS black - various possibilities for setpoint setting - 22 - MADE IN GERMANY Made in Germany We produce in Germany, in our own factories, enabling decisions to be made quickly and producing the desired results. To your advantage we can - react immediately make changes short term - - develop customer-specific - modify at customer‘s request High-quality craftmanship! Take advantage of the beneficial. CAPILLARIES Cu - naked Cu - naked - flexible copper capillary - non coated - diameter 1.0 mm - usable up for all ranges between -80 and +380° C Cu - PVC coated Cu - PVC coated - - - - Cu - single copper braided flexible copper capillary - PVC coated coat diameter 3.5 mm black or white usable up for ranges between -80 and +120° C Cu - single copper braided - flexible copper capillary - single copper braided - diameter 2.5 mm - usable up for all ranges between -80 and +380° C Cu - double copper braided Cu - double copper braided - flexible copper capillary double copper braided - diameter 3.5 mm - usable up for all ranges between -80 and +380° C stainless steel naked Stainless steel - naked - - - - flexible stainless steel AISI 316 Ti capillary - non coated diameter 1.0 mm usable up for all ranges between -80 and +380° C PROTECTION stainless steel - stainless steel protected Stainless steel - stainless steel protected - - - - - protection hose -PVC- heavy duty execution flexible INOX capillary stainless steel protection spiral diameter 3.5 mm usable up for all ranges Protection hose - PVC - heavy duty execution - flexible PVC hose 6 x 1 mm - usable up for all ranges protection hose -INOX jacket- Protection hose - INOX jacket - - - - heavy duty execution flexible INOX hose diameter 5.8 mm usable up for all ranges - 23 - - 24 Type 1 PROBES Type 1a, 1b, 1c - loose double male adaptor - standard thread sizes: 3/8 BSP or ½ BSP (sizes M 14 x 1,5, 3/4 BSP and 1 BSP are available on request) - combineable with pocket no. 9 - 4, 5, 6, 7.8, 8, 8.5, 10 or 12 mm, Cu or 8, 10 oder 12 mm INOX - typ 1b for gaseous medium - 14, 16 or 18 mm, Cu Type 2 Type 2a, b, c - no adaptor - upper part of probe fitted with 8, 10, or 12 mm ferrule - other diameters on request Type 3 Type 3a, b, c - plain - no adaptor - no ferrule - type 3c - diameters 6 or 8.5 mm - EL depending on range Type 4 Type 4a, b, c - adaptor with compression olive fitting („sliding nut“) - standard thread sizes 3/8 BSP or ½ BSP - to be combined with pocket no. 9 The client can determinate at a later date the fitting length within the range of the total probe length. The adaptor is screwed upon an annealed tube which can be bent behind the adaptor in conformity with the local requirements. - 25 - PROBES Type 5 Type 5a, b, c - union nut, standard ½ BSP Type 6 Type 6a, b, c - single adaptor - recommender for use with solids Types 1 - 6 (not 3c) also available in INOX! Type 7c Type 7c - - - - Type 7.1 knurled nut M 10x1, brass pressure spring diam. 8.5 mm (only in brass) to be fitted with pocket no. 8 Type 7.1 - clip spring - diam. 8.5 mm, brass - to be fitted with pocket no. 8 LEGEND Cu EL IG AG SW = copper = fitting length = internal thread = external thread = wrench size - 26 - POCKETS Nr. 8 Pocket no. 8 IG SW to be fitted with probe type no. 7c - EL: chooseable - AG: chooseable - IG: M 10 x 1 - SW: depends on AG - Ø: 10 mm EL AG Made of brass or stainless steel Ø Nr.9 Pocket no. 9 AG IG SW EL to be fitted with probe type no. 1 or 4 - EL: chooseable - AG: chooseable - IG: 3/8 BSP - SW: depending on AG - Ø: chooseable Made of brass or stainless steel Customized solutions Ø H I G H - Q U A L I T Y H A N D I C R A F T. MADE IN GERMANY - 27 - R O O M T H E R M O S TAT S WITH AND WITHOUT LCD RTC 01 Room thermostat with liquid filled capillary system order code: range -35...+35° C: range 0...40° C: RTC01_35035 RTC01_00040 - - - - - - - - - - ABS light grey, RAL 7035 IP 44 -35/+35° C or 0/+40° C deltaT = 3 ±1 K +60° C 1 SPDT-relais 16 A 250 V AC PG 9 2.000 mm, nickel plated 120 x 6 mm, nickel plated case: degree of protection: ranges: differential: max. probe temp.: circuit type: max. load: cable pass: capillary: probe: Also available with LCD, specifications see page 28 (LTM 1212). RTS 01 Room thermostat with lateral probe order code: range -35...+35° C: range 0...40° C: RTS01_35035 RTS01_00040 - - - - - - - ABS light grey, RAL 7035 IP 44 -35/+35° C or 0/+40° C deltaT = 3 ±1 K +60° C 1 SPDT-relais 16 A 250 case: degree of protection: ranges: differential: max. probe temp.: circuit type: max. load: Also available with LCD, specifications see page 28 (LTM 1212). TC 01 Thermostat with liquid filled capillary system Especialy designed for automatic temperature controll in refrigeration systems. order code: range -35...