Fluorescent Lighting for Explosion Proof, Hazardous and Hostile

advertisement

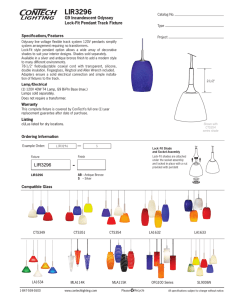

XP SERIES Fluorescent Lighting for Explosion Proof, Hazardous and Hostile Locations X P • Class I, Division 1, Groups C & D • Class I, Division 2, Groups C & D • Class II, Division 1 & 2, Groups E, F & G • Class III • Simultaneous Presence • UL 1598A Marine Outside Type • UL 1598, UL 844 & UL 924 • NEMA 3, 4X, 7CD & 9EFG • Paint Spray Booth • CSA Certified • 55°C Ambient Temperature (2 & 4 lamp) •IP66 9 XP SERIES Fluorescent Lighting for Hazardous and Hostile Locations Each XP Series fixture is individually tested for functional and dielectrical strength at the factory to assure quality and reliability and arrives assembled including reflectors, reducing installation time and cost. Fixture constructed of corrosion-resistant, copper-free aluminum alloy (less than 0.4% copper). Over-sized, finned ballast housing for 800 & 1500 mA fixtures provides greater heat dissipation and extended ballast life. Ballast housing easily accessible, externally mounted. Spring loaded sockets on both ends hold lamps firmly for maximum shock and vibration protection. Lamps included Class P, thermally protected and cold weather rated ballast is standard. -20° F starting supplied with 60-110 watt fixtures. 50° F starting supplied with 40 watt fixtures. Explosion-proof, impact and heat resistant glass tubes, provide lamp protection. Optional wire guard and/or clear polycarbonate shield available for additional security. Heavy gauge extruded aluminum reflectors (2.5 millimeters thick), with high gloss reflective finish. Resists dents and corrosion. Easy, quick removal for cleaning. Relamping can be done quickly from either end of the fixture. All lamp access covers are screw type and interchangeable, with “O-ring” seals. XP Series heavy duty fixtures are suitable for installation in environments where fire or explosion hazards may exist due to flammable gases or vapors, flammable liquids, combustible dust, ignitable fibers or flyings, as defined by ANSI/NFPA 70/NEC Article 500. These fixtures are also suitable for installation in wet locations and marine environments where equipment is subjected to salt water spray, either indoor or outdoor. 10 RIG-A-LITE FLOURESCENT XP Series Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed Catalog Number Logic XP 1 1 2 2 BASIC SERIES XP FLUORESCENT FIXTURE Class I, Division 1, Groups C & D Class I, Division 2, Groups C & D Class II, Division 1 and 2, Groups E, F & G Class III Simultaneous Presence NEMA 3, 4X, 7CD, 9EFG UL 1598, UL 1598A, UL 844 & UL 924 CSA Approved IP66 55°C Ambient Temp. (2 & 4 lamp) Class I, Zone 1, Groups IIA & IIB Class I, Zone 2, Groups IIA, IIB & IIC Suitable for Inside Paint Spray Booth LAMP CURRENT/LAMP WATTAGE 1500 = 1500mA, 110 Watt 800 = 800mA, 60 or 35 Watt 430 = 430mA, 34 or 20 Watt (export only) 425 = 425mA, 40 or 20 Watt (Slimline) 265 = 265mA, 17 or 32 Watt (T8 Lamp) 270 = 270mA, 40 Watt (Biaxial Lamp) T5 = T5, 28 Watt Lamp T5HO = T5HO, 54 Watt Lamp 3 5 4 3 6 NOMINAL FIXTURE LENGTH 2 = 2 Foot 4 = 4 Foot 4 NUMBER OF LAMPS 2L = 2 Lamp 3L = 3 Lamp 4L = 4 Lamp 5 VOLTAGE/FREQUENCY A = 120V 60HZ B = 236V 60HZ C = 277V 60HZ D = 220V 50HZ2 E = 12V DC F = 24V DC G = 32V DC H = 347V 60HZ U = 120 thru 277V 50/60 HZ N = 347 thru 480V 50/60 HZ 6 OPTIONS1 EM= Emergency Battery Backup F = Inline Fuse (External)3 R = Radio Interfereance Filter HL = High Lumen Ballast (T8 Only) 1Consult factory for pricing. available with 2 ft. H.O. 3 Fuse option not available for marine listed fixtures. 