Fundamentals of

circuits with contacts

Workbook

TP 1211

With CD-ROM

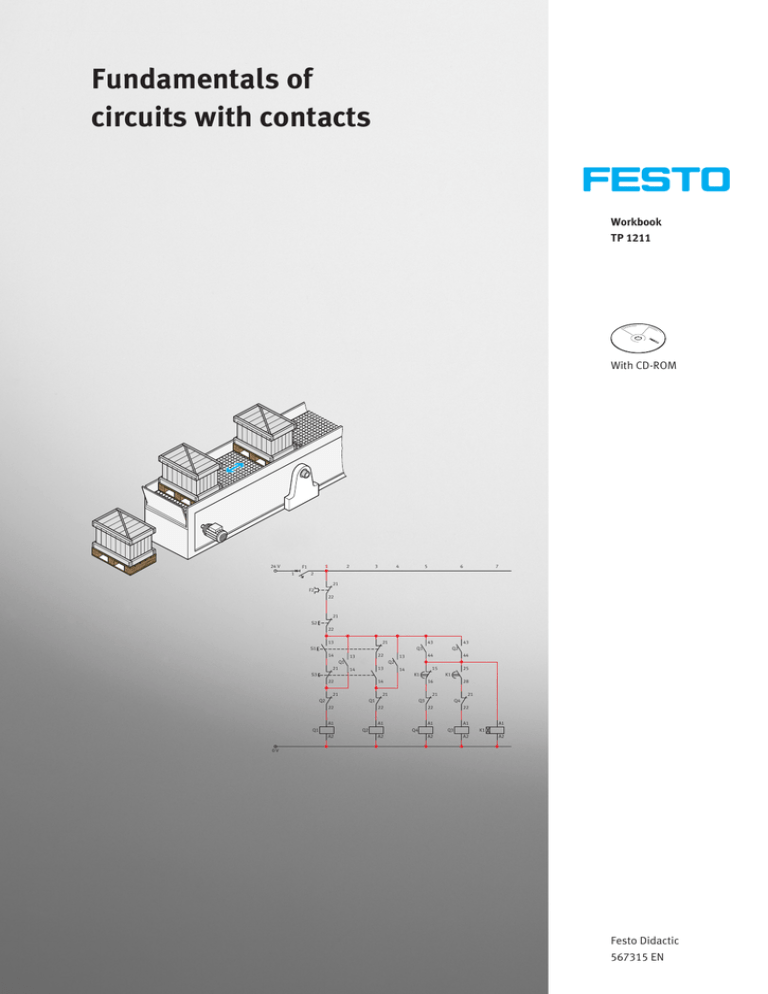

24 V

1

1

F1

2

3

4

5

6

7

2

21

F2

22

21

S2

22

13

S1

21

S3

Q1

13

22

14

13

22

Q2

Q1

21

14

14

21

Q1

22

A1

A2

Q2

Q1

Q2

14

K1

21

Q3

22

A1

A2

43

Q2

44

13

Q4

15

16

28

Q4

22

A1

25

K1

21

A2

43

44

Q3

21

22

A1

A2

K1

A1

A2

0V

Festo Didactic

567315 EN

Order number:

Revision level:

Author:

Editor:

Graphics:

Layout:

567315

09/2011

Jürgen Stumpp

Frank Ebel

Doris Schwarzenberger

10/2011, Frank Ebel

© Festo Didactic GmbH & Co. KG, 73770 Denkendorf, Germany, 2011

Internet: www.festo-didactic.com

E-mail: did@de.festo.com

The copying, distribution and utilization of this document as well as the communication of its contents to

others without expressed authorization is prohibited. Offenders will be held liable for the payment of

damages. All rights reserved, in particular the right to carry out patent, utility model or ornamental design

registration.

Table of contents

Use for intended purpose __________________________________________________________________ IV

Preface _________________________________________________________________________________ V

Introduction ____________________________________________________________________________ VII

Work instructions and safety precautions ____________________________________________________ VIII

Training package for fundamentals of circuits with contacts _____________________________________ IX

Learning objective _________________________________________________________________________X

Allocation of learning objectives per exercise __________________________________________________ XI

Equipment set __________________________________________________________________________ XIII

Allocation of components per exercise _______________________________________________________ XV

Notes for the teacher/trainer_______________________________________________________________ XVI

Structure of the exercises ________________________________________________________________ XVII

Component designations _________________________________________________________________ XVII

CD-ROM contents _______________________________________________________________________ XVIII

