High-speed DC circuit-breakers for Rolling Stock Type

advertisement

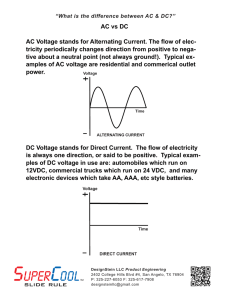

COMPONENTS High-speed DC circuit-breakers for Rolling Stock Type UR6, UR10 & UR15 General information UR6, UR10 and UR15 are DC high-speed current limiting circuit-breakers with natural cooling, trip free, single pole, bi-directional, with electromagnetic blow-out, electric control circuits and direct over-current instantaneous release. Of open type construction, the UR6, UR10 and UR15 can also be delivered with protective enclosure IP55 for roof or under-frame mounting on traction vehicles. These circuit-breakers are primarily designed to protect main and auxiliary circuits of DC traction vehicles against short-circuits and overload currents, as well as to connect or isolate these circuits to and from the vehicles power supply. Selecting the right product for your vehicles requires careful consideration and computing from Sécheron, for the application load cycle, the environmental temperature and high-voltage cable or busbar section. Applications • Protection of electric traction and auxiliary circuits on Metro, EMU and LRV vehicles Main features • • • • • • • • • • • • • • • • • Cadmium free (UR10/15) Conventional thermal current 1000 A for UR6/10 (UR10 designed for heavy applications) and 1500 A for UR15 Rated operational voltage 900 Vdc and 1800 Vdc Rated insulation voltage 2300 Vdc Safe with a high insulation level: over-voltage category OV4 Pollution degree PD3 Limited maximum arc voltage Electro-magnetic closing and reduced holding power Optional integrated ECO-Drive control module, to manage the closing - holding sequences, and to save holding energy consumption and operational costs Optional -50 °C version High mechanical and electrical endurance: operational frequency C3 Very low maintenance requirements with 100’000 operations minimum mechanical durability and 500’000 operations minimum lifetime Compact and light weight Proven design with worldwide experience and acceptance Roof or underframe mounting on the vehicle, when delivered with its protective enclosure Insulation material according to EN45545-2:2013 Reference standards IEC/EN60077-1/3 and IEC/EN 61373 Breaking current parameters I IEC-60077 T tm 8 [ms] Iss 7 0.63 Iss 6 t di/d Îss Îd 5 Id Ûarc U tb t 4 3 Ue tm Iss Îss Id Îd di/dt T Ue Ûarc tm tb = = = = = = = = = = 2 105 t Short-circuit current Peak of Iss Setting of over-current release Cut off current Initial current rate of rise Circuit time constant Rated operational voltage Peak of the arc voltage Opening time Total break time 2 3 4 5 6 8 106 2.106 di/dt [A/s] Opening time Relationship between opening time tm and the initial rate of rise of current di/dt for direct over-current instantaneous release. Example for an initial rate of rise of current of 8.105 A/s: the opening time is about 3.9 ms. 2 Data for product selection Symbol Unit UR6 UR10 MAIN HIGH VOLTAGE CIRCUIT UR15 Rated operational voltage Ue[Vdc] - Arc chute type 31 and 41 900 900 900 - Arc chute type 32 and 42 1800 1800 1800 Maximum operational voltage [Vdc] - Arc chute type 31 and 41 1000 1000 1000 - Arc chute type 32 and 42 2000 2000 2000 Rated insulation voltage Ui[Vdc] 230023002300 Rated operational current Ie [A]100010001500 Conventional free air thermal current (1)Ith[A]100010001500 Overload capacity (2)[A] - 10 s 2400 (3)3200(3)3600 - 1 mn 1600 2200 3600 - 5 mn 1400 1700 2680 - 1 hour 1090 1150 1750 Operational categoryC3C3C3 Over-voltage category OV4OV4OV4 Rated short-circuit making and breaking capacity / Time constant - Arc chute type 31 and 41 Iss / T1 [kA]/[ms] - - Iss / T2 [kA]/[ms] 30/15 30/15 30/15 Iss / T3 [kA]/[ms] 30/50 30/50 30/50 Iss / T4 [kA]/[ms] 30/150 30/150 30/150 - Arc chute type 32 and 42 