+35° C: range 0...40° C: TC01_35035 TC01_00040 - - - - - - - -35/+35° C or 0/+40° C deltaT = 3 ±1 K +60° C 1 SPDT-relais 16 A 250 V AC 2.000 mm, nickel plated 120 x 6 mm, nickel plated ranges: differential: max. probe temp.: circuit type: max. load: capillary: probe: - 28 - D I G I TA L M E A S U R E M E N T D I G I TA L T H E R M O M E T E R S LTM 1212 Battery powered LCD thermometer with integrated spring clips for frontpanelmounting - - - - - - - - - switchabel from ° C to °F display: 3 1/2 digits display size: 13 mm range: -40...+110° C resolution: 0,1° C accuracy: ± 1,5% measuring cycle: 10 sec. power supply: 2 knob cells cable: 3.000 mm, PVC, white options: - mounting adapter, black or white for panel cut-out 25 x 58 LTM 2558 Battery powered LCD thermometer with integrated spring clips for frontpanelmounting - - - - - - - - - - LTS 58 Solarpowered LCD Thermometer with integrated spring clips for frontpanelmounting - - - - - - - - AR 203 frontpanel cut-out 25 x 58 battery box frontside switchabel from ° C to °F display: 3 1/2 digits display size: 13 mm range: -40...+110° C resolution: 0,1° C accuracy: ± 1,5% measuring cycle: 10 sec. power supply: knob cell battery, type LR44 frontpanel cut-out 59,5 x 26 display: 3 1/2 digits display size: 13 mm range: -50...+80° C resolution: 0,1° C accuracy: ± 2° C measuring cycle: 10 sec. power supply: solar powered Digital second thermometer with sensor Applicable at ambient temperature from -20/+40° C, and therefore adapted for use in cooling rooms. - range: - display: - resolution: - accuracy: - power supply: - dimensions: - delivered in case -50...+650° C 3 1/2 digits, 13 mm 1° C ± 1 % of total range 50...+650° C 9 V battery, type IEC 6F22 120 x 60 x 40 mm (lxbxh) - 29 - D I G I TA L M E A S U R E M E N T D I G I TA L T H E R M O M E T E R S LTM 2015 20 Battery operated, for wall mounting 15 15 7,5 - case: - protection: - display: Ø =7 - range: - resolution: - accuracy: - measuring cycle: ABS light grey IP 52 h = 57 mm, 3 digits, 7-segments, red, -50...+110° C 0,1° C -20 ° C to 70° C ± 0,5° C 15 sec. options: - power supply: 12 VDC oder 230VAC 3,7 Recalibration in case of sensor change possible. LTM 1100 LED thermometer for panel mounting with back flange - display: - range: - resolution: - connection: - power supply: h = 20 mm, 4 digits, 7-segments, red -50...+110° C (others on request) 0,5° C (0,2° or 0,1° on request) 9 pc. (screw terminals) 12 VDC or 240 VAC With sensor detection. Type a b c d d1 e D l L LTM 1100 HBR/V 14 50 7 105 102 16 128 4,2 116 options: - adjusting max/min - optical allert - adjustable display resolution - red or green digits - further mounting options (u-clamp, front flange) D I G I TA L P R E S S U R E G A U G E DM 100_LR Digital pressure measurement Exchange of analogue pressure gauges. Different connections available. - different measurement ranges - higher measurement accuracy - easy to read out - different connections -LCD - mit protective rubber cup Specification DM 100_LR: - range: 0...600 bar relativ - accuracy: 0,5 % FS - operating temperature: -25...+75° C / RH 60 % - 30 - PRESSURE GAUGES Pressure gauge Gauge pressure is the pressure relative to the local atmospheric or ambient pressure. Pressure is measured in any unit of force divided by any unit of area. The gauges are are available in different ranges, in different measuring parameters and various types of materials. Ranges are shown in bar and PSI and all different kind of common refrigerants. Combinations of the refrigerants can be made up to the customers choice. Different kind of connections can be choosen as well as different kind of fixations. Features: - diameter of the gauge - material of the housing - material of the interior - material/Thread of the connection - mounting options -accuracy Customer option: - your logo - combination of refrigerants PRESSURE GAUGES - 31 - G E N E R A L I N F O R M AT I O N S High- and Low-pressure gauges Types: - - - - - - - - - 2 pressure scales bar + psi 4 coloured scale for refrigerants accuracy: class. 