Exercises and solutions

Exercise 1: Commissioning a stirrer __________________________________________________________3

Exercise 2: Operating the stirrer via a self-holding circuit _______________________________________ 11

Exercise 3: Converting a drill press from switch to pushbutton operation for

clockwise/anti-clockwise rotation ________________________________________________ 19

Exercise 4: Connecting a pneumatic compressor via a star-delta contactor circuit ___________________ 29

Exercise 5: Connecting a pneumatic compressor via an automatic star-delta contactor circuit _________ 39

Exercise 6: Connecting a 3-phase drive to a reversing contactor circuit

with automatic star-delta start-up ________________________________________________ 47

Exercises and work sheets

Exercise 1: Commissioning a stirrer __________________________________________________________3

Exercise 2: Operating the stirrer via a self-holding circuit _______________________________________ 11

Exercise 3: Converting a drill press from switch to pushbutton operation for

clockwise/anti-clockwise rotation ________________________________________________ 19

Exercise 4: Connecting a pneumatic compressor via a star-delta contactor circuit ___________________ 29

Exercise 5: Connecting a pneumatic compressor via an automatic star-delta contactor circuit _________ 39

Exercise 6: Connecting a 3-phase drive to a reversing contactor circuit

with automatic star-delta start-up ________________________________________________ 47

© Festo Didactic GmbH & Co. KG 567315

III

Use for intended purpose

The training package for fundamentals of circuits with contacts may only be used:

For its intended purpose in teaching and training applications

When its safety functions are in flawless condition

The components included in the training package are laid out in accordance with the latest technology, as

well as recognised safety rules. Nevertheless, life and limb of the user and third parties may be endangered,

and the components may be impaired, if they are used improperly.

The training system from Festo Didactic has been developed and manufactured exclusively for training and

vocational education in the fields of automation and technology. The respective training companies and/or

trainers must ensure that all trainees observe the safety precautions which are described in this workbook.

Festo Didactic hereby excludes any and all liability for damages suffered by trainees, the training company

and/or any third parties, which occur during use of the equipment set in situations which serve any purpose

other than training and/or vocational education, unless such damages have been caused by Festo Didactic

due to malicious intent or gross negligence.

IV

© Festo Didactic GmbH & Co. KG 567315

Preface

Festo Didactic’s training system for automation technology is geared towards various educational

backgrounds and vocational requirements. The training system is therefore broken down as follows:

Technology oriented training packages

Mechatronics and factory automation

Process automation and control technology

Robotino® – training and research with mobile robots

Hybrid learning factories

The technology packages deal with various technologies including pneumatics, electropneumatics,

hydraulics, electrohydraulics, proportional hydraulics, programmable logic controllers, sensor technology,

electrical engineering and electric drives.

The modular design of the training system allows for applications which go above and beyond the

limitations of the individual packages. For example, PLC actuation of pneumatic, hydraulic and electric

drives is possible.

© Festo Didactic GmbH & Co. KG 567315

V

All training packages have the same, identical structure:

Hardware

Teachware

Software

Seminars

The hardware is comprised of industrial components and systems that are specially designed for training

purposes.

The structure of the teachware corresponds to that of the hardware. It includes:

Textbooks (with exercises and examples)

Workbooks (with practical exercises, supplementary instructions and solutions)

Exercise book (with practical exercises and supplementary explanations)

Transparencies and videos (for dynamic instruction)

The teaching and learning media are available in several languages. They’re intended for use in classroom

instruction, but are also suitable for self-study.

Where software is concerned, computer training programs, as well as simulation, visualisation, project

engineering, design engineering and programming software, are made available.

A wide range of seminar offerings covering the contents of the training packages complete the programme

for training and vocational education.

If you have any suggestions or feedback about this manual,

please send us an e-mail at did@de.festo.com.

The authors and Festo Didactic look forward to your comments.

VI

© Festo Didactic GmbH & Co. KG 567315

Introduction

This workbook is part of the training system for automation technology from Festo Didactic GmbH & Co. KG.

The system provides a solid basis for practice-oriented training and vocational education. Training package

TP 1211 deals with the subject of fundamentals of circuits with contacts.

Special emphasis is placed on the setup and function of the components, as well as their wiring and

adjustment.

A permanent workstation equipped with an A4 frame and a 400 V AC power supply are prerequisites for

setting up the circuits.

Each of the circuits for all 6 exercises is set up using the TP 1211 equipment set.

Data sheets for the individual components are also available (contactors, motor protection switches etc.).