Iss / T1 [kA]/[ms] - - Iss / T2 [kA]/[ms] 30/15 30/15 30/15 Iss / T3 [kA]/[ms] 30/40 30/40 30/40 Iss / T4 [kA]/[ms] 30/100 30/100 30/100 Direct over-current instantaneous release (4) Power frequency withstand voltage [kA] 0.45 - 2.4 0.6 - 3.2 0.9 - 3.6 U50 - Between opened main contact [kV] 8 8 8 - Between closed main contact and earth & control circuit [kV] 10 10 10 - Between low voltage circuits and earth [kV] 2 2 2 Rated impulse withstand voltage Uimp[kVdc] 181818 Maximum peak arc voltage - Arc chute 900 VdcÛarc[kVdc] 1.1 - 3.0 1.1 - 3.0 1.1 - 3.0 - Arc chute 1800 Vdc 2.1 - 6.1 2.1 - 6.1 2.1 - 6.1 (1) At Tamb = + 40°C and tested with a size of high voltage connection per terminal: 2 x 240 mm² for UR6/10 and 3 x 300 mm² for UR15. Non cumulative overloads at Tamb=+40°C, starting from breaker’s cold state, and with high voltage connection size as per (1). The values are based on trip setting range 1.2 - 2.4 kA for UR6, 1.5 - 3.2 kA for UR10 and 1.8 - 3.6 kA for UR15. May the selected trip setting range be different, maximum values of the overload capacity should match the maximum value of the selected tripping range. (4) For range selection, refer to the table page 4. (2) (3) LOW VOLTAGE AUXILIARY CIRCUIT Control circuit Nominal voltage Un[Vdc] 24, 32, 36, 48, 72, 87, 96, 110 Range of voltage [0.7 - 1.25] Un Nominal closing power (5)Pc [W]/[s] 835/1 Nominal holding power for electric holding (5)[W] 2.5 Nominal opening power for electric holding (5)[W] 0 Nominal holding power for magnetic holding (5)[W] 0 Nominal opening power for magnetic holding (5) [W]/[s] 35/1 Mechanical opening time on opening order (6) (Electric / Magnetic) [ms] 5-10 / 10-20 Mechanical closing time on closing order (5) (6) (Electric / Magnetic) tc [ms] ~ 70 / ~ 70 Auxiliary contacts Type of contacts Potential free (PF) Number of auxiliary contacts 2a + 2b or 6a + 6b Rated voltage [Vdc] 24 to 110 Conventional thermal current [A] 10 Switching categories according to EN60947 (silver contacts) - AC-15 230 VAC 1.0 A - DC-13 110 VDC 0.5 A Minimum let-through current at 24 Vdc (7)[mA] ≥10 (silver contacts) or 4≤I<10 (gold contacts) Low voltage interface Type of connection - Without protective enclosure Direct (screw connection) - With protective enclosure Connector type Harting or VEAM (5) (6) (7) At Un and Tamb = +20°C. Starting when the signal is received by the coil. For a dry and clean environment. OPERATING CONDITIONS Installation Vibrations and shocks (according to IEC/EN61373) Altitude [m] Working ambient temperature Tamb [°C] Relative humidity Pollution degree Minimum mechanical durability N [Operations] (8) (9) Outdoor with optional enclosure (refer to page 9 and 10) For ambient temperature <-25°C, please contact Sécheron. 3 Indoor or outdoor (8) Category 1, class B < 1’400 - 25 to + 70 (9) 95 % at + 40°C PD3 5 x 100’000 Required informations for breaker selection In order to select the appropriate breaker suited to your application, the following informations must be provided to Sécheron. Once these data computed, and in function of the maximum allowed temperature rise of the critical parts of the different breakers UR6/10/15, Sécheron will recommend the breaker type that matches your application. The following data and informations must be sent to Sécheron for computing. 1 - Application load cycle An excel table with the load cycles the breaker will have to withstand in the application, shall be sent to Sécheron for computing, and shall include as a minimum the following informations: • The peak value Ip3 and the i² x t of the most energetical load of the vehicle’s trip • The highest peak value Ip1 of the vehicle’s trip and its duration • The Irms current (Root Means Square) of the vehicle’s trip rms current [A] Real current Braking current Ip1 Ip2 Ip3 I rms i² x t [s] t1 Load cycle x load cycles Load cycle y load cycles Load cycle Vehicle’s trip 2 - Maximum working ambient temperature of the circuit-breaker in the application ......... °C 3 - High voltage connection type and number of connection per high voltage terminal - Cable: - Busbar: :1 :2 :3 :1 :2 :3 4 - Individual high voltage connection size - Cable: ........ mm² - Busbar: ........ mm x ......... mm Note: It is recommended that the current density of the high voltage connections wired to the DC circuit-breaker and related to the rms current of the application shall not exceed 1.7 ~ 2.0 A/mm². For current density that exceeds the recommended value, the breaker thermal current may have to be derated in function of the application. Direct over-current instantaneous release Available setting ranges (in kA) with their corresponding designation code for selection page 12. UR6 UR10 UR15 Designation code Standard Option 0.45- 0.9 - - F 0.6-1.2 0.6-1.2 - A 0.9-1.8 0.9-1.8 0.9-1.8 B 1.2-2.4 1.2-2.4 C 1.2-2.4 - 1.5-3.2 - D - - E 1.8-3.6 4 Information for product integration Main dimensions 60(1) 900V: 165 1800V: 305 60(1) Dimensions without tolerances are indicative. All dimensions are in mm. The maximum allowed flatness deviation of the support frame is 0.5 mm. 42.5 20 67.5 M16 Ø14 11 UR6/UR10: 40 30 UR15: 65 115 130 30 190 135(2) 115 20 10 420 10 10 40 145 Ø9 10 40 145 165 165 10 10 40 115 Ø9 Ø14 10 Ø14 Ø9 30 190 20 M16 Ø9 20 420 130 20 135(2) Ø14 40 180 42.5 20 67.5 40 900V: 165 1800V: 305 180 UR15 11 115 40 145 145 165 165 10 Space needed for the removal of the arc chute. Space needed for the removal of the auxiliary housing. C Insulation distances C HV 90 LV HV LV A 420 90 (2) UR15 UR6/10 UR6/UR10: 40 30 UR15: 65 (1) UR6/10 B 165 Minimum insulation distances [mm] A A 420 To insulating wall To earth UR6 A BUR10 165 UR15B A 90 90 90 B 55 55 55 C 0 0 0 A 350 350 350 B 200 200 200 C 150 150 150 Weights Weights (1) [kg] (1) UR6 UR10 UR15 Arc chute 900 V 27 28 29 Arc chute 1800 V 37 38 39 Weights for standard circuit-breaker without any option. 5 B UR26/36/40/46 S V= + UR26/36/40/46 UR26/36/40/46 UR26/36/40/46 S UR26/36/40/46 V= S UR26/36/40/46 V= + V= + V= + + S S B DB DB DB DB 0,5 0,5 C C C C C t [s] t [s] t [s] 1 t [s] 1 0,5 ttc+1 1 0,5c+1 c+0.5 0,5 1 c+0.5 tc+1 c+0.5 tc+1 c+0.5 E F F F F Rp Rp Rp Rs Rp Rs Rs Rs – – – A – A A UR60/80 D E V= + 100% D 100% E V= D + 100% E V= D + 100% S V= S V= + 100% +V= + F + F F + ~ 1 F ES E D D E UR60/80 S V= SS S V=V=V= A V= S +A B + +Ie A B + IIee AF+F B F B 100% I 0 0,5 – – 0 0 ~ 20% 0 0 0 tc– +0.5 1 –~ 20% 0,5 0,5 0,5 0,5 Ie A 1 1 1 1 B IUR60/80 CBA e I AUR60/80 I Ie eUR60/80 V= B V= e 100%+ 100% V= + 100% V= + 100% + R1 Rs R1 R1 R1 F F F F t [s] t [s] t [s] t [s] 0t +1 tc tcc+1 tc~tc20% tc tc+0.5 +0.5 tc+1 tc tc+0.5 tc+1 0 tc+0.5 ~ 1 20% 0,5 Customer’s scope Sécheron’s scope UR60/80 + E Rs Rs Rs Rs t [s] t [s] t [s] t [s] tc tc+1 tc+1 tc+0.5 tc tc+0.5tc+1 tc+0.5 tc+1 t 0 c 0,5 tc+0.5 1 tc tc+0.5 – F t [s] – E Rs S F Rs Rs Rs – – – tc+1 Customer’s scope Sécheron’s scope Maintien magnétique pour UR60/80 Maintien magnétique pour UR60/80 A MaintienAmagnétique 80 magnétique pour pour UR60/80 UR60/80 A idem pour A 80 (maintien électrique idem que UR26-36-40-46) Maintien (maintien que UR26-36-40-46) Maintienélectrique magnétique UR60/80 Maintien magnétique pourque UR60/80 A A 80 (maintien électrique idem UR26-36-40-46) 26-36-40-46) Maintien magnétique pour UR60/80 A Maintien magnétique pourque UR60/80 (maintien électrique idem UR26-36-40-46) A 80 26-36-40-46) (maintien électrique idem que UR26-36-40-46) B A Start (maintien électrique idem theUR26-36-40-46) closing pulse: the A 26-36-40-46) theBcontacts F +que G UR26-36-40-46) close. (maintien B B Start of the