2Not Catalog logic is for explaining catalog number structure only. Not all combinations are possible; consult factory for catalog numbers not listed in charts. www.rigalite.com 11 FLUORESCENT Series XP XPSeries Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed Certification Guide CLASS II CLASS l DIVISION 1 SIMULTANEOUS AMBIENT DIVISION 1 GROUPS E, F & G PRESENCE UL XP SERIES °C GROUPS C & D CLASS III CLASS I & II 1598A CSA XP2652L 55 T6 T6 T6 YESYES XP2702L 55 T6 T6 T6 YESNO XP2703L 40 T6 T6 T6 YESNO XP2704L 55 T6 T6 T6 YESNO XP4252L 55 T4A T4A T4A YESYES XP4253L 40 T4A T4A T4A YESYES XP4254L 55 T4A T4A T4A YESYES XP4302L 55 T6 T6 T6 YESYES XP4303L 40 T6 T6 T6 YESYES XP4304L 55 T6 T6 T6 YESYES XP8002L 55 T6 T6 T6 YESYES XP8003L 40 T6 T6 T6 YESYES XP8004L 55 T6 T6 T6 YESYES XP15002L 55 T6 T6 T6 YESYES XP15003L 40 T6 T6 T6 YESYES XP15004L 55 T6 T6 T6 YESYES XPT5HO2L55 T6 T6 T6 YESYES XPT5HO3L 40 T6 T6 T6 YESYES XPT5HO4L 55 T6 T6 T6 YESYES 12 RIG-A-LITE FLUORESCENT XP Series Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed 2-Lamp XP • Class I, Division 1, Groups C and D; Class I, Division 2, Groups C and D; Class II, Division 1 and 2, Groups E, F and G; Class III • UL 844 for Hazardous Locations and use inside paint spray booths and rooms. Also meets requirements for NFPA Standard 33 and NEC Article 516 • Simultaneous Presence • UL 1598A Marine Outside Type • CSA Approved • Class I, Zone 1, Groups IIA and IIB • Class I, Zone 2, Groups IIA, IIB and IIC • Seismic tested by Structural Dynamics Research Corporation (full scale fragility qualification) tested in frequencies of 1 to 31.6 Hertz in 3-plane axis with maximum G force of 18.67 achieved • NEMA 3, 4X, 7CD, 9EFG (Lamps included) Description Two-Lamp Four Foot Fixture Two-Lamp Two Foot Fixture www.rigalite.com Hub Size (inches) Voltage Catalog Number 32 Watt, Instant Start, Medium Bi-Pin T8 48" 265mA 1/2 120-277V 50/60 HZ XP265-4-2L-U 34 Watt, Rapid Start F40T12 Medium Bi-Pin 430mA, 48" (export only) 1/2 120-277V 60 HZ XP430-4-2L-U 40 Watt, Instant Start F48T12, Slimline, Single Pin 425mA, 48" 1/2 12V DC 24V DC 32V DC XP425-4-2L-E XP425-4-2L-F XP425-4-2L-G 1/2 120-277V 50/60 HZ XP800-4-2L-U 110 Watt, Rapid Start, Very High Output, F48T12/VHO Recessed Double Contact 1500mA, 48" 1/2 120V/60 HZ 277V/60 HZ 220V/50 HZ XP1500-4-2L-A XP1500-4-2L-C XP1500-4-2L-D 54 Watt, T5 HO Miniature Bi-Pin 2 Lamp, 48" 1/2 120-277V 50/60 HZ XPT5HO-4-2LU 17 Watt, Instant Start, Medium Bi-Pin T-8 24" 265mA 1/2 120-277V 50/60 HZ XP265-2-2L-U 20 Watt, Rapid Start, F20T12 Medium Bi-Pin, 430mA, 24" (export only) 1/2 120-277V 60 HZ XP430-2-2L-U 20 Watt, Instant Start, F24T12 Slimline, Single Pin, 425mA, 24" 1/2 12V DC 24V DC 32V DC XP425-2-2L-E XP425-2-2L-F XP425-2-2L-G 35 Watt, Rapid Start, High Output F24T12/HO Recessed Double Contact 800mA, 24" 1/2 120-277V 50/60 HZ XP800-2-2L-U 60 Watt, Rapid Start, High Output, F48T12/HO Recessed Double Contact, 800mA, 48" 13 FLUORESCENT Series XP XPSeries Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed Candlepower Distribution XP265-4-2L Deg. Parl. 22.5 45 67.5 Fluorescent Photometrics Norm 0 1210 1210 1210 1210 1210 5 1210 1211 1210 1208 1208 15 1173 1177 1184 1191 1192 25 1088 1099 1116 1125 1129 35 963 983 1010 1032 1041 45 806 836 878 917 935 55 616 661 729 816 851 65 397 459 597 723 774 75 187 281 487 604 631 85 24 124 189 221 235 90 2 32 86 125 141 Coefficients of Utilization % Effective Ceiling Cavity Reflectance lcc % Wall Reflectance lw Room Cavity Ratio RCR 0 1 2 3 4 5 6 7 8 9 10 80 70 70 50 30 10 70 50 30 10 .83 .72 .64 .58 .52 .47 .44 .40 .37 .35 .32 503010 0 503010 503010 503010 0 .75.75.75 .61.59.56 .52.48.44 44 .40.36 .39.34.29 .34.29.25 .31.25.21 .28.22.18 .25.20.16 .23.18.14 .21 .16 .13 .72.72.72 .59.56.54 .49.46.43 .42.38.35 .37.33.29 .33.28.24 .29.25.21 .27.22.18 .24.19.16 .22.17.14 .20 .16 .12 .71 .53 .41 .33 .27 .23 .19 .16 .14 .12 .11 20% Effective Floor Cavity Reflectance .85 .74 .66 .60 .54 .49 .45 .42 .38 .36 .33 .85 .70 .59 .50 .44 .39 .34 .31 .28 .25 .23 .85 .65 .53 .43 .36 .31 .27 .24 .21 .19 .17 .85 .62 .47 .38 .31 .26 .22 .19 .16 .14 .13 .83 .68 .57 .49 .43 .38 .34 .30 .27 .25 .23 .83 .64 .52 .43 .36 .31 .27 .23 .21 .19 .17 .83 .60 .47 .37 .30 .26 .22 .19 .16 .15 .13 .79.79.79 .64.61.58 .54.50.45 .47.41.36 .41.35.30 .36.30.25 .32.26.21 .29.23.18 .26.20.16 .24.18.14 .22 .16 .13 2-Lamp Fixture Dimensions (inches) Dimensions (inches) XP SERIES A BC D 2-Lamp, 4 ft. Fixture (40, 60, 110 watt) 53 48.5 6.5 7 2-Lamp, 2 ft. Fixture (20 and 35 watt) 29 24.5 6.5 7 Boxed Weight Shipping Volume (Boxed Fixtures) 11.5 65 lbs. 4.7 cu. ft. 11.5 50 lbs. 3.1 cu. ft. E 14 RIG-A-LITE FLUORESCENT XP Series Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed 3-Lamp XP • Class I, Division 1, Groups C and D; Class I, Division 2, Groups