© Festo Didactic GmbH & Co. KG 567315

VII

Work instructions and safety precautions

General

Trainees should only work with the circuits under the supervision of a trainer.

Observe specifications included in the data sheets for the individual components, and in particular all

safety instructions!

Faults which may impair safety must not be generated in the training environment and must be

eliminated immediately.

Mechanical setup

Mount all components on the A4 frame.

Adhere to the instructions regarding positioning of the components.

Electrical setup

Electrical connections must only be established and interrupted in the absence of voltage!

Only use connector cables with safety plugs for electrical connections.

Only pull the plug when disconnecting connector cables – never pull the cable.

VIII

© Festo Didactic GmbH & Co. KG 567315

Training package for fundamentals of circuits with contacts

The TP 1211 training package consists of a multitude of individual training materials. The subject of this

package is the fundamentals of circuits with contacts. Individual components included in the TP 1211

training package can also be included in other packages.

Important components of TP 1211

Permanent workstation with A4 frame

Equipment sets or individual components (e.g. contactors, motor protection switches, time relays,

auxiliary switching blocks)

Complete laboratory setups

Media

The teachware for the TP 1211 training package consists of a workbook. The workbook includes exercise

sheets for each of the 6 exercises, the solutions to each individual worksheet and a CD-ROM. A set of readyto-use exercise sheets and worksheets is included for each exercise.

Data sheets for the hardware components are made available along with the training package, and on the

CD-ROM.

You’ll find further training materials in our catalogue and on the Internet. The training system for automation

technology is continuously updated and expanded. Transparency sets, videos, CD-ROMs, DVDs and training

programmes as well as additional teachware, are offered in several languages.

© Festo Didactic GmbH & Co. KG 567315

IX

Learning objectives

Components

Become familiar with the setup and function of a pushbutton.

Become familiar with the difference between a pushbutton and a switch.

Become familiar with the difference between a normally open contact and a normally closed contact.

Become familiar with the setup and function of a contactor.

Become familiar with components used in primary circuits and control circuits.

Be able to connect and test a 3-phase socket.

Become familiar with the wiring and function of a time relay.

Become familiar with the wiring and function of an overcurrent trip.

Become familiar with the wiring and setup of an overcurrent trip in a star-delta contactor circuit.

Become familiar with the difference between an overcurrent trip and a motor protection switch.

Basic control circuits

X

Become familiar with inching operation.

Become familiar with the wiring and function of a self-holding circuit.

Become familiar with the wiring of an ON indicator and an OFF indicator.

Become familiar with the combination of a self-holding circuit with inching operation.

Become familiar with the wiring of normally open and normally closed contacts at several actuation

points.

Become familiar with the problems associated with a reversing contactor circuit.

Become familiar with wiring of the primary circuit for a reversing contactor circuit.

Become familiar with the reason for interlocking the two contactors (contactor interlocking).

Become familiar with the reason for a second interlock (pushbutton interlocking).

Become familiar with reversing the direction of rotation via OFF.

Become familiar with direct reversal of the direction of rotation.

Become familiar with the prerequisites for star-delta start-up.

Become familiar with the layout of a 3-phase motor for star-delta start-up using 230 V/400 V mains

power supply.

Become familiar with wiring of the primary circuit for a star-delta contactor circuit.

Become familiar with the designations of the three contactors used.

Become familiar with the reason for interlocking with star-delta start-up.

Become familiar with the control circuit for a manually operated star-delta contactor circuit.

Become familiar with the control circuit for an automatic star-delta contactor circuit.

Become familiar with the most important disadvantage of star-delta start-up.

Become familiar with the setup and function of the primary circuit of a reversing contactor circuit with

automatic star-delta start-up.

Become familiar with the setup and function of the control circuit of a reversing contactor circuit with

automatic star-delta start-up.

© Festo Didactic GmbH & Co. KG 567315

Allocation of learning objectives per exercise

Exercise

1

2

3

4

5

6

Learning objectives

Become familiar with the setup and function of a pushbutton.

•

Become familiar with the difference between a pushbutton and a switch.

•

Become familiar with the difference between a normally open contact and a normally closed

contact.

•

Become familiar with the setup and function of a contactor.

•

Become familiar with inching operation.

•

Become familiar with components used in primary circuits and control circuits.

•

Become familiar with the wiring and function of a self-holding circuit.

•

Become familiar with the wiring of an ON indicator and an OFF indicator.

•

Become familiar with the combination of a self-holding circuit with inching operation.

•

Become familiar with the wiring of normally open and normally closed contacts at several

actuation points.

