Thermometer and method of determining temperature in a vacuum

advertisement

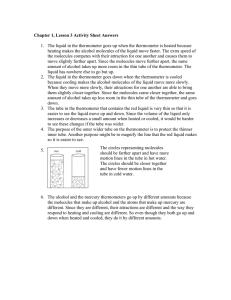

Feb- 12, 1952 R. |_. BRUNSING THERMOMETER AND METHOD OF DETERMINING TEMPERATURE IN A VACUUM COOLING CHAMBER FOR COOLING VEGETABLES 2,585,086 Filed'Feb. 14, 1950 INVENTOR. /Pz'x z. z/Pu/xsf/mv 4170190276‘ Patented Feb. 12, 1952 2,585,086 UNITED STATES PATENT. ‘OFFICE .~ THERMOMETER ‘AND METHOD ‘OFKDETERF, MINING TEMPERATURE ‘IN A VACUUM COOLING CHAMBER FOR COOLING VEGE TABLES Rex L.. Brunsing, San Francisco, Calif, assignor toVacuumv Cooling Company, San Francisco, Calif., a corporation of Nevada Application February 14, 1950, Serial No. 144,186 9 Claims. (01. '62—1'52) 1 2 Fig. 2 is: a'sidet-elevatlonalview of the tem This invention relates tora “thermometer or temperature control means for indicating the v"temperature within-a body ‘of vegetables in a "vacuum cooling chamber. perature control unit or‘. bulb. Fig.~ 3 is a sectional view‘ taken along line 3 ' of Fig. 2. Certain types of ‘vegetables; such, for example, ' > ' In detail, the vacuum tube is indicated ‘at.’ I, . and may be provided with gates 2, 3 at its oppo as .lettuce, cabbage, etc., when .preecooled by site ends for loading produce, such as. lettuce, placing them in a vacuum chamber and evapo .into the tube at one end and for withdrawal of - rating ‘surface moisturetrom within the‘ heads, the-produce from theopposite end. ~Suchlettuce present . problems-‘that have heretofore retarded the use of the vacuum ‘cooling system because 10 may be in crates 4 (indicated in dotted-lines)‘ that are on cars or trucks-5 mounted on tracked; that "'no' dependable :method was known for :uniformly extend from end toend of the tube. ‘Loading and unloading platforms or tracks (not shown) may-extend to and from opposite ends of tracks lowering ' the?temperaturev throughoutv the heads " to“ substantially‘ 329. F. .’In my copendingxapplicationiSerial No. 144,185, v?led Febrnary14, 1950,..I. have shownia method .~ Bat opposite ends of the tube. ' The tube iscon "for ‘satisfactorily. lowering the temperature. . The 'nected with a P1138101’ conduit 1 that .is in turn connected with any suitable means (not, shown) .for reducing the pressure within the tube‘l to "method shown in said vapplication requires ‘thrusting the pressure :type ‘thermometer be ‘“tween .headsof lettuce, which’operation some . shippers‘dislike‘becauserof. the possibility of mu ~tilatingfthe outer leaves’of one-or more-heads of lettuce. Also, while said method is satis factory where the ‘produceis loaded intoithe 'say'about- an inch of mercury. 20 - - Conventional valve means anywhere-in tube I or conduit 1 may be provided for breaking the . vacuum and. for admitting - atmospheric air; "into "the tube ‘for-equalizing: the pressure therein with atmospheric pressure. vacuum chamber or tube through one end thereof The present invention is concerned with the ".and is unloaded from the same end, it ‘is not; r 25 means to enable an operatoroutside the tube ‘convenient where the produce is loaded. .into one ' to know the temperature within the body otpro end of .the vacuum tubes-and is unloaded from iduce and especially between heads of lettuce in ' the oppositeend. . Attempts to solve the I problem .iby using ‘the the crates without. ‘having to place a ‘thermom conventional "wet bulb thermometers ~were"lun- r.1a eter between said heads. It might :be here stated . that a conventional wet bulb thermometer placed “successful, and equally‘ unsuccessful were at within’ the tube I does not accurately-give this “tempts to'use any: of the conventional thermom eters in the chambercutside the load of‘ produce. temperature. nor would a thermometerof any .One of the‘ main objects of. thepresent inven kind merely placed within the tube outside-the ‘body of produce. tion is the :provision .of :a. thermometer that .may The thermometer of this invention comprisesv a irberplaced' within. the ‘vacuum. chamber at: apoint ' conventional :pressure type thermometer ‘having ‘outside the load ofcproduce to? be cooled,.v and an elongated hollow body I0 that contains-a which thermometer will closely follovwthetram ‘?uid, usually gas," and which body. is connected perature variations that occur betweenirheads 1st .l'ettuce','iwhere it ‘is. essential to know the exact 1 40 at onelend bya pipe or tube H (Fig.2)vwith-a : temperature. Bourdon gauge I2 (Fig. 1), or the equivalent, : outside the tube I, for registering the tempera .Another'object "of' the invention ‘is the :pro ture at the body I. This pipe- II is usually, an ' vision of means'within. a vacuum tube'or vacuum armored tube and in the present instance it con ‘cooling chamber that ‘need not be moved or ‘changed, and that will quickly .andv accurately: 45 nects’ with .a coupling that extends air. tight . follow temperature variations in the chamber in wthrougha wall of the. tube l,. which couplingzis in‘ turn connected with the‘gauge I2. vthe exact place inaload of producein said cham her. that is essential to the proper