C and D; Class II, Division 1 and 2, Groups E, F and G; Class III • UL 844 for Hazardous Locations and use inside paint spray booths and rooms. Also meets requirements for NFPA Standard 33 and NEC Article 516 • Simultaneous Presence • UL 1598A Marine Outside Type • CSA Approved • Zone 1, Groups IIA and IIB • Zone 2, Groups IIA, IIB and IIC • Seismic tested by Structural Dynamics Research Corporation (full scale fragility qualification) tested in frequencies of 1 to 31.6 Hertz in 3-plane axis with maximum G force of 18.67 achieved • NEMA 3, 4X, 7CD, 9EFG (Lamps included) Hub Size (inches) Voltage 3/4 120-277V 50/60 HZ 3/4 120-277V 50/60 HZ XP430-4-3L-U 60 Watt, Rapid Start, High Output, F48T12/HO Recessed Double Contact, 800mA, 48" 3/4 120-277V 50/60 HZ XP800-4-3L-U 110 Watt, Rapid Start, Very High Output, F48T12/VHO Recessed Double Contact, 1500mA, 48" 3/4 120V/60 HZ XP1500-4-3L-A 277V/60 HZ XP1500-4-3L-C 54 Watt, T5HO Miniature Bi-Pin 48" 3/4 120-277V 50/60 HZ XPT5HO-4-3L-U Description Three-Lamp Four Foot Fixture 32 Watt, Instant Start, Medium Bi-Pin, T8 265mA, 48" 34 Watt, Rapid Start F40T12, Medium Bi-Pin, 430mA, 48" (export only) Catalog Number XP265-4-3L-U 3-Lamp Fixture Dimensions (inches) Dimensions (inches) XP SERIES A 3-Lamp, 4 ft. Fixture (34, 60, 110 Watt) 53 BC 48.5 8.94 D 16.63 Boxed Weight 85 lbs. Shipping Volume (Boxed Fixtures) 10.5 cu. ft. Add 5/8 inch to fixture height and 1/4 inch to width when wire guard is used. www.rigalite.com 15 FLUORESCENT Series XP XPSeries Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed Fluorescent Photometrics Candlepower Distribution XP265-4-3L Deg. Parl. 22.5 45 67.5 Norm 0 1946 1946 1946 1946 1946 5 1943 1942 1939 1937 1936 15 1876 1877 1896 1918 1925 25 1736 1755 1814 1851 1859 35 1543 1593 1662 1700 1708 45 1294 1375 1436 1476 1496 55 990 1081 1159 1235 1246 65 613 710 820 789 760 75 245 353 350 279 248 85 13 30 35 38 37 90 0 0 0 0 0 Coefficients of Utilization % Effective Ceiling Cavity Reflectance lcc % Wall Reflectance lw Room Cavity Ratio RCR 0 1 2 3 4 5 6 7 8 9 10 80 70 70 50 30 10 70 50 30 10 .77 .69 .62 .56 .50 .46 .42 .39 .36 .33 .31 503010 0 503010 503010 503010 0 .70.70.70 .60.58.56 .51.48.45 .44.40.37 .39.34.31 .34.30.26 .31.26.22 .28.23.19 .25.20.17 .23.18.15 .21.16.13 .67.67.67 .58.56.55 .49.47.44 .43.39.36 .37.34.30 .33.29.26 .30.25.22 .27.22.19 .24.20.17 .22.18.15 .20.16.13 .66 .53 .43 .35 .29 .24 .21 .18 .15 .13 .12 20% Effective Floor Cavity Reflectance .79 .71 .64 .57 .52 .47 .43 .40 .37 .34 .32 .79 .67 .57 .50 .43 .38 .34 .30 .27 .25 .23 .79 .64 .52 .44 .37 .32 .27 .24 .21 .19 .17 .79 .61 .48 .39 .32 .27 .23 .20 .17 .15 .13 .77 .66 .56 .48 .42 .37 .33 .30 .27 .24 .22 .77 .63 .51 .43 .36 .31 .27 .24 .21 .19 .17 .77 .60 .47 .38 .32 .27 .23 .20 .17 .15 .13 .73.73.73 .63.60.58 .54.50.46 .46.42.38 .41.35.31 .36.30.26 .32.26.22 .29.23.19 .26.21.17 .24.19.15 .22.17.13 16 RIG-A-LITE FLUORESCENT XP Series Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed 4-Lamp XP • Class I, Division 1, Groups C and D; Class I, Division 2, Groups C and D; Class II, Division 1 and 2, Groups E, F and G; Class III • UL 844 for Hazardous Locations and use inside paint spray booths and rooms. Also meets requirements for NFPA Standard 33 and NEC Article 516 • Simultaneous Presence • UL 1598A Marine Outside Type • CSA Approved • Zone 1, Groups IIA and IIB • Zone 2, Groups IIA, IIB and IIC • Seismic tested by Structural Dynamics Research Corporation (full scale fragility qualification) tested in frequencies of 1 to 31.6 Hertz in 3-plane axis with maximum G force of 18.67 achieved • NEMA 3, 4X, 7CD, 9EFG (Lamps included) Hub Size (inches) Voltage Catalog Number 32 Watt, Instant Start, Medium Bi-Pin, T8 265mA, 48" 3/4 120-277V 50/60 HZ XP265-4-4L-U 34 Watt, Rapid Start, F40T12 Medium Bi-Pin, 430mA, 48" (export only) 3/4 120-277V 50/60 HZ XP430-4-4L-U 60 Watt, Rapid Start, High Output, F48T12/HO Recessed Double Contact, 800mA, 48" 3/4 120-277V 50/60 HZ XP800-4-4L-U 110 Watt, Rapid Start, Very High Output, F48T12/VHO Recessed Double Contact, 1500mA, 48" 3/4 120-277V 50/60 HZ XP1500-4-4L-U 54 Watt T5HO Miniature Bi-Pin 4 Lamp, 48" 3/4 120-277V 50/60 HZ XPT5HO-4-4L-U Description Four-Lamp