closing pulse: électrique idemofque (maintien électrique idem que UR26-36-40-46) 26-36-40-46) B B B B C C C C D D D D E E E E Rs UR60/80 S SS V= + E F E F F E Rp Rp Rp Rs Rs Rs Rs– UR60/80 V= V= V= S + V= + + + D F Rp Rp – UR60/80 UR60/80 D D C S S tc – – DCC SB D SC E F E F E F E F 0 0 0 ~ 20% ~ 20% – ~ 20%0 – 00,5 0,51 1 –0 1 – 00,5 F – Rp Rp Rp Rs Rp Rs Rs Rs E E F E F E – – –A –A UR60/80 B D D 100% D D C C C C e 100% 100%F E 100% F G F E F Rs G G E F R1 G Rs G R1 R1 E F G Rs R1 G E ~F 5% G t [s] t t[s][s] t [s] ~ 5% Rs R1 G t0[s]~ 5% t [s] –0 – – 1 ~ 20% t [s] t0[s] – – 0,5 0 1 0,5 – 0 ~ 20% – 0,5 1 0 0 – 0 0,5 tct+1[s] 1 tc ~ 20% 5% t [s] – – E E E E Rp – + S S S F Rs B A C V=D Ie D UR60/80 A IE D BeB CSSV=B IeC CD Ie E IUR60/80 S B D CE UR60/80 eV= F Magnetic holding: M type Electric holding: E type E E E E S V= E+ S S + V= + V= + + S S S + V= V=+ UR26/36/40/46 + UR26/36/40/46 UR26/36/40/46 UR26/36/40/46 S V= S UR26/36/40/46 V= S V= Low voltage control diagram + UR26/36/40/46 UR26/36/40/46 UR26/36/40/46V= A A contacts E close. B Closing pulse: 0.5 to 1 s, then theB contacts E open. Closing pulse: 0.5 to 1 s. C C B B Maintien magnétique pour C UR60/80 pour UR60/80 Maintien magnétique A C Holding: achieved by the permanent magnet. Start of the holding current: the contact G opens. C A (maintien électrique idem que UR26-36-40-46) C D C D idem que UR26-36-40-46) Cprovoke a current D Opening: the contacts F close to Holding: a R1 resistance limits the holding current to (maintien électrique D D E B to the D pulse of the opposite polarity current. D closing B 5% of the closing current. E E D E E Opening: the contact F opens to provoke the E The duration of this pulse is 0.5-1 s, then the contact C E F opens. The opening current is E20 % of theC closing interruption of the holding current. current. D D E E, F, G: Control relay’s contact. E R1: Resistor to be inserted in the holding circuit of the E type; the power to be considered for the resistor choice is 280 W (4x70 W). Rs: Resistor to be inserted in series with the coil in the opening circuit of the M type; the power to be considered for the resistor choice is 70 W (277 W / 4). Rp: Resistor to be inserted in parallel with the closing coil in the opening circuit of the M type. S: Automatic circuit-breaker. Typical value for closing coils for UR6/10/15 Coil characteristics Unom Closing Inom Imin E Imin M M type opening E type holding Pulse 0.5 to 1s Imax R1 Inom Imin Pulse 0.5 to 1s Imax Rs Rp Inom Imin Imax [V] [A] [A] [A] [A] [Ω] [A] [A] [A] [Ω] [Ω] [A] [A] [A] 24 34.5 18.7 20.7 58.6 12.3 1.85 1.27 2.34 1.29 0.66 7.18 4.25 10.71 36 24.2 13.0 14.5 41.0 26.6 1.28 0.88 1.62 3.00 1.50 4.82 2.87 7.15 48 19.4 10.5 11.6 32.9 45.9 0.99 0.68 1.26 5.15 2.45 3.74 2.22 5.55 72 12.1 6.5 7.2 20.5 106.5 0.64 0.44 0.81 12.00 6.00 2.41 1.43 3.57 110 7.6 4.1 4.6 12.9 253.0 0.41 0.28 0.52 28.50 14.60 1.55 0.92 2.30 220 3.8 2.0 2.3 6.4 1014 0.21 0.14 0.26 114 59.00 0.77 0.46 1.15 6 Rs Standard: xxxxx Standard HAN: poles Low18 voltage interface Standard: xxxx Standard HAN: 28 poles Without protective enclosure Brochure Brochure ANSI EN Brochure Brochure Brochure Brochure ANSI EN ANSI EN HARTING HARTING HARTING 23 2 or 6 auxiliary switches 23 Configuration with Standard: xxxxx xxxx Standard: xxxx Standard: xxxxx Standard: I I 24 24 Direct connection on auxiliary switches and closing coil. 19 17 15 13 11 9 7 5 3 1 C4 C2 15 14 12 11 9 8 6 5 3 2 A1 21 A2 A5 A6 A9 A10 A13 A14 A17 A18 C5 C6 21 5 6 4 2 9 10 Standard: xxxxx Standard: xxxx 23 23 the auxiliary 23 Low voltage cables go through PG 11 glands of I 23 I I I 24 24 24 24 A B C D E F B E contacts housing. (1) (1) 23 24 19 17 21 I (1) 15 13 11 9 11 12 7 8 22 7 5 3 1 20 18 16 14 15 13 11 9 7 5 I> 3 1 20 18 16 14 12 10 8 6 19 17 21 