cooling of :said The body I 0 is normally horizontal,v and spaced . produce-without freezing the same or. any: part above the same, and-parallel- therewith, is axtube I3 that is parallel with body I. One end oftube Other' objects and advantages will- appear in I3’ :is .closed and the .opposite‘end ‘is' connected the description: and in the claims. by an extension M of said tube with a source ‘of . In the drawings,-Fig. 1 is a semi-diagrammatic water I5 under pressure from outside: the vacuum .side view of a vacuum cooling tube with the pres :..chamber. This tube iii-extends air tight through ent invention indicatedtherein. ‘5- a. wall of the vacuum‘chamber and any suitable thereof. . > 2,585,086 3 At this point, where headed let tuce is being cooled, the operator will stop fur 7 temperature. control valve I6 may be in said tube outside said vacuum chamber between said tube and said source. The source of water may be ordinary ther evacuation of air from the chamber, but the latter will stay closed. The temperature within tap water that is at substantially atmospheric temperature, which would substantially corre Or the chamber will continue to drop, and evapora tion of moisture from the wicking will continue spond with the temperature of the lettuce heads until the thermometer registers 32° F, when the operator will open the chamber to the atmos phere and further cooling will cease. before they are pre-cooled. This water is under pressure and the ?ow may be controlled by valve I 6, although the thermometer structure itself in cludes a control feature, as will later be ex plained. Wicking material I8 encloses the tube I3 and the body I0 of the thermometer from end to end, 10 By the present thermometer assembly it has been discovered that the temperature registered by the thermometer will so exactly follow the - temperature that exists between the heads of let tuce in the load as accurate as though the ther such as the conventional tubular wick used in 15 mometer itself, apart from the wicking and wa ter supply, were positioned between the heads as lamps, thus providing a uniform layer around described in my copending application. Hence, the tube and thermometer. The wicking I8 ex in those instances when it is impractical or unde tends between the tube I3 and body In to provide sirable to follow the procedure mentioned in my a web I9 (Fig. 3). By making the wicking I8 in this wicking preferably being of the woven type, the form of a fairly large tube and inserting the 20 said copending application, the present appara body I 0 within the same at one side and the tube I3 at the opposite side and then drawing the ’ tus is substantially as ei?cient in giving the de sired temperature. It is also pertinent to note that in the present wicking tightly about the said body and tube by case, the lettuce is not torn or multilated by bringing the wicking together between them, the preferred type of structure is formed since the 25 thrusting the thermometer into a crate of lettuce. The thermometer is preferably positioned out of wicking is of uniform weave, and thickness the flow of moisture vapor from the lettuce to the throughout. exhaust conduit, inasmuch as greater accuracy Pressure plates 20, 2I (Figs. 2, 3) comprising can be obtained where the thermometer is adja elongated metal strips held the web I9 flat be tween them, and one longitudinally extending 30 cent an end of the vacuum chamber. The wicking is saturated with water supplied marginal portion 22 of each plate is curved to from a source at atmospheric room temperature, partially extend around opposite sides of tube I3 the length of the latter. Bolts 23 extending through the plates 20, 2| at spaced points there which may normally be about 70° F., and is kept saturated throughout the evaporation step. Ob along are provided with wing nuts 24 to enable‘ 35 viously under similar circumstances, the conven tional wet bulb wick would freeze. This feed of the operation to vary the pressure of the plates water to the thermometer is vfast enough under on the web I9 as desired. the conditions herein described to prevent sub Where the Wicking extends around the body It stantial interior cooling of the‘water in the water of the pressure thermometer it is fully exposed for evaporation of moisture, and the wickingl 40 supply tube. As soon as the vacuum is broken, and atmospheric air is admitted to the chamber, along the upper half of tube I3 is also so exposed. the thermometer will be ‘almost immediately This tube I 3 is provided with a row of small open warmed by the supply of relatively warm water ings 25 that open into the portion of the wick to thus re?ect the elevated temperature. that is covered by a pressure plate. Normally The loading and unloading of the vacuum one row of such openings is found to be adequate, 45 chamber may be very fast due to the present although the position of the openings may be system, and the thermometer will follow tem staggered so that a substantial equal number perature changes in the chamber as fast as they open