•

Become familiar with the problems associated with a reversing contactor circuit.

•

Become familiar with wiring of the primary circuit for a reversing contactor circuit.

•

Be able to connect and test a 3-phase socket.

•

Become familiar with the reason for interlocking the two contactors (contactor interlocking).

•

Become familiar with the reason for a second interlock (pushbutton interlocking).

•

Become familiar with reversing the direction of rotation via OFF.

•

Become familiar with direct reversal of the direction of rotation.

•

Become familiar with the prerequisites for star-delta start-up.

Become familiar with the layout of a 3-phase motor for star-delta start-up using 230 V/400 V

mains power supply.

•

•

Become familiar with wiring of the primary circuit for a star-delta contactor circuit.

•

Become familiar with the designations of the three contactors used.

•

Become familiar with the reason for interlocking with star-delta start-up.

•

Become familiar with the control circuit for a manually operated star-delta contactor circuit.

•

© Festo Didactic GmbH & Co. KG 567315

XI

Exercise

1

2

3

4

5

6

Learning objectives

XII

Become familiar with the wiring and function of a time relay.

•

Become familiar with the wiring and function of an overcurrent trip.

•

Become familiar with the wiring and setup of an overcurrent trip in a star-delta contactor circuit.

•

Become familiar with the difference between an overcurrent trip and a motor protection switch.

•

Become familiar with the control circuit for an automatic star-delta contactor circuit.

•

Become familiar with the most important disadvantage of star-delta start-up.

•

Become familiar with the setup and function of the primary circuit of a reversing contactor

circuit with automatic star-delta start-up.

•

Become familiar with the setup of the control circuit of a reversing contactor circuit with

automatic star-delta start-up.

•

© Festo Didactic GmbH & Co. KG 567315

Equipment set

The equipment set for fundamentals of circuits with contacts imparts knowledge about the use of contactors

for controlling electrical machines. The equipment set includes all the components which are necessary for

mastering the specified learning objectives, and can be supplemented with any other equipment sets. A

laboratory workstation, optionally with A4 frame, and 400 V AC electrical supply power are also required in

order to set up functional circuits.

Equipment set for fundamentals of circuits with contacts, order number 571811

Component

Order no.

Quantity

3-phase power supply

571812

1

24 V power supply unit

571813

1

Contactor board

571814

1

Contactor set for motor technology

571816

1

Operator and signalling unit

571815

1

Overview of contactor set for motor technology, order number 571816

Component

Quantity

Circuit breaker, single pole

1

Circuit breaker, 3-pole

1

Motor protection switch, 0.35 to 0.5 A with auxiliary switch, 1 NO and 1 NC contact

1

Motor protection relay (overload relay), 0.35 to 0.5 A

1

Power contactor, 4 kW

4

Auxiliary switching block for power contactor, 4 kW

4

Overvoltage limiter

4

Multi-function time relay

1

Relay including socket

3

© Festo Didactic GmbH & Co. KG 567315

XIII

Graphic symbols, equipment set

Component

Graphic symbol

Circuit breaker, single pole

1

F1

2

Circuit breaker, 3-pole

1

3

5

2

4

6

F1

R1

Overvoltage limiter

U

1

3

5

13

I>

2

I>

4

I>

6

14

1

3

5

2

4

6

21

Q1

22

STOP

TEST

Motor protection relay (overload relay)

RESET

Motor protection switch with auxiliary switch, 1 NO and

1 NC contact

95

97

F1

Power contactor, 4 kW, with auxiliary switching block,

2 NO and 2 NC contacts

Multi-function time relay

(described function: star-delta)

98

96

A1

1

3

5

13

A2

2

4

6

14

21

31

43

Q1

17

A3

A1

22

32

44

27

K1

18

A2

Relays

A1

13

23

A2

14

24

28

31

41

K1

Operating units

3

S1

1

S2

4

42

32

3

S3

2

4

Indicators

P1

XIV

© Festo Didactic GmbH & Co. KG 567315

Allocation of components per exercise

Exercise

1

2

3

4

5

6

Circuit breaker, single pole, A, 4 A

1

1

1

1

1

1

Circuit breaker, 3-pole, C, 4 A

1

1

1

1

1

1

1

1

Component

Motor protection switch, 0.35 to 0.5 A

Motor protection relay (overload relay), 0.35 to 0.5 A

Power contactor, 4 kW

1

1

Auxiliary switching block for power contactor, 4 kW

Overvoltage limiter

1

1

2

3

3

4

1

2

3

3

4

1

2

3

3

4

1

1

Multi-function time relay

Contactor board

1

1

1

1

1

1

Operator and signalling unit

1

1

1

1

1

1

24 V power supply unit

1

1

1

1

1

1

3-phase power supply

1

1

1

1

1

1

Note

You will need one of the following for use as an electrical machine for all the exercises, for example:

a 3-phase asynchronous motor, 400/690 V (order number 571875)

or

a MPS transfer line MT AC400 (order number C93104)