22 3 1 12 10 8 6 20 18 16 14 Harting type > 4 2 8 6 HAN® 22 20 18 A3 A4 12 11 (1) 4 (I2>) Standard: xxxxx31 29 23 24 (1) 3 1 (I>) (WI) Standard: xxxxx 31 29 (I>) (WI) 31 29 27 25 27 25 23 24 21 I 9 10 (1) 19 17 21 B E 7 8 11 12 23 (I>) 32 30 28 26 19 17 22 15 13 15 13 (WI)(I>) (WI) 24 Standard: xxxx C3 C1 11 9 I> 11 9 (1) 27 25 7 5 3 131 29 31 29 20 18 16 14 12 10 8 6 7 5 3 1 (I>) (WI) 31 29 27 25 28 26 HAN® I> 22 20 18 16 14 12 10 I> 4 2 8 6 32 30 1 4 22 28 26 12 11 9 8 6 5 13 10 7 4 VEAM type connector (option for protective enclosure): 27 25 A I I A5 A6 A9 A10 A13 A14 A17 A18 21 B C7 C8 23 24 C A3 A4 Type : CO D A7 A8 E 15 14 F 12 11 (I>) I> 9 8 6 5 3 2 2 23 24 (WI) 27 25 3 231 29 10 7 4 I 15 14 12 11 9 8 6 xxxx 5 3 Standard: A11 A12 A15 A16 A19 A20 19 17 15 1315 14 11 912 11 7 5 9 8 3 1 6 5 21 22 32 30 28 26 13 27 25 21 4 2 23 24 21 31 29 23 24 I ® M 28 22 Harting type4 2HAN 22 Harting type M2018 32 30 28 26 32 30 28 26 18 16 14 12 10 8 6 32 30 28 26 (6a + 6b auxiliary switches) (2a + 2b auxiliary switches) 32 30 22 1 15 14 Type : CO 7 A1 A2 (I>)C5 C6 (WI) C4 C2 21 1 4 3 2 Type : PF : CO Type Standard: xxxx Type : CO 15 13 11 9Standard: 7xxxxx 5 3 1 xxxx Standard: I I> 6 5 7 I> 10 > I 5 24 6 27 25 19 17 21 23 (WI) 3 2 10 A11 A12 A15 A16 A19 A20 9 8 I> 13 I(standard for protective enclosure): I Standard HPR: 18 poles Standard HPR: 28 poles Type : PF Standard: xxxxx Type : PF A7 A8 16 1413 12 1010 8 6 7 4 2 4 I> 22 M connector Type : PF 12 10 15 14 22 4 2 15 1315 14 11 9 12 11 7 5 9 38 1 6 5 22 13 C7 C8 21 With protective I> enclosure 22 19 17 21 (1) 21 23 4 2 C3 C1 I 24 I 21 1 VEAM type 30 22pins type 13 pins 22 VEAM 20 18 16 1413 12 1010 8 6 7 4 2 4 28 26 1 32 30 (6a + 6b auxiliary switches (2a + 2b auxiliary switches) I> I> or 6a + 4b in 24 Vdc) I> 13 10 7 1 4 Légende Légende Légende Légende Légende Note: Low voltage connectors are delivered I> with all pins mounted. 15 14 12 11 9 8 13 10 7 Direct Direct Low voltage wiring diagrams Legend a> b a b a b (WI) main Circuit-breaker I contact a bI (WI)(I>) a b a b closing Circuit-breaker (WI) coilI> a b a b I I> (WI) I I>(WI) I a (WI) (I>) (I>) (I>) b a (WI) on coil Varistor b (WI)- Switch I> PF 1a+1b I (I>) (WI) Connector male contact (WI) Direct connection (Configuration without protective enclosure) Auxiliary contacts - 2a + 2b configuration V U (1) (1) (1) V U (1) 3 1 33 11 3 1 B EB E 4 2 44 22 4 2 Auxiliary contacts - 6a + 6b configuration V (1) U Double cable only for 24Vdc control voltage. 7 (1) (1) V U (1) (1) 3 1 33 11 33 11 33 11 3 31 1 3 1 3 1 A BA CB DC ED FE F 4 2 44 22 44 22 44 22 4 42 2 44 22 4 2 1 3 U (1) U (1) B E B E 4 2 4 2 4 2 4 2 U (1) U (1) A B A C B D C E D F E F 4 2 4 2 4 2 4 2 4 2 4 2 4 2 4 2 4 2 4 2 4 2 4 2 Harting type HAN connector (Standard for protective enclosure) OnlyHAN: the pins to your selected configuration page 12 Standard will beHAN: wiredHAN: according to the below’s pin assignment. The Standard 18related poles Standard 28 poles Standard HAN: 18 poles 28 poles connector will be delivered with all pins mounted even if not all wired. Auxiliary contacts - 6a + 6b configuration Harting Type HAN® M 28 Auxiliary contacts - 2a + 2b configuration Harting Type HAN® M 18 VEAM VEAM (1) (1) (1) 4 2 3 1 (1) (1) 4 2 5 6 59 10 6 9 10 B E B E 7 8 11 7 12 8 11 12 (1) C4 C2 (1) C4 C2 (1) 3 1 C3 C1 (1) C3 C1 C5 C6 A1C6 A2 C5 A5 A2 A6 A1 A AB C B C7 C8 A3C8 A4 C7 A7 A4 A8 A3 A9 A14 A13 A17 A14 A18 A17 A18 A5 A10 A6 A13 A9 A10 D C E D F E F A15 A12 A16 A15 A19 A16 A20 A19 A20 A11 A7 A12 A8 A11 Type : PF Type : PF Double cable only for 24Vdc control voltage. VEAM type connector (Option for protective enclosure) Only the pins related to your selected configuration page 12 will be wired according to the below’s pin assignment. The connector will