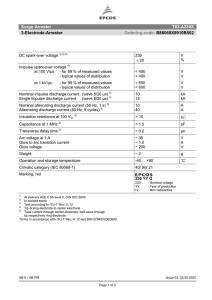

IEEE standard for metal-oxide surge arresters for AC power circuits

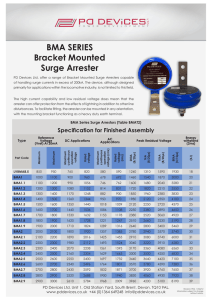

advertisement