1.6 connection: brass, bottom or back socket: 1/4 SAE or 1/8 NPT Options: type R: bottom connection type H: bottom connection with back flange type P: back connection type F: back connection with front flange - all actual refrigerant scales - other socket threads on request - pressure scale in MPa MB / MR High- and Low-pressure gauges dry, pulsfree - case: steel sheet pvc coated - range: low -1/+18 bar blue high -1/+38 bar red - connection: brass, bottom or back - socket: 1/4 SAE or 1/8 NPT - zero adjustment frontside options: - - all actual refrigerant scales - - other socket threads on request Type NG A C D MB618/MR638 63 28 6 68,3 MB818/MR838 80 29 6,3 86 F G 1/4 SAE 1/8 NPT 10 - 10 H K SW 91 9 14 105 9 14 MK High- and Low-pressure gauges dry, pulsfree ABS, black - case: - pressure: low -1/+18 bar blue high -1/+38 bar red - connection: brass, bottom or back - socket: 1/4 SAE or 1/8 NPT - zero adjustment frontside options: - all actual refrigerant scales - other socket threads on request Type MK8H NG 80 A B 20 8 C d D E G H L SW 3,5 80 86 1-3 1/4 SAE 1/8 NPT 16 13 - 10 14 MX High- and Low-pressure gauges dry, pulsfree - case: steel sheet pvc coated - range: low -1/+18 bar blue high -1/+38 bar red - connection: brass, bottom or back - socket: 1/4 SAE or 1/8 NPT - zero adjustment frontside options: - all actual refrigerant scales - other socket threads on request Type NG A C D F G H I L M O SW MG6F 63 29 7,3 68,3 13 1/4 SAE 60 4,5 75 84,5 64 14 - 32 - PRESSURE GAUGES G LY C E R I N E F I L L E D MG6F / MG8F High- and Low-pressure gauges - front flange INOX case - glycerine filled - case: - range: - connection: - socket: INOX low -1/+18 bar high -1/+38 bar brass, bottom or back 1/4 SAE or 1/8 NPT, brass options: - all actual refrigerant scales - other socket threads on request - zero adjustment frontside Type NG A C D F G H I L M O SW MG6F 63 29 7,3 68,3 13 60 4,5 75 84,5 64 14 MG8F 80 29 7,5 86 10 1/4 SAE 1/8 NPT 60 5 96 110 82 14 MG6H / MG8H High- and Low-pressure gauges - back flange INOX case - glycerine filled - case: - range: - connection: - socket: INOX low -1/+18 bar high -1/+38 bar brass, bottom or back 1/4 SAE or 1/8 NPT, brass types: - type R: bottom connection - type H: bottom connection with back flange - type P: back connection - type F: back connection with front flange Type NG A C D MG6H 63 32 6 68,3 MG8H 80 34,5 6,3 86 F G 13 - 10 1/4 SAE 1/8 NPT H I L M O SW 90 14 4,5 75 83,5 14 107 15 5 96 110 14 MG6U / MG8U Bottom connection options: - all actual refrigerant scales - other socket threads on request - zero adjustment frontside High- and Low-pressure gauges INOX case - glycerine filled Back connection for panel mounting - case: - range: - connection: - socket: INOX low -1/+18 bar high -1/+38 bar brass, bottom or back 1/4 SAE or 1/8 NPT, brass options: - all actual refrigerant scales - other socket threads on request - zero adjustment frontside Type NG A C D MG6U 63 MG8U 80 28 6 68,3 29 6,3 86 F G H K SW 10 - 10 1/4 SAE 1/8 NPT 91 9 14 105 9 14 - 33 - PRESSURE GAUGES NH3 PRESSURE GAUGE GENERAL INFORMATIONS 4“ NH3 - Pressure Gauge all stainless steel construction - socket: - elastic element: - accuracy: -ranges: bar -1/+ 9 bar -1/+15 bar -1/+24 bar AISI 316L AISI 316L class 1.0 options: - glycerine filled - other connectors NH3 -70/+25° C -70/+40° C -70/+56° C types: - type R: bottom connection - type H: bottom connection with back flange - type F: back connection with u-clamp M10HNH3 Type H with back flange bottom connection, G 1/2“ Type M10HNH3 F A C D d H K M I Ch 1/2“ 61 12,5 100 110,5 52 30 134 118 22 M10NH3H Type P back connection, G 1/2“ Type M10HNH3H F A C D d H K M I Ch 1/2“ 61 12,5 100 110,5 52 30 134 118 22 M10NH3U Type R bottom connection, G 1/2“ Type M10NH3U F A C D d H T K Ch 1/2“ 48 12,5 100 110,5 143,3 38 16 22 - 34 PMK 02 MANIFOLD PM 02 case - set of 3 pressure hoses red / blue / yellow - high and low pressure quick coupler for R 134a - case with inset PM 02 hoses 2-valve-manifold - PM02_63: - PM02_63GK: - PM02_80: pressure gauges, diam. 63 mm pressure gauges, diam. 63 mm with blue / red rubber protective cap pressure gauges, diam. 80 mm options - diam. 63: - diam. 63/80: with blue / red rubber protective cap with inox housing with glycerine filling scales - R502, R22, R12 -3-colored -bar -Kpa connections - pressure: - vacuum: 1/4 SAE (7/16“ - 20UNF) 3/8 SAE (5/8“ - 18UNF) accessories - hose set: 3 hoses, 3 ft, red, blue, yellow - quick coupler set: high and low pressure for 134a, 7/16“-20UNF (1/4 SAE), straight - case with inlets PM 02 hoses - set of 3 pressure hoses: red / blue / yellow connections - high and low pressure quick coupler set for R 134a, conn. 7/16“-20UNF (1/4 SAE), straight PM 02_80 PM02_80 manifold, diam. 80 mm (3,15“) PM 02 - 2-valve manifold - high and low pressure gauges diam. 63 mm (2,5“), 80 mm (3,15“) -adjustable - with calibration screw -pulsfree - pressure range in bar + Psi - temperature range in ° C - coloured scales for refrigerants PM 02_60 GK PM02_63GK manifold, diam. 63 mm (2,5“) with rubber protective cap connections - pressure: - vacuum: 1/4 SAE (7/16“ - 20UNF) 3/8 SAE (5/8“ - 18UNF) options - diam. 63: - diam. 63/80: with blue / red rubber protective cap with inox housing with glycerine filling scales - R502, R22, R12 -3-colored -bar -Kpa accessories - hose set: 3 hoses, 3 ft, red, blue, yellow - quick coupler set: high and low pressure for 134a, 7/16“-20UNF (1/4 SAE), straight - case with inlets - 35 - S M A R T P R E S S U R E G AT E SPG SmartPressureGate 1. Specifications: Supply Voltage: Consumption Current: Display: Output contact rating: Operating temperature: 85...264 VAC @ 47...63 Hz, 110...370 VDC 200mA 3 Digit LED for LP, 3 Digit LED for HP 5A @ 250VAC -25°...