poles be delivered with all pins mounted even Standard if not all wired. Standard HPR:HPR: 18 HPR:HPR: 28 poles Standard 18 poles Standard 28 poles Auxiliary contacts - 6a + 6b configuration VEAM Type 30 pins Auxiliary contacts - 2a + 2b configuration VEAM Type 13 pins (1) (1) 6 13 4 2 1 2 5 6 7 8 1 2 59 10 6 7 8 9 10 B B E B E B E E 9 10 3 4 11 7 12 8 9 10 11 12 (1) (1) 11 12 3 1 (1) (1) 6 13 (1)4 2 (1) 11 12 3 1 (1) 3 4 7 8 (1) (1) S P C4 C2 (1) (1) G E S P (1) C4 C2 (1) (1) R O (1) C3 C1 RO C5 C6 Z X G E A1C6 A2 C5 A A B A AB H F a Y H F A3C8 A4 C7 C7 C8 C3 C1 d b(*) C A(*) K I( ) V T d b(*) Z X V T C A* K I A5 A2 A6 A9 A14 A13 A17 A14 A18 A17 A18 A1 A5 A10 A6 A13 A9 A10 C B C B D C D C E D E D F E F E F F D B(*) L J( ) W U e c(*) a Y D B* L J W U e c(*) A7 A4 A8 A11 A15 A12 A16 A15 A19 A16 A20 A19 A20 A3 A7 A12 A8 A11 Note: For 24Vdc configuration, pins with (*) are not wired (6a + 4b configuration). Double cable only for 24Vdc control voltage. Options (subject to additional costs) ECO-Drive integrated control module Légende Légende The ECO-Drive is a small control module directly integrated on the UR6, UR10 and UR15 breaker, for both stand-alone version or when delivered with protective enclosure, for configuration with electric holding and 2 auxiliary switches. The ECO-Drive is installed on the UR breaker’s closing device and manages the closing - holding sequences once it receives a closing order from the vehicle. Additional weight with this option is 0.6 kg. ba a b ba b) (WI (WI) I> I> I I(I>) (I>)(WI) (WI) 170 a ECO-Drive 165 * 36 135* Space needed for the removal of the auxiliary housing This option offers many advantages to the system integrators including the following features: • UR6/10/15 breakers do not need additional hardware anymore to manage the closing - holding sequence • Reduction of the overall space necessary to operate the circuit-breaker • Reduction of overall installation costs of the DC circuit-breaker • Reduction of holding power consumption and operational costs versus conventional holding variant • Reduction of the risks of damaging the closing coil during commissioning and service operations The UR breaker together with the ECO-Drive is fully compliant for electromagnetic compatibility with EN 50121-3-2 and with EN 50155: § 5.1.1.2 short (10 ms) interruptions class S2 and § 5.1.3: voltage dips / variation (at 0.6Un during 100ms) class C1. 8 Low voltage wiring diagrams Direct connection (configuration without protective enclosure) Un 5 6 k0 + - k1 U EF + - Vbat P 1 2 Vbat N 8 ORDP 7 ORDN 3 C 1 3 B 4 1 Un E 2 4 1 terminal Wago - Un k0 + - k1 + UEF - Vbat P Vbat N 2 2 k1 U EF + - C 8 ORDP 7 ORDN Customer’s scope Harting type HAN® M connector (configuration with protective enclosure) Sécheron’s scope 5 3 1 5 6 k0 + 9 10 6 Vbat P 2 4 Vbat N 15 ORDP 16 ORDN C B E Harting connector 7 8 11 12 Technical data Control circuit Nominal voltage Un [VDC] 24, 32, 36, 48, 72, 87, 110 Range of voltage [ 0.7 - 1.25 ] Un Idle (standby) power Nominal closing power (1) Pc (1) Mechanical opening time on opening order (2) Mechanical closing time on closing order (1) (2) <1.6 [W]/[s] 835/1 [W] <8 5 8± Nominal opening power for electric holding 36 Nominal holding power for electric holding (1) [W] (1) (2) tc [W] < 1.6 (Idle power - see above) [ms] 5-10 [ms] ~ 70 At Un and Tamb = +20°C. Starting when the signal is received by the coil. 35 HV 5 Protective enclosures 5 69 511 The TDP/TDS enclosures for UR6-31/UR10-41/UR15-41 or UR6-32/UR10-42/UR15-42 can be mounted on the vehicle’s roof or under the vehicle’s frame. LV UR6-31/UR10-41/UR15-41 TDS UR6-31/UR10-41/UR15-41TDS/TDP Weight with breaker: 46 / 47/ 48 kg ( IP55) Example of TDP box fixing on the vehicle’s roof (1) 60 UR6-31/UR10-41/UR15-41 TDP 15 30 (1) 8± 36 5 5 69 XX 5 35 HV m m 373 LV supporting frame and fixing screws are not delivered with the enclosure LV: low voltage connection HV: high voltage connection Note: Color for URxx.31/41 enclosure is black. 