Four Foot Fixture 4-Lamp Fixture Dimensions (inches) Dimensions (inches) XP SERIES A 4-Lamp, 4 ft. Fixture (40, 60, 110 watt) 53 www.rigalite.com BC 49.4 6.8 D 11.3 E 23.2 Boxed Weight Shipping Volume (Boxed Fixtures) 138 lbs. 10.8 cu. ft. 17 FLUORESCENT Series XP XPSeries Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed Candlepower Distribution XP265-4-4L Deg. Parl. 22.5 45 67.5 Fluorescent Photometrics Norm 0 2495 2495 2495 2495 2495 5 2492 2493 2494 2493 2495 15 2411 2420 2438 2452 2459 25 2229 2257 2293 2322 2333 35 1975 2021 2080 2136 2160 45 1642 1715 1810 1904 1945 55 1253 1355 1506 1692 1769 65 807 939 1233 1510 1615 75 371 574 991 1210 1262 85 43 225 303 354 374 90 2 38 99 148 165 Coefficients of Utilization % Effective Ceiling Cavity Reflectance lcc % Wall Reflectance lw Room Cavity Ratio RCR 0 1 2 3 4 5 6 7 8 9 10 80 70 70 50 30 10 70 50 30 10 .84 .74 .65 .59 .53 .48 .44 .41 .38 .35 .33 503010 0 503010 503010 503010 0 .77.77.77 .63.60.58 .53.49.45 .45.41.36 .40.34.30 .35.30.25 .31.26.22 .28.23.19 .26.20.16 .23.18.14 .22.16.13 .73.73.73 .60.58.56 .51.47.44 .43.39.36 .38.33.30 .34.29.25 .30.25.21 .27.22.19 .25.20.16 .23.18.14 .21.16.13 .72 .54 .42 .34 .28 .23 .20 .17 .15 .13 .11 20% Effective Floor Cavity Reflectance .86 .76 .67 .61 .55 .50 .46 .42 .39 .36 .34 .86 .71 .60 .51 .45 .39 .35 .31 .28 .26 .24 .86 .67 .54 .44 .37 .32 .28 .24 .21 .19 .17 .86 .63 .48 .39 .32 .26 .22 .19 .17 .15 .13 .84 .69 .58 .50 .44 .38 .34 .31 .28 .25 .23 .84 .65 .53 .43 .37 .31 .27 .24 .21 .19 .17 84 .62 .48 .38 .31 .26 .22 .19 .27 .15 .13 .80.80.80 .66.63.60 .56.51.46 .48.42.37 .42.35.31 .37.30.26 .33.27.22 .29.23.19 .27.21.17 .24.19.15 .22.17.13 18 RIG-A-LITE FLUORESCENT XP Series Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed 2-Lamp Biaxial XP • Class I, Division 1, Groups C and D; Class I, Division 2, Groups C and D; Class II, Division 1 and 2, Groups E, F and G; Class III • UL 844 for Hazardous Locations and use inside paint spray booths and rooms. Also meets requirements for NFPA Standard 33 and NEC Article 516 • Simultaneous Presence • UL 1598A Marine Outside Type • CSA Approved • Zone 1, Groups IIA and IIB • Zone 2, Groups IIA, IIB and IIC • Seismic tested by Structural Dynamics Research Corporation (full scale fragility qualification) tested in frequencies of 1 to 31.6 Hertz in 3-plane axis with maximum G force of 18.67 achieved • NEMA 3, 4X, 7CD, 9EFG Two-Lamp Two Foot Fixture Description Hub Size (inches) 40 Watt, Rapid Start Single Ended Biaxial 4 Pin, 270mA, 22 1/2" 1/2 (Lamps included) Voltage Catalog Number 120-277V 50/60 HZ XP270-2-2L-U 2-Lamp Fixture Dimensions (inches) www.rigalite.com 19 FLUORESCENT Series XP XPSeries Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed 3-Lamp Biaxial XP • Class I, Division 1, Groups C and D; Class I, Division 2, Groups C and D; Class II, Division 1 and 2, Groups E, F and G; Class III • UL 844 for Hazardous Locations and use inside paint spray booths and rooms. Also meets requirements for NFPA Standard 33 and NEC Article 516 • Simultaneous Presence • UL 1598A Marine Outside Type • CSA Approved • Zone 1, Groups IIA and IIB • Zone 2, Groups IIA, IIB and IIC • Seismic tested by Structural Dynamics Research Corporation (full scale fragility qualification) tested in frequencies of 1 to 31.6 Hertz in 3-plane axis with maximum G force of 18.67 achieved • NEMA 3, 4X, 7CD, 9EFG Three-Lamp Two Foot Fixture (Lamps included) Description Hub Size (inches) Voltage Catalog Number 40 Watt, Rapid Start Single Ended Biaxial 4 Pin, 270mA, 22 1/2" 3/4 120-277V 50/60 HZ XP270-2-3L-U 3-Lamp XP Series Dimensions (inches) XP SERIES Dimensions (inches) A BC 3-Lamp, 2 ft Fixture (Biaxial) 29 24.5 8.94 D 16.63 Boxed Weight Shipping Volume (Boxed Fixtures) 48 lbs. 5.5 cu. ft. Add 5/8 inch to fixture height and 1/4 inch to width when wire guard is used. 20 RIG-A-LITE FLUORESCENT XP Series Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed 4-Lamp Biaxial XP • Class I, Division 1, Groups C and D; Class I, Division 2, Groups C and D; Class II, Division 1 and 2, Groups E, F and G; Class III • UL 844 for Hazardous Locations and use inside paint spray booths and rooms. Also meets requirements for NFPA