+75° C RH 60 % 2. Pressure Ranges: Low pressure (LP) relative High pressure (HP) relative Pressure Range -1...+19 bar / -14...+275 psi 0...50 bar / 0...+725 psi Accurancy ±0,5 % Fullscale ±0,1 bar / ±1,5 psi Overload warning THE S MA RT S O L U T I O N FOR S MA RT P E O P L E . SmartPressureGate All in one product Exchange of common solution with pressure gauge and mechanical pressure switches. - 1 pc high pressure gauge - 1 pc low pressure gauge - 1 dual pressure controller - 2 pressure controller Get more for less More function for less - less installation time - less material - less leakage - less space on the frame - 2 mechanical connections instead of six - 1 central electrical connection - 1 fixing point Make hard work to easy play - less setting expenses - easy to program - less setting time - exact setting point - no readjustment Punctual like Germans - accuracy up to ±0.5 % Fullscale - made in Germany Full control Communication connection via RS485 with modbus RTU protocol. It is possible to monitor, manage alarms and outputs and log all data. Simple exchange of mechanical components by same mounting points and connections. MA DE IN GE R M A N Y 19,2 bar / 278 psi Overload ±0,5 bar / ±7,3 psi 0,1 % overload (OFL is blinking and acoustic warning) 50,5 bar / 732 psi 0,3% overload (OFL in display and acoustic warning) 19,6 bar / 284 psi 51,5 bar / 746 psi Physical Overload 40 bar / 580 psi 100 bar / 1450 psi Burst pressure 70 bar / 1015 psi 150 bar / 2175 psi - 36 - CAPSULE PRESSSURE GAUGE B AY O N E T T Y P E KFM_Bajo Capsule Pressure Gauges EN 837-3 wetted parts in copper alloy Service intended: Suitable for all gaseous media that will not obstruct the pressure system. - protection: IP 45 - connection: DS 63: 1/4 BSP M, brass (SW 14) DS 100: ½ BSP M, brass (SW 22) - other threads: (e.g. NPT) on request - window: glass - zero point adjustment: adjusting screw in dial - accuracy: class 1.6 (±1.6 % FS) - ranges: according to Norm DS 63: 0/25 mbar to 0/1000 mbar, DS 100, 160: 0/16 mbar to 0/1000 mbar - pressure, vacuum and compound Panel cut-out (mm) DS Type F* options: - special dial (logo, special graduation etc.) - laminated safety glass window (DS 100 only) - case with BLOW OUT (DS 100 only) - accuracy class 1.0 (DS 100) Type KB* 63 65 64 100 105 103 Dimensions (mm) DS b b1 b2 c D d1 d2 d3 d4 G h 63 39 45 53 11 64 75 85 3,5 67 G 1/4 B 61 SW 14 100 49 55 87 15 101 116 132 4,8 107 G 1/2 B 78 22 Mounting styles Type R* bottom connection Type KB* centric back connection with u-clamp for panel-mounting Type P* centric back connection Type H* bottom connection with back flange for wall mounting Type F* centric back connection with front flange for panel mounting *Verisons: - Type R: Bottom connection - Type H: Bottom connection with back flange - Type P: Centric back connection - Type F: Centric back connection with front flange - Type KB: Centric back connection, with u-clamp CAPSULE PRESSSURE GAUGE - 37 - ABS-CASE WITH SPRING CLIPS KFM_Klips_K Capsule Pressure Gauges EN 837-3 - ABS plastic case wetted parts in copper alloy Service intended: Suitable for all gaseous media that will not obstruct the pressure system. - protection: IP 45 - connection: DS 50: 1/8“ BSP M, brass (SW 14,17) DS 100: ½ BSP M, brass (SW 22) - other threads: (e.g. NPT) on request - window: plexiglass - zero point adjustment: adjusting screw in dial - accuracy: class 1.6 (±1.6 % FS) - ranges: according to Norm DS 50 and DS 63: 0/25 mbar to 0/1000 mbar, DS 100: 0/16 mbar to 0/1000 mbar - pressure, vacuum and compound options: - special dial (logo, special graduation etc.) Dimensions (mm) DS b b1 b2 c d D e G h SW 50 36 - 61 6 49 57,5 13 1/8 50 17 63 40 3,5 63 13 61,5 68 13 1/4 55 17 100 42 - 75 13 99 104 13 1/2 82 22 Mounting styles Type R* bottom connection Type P* centric back connection Type KB* centric back connection with u-clamp for panel-mounting LEGEND front view DS SW = dial size = wrench flats - 