Renmark Hazardous Location Classifications

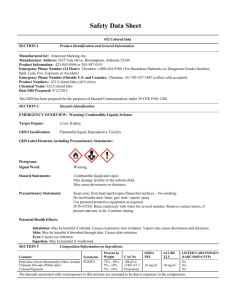

advertisement

HAZARDOUS LOCATION CLASSIFICATIONS *Information obtained from Underwriters Laboratory www.ul.com CLASS I: FLAMMABLE GASES, VAPORS OR LIQUIDS ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Area Classification Comparison ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Division 1 Where ignitable concentrations of flammable gases, vapors or liquids can exist all of the time or some of the time under normal operating conditions. Zone 0 Where ignitable concentrations of flammable gases, vapors or liquids are present continuously or for long periods of time under normal operating conditions. Zone 1 Where ignitable concentrations of flammable gases, vapors or liquids are likely to exist under normal operating conditions. Division 2 Where ignitable concentrations of flammable gases, vapors or liquids are not likely to exist under normal operating conditions. Zone 2 Where ignitable concentrations of flammable gases, vapors or liquids are not likely to occur under normal operating conditions and if they do occur, will exist only for a short periods of time. Class I, Division 1 A Class I, Division 1 location is a location: • In which ignitable concentrations of flammable gases, flammable liquid–produced vapors, or combustible liquid–produced vapors can exist under normal operating conditions, or • In which ignitable concentrations of such flammable gases, flammable liquid–produced vapors, or combustible liquids above their flash points may exist frequently because of repair or maintenance operations or because of leakage, or • In which breakdown or faulty operation of equipment or processes might release ignitable concentrations of flammable gases, flammable liquid–produced vapors, or combustible liquid–produced vapors and might also cause simultaneous failure of electrical equipment in such a way as to directly cause the electrical equipment to become a source of ignition. *Information obtained from Underwriters Laboratory www.ul.com Class I, Division 2 A Class I, Division 2 location is a location: • In which volatile flammable gases, flammable liquid–produced vapors, or combustible liquid– produced vapors are handled, processed, or used, but in which the liquids, vapors, or gases will normally be confined within closed containers or closed systems from which they can escape only in case of accidental rupture or breakdown of such containers or systems or in case of abnormal operation of equipment, or • In which ignitable concentrations of flammable gases, flammable liquid–produced vapors, or combustible liquid–produced vapors are normally prevented by positive mechanical ventilation and which might become hazardous through failure or abnormal operation of the ventilating equipment, or • That is adjacent to a Class I, Division 1 location, and to which ignitable concentrations of flammable gases, flammable liquid–produced vapors, or combustible liquid–produced vapors above their flash points might occasionally be communicated unless such communication is prevented by adequate positive -pressure ventilation from a source of clean air and effective A Class I, Zone 0 A Class I, Zone 0 location is a location in which: • Ignitable concentrations of flammable gases or vapors are present continuously, or • Ignitable concentrations of flammable gases or vapors are present for long periods of time. Class I, Zone 1 A Class I, Zone 1 location is a location: • In which ignitable concentrations of flammable gases or vapors are likely to exist under normal operating conditions; or • In which ignitable concentrations of flammable gases or vapors may exist frequently because of repair or maintenance operations or because of leakage; or • In which equipment is operated or processes are carried on, of such a nature that equipment breakdown or faulty operations could result in the release of ignitable concentrations of flammable gases or vapors and also cause simultaneous failure of electrical equipment in a mode to cause the electrical equipment to become a source of ignition; or • That is adjacent to a Class I, Zone 0 location from which ignitable concentrations of vapors could be communicated, unless communication is prevented by adequate positive pressure ventilation from a source of clean air and effective safeguards against ventilation failure are provided. *Information obtained from Underwriters Laboratory www.ul.com Class I, Zone 2 A Class I, Zone 2 location is a location: • In which ignitable concentrations of flammable gases or vapors are not likely to occur in normal operation and, if they do occur, will exist only for a short period; or • In which volatile flammable liquids, flammable gases, or flammable vapors are handled, processed, or used but in which the liquids, gases, or vapors normally are confined within closed containers of closed systems from which they can escape, only as a result of accidental rupture or breakdown of the containers or system, or as a result of the abnormal operation of the equipment with which the liquids or gases are handled, processed, or used; or • In which ignitable concentrations of flammable gases or vapors normally are prevented by positive mechanical ventilation but which may become hazardous as a result of failure or abnormal operation of the ventilation equipment; or • That is adjacent to a Class I, Zone 1 location, from which ignitable concentrations of flammable gases or vapors could be communicated, unless such communication is prevented by adequate positive - pressure ventilation from a source of clean air and effective safeguards against ventilation failure are provided. ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Gas Group Comparison ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ A (Acetylene) B (Hydrogen) IIC (Acetylene & Hydrogen) C (Ethylene) IIB (Ethylene) D (Propane) IIA (Propane) Division 1 & 2 Gas Groups • Group A: Acetylene • Group B: Flammable gas, flammable liquid–produced vapor, or combustible liquid– produced vapor mixed with air that may burn or explode, having either a maximum experimental safe gap (MESG) value less than or equal to 0.45 mm or a minimum igniting current ratio (MIC ratio) less than or equal to 0.40 • Group C: Flammable gas, flammable liquid–produced vapor, or combustible liquid– produced vapor mixed with air that may burn or explode, having either a maximum experimental safe gap (MESG) value greater than 0.45 mm and less than or equal to 0.75 mm, or a minimum igniting current ratio (MIC ratio) greater than 0.40 and less than or equal to 0.80 *Information obtained from Underwriters Laboratory www.ul.com • Group D: Flammable gas, flammable liquid–produced vapor, or combustible liquid– produced vapor mixed with air that may burn or explode, having either a maximum experimental safe gap (MESG) value greater than 0.75 mm or a minimum igniting current ratio (MIC ratio) greater than 0.80 Zone 0, 1 & 2 Gas Groups • Group IIC: Atmospheres containing acetylene, hydrogen, or flammable gas, flammable liquid–produced vapor, or combustible liquid–produced vapor mixed with air that may burn or explode, having either a maximum experimental safe gap (MESG) value less than or equal to 0.50 mm or minimum igniting current ratio (MIC ratio) less than or equal to 0.45 • Group IIB: Atmospheres containing acetaldehyde, ethylene, or flammable gas, flammable liquid–produced vapor, or combustible liquid–produced vapor mixed with air that may burn or explode, having either maximum experimental safe gap (MESG) values greater than 0.50 mm and less than or equal to 0.90 mm or minimum igniting current ratio (MIC ratio) greater than 0.45 and less than or equal to 0.80 • Group IIA: Atmospheres containing acetone, ammonia, ethyl alcohol, gasoline, methane, propane, or flammable gas, flammable liquid–produced vapor, or combustible liquid– produced vapor mixed with air that may burn or explode, having either a maximum experimental safe gap (MESG) value greater than 0.90 mm or minimum igniting current ratio (MIC ratio) greater than 0.80 MESG (Maximum Experimental Safe Gap): The maximum clearance between two parallel metal surfaces that has been found, under specified test conditions, to prevent an explosion in a test chamber from being propagated to a secondary chamber containing the same gas or vapor at the same concentration. MIC (Minimum Igniting Current) Ratio: The ratio of the minimum current required from an inductive spark discharge to ignite the most easily ignitable mixture of a gas or vapor, divided by the minimum current required from an inductive spark discharge to ignite methane under the same test conditions. ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Temperature Class Comparison, °F ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Division 1 and 2 Zone 0, 1 and 2 T1 (≤842°F) T1 (≤842°F) T2 ( 572°F) T2 (≤572°F) T2A, T2B, T2C, T2D (≤536°F, ≤500°F, ≤446°F, ≤419°F) --- T3 ( 392°F) T3 (≤392°F) T3A, T3B, T3C ( 356°F, 329°F, 320°F) --- T4 ( 275°F) T4 (≤275°F) T4A ( 248°F) --- T5 ( 212°F) T5 (≤212°F) T6 ( 185°F) T6 (≤185°F) *Information obtained from Underwriters Laboratory www.ul.com CLASS II: COMBUSTIBLE DUSTS ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Area Classification Comparison ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Division 1 Where ignitable concentrations of combustible dust can exist all of the time or some of the time under normal operating conditions. Zone 20 Where ignitable concentrations of combustible dust or ignitable fibers/flyings are present continuously or for long periods of time under normal operating conditions. Zone 21 Where ignitable concentrations of combustible dust or ignitable fibers/flyings are likely to exist under normal operating conditions. Division 2 Where ignitable concentrations of combustible dust are not likely to exist under normal operating conditions. Zone 22 Where ignitable concentrations of combustible dust or ignitable fibers/flyings are not likely to exist under normal operating conditions. Class II, Division 1 A Class II, Division 1 location is a location: • In which combustible dust is in the air under normal operating conditions in quantities sufficient to produce explosive or ignitable mixtures, or • Where mechanical failure or abnormal operation of machinery or equipment might cause such explosive or ignitable mixtures to be produced, and might also provide a source of ignition through simultaneous failure of electrical equipment, through operation of protection devices, or from other causes, or • In which Group E combustible dusts may be present in quantities sufficient to be hazardous. Class II, Division 2 A Class II, Division 2 location is a location: • In which combustible dust due to abnormal operations may be present in the air in quantities sufficient to produce explosive or ignitable mixtures; or • Where combustible dust accumulations are present but are normally insufficient to interfere with the normal operation of electrical equipment or other apparatus, but could as a result of *Information obtained from Underwriters Laboratory www.ul.com infrequent