Standard 33 and NEC Article 516 • Simultaneous Presence • UL 1598A Marine Outside Type • CSA Approved • Zone 1, Groups IIA and IIB • Zone 2, Groups IIA, IIB and IIC • Seismic tested by Structural Dynamics Research Corporation (full scale fragility qualification) tested in frequencies of 1 to 31.6 Hertz in 3-plane axis with maximum G force of 18.67 achieved • NEMA 3, 4X, 7CD, 9EFG Four-Lamp Four Foot Fixture XP SERIES XP 4ft. SERIES 4-Lamp. Fixture (Biaxial) Description Hub Size (inches) Voltage Catalog Number 40 Watt, Rapid Start Single Ended Biaxial 4 Pin, 270mA, 22 1/2" 1/2 120-277V 50/60 HZ XP270-4-4L-U 4-Lamp. 4ft. Fixture (Biaxial) www.rigalite.com (Lamps included) A 53A 53 Dimensions(inches) BDimensions(inches) C D B C D 49.38 6.5 7 49.38 6.5 7 E 11.5 Boxed Shipping Volume E Weight (Boxed Fixtures) Boxed Shipping Volume Weight (Boxed Fixtures) 11.5 70 4.7 Cu.ft. 70 4.7 Cu.ft. 21 FLUORESCENT Series XP XPSeries Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed XP Series Emergency • Class I, Division 1, Groups C and D; Class I, Division 2, Groups C and D; Class II, Divisions 1 & 2, Groups E, F, and G; Class III • UL listed and labeled 1598, 844 and 924 • Emergency illumination exceeds NEC, NFPA Life Safety Code and UL 90 minute requirement • Factory-sealed • NEMA 3, 4X, 7CD, 9EFG: IP66 • Zone 1, Groups IIA and IIB • Zone 2, Groups IIA, IIB and IIC (Lamps included) Hub Size (inches) Voltage Catalog Number 34 Watt, Rapid Start F40T12 Medium Bi-Pin 430mA, 48" (export only) 1/2 120V/60 HZ 277V/60 HZ 220V/50 HZ XP430-4-2L-U-EM XP430-4-2L-U-EM XP430-4-2L-U-EM 60 Watt, Rapid Start, High Output F48T12 Recessed Double Contact, 800mA, 48" 1/2 120V-277V 50/60 HZ XP800-4-2L-U-EM 32 Watt, Instant Start Medium Bi-Pin T8 265mA, 48" 1/2 120V-277V 50/60 HZ XP265-4-2L-U-EM 54 Watt, Program Start, High Output T5HO Miniature Bi-Pin 48" 1/2 120V-277V 50/60 HZ XPT5HO-4-2L-U-EM 28 Watt, Program Start, T5, Miniature Bi-Pin 48" 1/2 120V-277V 50/60 HZ XPT5-4-2L-U-EM 34 Watt, Rapid Start F40T12 Medium Bi-Pin 430mA, 48" (export only) 1/2 120V/60 HZ 277V/60 HZ 220V/50 HZ XP430-4-3L-U-EM XP430-4-3L-U-EM XP430-4-3L-U-EM 60 Watt, Rapid Start, High Output F48T12 Recessed Double Contact, 800mA, 48" 1/2 120V-277V 50/60 HZ XP800-4-3L-U-EM 32 Watt, Instant Start Medium Bi-Pin T8 265mA, 48" 1/2 120V-277V 50/60 HZ XP265-4-3L-U-EM 54 Watt, Instant Start, High Output T5HO Miniature Bi-Pin 48" 1/2 120V-277V 50/60 HZ XPT5HO-4-3L-U-EM 28 Watt, Program Start, T5, Miniature Bi-Pin 48" 1/2 120V-277V 50/60 HZ XPT5-4-3L-U-EM Description Two Lamp Four Foot Emergency Fixture Three Lamp Four Foot Emergency Fixture 22 RIG-A-LITE FLUORESCENT XP Series Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed XP Series Emergency Fixture Dimensions (inches) XP SERIES 2-Lamp. 4ft. Emergency Fixture A 53 Dimensions(inches) B C D 49.38 6.5 7 E 11.5 Boxed Weight 70 Shipping Volume (Boxed Fixtures) 5.3 Cu.ft. Description/Features •Self-contained unitized construction •Explosion-proof housing, corrosion-resistant, copper-free aluminum •Contains sealed, maintenance-free high temperature rechargeable nickel cadmium battery charger and AC ballast •Explosion-proof test switch and charging indicator pilot light •Same fixture body as standard XP Series fixture allows the fixture to be used for both normal and emergency operation. Emergency mode does not affect normal fixture operation Operation Fixture operates normally on 120V, 277V 60HZ or 220V 50HZ as specified. When AC power fails, fixture automatically switches to the emergency mode, keeping one lamp illuminated, providing up to 1200 lumens for at least 90 minutes of safe egress lighting, regardless of type of lamps. When AC power is restored, the unit switches to charging mode and normal lighting resumes. The charging indicator light provides a visual indication that the battery is charging. www.rigalite.com 23 FLUORESCENT Series XP XPSeries Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed Accessories POLYCARBONATE SHIELDS STAINLESS STEEL GUARDS DESCRIPTION 2-Lamp 2-Ft. Fixtures 2-Lamp 4-Ft. Fixtures 3-Lamp 4-Ft. Fixtures CATALOG NUMBER 86321 86320 86345 Four Lamp Fixtures Require Two Cat. #86320 Guards Wall/Ceiling Mounting Kit