38 - CAPSULE PRESSSURE GAUGE S N A P - I N W I N D O W, S TA I N L E S S S T E E L KFM_Klips Capsule Pressure Gauges EN 837-3 - Snap-in window, wetted parts in copper alloy Service intended: Suitable for all gaseous media that will not obstruct the pressure system. - protection: IP 45 - connection: DS 63: 1/4 BSP M, brass (SW 14) DS 100 : ½ BSP M, brass (SW 22) - other threads: (e.g. NPT) on request - window: plexiglass - zero point adjustment: adjusting screw in dial - accuracy: class 1.6 (±1.6 % FS) - ranges: according to Norm DS 63: 0/25 mbar to 0/1000 mbar, DS 100: 0/16 mbar to 0/1000 mbar - pressure, vacuum and compound Panel cut-out (mm) DS Type F* 63 65 options: - special dial (logo, special graduation etc.) Dimensions (mm) DS a a1 b b1 b2 Øc c1 d1 d2 d3 63 9,5 12 33,7 36,2 35,7 5 2 75 85 3,5 100 DS 15,6 d6 19,1 G 44 g 47,5 g1 45,6 h 6 s 3 s1 116 s2 132 s3 4,8 SW 63 64 G1/4B 56,7 58,7 52,7 3,7 5,5 3 2 14 100 101 G1/2B 76 77,6 87 3,5 5,5 3,5 2 22 Mounting styles Type R* bottom connection Type H* bottom connection with back flange for wall mounting Type P* centric back connection Type F* centric back connection with front flange for panel mounting *Verisons: - Type R: Bottom connection - Type H: Bottom connection with back flange - Type P: Centric back connection - Type F: Centric back connection with front flange - Type KB: Centric back connection, with u-clamp - 39 - CAPSULE PRESSSURE GAUGE A L L S TA I N L E S S S T E E L C O N S T R U C T I O N KFM_VA Capsule Pressure Gauges EN 837-3 - Snap-in window, wetted parts in copper alloy Service intended: Suitable for all gaseous media that will not obstruct the pressure system e.g. for chemical industry. - protection: IP 45 - connection: DS 63: 1/4 BSP M INOX (SW 14) DS 100: ½ BSP M INOX (SW 22) - other threads: (e.g. NPT) on request - window: glass - zero point adjustment: adjusting screw in dial - accuracy: aclass 1.6 (±1.6 % FS) - ranges: according to Norm 0/25 mbar to 0/1000 mbar - pressure, vacuum and compound options: - special dial (logo, special graduation etc.) - laminated safety glass window (DS 100) - case with BLOW OUT (DS 100) - accuracy class 1.0 (DS 100) Panel cut-out (mm) DS Type F* Type KB* 63 65 not available 100 105 103 Dimensions (mm) DS b b1 b2 c D d1 d2 d3 G h SW 63 39 45 53 11 64 75 85 3,5 G 1/4 B 61 14 100 49 55 87 15 101 116 132 4,8 G 1/2 B 78 22 Mounting styles Type R* bottom connection Type P* centric back connection Type KB* centric back connection with u-clamp for panel-mounting Type H* bottom connection with back flange for wall mounting Type F* centric back connection with front flange for panel mounting - 40 - HAND PUMPS Hand pumps Hand pumps for sucking, transfilling or dosing of liquids like Diesel, oil, or water. Our series HAP with the double adaptor at the transfilling pump cylinder enables the user to transfill liquids in one go. By pulling the pump handle the liquid will be sucked into the pump cylinder and by pushing the pump handle the liquid will be pressed out off the pump cylinder. A footplate at the types 600 F and 3000 F makes pumping easier by using both hands. Our series HAP-02 with just one adaptor makes this types usable for sucking or filling. Our series HDP is made of clear PLEXIGLAS with a ml- scale on the body, especially designed for measuring the sucked liquid or exact dosing of liquid for filling. Caution Not suitable for petrol, fuel, brake fluid, acids or alkaline solutions. Pump versions for corrosive liquids on request. Design in stainless steel and with resistant seals. HAND PUMPS F O R S O L A R I N S TA L L AT I O N S HAP 21_SOL Solar plant hand filling pump, HAP 21_SOL (double action) Filling pump made of aluminium with connections to the solar plant, for refilling of the heat transfer medium and for pressure adjustment in the heating system. Connet the double action pump (with thread and hose) with the cooling system of the solar plant. The heat transfer medium can be transferred directly out of the original tank. - height adjustment: - pressure: - body: - length: - lifting height: - hose length: - connection thread: with different cone plugs up to about 30 bar Ø 25 mm 400 mm 270 mm 600 mm G 3/4“ Easy to operate even at high backpressure. HAP 02_SOL Solar plant hand filling pump, HAP 02_SOL Filling pump made of aluminium with G 3/4 BSP thread. For refilling of the heat transfer medium in the heating system, with connection direct to the solar plant. The heat transfer medium can be transferred directly out of the original tank into the solar plant. - pressure: - body: - length: - lifting height: - hose length: - connection thread: up to about 6 bar Ø 34 mm 220 mm approx. 