9 XX: dimension with mobile connector. For values refer to page 11 ( based on the type of connector selected ) 15 40 (1) UR6-32/UR10-42/UR15-42 UR6- 32/UR10-42/UR15-42 TDS (1) Example of TDS box fixing under the vehicle’s frame 60 TDP UR6-32/UR10-42/UR15-42 TDS/TDP Weight with breaker: 60 / 61 / 62 kg ( IP55) 15 15 30 40 (1) (1) 36 8± 5 supporting frame and fixing screws are not delivered with the enclosure XX m m 35 HV 5 5 69 511 LV: low voltage connection HV: high voltage connection LV Note: Color for URxx.32/42 enclosure is grey. XX: dimension with mobile connector. For values refer to page 11 ( based on the type of connector selected ) Cable glands type selection High voltage cable diameter [mm] and cable glands UR6/10 UR15 14.1 - 17.0 mm (M25x1.5) - B 17.1 - 19.0 mm (M32x1.5) - C 19.1 - 24.0 mm (M32x1.5) - D 24.1 - 26.0 mm (M40x1.5) - E 26.1 - 33.0 mm (M40x1.5) - F - 27.0 - 32.0 mm (M50X1.5) G - 32.1 - 34.0 mm (M50X1.5) H 5 35 373 Type PG (1) HV 5 8± - - LV Option 5 - 14.0 mm (M25x1.5) 36 Metric Designation code (1) 5 69 A 34.1 - 36.0 mm (M50X1.5) I - 36.1 - 40.0 mm (M50X1.5) J 12.5 - 14.0 mm (PG21) - K 14.1 - 17.0 mm (PG21) - L 17.1 - 19.0 mm (PG21) - M 19.1 - 24.0 mm (PG29) - N 24.1 - 26.0 mm (PG29) - P 26.1 - 33.0 mm (PG36) - Q - 27.0 - 35.0 mm (PG36) R For selection page 12. Cable glands standard configuration The high voltage cable gland plate will be delivered assembled according to the diagram shown below. The customer can easily change the position of these glands and protection caps according to its own needs. Designation code (line 18, page 12) 2 Cables 3 Cables 4 Cables 5 Cables 6 Cables Code: 2 Code: 3 Code: 4 Code: 5 Code: 6 Position of cable glands (line 19, page 12) UR6 UR10 UR15 10 BIM1 indirect release The indirect release enables to shorten the opening time when required by specific application. Opening time UR6 / 10 / 15 Control mode 2-5 ms BIM1 CID-3* terminals The terminals allow the connection between 2.5 mm² cables from the BIM and 6mm² cables from the CID-3. * Not included in the DC circuit-breaker To be ordered separately. Refer to brochure SG101783 Designation code for separately ordered mobile connector (for optional protective enclosure) Auxiliary switches Device Number 2a+2b Type PF Mobile connector Fixed connector type Harting HAN® M 18 Number of pin Size 2.5 mm² 4 Size 1.5 mm² Size 2 mm2 14 - Cable gland 6a+6b PF 4 24 4 UR6 UR10 UR15 2a+2b 6a+6b (1) PF PF - 8 SG102955R00001 460 ± 5 SG102955R00003 431 ± 5 SG102955R00002 460 ± 5 SG102955R00004 431 ± 5 SG100025R00007 (for 24Vdc) 430 ± 5 SG100025R00008 (for 36-110Vdc) 430 ± 5 SG100025R2 (for 24-110Vdc) 430 ± 5 M32 - VEAM type 13 pins VEAM type 30 pins Connector M32 UR6 UR10 UR15 Harting HAN® M 28 Sécheron’s number Overall width: XX [mm] (1) PG29 - - 10 6 24 - PG29 Overall dimension of the enclosure with the selected mobile connector (Harting or VEAM). See drawing below. Designation code for ordering Designation code information • Be sure to establish the designation code from our latest version of the brochure by downloading it from our website “www.secheron.com”. • Be careful to write down the complete alphanumerical designation code with 20 characters when placing your order. • The customer shall write down the setting value Ids in its order form. • For technical reasons some variants and options indicated in the designation code might not be combined. • The bold part of this designation code defines the device type, and the complete designation defines the identification number of the product, as displayed on the identification