Catalog Number: 53041 (For 2-lamp fixtures only) Shipping Weight: 5 lbs. Beam Mounting Kit Catalog Number: 53035 (For 2-lamp fixtures only) Shipping Weight: 5 lbs. 3-Lamp 2-Lamp 2-Lamp 3-Lamp DESCRIPTION 2-Ft. Fixtures 2-Ft. Fixtures 4-Ft. Fixtures 4-Ft. Fixtures CATALOG NUMBER 86000 86001 86002 86003* Four Lamp Fixtures Require Two Cat. #86002 Shields. *One 86345 guard required. Shock Mounting Kit Catalog Number: 53036 (For 2-lamp fixtures only) Shipping Weight: 5 lbs. Drop Mounting Kit Catalog Number: 53037 (For 2-lamp fixtures only) Shipping Weight: 5 lbs. Unistrut Mounting Kit Catalog Number: 53047 (For 4-lamp fixtures only) Shipping Weight: 5 lbs. 24 RIG-A-LITE FLUORESCENT XP Series Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed Typical Installations BEAM DROP SHOCK WALL OR CEILING www.rigalite.com 25 FLUORESCENT Series XP XPSeries Explosion Proof • Paint Spray Booth • UL 844 • UL 1598A Marine Outside Type • CSA Certified • Factory Sealed SWIVEL RIGID FLEXIBLE 26 RIG-A-LITE INSTALLATIONS DATA SHEET 53035 XP MOUNTING KIT – BEAM CLAMP (For XP Series Fluorescent Fixtures) Item No. Part No. 1 2 3 4 5 6 7 8 28297 28240 28203 26211 26029 28180 28209 10128 Description SCREW HEX HD 3/8-16 X 1 SPLIT LOCK WASHER 3/8 SCREW SQ HD 3/8-16 X 2-1/4 BEAM CLAMP BUSHING RE 1/2 NPT TO 3/8 SCREW HEX NUT 3/8-16 EYE BOLT 3/8-16 SAFETY CABLE Qty. 2 3 2 2 2 1 1 1 Rig-A-Lite 8500 Hansen Road. • P.O. Box 12942 • Houston, Texas 77217 Phone: (713) 943-0340 • Fax: (713) 943-8354 • E Mail: Info@rigalite.com Rig-A-Lite XP Series Mounting Kit 53048 Revised: 09/21/2010 INSTALLATION DATA SHEET XP SERIES WARNING! 1. TO PREVENT RISK OF ELECTRICAL SHOCK, DEACTIVATE/DISCONNECT POWER SUPPLY BEFORE INSTALLING MAINTAINING OR RELAMPING FIXTURE. 2. TO REDUCE THE RISK OF FIRE OR EXPLOSION, DO NOT INSTALL WHERE THE MARKED OPERATING TEMPERATURE EXCEEDS THE IGNITION TEMPERATURE OF THE HAZARDOUS ATMOSPHERE(S). 3. THIS FIXTURE SHOULD BE INSTALLED BY QUALIFIED TECHNICIANS IN STRICT ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE AND ANY LOCAL REQUIREMENTS. INSTALLATION: 1. Before installing, make sure that the circuit is deactivated. 2. This unit is furnished completely assembled. Before installing, check the fixture label to insure correct voltage and frequency. OPERATIONAL DATA: Operate this fixture at its rated voltage. See fixture label for data. To receive the full benefit of rated lamp output and to prolong ballast life, it is essential that voltage supply to the fixture be maintained within the following limits: NOMINAL VOLTAGE 120 220 236 277 APPLIED VOLTAGE RANGE MINIMUM MAXIMUM 110 125 205 232 220 250 255 290 MAINTENANCE: 1. Although no routine maintenance is required to keep this fixture functional, it should be checked periodically to ensure that it is working properly and to look for external damage. 2. For optimum performance, keep light transmission parts of the fixture clean. Any commercial glass cleaner can be used to clean the glass tubes. 3. To relamp, disconnect supply circuit. Remove the cover on either side of the fixture. Loosen lampholder bracket screws. Twist and remove lampholder bracket. Withdraw old lamp and insert new lamp in opposite lampholder. Replace lampholder into position on the lamp. Twist slightly to place lampholder bracket under screw heads and tighten screws. Replace cover. 4. An optional stainless steel wire guard, polycarbonate shield or both can be installed to protect the PYREX tubes. Refer to our catalog or www.rigalite.com for more information. 5. In the event of PYREX tube breakage, it will be necessary to replace the damaged unit with a factory sealed housing assembly in order to maintain fixture integrity. Refer to our catalog or www.rigalite.com for more information. 6. when replacing the ballast, it should be a Class P type offering thermal protection. Revised: 09/21/2010 INSTALLATION DATA SHEET XP SERIES WIRING DA~ ONE LAMP EMERGENCY OPERATION - SWITCHED FIXTURE ONE LAMP EMERGENCY OPERATION UNSWITCHED FIXTURE - r-.-::::::;: :: I I"'"'" V~ ... ... ... ... "'" ... ... "'" ... TWO-LAMP - UNSWITCHED FIXTURE r , ++ I;! !1 ~ I -~__I ~ I i, : EMERGENCY OPERATION r: rat T ~ : i : oG1 !:~ "'" . ,: CVlTCM 1~; i !!L I:,:~:: I l SWITCHED FIXTURE ~ ~I' l I~ :~:="Ili g~1 L EMERGENCY OPERATION v_ .J/L!1l~_fCJ#~tr I : TWo-LAMP r a...o.a: ~ s_~~._ V )IDIGT~; --.