80 mm 500 mm G 3/4“ Easy to operate, quickly to connect. - 41 - - 42 - HAND PUMPS TRANSFILLING PUMP HAP 21 HAP-21 CMK Transfilling pump Barrel pump manually, for oil, brake fluid and other non flammable and non aggressive fluids. Example of use „Service a/c compressor“: The compressor oil is pumped out from the canister into the crankcase, without letting air or humidity into the circuit of the refrigerator. An evacuation of the refrigeration compressor is not necessary. HAP 21 C MK Master Kit HAP 21 C Example Robust PVC case, black with: - HAP 21 C - HAP21C_Konus50/35 - HAP21C_Schl-Konus - HAP21C_Schl-SAE - HAP21C_Schl-PVC - weight: - dimensions: HAP 21 C pump rubber cone 50/35 3 rubber cones for tube 30/15; 40/20; 50/35 tube 900 mm, with 1/4 SAE connection (yellow, blue or red) tube, PVC clear, 7x1.5; 1.000 mm with 1/4 BSP approx. 1kg 400 x 300 x 70 mm Transfilling pump in aluminium design for oil, brake fluid and other non flammable and non aggressive fluids - made of aluminium - height adjustable - pump connection: - barrel connection: - sucking connection: HAP 21_LR 1/4 SAE (to fit hose HAP21C_Schl-SAE) rubber conus 41/24 1/4 BSP (to fit hose HAP21C_Schl-PVC ) - - - - reachable pressure: weight: dimensions: hub: 30 bar 500 g net (without accessories) Ø 25 mm, length 400 - 700 mm approx. 270 mm Transfilling pump in aluminium design for oil, brake fluid and other non flammable and non aggressive fluids - - - - HAP 125_1 barrel extraction pump height adjustable made of aluminium with union nut for canister fitting - connection: - dimensions: - hub: 1/4 SAE, brass Ø 25 mm, length 400 - 700 mm approx. 270 mm connection: - pressure side: - sucking side: - pump dimensions: - hub: 1/4 SAE, brass G 1/4 BSP (different adaptors available, see accessories) Ø 25 mm, length 400 - 700 mm approx. 270 mm Transfilling pump in aluminium design with double connection - - - - - hand operated transfilling pump height adjustable made of aluminium with double connector volume approx. 400 ml / stroke - 43 - HAND PUMPS BARREL EXTRACTION PUMP HAP 20 Barrel extraction pump - made of aluminium - with integrated filter - height adjustable For the extraction process, insert the vacuum pipe into the opening of the container (canister, drum) until it reaches the bottom. The pump is supplied with a vertically adjustable foot, permitting use with containers of a variety of sizes. The manually operated pump, with an integrated filter in the suction pipe, can be used with openings of 45 mm in diameter and upwards. Supplied with a transparent pressure hose. - hose diameter: - hose length: HAP 21_B 20 mm, with screw coupling. 1.40 m Manuell barre lpump made of aluminium inclusive 10 l barrel with scale and handle - height adjustable - pump conn.: - barrel conn.: - sucking conn.: - reachable pressure: - hub: - barrel volume: 1/4 SAE (to fit hose HAP21C_Schl-SAE) screw cap with clamping sleeve PVC hose 120 mm 30 bar approx. 300 mm 10 l ACCESSORIES HAP 21 C_Konus 50/35 Pump rubber conus for HAP 21C to fit into barrels with outlet Ø 35...50 mm - material: - dimensions.: rubber, black 50 / 35 mm order code: P-HAP21C_Konus50/35 HAP 21 C_Schl-Konus HAP 21 C_Schl-SAE HAP 21 C_Schl-PVC Flexible tube to be fit to HAP 21C outlet - material suitable for refrigerants and a/c oils - colours: yellow, red or blue - length: 900 mm - connectors: 2 x 1/4 SAE PVC tube to fit on HAP 21C inlet - material: - length: - adapter: - seal: order code: P-HAP21C_Schl-SAE order code: P-HAP21C_Schl-PVC HAP 21 C_Schl-Konus set of 3 tube rubber cones for HAP 21C to fit tube HAP21C_Schl-PVC into different barrel outlets - material: rubber, black - dimensions.: 30/15, 40/20 and 50 / 35 mm - Inner Ø: 9,5 mm for tube 7x1.5 order code: P-HAP21C_Schl-Konus PVC, clear, 7x1.5 1.000 mm 1/4 BSP, brass O-ring 5 x 3, Perbunan included - 44 - HAND PUMPS TRANSFILLING PUMP HAP 125. 250, 600 Transfilling pump with double connector - - - hand operated transfilling pump with double connector 2 hoses each 500 mm sucking side with female nut G 3/8“ BSP and adaptor for hoses with inner diameter 10/15 mm HAP 600_F Type order code ml HAP 125 P-HAP125_S 125 HAP 250 P-HAP250_S 250 HAP 600 P-HAP600_S 600 Transfilling pump with double connector and baseplate - hand operated transfilling pump with double connector -baseplate - volume approx. 600 ml / stroke - 2 hoses each 500 mm - sucking side with female nut G 3/8“ BSP and adaptor for hoses with inner diameter 10/15 mm order code: -P-HAP600_F HAP 3000_F Transfilling pump with double connector and baseplate - hand operated transfilling pump with double connector -baseplate - volume approx. 