IEC Type Test Report: PVN Polymer Arrester Performance

advertisement

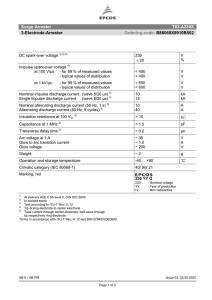

IEC Type Test Report Report No. EU1344-HR-00 Type PVN Polymer Arrester 10,000 A Line Discharge Class 3 This report records the results of this type test made on 10 kA Class 3 arresters rated 3 thru 180 kV in accordance with IEC Standard 60099-4, 2004, “Surge arresters - Part 4: Metal-oxide surge arresters without gaps for a.c. systems.” To the best of our knowledge and within the usual limits of testing practice, tests performed on the Type PVN 10 kA Class 3 arresters demonstrate full compliance with the relevant clause of the referenced standard. D. W. Lenk P.E. Principal Engineer M. G. Comber Manager, Engineering Date: 1/16/2006 Separate reports provide details of each test, according to the following table: Report No. EU1344-HR-01 EU1344-HR-02 EU1344-HR-03 EU1344-HR-04 EU1344-HR-05 EU1344-HR-06 EU1344-HR-07 EU1344-HR-08 EU1344-HR-09 EU1344-HR-10 EU1344-HR-11 EU1344-HR-12 EU1344-HR-13 Description Insulation Withstand Test Residual Voltage Long Duration Current Withstand Accelerated Aging Procedure Heat Dissipation Behavior of Test Section Switching Surge Operating Duty Partial Discharge Power Frequency Voltage Versus Time Short Circuit Bending Moment Moisture Ingress RIV Weather Ageing Clause 10.8.2 10.8.3 10.8.4 10.8.5 10.8.5 10.8.5 10.8.8 Annex D 5.11 10.8.9 10.8.13 10.8.12 10.8.14 Issue date 1/16/2006 1/16/2006 1/16/2006 1/16/2006 1/16/2006 1/16/2006 1/16/2006 1/16/2006 1/16/2006 1/16/2006 1/16/2006 1/16/2006 1/16/2006 IEC Type Test Report Report No. EU1344-HR-01 Type PVN Polymer Arrester 10,000 A Line Discharge Class 3 Insulation withstand tests on the arrester housing This report records the results of this type test made on IEC 10 kA Class 3 arresters rated 3 thru 228 kV in accordance with IEC Standard 60099-4, 2004, “Surge arresters - Part 4: Metal-oxide surge arresters without gaps for a.c. systems.” To the best of our knowledge and within the usual limits of testing practice, tests performed on IEC 10 kA Class 3 arresters demonstrate full compliance with the relevant clause of the referenced standard. Dennis W. Lenk P.E. Principal Engineer M.G. Comber Manager, Engineering Date: 1/16/2006 IEC Type Test Report Insulation withstand tests on the arrester housing iec CLAUSE 10.8.2 Table 1 summarizes polymer housing minimum leakage and strike distances for each arrester rating, and 60 Hz and impulse withstand requirements for each housing size. In all cases, the actual withstand values of each arrester housing exceed the minimum values specified in the Standard. Table 1. Insulation Withstand Requirements of PVN IEC 10 kA Class 3 Arresters. Arrester MCOV 2.55 5.1 7.65 8.4 10.2 12.7 15.3 17 19.5 22 24.4 29 31.5 36.5 39 42 48 57 70 76 84 88 98 106 115 131 140 144 152 180 Leakage Distance (mm) 584 584 584 584 787 787 787 1168 1168 1168 1168 1168 1575 1575 1575 1981 1981 2337 3150 3150 3962 3962 3962 3962 4724 5944 5944 5944 5944 7925 Imp w/s Req’d (KVc) 9.9 19.8 29.5 32.9 39.4 49.3 59.2 66.6 75.5 86.2 95 113 123 143 152 171 193 227 286 304 341 341 386 412 456 532 545 569 607 723 Imp w/s Actual (KVc) 120 120 120 120 161 161 161 241 241 241 241 241 321 321 321 401 401 450 639 639 700 700 660 660 817 1050 1050 1050 1050 1520 -2- 60 HZ 1 Minute Wet w/s Req’d (kVrms) 4.7 9.4 14 15.6 18.7 23.4 28.1 31.6 35.9 41 45.2 53.9 58.5 68 72 81 92 108 136 145 162 162 184 196 217 253 259 271 288 343 60 HZ 1 Minute Wet w/s Actual (kVrms) 57 57 57 57 74 74 74 109 109 109 109 109 145 145 145 182 182 200 295 295 320 320 306 306 385 410 410 410 410 500 IEC Type Test Report Report No. EU1344-HR-02 Type PVN Polymer Arrester 10,000 A Line Discharge Class 3 Residual Voltage This report records the results of type tests made on Type PVN 10 kA Line Discharge Class 3 arresters, rated up to 228 kV. Tests were performed in accordance with procedures of IEC Standard 60099-4, 2004, “Surge arresters - Part 4: Metal-oxide surge arresters without gaps for a.c. systems.” To the best of our knowledge and within the usual limits of testing practice, tests performed on these arresters demonstrate compliance with the relevant clause of the referenced standard. Dennis. W. Lenk P.E. Principal Engineer M.G. Comber Manager, Engineering Date:1/16/2006 1 IEC TYPE TEST REPORT Residual Voltage TESTS PERFORMED: Residual voltage measurements were made on three single resistor elements. Tests were conducted in accordance with clause 10.8.3 of IEC 60099-4, to determine steep current impulse residual voltages at 10 kA, lightning impulse residual voltages at 