© Festo Didactic GmbH & Co. KG 567315

XV

Notes for the teacher/trainer

Learning objectives

The basic learning objective of this workbook is to become familiar with fundamental control circuits and

their practical setup. The combination of both theory and practice ensures faster progress and longer-lasting

learning. The more specific learning objectives are documented in the matrix. Concrete, individual learning

objectives are assigned to each exercise.

Required time

The time required for working through the exercises depends on the learner’s previous knowledge of the

subject matter. For apprentices in the field of electrical installation this is approx. 1 week. For a skilled

worker it is approx. 2 days.

Equipment set components

The workbook and the equipment set match each other. Only the components included in one TP 1211

equipment set are required for all 6 exercises.

Standards

The following standards are used in this workbook:

EN 60617-2 to

EN 60617-8:

Graphical symbols for circuit diagrams

EN 61346-2:

Industrial systems, installations and equipment and industrial products –

Structuring principles and reference designations

Identification within the workbook

Solutions and supplements in graphics or diagrams appear in red.

Designations in the worksheets

Texts which require completion are identified with a grid or grey table cells.

Graphics which require completion include a grid.

Training notes

These provide additional information about the individual components and circuits. These notes are not

included in the worksheets.

XVI

© Festo Didactic GmbH & Co. KG 567315

Structure of the exercises

All 6 exercises have the same structure and can be broken down into:

Title

Learning objectives

Presentation of the problem

Layout

Project assignment

Work aides

Worksheets

The workbook contains the solutions to each worksheet.

Component designations

The components are designated in circuit diagrams in accordance with the EN 61346-2 standard. Letters are

assigned depending on component type. Consecutive numbers are assigned if several components of the

same type are included within a single circuit.

Relays:

Switches/pushbuttons:

Contactors:

Fuses:

Signal devices:

K, K1, K2 etc.

S, S1, S2 etc.

Q, Q1, Q2 etc.

F, F1, F2 etc.

P, P1, P2 etc.

© Festo Didactic GmbH & Co. KG 567315

XVII

CD-ROM contents

The workbook is included on the CD-ROM as a PDF file. The CD-ROM also provides you with additional

media.

The CD-ROM contains the following folders:

Operating instructions

Images

Data sheets

Product information

Operating instructions

Operating instructions for various components included in the training package are available. These

instructions are helpful when using and commissioning the components.

Images

Photos and graphics of components and industrial applications are made available. These can be used to

illustrate individual tasks or to supplement project presentations.

Data sheets

The data sheets for the components included in the training package are available as PDF files.

Product information

The manufacturer’s product information is provided for selected components. The representations and

descriptions of the components in this format are intended to demonstrate how they are presented in an

industrial catalogue. Additional information regarding the components is also included here.

XVIII

© Festo Didactic GmbH & Co. KG 567315

Table of contents

Exercises and solutions

Exercise 1: Commissioning a stirrer __________________________________________________________3

Exercise 2: Operating the stirrer via a self-holding circuit _______________________________________ 11

Exercise 3: Converting a drill press from switch to pushbutton operation for

clockwise/anti-clockwise rotation ________________________________________________ 19

Exercise 4: Connecting a pneumatic compressor via a star-delta contactor circuit ___________________ 29

Exercise 5: Connecting a pneumatic compressor via an automatic star-delta contactor circuit _________ 39

Exercise 6: Connecting a 3-phase drive to a reversing contactor circuit

with automatic star-delta start-up ________________________________________________ 47

© Festo Didactic GmbH & Co. KG 567315

1

Table of contents

2

© Festo Didactic GmbH & Co. KG 567315

Exercise 1

Commissioning a stirrer

Learning objectives

After completing this exercise:

You’ll be familiar with the setup and function of a pushbutton.

You’ll be familiar with the difference between a pushbutton and a switch.

You’ll be familiar with the difference between a normally open contact and a normally closed contact.

You’ll be familiar with the setup and function of a contactor.

You’ll be familiar with inching operation.

You’ll be able to identify the components used in primary circuits and control circuits.