3000 ml / stroke - 2 hoses each 500 mm - sucking side with female nut G 3/8“ BSP and adaptor for hoses with inner diameter 10/15 mm order code: -P-HAP3000_F - 45 - HAND PUMPS SUCKING PUMP HAP 02 Hand operated sucking pump - - - - - made of aluminium and ABS deliverable in 4 sizes volumes 125, 250, 600 or 1.000 ml clear PVC hose, 1 m delivered in box Type order code ml HAP 02-125 P-HAP02-125 125 HAP 02-250 P-HAP02-250 250 HAP 02-600 P-HAP02-600 600 HAP 02-1000 P-HAP02-1000 1000 DOSING PUMP HDP 500 / HDP 125 U Hand operated dosing pump with plexiglass body - - - - - scale on body in ml made of plexiglass and aluminium deliverable in 3 sizes volumes 125, 500 or 1.000 ml clear PVC hose Type order code ml HDP 125 P-HDP-125 125 HDP 500 P-HDP-500 250 HDP 1000 P-HDP-1000 600 Hand operated dosing pump, universal Independent of the fluid, - can be used for brake fluid four different versions available:i Type order code ml HDP 125_U 060445_1 125 HDP 250_U 060446_1 250 HDP 500_U 060447_1 500 HDP 1000_U 060448_1 1000 HAPA / Adapter Nr. order code 1 2 3 4 5 7 6 8 9 Types l Ø 1 HAPA_G 600/10 adapter straight 600 10 2 HAPA_G 200/10 adapter straight 200 10 3 HAPA_G 090/10 adapter straight 90 10 4 HAPA_G 130/06 adapter straight 130 6 5 HAPA_W 250/10 angle adapter 30° 250 10 6 HAPA_W 200/10 angle adapter 30° 200 10 7 HAPA_W 130/10 angle adapter 30° 130 10 8 HAPA_SW 135/8 angle adapter short 135° + hose connection --- 8 9 HAPA_SD 180/8 bow adapter 180° + hose connection --- 8 Adapter for HAP 02 und HDP These adapters will enable you to do your job even in tight or hidden places easily. While using the adapter the tube connection of the hand pump will be replaced by the required HAP-adapter (HAPA). Connection 1/4“. Adapter no. 8 and no. 9 are with tube connector and can be used together with the delivered tube. - 46 - REFRACTOMETER Refractometer to determining the density of liquids. Accurate and safe check on fluids‘ condition. Different scales for easy reading off the result: - anti-freeze protection of radiator coolant - anti-freeze protection of windshield washer fluid - density of battery acid - Oechsle (°Oe) - Brix (°Bx) - further scales on request Case - ABS-body in different colors - body made of aluminium - in corporate color Printing on clap - in different colors - with your company logo Inclusive pipett to apply the fluids. - 47 - REFRACTOMETER FT 2030_AL Refractometer - - - - - - Radiator antifreeze windshield washer battery acid optical indication via light / dark separation line adjustable ocular for setting up the personal visual acuity delivered in case with sampling pipette options: - various color combination on request - customized prism flap RFM Oechsle Refractometer with °Oechsle scale (The density is expressed by the alcoholic strength in degrees Oechsle) - optical indication via light / dark separation line - adjustable ocular for setting up the personal visual acuity - delivered in case with sampling pipette options: - various color combination on request - customized prism flap RFM 01 Refractometer with BRIX scale To determine the exact ratio of the water feed to the quantity of sugar. - optical indication via light / dark separation line - adjustable ocular for setting up the personal visual acuity - delivered in case with sampling pipette options: - various color combination on request - customized prism flap - 48 - G E N E R A L I N F O R M AT I O N S H O W YO U C AN REAC H U S ON TH E P HONE , AT O U R W E B S I T E O R AT TRAD E FAIRS. Your direct contact Our location -Address: LEITENBERGER Mess- und Regeltechnik GmbH Bahnhofstraße 32/33 72138 Kirchentellinsfurt Deutschland -Fon: +49 (0) 7121 / 908-0 -Fax: +49 (0) 7121 / 908-200 -Email: mrt-info@leitenberger.de -Management: Achim Leitenberger und Gernot Coulon -Distribution: Worldwide Christine Hipp Fon: +49 (0) 7121 / 908 205 Email: c.hipp@lr-germany.de Germany, Austria, Switzerland, Belgium, Netherlands, Luxembourg Athanasios Trigkidis Fon: +49 (0) 7121 / 908 207 Email: a.trigkidis@lr-germany.de UK, Scandinavia, Greece, Australia Christoph Zimmermann Fon: +49 (0) 7121 / 908 206 Email: c.zimmermann@lr-germany.de - Order processing: Beate Mack Fon: +49 (0) 7121 / 908 105 Email: b.mack@lr-germany.de Silvia Barth Fon: +49 (0) 7121 / 908 104 Email: s.barth@lr-germany.de -Shipping: Beate Mack - Invoice processing : Fon: +49 (0) 7121 / 908 105 -Export: Email: b.mack@lr-germany.de Wü rzb urg APPROACH: Kar lsru he Stuttgart A 81 B 27 VISIT US AND LEARN MORE ABOUT O U R P R O D U C T R A N G E D I R E C T LY, L I V E O N