into the wicking along opposite sides of a occur. There is no material “lag.” plane extending longitudinally of the web and In the case of soft, puffy heads of lettuce, coplanar with said web. spinach, etc., the vacuum may be maintained Any suitable bracket members 26 may be pro constant and the moisture vapor continuously vided for securing the thermometer assembly removed, until the thermometer registers 32° F., horizontally within the vacuum chamber with and then the vacuum may be broken at once and said tube I3 uppermost. When so supported within the vacuum chamber the assembly is out 55 atmospheric pressure restored within the vacu um chamber. The cessation of evacuation need of the way of produce that is loaded into ‘the occur only where tightly headed vegetables are chamber and that is withdrawn therefrom. The operator does not manipulate said assembly. When the vacuum chamber is closed with a load of produce therein, such as lettuce or the like, the gauge I2 will register substantially the same temperature as that of the lettuce. As soon as the air is evacuated from the chamber, evap oration of moisture from the wicking I8 and from the lettuce will be accelerated and the gauge will commence to show a progressive decrease. All being cooled. I claim: ‘ ' ' 1. The method of causing a thermometer to follow the temperature variations within a body of leaf vegetables in a vacuum cooling system and which vegetables have vaporizable surface mois ture thereon that comprises the steps of placing said thermometer and said body of vegetables within an enclosed space and in spaced relation this time tap water, or water at substantially therein, withdrawing air from within said space atmospheric temperature will be supplied to tube I3 at a rate of speed to constantly replenish the to cause evaporation of said moisture and con sequent cooling of said vegetables, and simul water being evaporated from the wicking. The 70 taneously enclosing said thermometer within a temperature within the chamber will continue to thin layer of water in heat transfer relationship thereto and with said layersubjected to the in ?uence of the reduced air pressure within said duced temperature of say 35“ F. it has been found space, continuously conducting water from out that the temperature between the lettuce heads or in the outer leaves will actually be‘. the same 76 side said space through said space and to said be lowered and when the gauge indicates a re 2,585,086 thermometer at=a~rateofvspeed sufficient to maintain said ?lm substantiallyconstant. 6. TA temperatureiindicator for'userln aevacunm " cooling system. withinv a "vacuumzchambersvzcom » 2. The method of causing asthermometer to follow the temperature variationswithin a body of leaf vegetables in a vacuum cooling systemv and which vegetables have. vaporizablev surface moisture thereon that comprises the-steps of placing said thermometer and said body ofvege tables withinan enclosed‘. space and in spaced relation therein, withdrawing air from within; . said space to‘ cause evaporation of said moisture " and consequent‘ cooling of ‘said-vegetables," and simultaneously enclosing said thermometer within a thin layer of water in heat transfer relationship thereto and with said layer subjected to the in?uence of the reduced air pressure within said space, continuously conducting water from outside said space through said space and to said thermometer at a rate of speed sufficient to maine tain said ?lm substantially constant, and free from an excess of moisture above the amount of said layer. 3. The method of causing a thermometer to follow the temperature variations within a body of leaf vegetables in a vacuum cooling system and which vegetables have vaporizable surface moisture thereon that comprises the steps of prising, an elongated. pressure thermometer ‘for "a' fluid,v a ‘tube extending 'alongsidevs‘aid" ther mometer in spaced relation thereto formed-with a plurality‘ of relatively small apertures .for .dis ‘charge of ‘liquid therefrom, .said'tube being :closed atone end and provided'withm'eans:atiitsroppo site end for connecting the same with a source of liquid'for supplying liquid thereto, wicking material enclosing said thermometer and said tube and providing a web between said thermom eter and said tube for conducting liquid from said tube to said thermometer, a pair of opposed plates disposed between said tube and said ther mometer spacing said tube from said thermom eter and clamping said web under pressure be tween said plates and means for varying the pressure of said plates on said web for controlling 20 the rate of ?ow of liquid through said Web. 7. A temperature indicator for use in a vac uum cooling system within a vacuum chamber comprising, an elongated pressure thermometer for a ?uid, a tube extending alongside said ther mometer in spaced relation thereto formed with a plurality of relatively small apertures for dis charge of liquid therefrom, said tube being closed at one end and provided with means at its op placing said