~ i ~ ! ! L ! I I: I : i 1 i M":' ~,--, I 1 ---~I . ! l -.... ITEM NO. PART 1 28076 30300 SCREW. HEX HD SS BREATHER 26097 HOUSING. EMERGENCY BALLAST TOP SCREW. RD HD. SS 2 3 4 5 NO. 28140 28246 DESCRIPTION WASHER. SPUT LOCK. SS ary. 28 1 1 5 5 1 6 7 02001 26002 BLST. FLOOR EMERGENCY 1201277\160HZ HOUSING. EMERGENCY BALLAST BOTTOM 8 26016 28007 BRACKET. MOUNTING ANGLE SCREW. HEX HD CDPL 2 10 11 26324 COlIER. SCREW CAP 5 34032 GASKET. COVER SEAL 12 23006 28246 REFLECtOR. EMERGENCY RHS WASHER SPUT LOCK. 55 5 1 28171 SCREW. SOCKET HD. 55 8 15 16 28089 SCREW. PAN HD. 55 82052 WIRE. TOP LAMP GUIDE 16 4 17 82051 18 44005 WIRE. LOWER LAMP GUIDE LAMP FLUOR 800MA 60W HO COOL WHITE 48" 19 26206 20 21 26207 LAMPHOLDER ASSEMBLY 18" LEAD LAMPHOLDER AND WIREWAY ASSEMBLY-n" 22 26017 26202 HOUSING ASSEMBLY (FACtORY SEALED) HOUSING. BALlAST BOTTOM 23 23007 REFLECtOR. EMERGENCY LHS 1 1 9 13 14 1 1 8 4 2 2 2 1 24 26197 25 02011 HOUSING. BALLAST lOP BALLAST, 800MA. 120V 60HZ (AC BALLAST) 1 1 26 27 30387 UNION. XP Yz MALEIFEMALE 1 30070 1 28 24002 NIPPLE. CONDUIT ALUMINUM PUSHBUTTON AND PILOT UGHT ASSEMBLY 29 30 28180 28240 NUT. HEX CDPL WASHER. SPUT LOCK CDPL 2 1 2 EMERGENCY FLUORESCENT LIGHTING FIXTURE · · · CLASS I DIVISION 1 & 2, GROUP C & D CLASS II DIVISION 1 & 2, GROUP E, F & G CLASS III INSTALLATION, OPERATION and MAINTENANCE MANUAL IMPORTANT SAFEGUARDS When using electrical equipment, basic safety precautions should always be followed including the following: . DANGER Do not install or service unless area is known to be nonhazardous. fixture has more than one power supply connection. This READ AND FOllOW All SAFETY INSTRUCTIONS BEFORE INSTAlliNG THIS FIXTURE 1. This fixture should be installed in strict accordance with the National Electrical Code and any local requirements. 2. This fixture should be mounted in locations and at heights where it will not readily be subjected to tampering by unauthorized personnel. 3. To prevent ignition of hazardous atmosphere, disconnect fixture from the supply circuit before opening. Keep tightly closed when in operation. When AC power is disconnected, the emergency ballast output will be live. 4. To prevent high voltage from being present on the Emergency Ballast output leads (Red and Yellow), do not join the battery connector until installation is complete and AC power is supplied to the fixture. 5. To reduce the risk of electrical shock, disconnect both normal and emergency power supplies and battery connector (located inside the Junction Box) before servicing. 6. Emergency ballast inside this fixture requires an unswitched AC power source of 120V, or 277V 60HZ. 220V 50HZ available, but does not carry the UL Listing. 7. Do not mount near gas or electric heaters. 8. Do not let power supply cords touch hot surfaces. 9. Do not attempt to service the battery inside the Emergency Ballast of this fixture. Emergency Ballast incorporates a sealed, no maintenance battery that is not field replaceable. Contact Rig-A-Lite Company for information on factory replacements. 10. The use of accessory equipment not recommended by Rig-A-Lite may cause unsafe conditions. 11. Do not use this equipment for other than intended use. 12. Installation and servicing of this fixture should be performed by qualified personnel. SAVE THESE INSTRUCTIONS WALL/CEILING MOUNT KIT Part Number 53041 Includes 2 brac~ets, 2 hex' head pipe thread screws, 1 safety chain and assorted screws. _ 1\ , I I I f-. DROP MOUNT KIT Part Number 53037 Includes 2 beam clamps, 2 universal shock mount assemblies, 1 eye bolt, 1 safety cable and assorted screws. I BEAM CLAMP MOUNT KIT Part Number 53035 Includes 2 beam clamps, 2 stud hex mounts, 1 eye bolt, 1 safety cable and assorted screws. SHOCK MOUNT KIT Part Number 53036 Includes 2 shock mount assemblies, 2 beam clamps, 1 eye bolt, 1 safety cable and assorted screws. ). ill 3. After installation is complete, supply AC power to the fixture, and join the battery connector. 