A FA I R T R A D E , F O R E X A M P L E AT T H E C H I LV E N TA I N N Ü R N B E R G . A8 Mü Sin g en nch Tübingen en Kirchentellinsfurt Reutlingen PLEASE VISIT OUR WEBSITE TO THE FOLLOWING TOPICS: W W W. L R - P U M P E N . D E W W W. L R - T H E R M O M E T E R . D E AUTOTESTGERÄTE LEITENBERGER GMBH - 49 - AUTOTESTGERÄTE LEITENBERGER GMBH WORKSHOP EQUIPMENT PRO We produce the majority of our devices and almost all components ourselves. With a production scope which keeps surprising our customers of many years. Therefore we are independent from suppliers with this production scope. We develop and design our products and program the software for our instruments ourselves. From prototyp to serial production. Devices for our coustomers specific application. Our departments are specialized for: - 3D-print models - Software programming - Circuit board configuration - CNC processing - Manufacture by customer request - Screen printing - Laser printing - Serial production and more Content Our service: -Development -Training -Production - Spare parts service and repairs -Sales - Product care - Quality management - Technical advise for customers and dealers - ISO calibration service and dealers - Prototype construction PRODUCT RANGE • Cooling System •8 - 16 Transmission Cooling system testing equipment, cooling system tester case custom made, diagnostic, vacuum cooling system filler, accessory for vacuum cooling system fillers, adapters for testing cooling systems, CO2-leak detector, refractometer for different liquids, thermometer for cooling water • Engines Cylinder leakage testers for petrol and diesel engines, dead point gauge (TDC), compression testers, oil pressure testing equipment, topping up engine oil, digital thermometer, belt tension gauges, timing lights for petrol and diesel engines, accessories for timing lights, carburetor tester, revolution counter • Pumps Vacuum and pressure pumps, hand operated transfer pumps, hand metering pumps, hand suction pumps, accessories for manual vacuum extraction and metering pumps, barrel suction pumps, oil suction program • Fuel Injection System Common Rail high pressure tester, static and dynamic high pressure pump test, injector function test, return flow volume measurement, fuel identification, injection tester, diesel bleeding, fuel suction device, fuel consumption meter, accessory for diesel injection control units, fuel pressure and leakage tester, system pressure test on low pressure side, fuel supply pump tester, test benches for automatic testing, mini test bench • Brake System Brake fluid tester, refractometer, brake pressure testers for transport vehicles, brake pressure testers, digital brake pressure testers, vacuum brake bleeders, accessory vacuum brake bleeder, brake bleeder service unit, brake bleeder adapter kits 66 - 68 Service station for automatic transmission oil, pressure and vacuum pump for the suction, the refilling and the scavenge of gearbox-oil, gear oil filling pump, diagnose, oil pressure tester 18 - 28 • Electrical/ Charging System 69 - 82 Electric multifunction circuit testers, tester for battery and charging system, electronic protection, short circuit detector, code maintainer, multitester, glow plug testers, trailer lighting tester, illumination testers - tractor testers, accessory for Illumination testers 30 - 36 • Safety 84 - 87 Aero wipers testing and adjusting tools, electronic force measurement, tire pressure - checking and filling 38 - 56 • Exhaust System 88 - 91 Service equipment for SCR systems, test tools for charge air systems, filler units, suction pumps, pressure and tightness tester, leakage tester, test devices for exhaust systems, leakage test fresh air intake 58 - 65 • Miscellaneous 92 - 95 Vehicle body, service equipment for air conditioning systems, testing of pressure switches, barrel suction pump, protection covers, hydraulic, battery case tightness tester, spezial tools Index at the last two pages. Explanation: MB measuring range, GSK protective rubber cap, AG male thread, IG female thread, NG dial size Note: Delivery without batterie! All technical modification reserved without prior notice. ENGINEERED AND MADE IN GERMANY WWW.AUTOTESTGERAETE.DE - 50 - D R U C K & T E M P E R AT U R L E I T E N B E R G E R G M B H - 51 - C O N TA C T PRODUCT CATALOGUE NO. 03 LEITENBERGER Mess- und Regeltechnik GmbH Bahnhofstraße 32 / 33 72138 Kirchentellinsfurt Germany www.leitenberger.de +49 (0)7121/908-0 +49 (0)7121/908-200 mrt-info@leitenberger.de W W W. L E I T E N B E R G E R . D E Art.-Nr.: Katalog03_eng ISO 9001 : 2008 Registrier-Nr. 12 100 24343 TMS