malfunctioning of handling or processing equipment become suspended in the air; or • In which combustible dust accumulations on, in, or in the vicinity of the electrical equipment could be sufficient to interfere with the safe dissipation of heat from electrical equipment, or could be ignitable by abnormal operation or failure of electrical equipment. Zone 20 A Zone 20 location is a location in which: • Ignitable concentrations of combustible dust or ignitable fibers/flyings are present continuously. • Ignitable concentrations of combustible dust or ignitable fibers/flyings are present for long periods of time. Zone 21 A Zone 21 location is a location: • In which ignitable concentrations of combustible dust or ignitable fibers/flyings are likely to exist occasionally under normal operating conditions; or • In which ignitable concentrations of combustible dust or ignitable fibers/flyings may exist frequently because of repair or maintenance operations or because of leakage; or • In which equipment is operated or processes are carried on, of such a nature that equipment breakdown or faulty operations could result in the release of ignitable concentrations of combustible dust or ignitable fibers/flyings and also cause simultaneous failure of electrical equipment in a mode to cause the electrical equipment to become a source of ignition; or • That is adjacent to a Zone 20 location from which ignitable concentrations of dust or ignitable fibers/flyings could be communicated, unless communication is prevented by adequate positive pressure ventilation from a source of clean air and effective safeguards against ventilation failure are provided. Zone 22 A Zone 22 location is a location: • In which ignitable concentrations of combustible dust or ignitable fibers/flyings are not likely to occur in normal operation and, if they do occur, will only persist for a short period; or • In which combustible dust or fibers/flyings are handled, processed, or used but in which the dust or fibers/flyings are normally confined within closed containers of closed systems from which they can escape only as a result of the abnormal operation of the equipment with which the dust or fibers/flyings are handled, processed, or used; or • That is adjacent to a Zone 21 location, from which ignitable concentrations of dust or fibers/flyings could be communicated, unless such communication is prevented by adequate positive pressure ventilation from a source of clean air and effective safeguards against ventilation failure are provided. *Information obtained from Underwriters Laboratory www.ul.com ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Dust Group Comparison ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Class II, Division 1 and 2 Zone 20, 21 and 22 E (Metals – Division 1 only) F (Coal) None G (Grain) Division 1 & 2 Dust Groups • Group E: Atmospheres containing combustible metal dusts, including aluminum, magnesium, and their commercial alloys, or other combustible dusts whose particle size, abrasiveness, and conductivity present similar hazards in the use of electrical equipment. • Group F: Atmospheres containing combustible carbonaceous dusts that have more than 8 percent total entrapped volatiles (see ASTM D 3175-02, Standard Test Method for Volatile Matter in the Analysis Sample for Coal and Coke, for coal and coke dusts) or that have been sensitized by other materials so that they present an explosion hazard. Coal, carbon black, charcoal, and coke dusts are examples of carbonaceous dusts. • Group G: Atmospheres containing combustible dusts not included in Group E or F, including flour, grain, wood, plastic, and chemicals. Zone 20, 21 & 22 Dust Groups: None ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Temperature Class Comparison, °F ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Division 1 and 2 Zone 20, 21 and 22 T1 (≤842°F) T2 ( 572°F) T2A, T2B, T2C, T2D ( 536°F, 500°F, 446°F, 419°F) None T3 ( 392°F) Note: For Zone 20, 21 and 22, equipment shall be marked to T3A, T3B, T3C ( 356°F, 329°F, 320°F) T4 ( 275°F) T4A ( 248°F) T5 ( 212°F) T6 ( 185°F) *Information obtained from Underwriters Laboratory www.ul.com show the operating temperature. CLASS III: IGNITABLE FIBERS & FLYINGS ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Area Classifications ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Division 1 Where easily ignitable fibers/flyings are handled, manufactured, or used. Division 2 Where easily ignitable fibers/flyings are stored or handled other than in the process of manufacture. Class III, Division 1 A Class III, Division 1 location is a location in which easily ignitable fibers/flyings are handled, manufactured, or used. Class III, Division 2 A Class III, Division 2 location is a location in which easily ignitable fibers/flyings are stored or handled other than in the process of manufacture. ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Ignitable Fibers & Flyings Groups ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Class III, Division 1 and 2 None Division 1 & 2 Fibers & Flyings Groups: None ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Temperature Class, °F ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ Division 1 and 2 None Note: Article 503 of the NEC limits the maximum temperature for Class III equipment to 329°F (equivalent to a T-Code of T3B) for equipment not subject to overloading and to 248°F (equivalent to a T-Code of T4A) for equipment that maybe overloaded (such as motors or power transformers). *Information obtained from Underwriters Laboratory www.ul.com