Presentation of the problem

Two liquids are fed into a container and are mixed with the help of a stirrer. The stirrer is powered by a

3-phase motor. The 3-phase motor is run in inching mode operation.

You’ll need to select a suitable pushbutton and a contactor for controlling the motor.

Layout

Stirrer with drive unit

© Festo Didactic GmbH & Co. KG 567315

3

Exercise 1 – Commissioning a stirrer

1.

2.

3.

4.

5.

Assignments

Describe the function of a pushbutton and of a switch.

Describe the setup of a contactor.

Draft a contactor circuit for controlling a 3-phase motor and set it up.

Identify the components in the circuit setup.

Connect an asynchronous 3-phase motor with squirrel-cage rotor.

Work aides

Technical books, books of tables

Excerpts from manufacturers’ catalogues

Data sheets

Internet

Warning

Electrical connections must only be established and interrupted in the absence of voltage!

Comply with protection against accidental contact during the function test.

4

© Festo Didactic GmbH & Co. KG 567315

Exercise 1 – Commissioning a stirrer

Function and circuit symbol of a pushbutton and of a switch

–

–

–

–

Describe the function of a pushbutton (NO).

Describe the function of a pushbutton (NC).

Describe the function of a switch (NO).

List typical applications for each component.

3

1

4

2

3

4

Circuit symbols for pushbutton (NO), pushbutton (NC) and switch

Pushbutton (NO)

• Function

•

When the normally open pushbutton is actuated the contacts are closed and they remain closed

until the pushbutton is released. When the pushbutton is released, the contacts return to their

initial position and the circuit is interrupted (neutral position).

Applications

Actuating contactors, solenoid valves and controllers in general, ON pushbuttons.

Pushbutton (NC)

• Function

•

When the normally closed pushbutton is actuated the contacts are opened, and they remain open

until the pushbutton is released. When the pushbutton is released, the contacts return to their

initial position and the circuit is closed (neutral position).

Applications

Actuating contactors, solenoid valves and controllers in general, OFF pushbuttons.

Switch (NO)

• Function

•

When the switch is actuated the contacts are closed and they remain closed even after the switch

is released. When the switch is actuated once again, the contacts are opened and they remain

open. ON/OFF switching function.

Applications

Light switches, ON/OFF switches in general, control switches.

© Festo Didactic GmbH & Co. KG 567315

5

Exercise 1 – Commissioning a stirrer

–

Describe the difference between a pushbutton and a switch.

The pushbutton changes the status of its contacts when it’s actuated. When released, the pushbutton

returns to its initial position automatically (NO is re-opened, NC is re-closed).

When the switch is actuated, it’s detented in the actuated position and remains there (ON or OFF

position) until it’s actuated once again (ON/OFF switching function).

Layout of a contactor

1

2

1

3

A1

1

3

5

A2

2

4

6

2

4

7

A2

A1

6

5

Schematic diagram and circuit symbol for a contactor

Designations

Contactor coil with terminals A1 and A2.

Fixed iron core – is magnetised when the contactor coil is connected to nominal voltage (230 V, 24 V).

Moving iron coil – is attracted by the magnetised fixed iron core.

Moving contact with mechanical connection to the moving iron core.

Fixed contact to terminals 1 and 2 (NO contact).

Return spring – pushes moving iron core back to its initial position after magnetisation is deactivated.

Spring for spring loaded mounting of the moving contact – contact pressure increases when the

contactor is picked up.

6

© Festo Didactic GmbH & Co. KG 567315

Exercise 1 – Commissioning a stirrer

–

Match up the individual components with the correct designations.

Item

Designation

1

Spring for spring loaded mounting of the moving contact – contact pressure increases when the contactor is picked up.

2

Moving contact with mechanical connection to the moving iron core.

3

Fixed contact to terminals 1 and 2 (NO contact).

4

Moving iron core – is attracted by the magnetised fixed iron core.

5

Fixed iron core – is magnetised when the contactor coil is connected to nominal voltage (230 V, 24 V).

6

Contactor coil with terminals A1 and A2.

7

Return spring – pushes moving iron core back to its initial position after magnetisation is deactivated.

Planning and setting up a primary circuit and a control circuit

The 3-phase motor for the stirrer must be commissioned.

–

–

–

Complete the primary circuit for motor connection and enter the designations as they are specified in

the standards.

Complete the control circuit for inching operation (motor only runs as long as the pushbutton is pressed

and held).

Set up the circuit and test it for correct functioning.

Warning

Make sure that the circuit is switched off during setup!

Caution

Make sure that voltages and wiring are correct when connecting the contactor and the motor.