plate attached to the product. Example of customer’s choice: UR .6 31 T D - Z Z Z Z Z A 1 E C N 1 Line: 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 11 Designation code (options are subject to additional costs) - Order form LineDescription Designation Standard Options Customer’s choice 10 Breaker type UR UR UR 11 Conventional thermal current (1) - 1000 A (UR6) .6 - 1000 A (UR10) 10 - 1500 A (UR15) 15 12 Rated operational voltage- UR6 900 V 31 1800 V 32 - UR10/15 900 V 41 1800 V 42 13 Application Traction (according to IEC60077-3) T T 14 Mounting position Vertical D 15 Protective enclosure No - For roof mounting P For underframe mounting S 16 Type of low voltage connector (2)(3) NA Z Harting type HAN® M 2 VEAM 3 17 Type of high voltage cable gland plate (2) NA Z Metal - grounded M 18 Number of glands (2)(4) NA Z - UR6/10 4 4 Other selection according to table page 10 .... - UR15 only 6 6 19 Position of cable glands on plate (2)(4) NAZ Standard S 20 External diamater of the HV cables (2)(5) NA Z Metric glands - UR6 19.1 - 24.0 mm (M32x1.5) D - UR10 26.1 - 33.0 mm (M40x1.5) F - UR15 36.1 - 40.0 mm (M50x1.5) J Cable glands type PG (specific execution) - UR6 19.1 - 24.0 mm (PG29) N - UR10 26.1 - 33.0 mm (PG36) Q - UR15 27.0 - 35.0 mm (PG36) R Other selection according to table page 10 .... 21 Nominal control voltage 24 VDCA 36 VDCB 48 VDCC 72 VDCD 110 VDCE 32 VDC F 87 VDC G 96 VDC (6) H 22 Varistor on coil Yes (7)1 No (7) N 23 Control type Electric holding - without ECO-Drive E Magnetic holding - without ECO-Drive M Electric holding - with ECO-Drive (7) 4 24 Range of the direct over-current instaneous release - UR6/10/15 1.2 - 2.4 kA C - UR10 1.5 - 3.2 kA D - UR15 1.8 - 3.6 kA E Other selection according to table page 4 .... 25 Indirect release NoN N BIM1 1 26 Auxiliary contacts 2a + 2b - (switch PF) - Silver type 1 6a + 6b (8) - (switch PF) - Silver type 2 2a + 2b - (switch PF) - Gold type 3 6a + 6b (8)- (switch PF) - Gold type 4 (2) (3) (4) (5) According to Sécheron’s recommendation (refer to page 4). Options valid with a protectecive enclosure When ordering a breaker with a protective enclosure, the low voltage mobile connector must be ordered separately according to the description page 11. Refer to cable glands configuration scheme page 10. The customer will have to adapt the inner diameter of the gland seals by removing the unnecessary rubber rings. (6) Only possible with holding type electric E. In case control type “Electric holding - with ECO-Drive” is selected (line 23), select “No” for line 22. Option not compatible for breaker’s version with protective enclosure and 6a+6b auxiliary switches, nor for version with VEAM connector. (8) 6a + 4b configuration for 24 V DC control voltage for VEAM connector. (7) The low voltage connector must be ordered separately: Harting HAN® M 18: SG102955R00001 Harting HAN® M 28: Value of the setting of the direct over-current release: .......................[A] Place and date: SG102955R00002 Other type: SG................. Name: Signature: Sécheron SA Rue du Pré-Bouvier 25 1242 Satigny - Geneva CH-Switzerland Tel: +41 22 739 41 11 Fax: +41 22 739 48 11 info@secheron.com www.secheron.com This document is not contractual and contains information corresponding to the level of technology at the date of printing. Sécheron reserves the right to modify and/or improve the product, whose characteristics are described in these documents, as required by new technology at any time. It is the purchaser’s responsibility to inform himself, no matter what the circumstances, of the product’s maintenance conditions and requirements. Sécheron reserves all rights, especially those arising from our “General Delivery Conditions”. Copyright© 2015 Sécheron SA SG104136BEN_B07-0715 (1)