4. A short term discharge test may be conducted after -the Emergency Ballast has been charging for 1/2 hour. Charge for one week before conducting a long term discharge test. OPERATION 1. Operate this fixture at its rated voltage. See fixture label for data. To receive full benefit of rated lamp output and to prolong ballast life, it is essential that voltage supply to the fixture be maintained within the following limits: NOMINAL VOLTAGE 120 220 277 OPERATION VOLTAGE MINIMUM MAXIMUM 110 125 205 232 255 290 2. The AC ballast in this fixture is designed to operate on Grounded Neutral Systems only. For Line Systems with neither of the line wires at Ground potential, specially designed ballast are required. 3. When AC power is applied, the charge indicator light is illuminated, indicating that the battery is being charged. When power fails, the Emergency Ballast within this fixture switches to emergency power, operating either 1 or 2 lamps at reduced illumination for at least 90 minutes. MAINTENANCE All maintenance procedures are to be performed only when the atmosphere surrounding the fixture is non-hazardous. 1. Although no routine maintenance is required to keep this fixture functional, it should be checked periodically to ensure that it is working. The following schedule is recommended: a. Visually inspect the charging indicator light monthly. It should be illuminated. b. Test the emergency operation of the fixture once every 3 months. Either 1 or 2 lamps should operate at reduced illumination. c. Conduct a 90 minute discharge test once a year. Either 1 or 2 lamps should operate at reduced illumination for at least 90 minutes. d. Remove breather and clean with dry compressed air (no oil or water in air line). Direct air stream from inside breather to outside once a year or more often if dusty conditions prevail. Reinstall, taking care not to damage threads. Make sure breather is wrench tight. 2. To relamp the fixture disconnect both normal and emergency power supplies and battery connector of the emergency ballast. Remove lamp compartment cover. Loosen lampholder bracket screws. Twist and remove lamp holder bracket. Remove lamp. Insert new lamp in opposite lampholder. Replace lampholder into position . on lamp. Twist slightly to place lampholder bracket under screw ~'.~. . heads, and tighten screws. Replace cover. ~ , 3. When replacing AC Ballast, it should be of Class-P Thermallyprotected type. INSTAllATION WARNING: To prevent high voltage from being present on the Emergency Ballast output leads (Red and Yellow), do not join the battery connector (located inside the Junction Box) until installation is complete and AC power is supplied to the fixture (See Illustration 1). This should be done only when the area is non-hazardous. NOTE: Before installing this fixture, make sure that the necessary branch circuit wiring is available. The Emergency Ballast in this fixture requires an unswitched source of power and must be fed from the same branch circuit as the AC ballast; therefore, in switched fixtures the Emergency Ballast must be connected ahead of any local switching (See Illustration 2). UNS\lITCHED nXTURE - oa' ~ """" F'lXTURE ;::;; I 8MYT I --, I - rig. Illustration , S\lITCHED A rig. B Illustration 2 1 -... - 1. This unit is furnished completely assembled. Before installing, check the fixture label to insure correct voltage and frequency. 2. Typical XP Series fixture installations are shown below: Dummy (non-powered) end lowers for relamping clearance which is required when fixtures are mounted in close proximity. Flexible mounting provides free swing and impact protection. 1. Splice Box/Fixture Hanger 2. Flexible Pendant Hanger 3. Union 4. Rigid Support 5. Support Hook Note: Leave extra links to support fixture in relamping positions. Dummy (non-powered) end lowers for relamping clearance which is required when fixtures are mounted in close proximity. 1. Splice Box/Fixture Hanger 2. Swivel Hanger 3. Union 4. Rigid Support 5. Support Hook 6. Conduit Nipple Note: Leave extra links to support fixture in relamping position. Rigid mounted - for installations where relamping can be accomplished without lowering dummy end. 1. Splice Box/Fixture Hanger 2. Union 3. Rigid Support , I. Revised: 09/21/2010 INSTALLATION DATA SHEET XP SERIES