© Festo Didactic GmbH & Co. KG 567315

7

Exercise 1 – Commissioning a stirrer

Contactor circuit with inching operation

–

Complete the primary circuit and the control circuit for inching operation.

24 V

F1

L1

L2

L3

1

2

3

4

5

6

1

F2

1

2

13

S1

N

14

PE

A1

Q1

1

3

5

2

4

6

A2

Q1

0V

M1

3

M

Primary circuit for the contactor circuit

Control circuit for the contactor circuit

Identification of components in the primary and control circuits

Fuses, coil terminals, protective earth conductor, main contacts, pushbutton, contactor

–

8

Match the individual components with the correct designations.

Designation

Component

Q1

Contactor

1, 2, 3, 4, 5, 6

Main contacts

S1

Pushbutton

PE

Protective conductor

F1, F2

Fuses

A1, A2

Coil terminals

© Festo Didactic GmbH & Co. KG 567315

Exercise 1 – Commissioning a stirrer

Equipment list

In addition to the circuit diagram, complete project documentation also includes an equipment list.

–

Create an equipment list by entering the required number of components and the abbreviations used to

identify them in the circuit diagram in the table below.

Quantity

Identification

Designation

1

F1

Circuit breaker, 3-pole

1

Q1

Power contactor, 4 kW

1

M1

3-phase asynchronous motor

Quantity

Identification

Designation

1

F2

Circuit breaker, single pole

1

S1

Pushbutton (NO)

1

Q1

Power contactor, 4 kW

Primary circuit

Control circuit

© Festo Didactic GmbH & Co. KG 567315

9

Exercise 1 – Commissioning a stirrer

Connecting a 3-phase asynchronous motor with squirrel-cage rotor

A 3-phase asynchronous motor with squirrel-cage rotor can be wired in either star or delta configuration.

–

Complete the circuits for the windings in both star and delta configuration.

L1

L2

L1

L3

L2

L3

V1

U2

V1

V2

U2

W2

U1

U1

W2

W1

Star circuit

–

W1

Delta circuit

Fill in the locations of the jumpers on the terminal board for both star and delta configuration.

Star circuit

10

V2

U1

V1

W1

U1

V1

W1

U1

V1

W1

U1

V1

W1

W2

U2

V2

U2

V2

W2

W2

U2

V2

U2

V2

W2

Delta circuit

© Festo Didactic GmbH & Co. KG 567315

Table of contents

Exercises and work sheets

Exercise 1: Commissioning a stirrer __________________________________________________________3

Exercise 2: Operating the stirrer via a self-holding circuit _______________________________________ 11

Exercise 3: Converting a drill press from switch to pushbutton operation for

clockwise/anti-clockwise rotation ________________________________________________ 19

Exercise 4: Connecting a pneumatic compressor via a star-delta contactor circuit ___________________ 29

Exercise 5: Connecting a pneumatic compressor via an automatic star-delta contactor circuit _________ 39

Exercise 6: Connecting a 3-phase drive to a reversing contactor circuit

with automatic star-delta start-up ________________________________________________ 47

© Festo Didactic GmbH & Co. KG 567315

1

2

© Festo Didactic GmbH & Co. KG 567315

Exercise 1

Commissioning a stirrer

Learning objectives

After completing this exercise:

You’ll be familiar with the setup and function of a pushbutton.

You’ll be familiar with the difference between a pushbutton and a switch.

You’ll be familiar with the difference between a normally open contact and a normally closed contact.

You’ll be familiar with the setup and function of a contactor.

You’ll be familiar with inching operation.

You’ll be able to identify the components used in primary circuits and control circuits.

Presentation of the problem

Two liquids are fed into a container and are mixed with the help of a stirrer. The stirrer is powered by a

3-phase motor. The 3-phase motor is run in inching mode operation.

You’ll need to select a suitable pushbutton and a contactor for controlling the motor.

Layout

Stirrer with drive unit

© Festo Didactic GmbH & Co. KG 567315

3

Exercise 1 – Commissioning a stirrer

1.

2.

3.

4.

5.

Assignments

Describe the function of a pushbutton and of a switch.

Describe the setup of a contactor.

Draft a contactor circuit for controlling a 3-phase motor and set it up.

Identify the components in the circuit setup.

Connect an asynchronous 3-phase motor with squirrel-cage rotor.

Work aides

Technical books, books of tables

Excerpts from manufacturers’ catalogues

Data sheets

Internet

Warning

Electrical connections must only be established and interrupted in the absence of voltage!