thermometer and said body of vege posite end for connecting the same with a source tables within an enclosed space and in spaced relation therein, withdrawing air. from within 30 of liquid for supplying liquid thereto, wicking material enclosing said thermometer and said said space to cause evaporation of said moisture tube and providing a web between said ther and consequent cooling of said vegetables, and mometer and said tube for conducting liquid simultaneously enclosing said thermometer with from said tube to said thermometer, a pair of in a thin layer of water in heat transfer relation ship thereto and with said layer subjected to the 5-‘ opposed plates disposed between said tube and said thermometer, a pair of opposed plates dis in?uence of the reduced air pressure within said posed between said tube and said thermometer space, continuously conducting water from out spacing ‘said tube from said thermometer and side said space through said space and to said clamping said web under pressure between said thermometer at a rate of speed su?icient to main plates and means for varying the pressure of tain said ?lm substantially constant, said water said plates on said web for controlling the rate being supplied to within said space at substan of flow of liquid through said web, said plates tially atmospheric temperature. being formed with extensions partially extending 4. In combination with a vacuum tube adapted around said thermometer with the said wick to contain vegetables for cooling the same, a ing material between said extensions and said temperature recording instrument comprising a thermometer, and means for supporting said thermometer and a conduit for a liquid in side thermometer and said tube horizontally with by side spaced relationship within said vacuum in said chamber with said tube above said ther tube, a moisture conductor of ?brous material mometer. enclosing said thermometer and said conduit and 8. In combination with a vacuum tube adapted disposed between said thermometer and said con 50 to contain vegetables for cooling the latter, a duit for conducting moisture from said conduit thermometer supported within said tube, a layer to said thermometer, openings formed in said of moisture absorbent, moisture conductive ma conduit for ejecting liquid therefrom to said con terial enclosing said thermometer, a conduit ductor, means for supplying liquid to said conduit from outside said tube, a temperature indicator 55 connected with a source of water outside said tube and extending into said tube to said layer outside said tube and means connecting said for conducting water from said source to said thermometer with said indicator for indicating layer, said conduit being apertured at said layer the temperature at said thermometer, means for . for discharge of water therefrom to said layer, controlling the rate of flow of liquid through said wicking material from said conduit to said ther-‘ 60 a temperature indicator outside said tube con nected with said thermometer for indicating out mometer. ~ side said tube the temperature at said indicator. 5. A temperature indicator for use in a vacuum cooling system within a vacuum chamber com prising, an elongated pressure thermometer for a 9. In combination with a vacuum tube adapted to contain vegetables for cooling the latter, a fluid, a tube extending alongside said thermom 65 thermometer supported within said tube, a layer of moisture absorbent, moisture conductive ma eter in‘spaced relation thereto formed with a plurality‘ of relatively small apertures for dis terial enclosing said thermometer, a conduit connected with a source of water outside said charge of liquid therefrom, said tube being closed tube at substantially tap water temperature and at one end and provided with means at its oppo site end for connecting the same with a source 70 extending into said tube to said layer for con ducting water from said source to‘said layer, of liquid for supplying liquid thereto, wieking said conduit being apertured at said layer for material enclosing said thermometer and said discharge of water therefrom to said layer, a tube and providing a web between said thermom temperature indicator outside said tube con eter and said tube for conducting liquid from 75 nected with said thermometer for indicating said tube to said thermometer. 2,585,086 7 ."outside' said tube the temperature at said in- dicator' 3' Suction conduit opening into the up‘ per side 01' said tube for withdrawing air and 8 - ' REFERENCES CITED The following references are of record in the me of this patent; the evaporated moisture from within said tube, , and means for supporting said thermometer UNITED STATES PATENTS within the upper portion of said tube spaced 0 Number Name Date from said suction conduit so as to be out of the 1,404,400 Moon ____________ __ Jan. 24, 1922 direct ?ow of air into said suction conduit. 2,494,769 Mabey ___________ __ Jan. 17, 1950 FOREIGN PATENTS REX L. BRUNSING. ‘ 10 Number 389,535 w Country Date Great Britain ____ __ Mar. 23, 1933