Comply with protection against accidental contact during the function test.

4

Name: __________________________________ Date: ____________

© Festo Didactic GmbH & Co. KG 567315

Exercise 1 – Commissioning a stirrer

Function and circuit symbol of a pushbutton and of a switch

–

–

–

–

Describe the function of a pushbutton (NO).

Describe the function of a pushbutton (NC).

Describe the function of a switch (NO).

List typical applications for each component.

3

4

1

2

3

4

Circuit symbols for pushbutton (NO), pushbutton (NC) and switch

Pushbutton (NO)

Function

Applications

Pushbutton (NC)

Function

Applications

Switch (NO)

Function

Applications

© Festo Didactic GmbH & Co. KG 567315

Name: __________________________________ Date: ____________

5

Exercise 1 – Commissioning a stirrer

–

Describe the difference between a pushbutton and a switch.

Layout of a contactor

1

2

1

3

A1

1

3

5

A2

2

4

6

2

4

7

A2

A1

6

5

Schematic diagram and circuit symbol for a contactor

Designations

Contactor coil with terminals A1 and A2.

Fixed iron core – is magnetised when the contactor coil is connected to nominal voltage (230 V, 24 V).

Moving iron coil – is attracted by the magnetised fixed iron core.

Moving contact with mechanical connection to the moving iron core.

Fixed contact to terminals 1 and 2 (NO contact).

Return spring – pushes moving iron core back to its initial position after magnetisation is deactivated.

Spring for spring loaded mounting of the moving contact – contact pressure increases when the

contactor is picked up.

6

Name: __________________________________ Date: ____________

© Festo Didactic GmbH & Co. KG 567315

Exercise 1 – Commissioning a stirrer

–

Match up the individual components with the correct designations.

Item

Designation

1

2

3

4

5

6

7

Planning and setting up a primary circuit and a control circuit

The 3-phase motor for the stirrer must be commissioned.

–

–

–

Complete the primary circuit for motor connection and enter the designations as they are specified in

the standards.

Complete the control circuit for inching operation (motor only runs as long as the pushbutton is pressed

and held).

Set up the circuit and test it for correct functioning.

Warning

Make sure that the circuit is switched off during setup!

Caution

Make sure that voltages and wiring are correct when connecting the contactor and the motor.

© Festo Didactic GmbH & Co. KG 567315

Name: __________________________________ Date: ____________

7

Exercise 1 – Commissioning a stirrer

Contactor circuit with inching operation

–

Complete the primary circuit and the control circuit for inching operation.

24 V

L1

L2

L3

1

2

3

4

5

6

13

N

14

PE

A1

1

3

5

2

4

6

A2

0V

3

M

Primary circuit for the contactor circuit

Control circuit for the contactor circuit

Identification of components in the primary and control circuits

Fuses, coil terminals, protective earth conductor, main contacts, pushbutton, contactor

–

Match the individual components with the correct designations.

Designation

Component

Q1

1, 2, 3, 4, 5, 6

S1

PE

F1, F2

A1, A2

8

Name: __________________________________ Date: ____________

© Festo Didactic GmbH & Co. KG 567315

Exercise 1 – Commissioning a stirrer

Equipment list

In addition to the circuit diagram, complete project documentation also includes an equipment list.

–

Create an equipment list by entering the required number of components and the abbreviations used to

identify them in the circuit diagram in the table below.

Quantity

Identification

Designation

Circuit breaker, 3-pole

Power contactor, 4 kW

3-phase asynchronous motor

Primary circuit

Quantity

Identification

Designation

Circuit breaker, single pole

Pushbutton (NO)

Power contactor, 4 kW

Control circuit

© Festo Didactic GmbH & Co. KG 567315

Name: __________________________________ Date: ____________

9

Exercise 1 – Commissioning a stirrer

Connecting a 3-phase asynchronous motor with squirrel-cage rotor

A 3-phase asynchronous motor with squirrel-cage rotor can be wired in either star or delta configuration.

–

Complete the circuits for the windings in both star and delta configuration.

V1

U2

V1

V2

U2

W2

U1

V2

W2

U1

Star circuit

–

Delta circuit

Fill in the locations of the jumpers on the terminal board for both star and delta configuration.

Star circuit

10

W1

W1

U1

V1

W1

U1

V1

W1

U1

V1

W1

U1

V1

W1

W2

U2

V2

U2

V2

W2

W2

U2

V2

U2

V2

W2

Delta circuit

Name: __________________________________ Date: ____________

© Festo Didactic GmbH & Co. KG 567315