5 kA, 10 kA and 20 kA, and switching impulse residual voltages at 0.25 kA and 1 kA. Oscillograms of current and voltage were obtained for each test. For each test sample, all measured voltages have been rationalized to the lightning impulse residual voltage of that sample at nominal discharge current (10 kA 8/20), and the results have been displayed in graphical form. RESULTS: Tables 1, 2 and 3 show the residual voltages measured on test samples 1, 2 and 3, respectively. For each test sample, the measured residual voltages have been expressed in per unit of the lightning impulse residual voltage at nominal discharge current (10 kA, 8/20). Table 1. Measurements made on test sample 1 Test Wave Steep current Lightning impulse Switching impulse Current magnitude kA 10 5 10 20 0.25 1 Waveshape μs 1/2 8/20 47/91 Residual Voltage kV 13.695 11.895 12.754 13.879 9.938 10.505 p.u. 1.074 0.933 1.000 1.088 0.779 0.824 Oscillogram number 28 7 10 13 19 25 Table 2. Measurements made on test sample 2 Test wave Steep current Lightning impulse Switching impulse Current magnitude kA 10 5 10 20 0.25 1 Waveshape μs 1/2 8/20 47/91 Residual Voltage kV 13.707 11.868 12.746 13.854 9.875 10.484 p.u. 1.075 0.931 1.000 1.087 0.775 0.823 Oscillogram number 29 8 11 14 20 26 Table 3. Measurements made on test sample 3 Test wave Current Waveshape Residual Voltage Oscillogram 2 Steep current Lightning impulse Switching impulse magnitude kA 10 5 10 20 0.25 1 μs 1/2 kV 13.504 11.697 12.547 13.683 9.706 10.295 8/20 47/91 p.u. 1.076 0.932 1.000 1.091 0.774 0.821 number 30 9 12 15 21 27 The results are shown graphically in the following chart. When expressed in terms of per unit of the residual voltage at nominal discharge current, the residual voltages of Type PVN arresters for steep front, lightning impulse and switching impulse do not exceed values shown in this chart. 1.1 Residual voltage - p.u. Steep front Lightning impulse 1 0.9 0.8 Switching impulse 0.7 0 5 10 15 20 Current - kA 3 Annex Oscillograms 4 Annex Oscillograms 5 Oscillogram 7 Sample 1 6 Oscillogram 8 Sample 2 7 Oscillogroam 9 Sample 3 8 Oscillogram 10 Sample 1 9 Oscillogram 11 Sample 2 10 Oscillogram 12 Sample 3 11 Oscillogram 13 Sample 1 12 Oscillogram 14 Sample 2 13 Oscillogram 15 Sample 3 14 Oscillogram 19 Sample 1 15 Oscillogram 20 Sample 2 16 Oscillogram 21 Sample 3 17 Oscillogram 25 Sample 1 18 Oscillogram 26 Sample 2 19 Oscillogram 27 Sample 3 20 Oscillogram 28 Sample 1 21 Oscillogram 29 Sample 2 22 Oscillogram 30 Sample 3 23 IEC Type Test Report Report No. EU1344-HR-03 Type PVN Polymer Arrester 10,000 A Line Discharge Class 3 Long Duration Current Impulse Withstand Tests This report records the results of this type test made on 10 kA Class 3 arresters rated 3 thru 228 kV in accordance with IEC Standard 60099-4, 2004 “Surge arresters - Part 4: Metal-oxide surge arresters without gaps for a.c. systems.” To the best of our knowledge and within the usual limits of testing practice, tests performed on 10 kA Class 3 arresters demonstrate full compliance with the relevant clause of the referenced standard. D. W. Lenk P.E. Principal Engineer M.G. Comber Manager, Engineering Date: 1/16/2006 IEC Type Test Report Long Duration Current Impulse Withstand Tests iec Clause 10.8.4 Sample Preparation The test was conducted in accordance with Section 10.8.4 of IEC 99-4 2004 Standard on the three samples. Each test sample consisted of (2) 60 mm diameter mov discs, 70 mm total length. Test Parameters and Procedure The test setup is intended to model a Type PVN arrester applied as a Class 3 Line Discharge arrester. The generator parameters conform to the Class 3 Line Discharge requirements as defines in Table 5 of IEC 99-4 standard. The generator, initial measurements and prorated section parameters are defined as follows: Test Parameters Sample #1 Sample #2 Sample #3 Initial Residual Voltage @ 10 kA, 8/20 µS Switching Residual Voltage @ 250 A: Ures Reference Current: Iref Reference Voltage (kVc): Vref Maximum COV (rms): Uc Maximum Rating (rms): Ur Arrester Classification Line Discharge Class Virtual Duration of Peak (90-90%) Max. Generator Impedance: Z g Min. Generator Charging Voltage: UL 22.343 kV 16.996 kV 1 mA 12.944 kV 7.763 kV 9.502 kV 10 kA 3 2400 µS 12.35 Ω 26.606 kV 22.311 kV 16.983 kV 1 mA 12.902 kV 7.738 kV 9.471 kV 10 kA 3 2400 µS 12.31 Ω 26.519 kV 22.408 kV 17.061 kV 1 mA 12.914 kV 7.745 kV 9.480 kV 10 kA 3 2400 µS 12.32 Ω 26.544 kV Before the transmission line discharge test, the 10 kA, 8/20 µS discharge voltage of the test sample was measured. The procedure was performed per Section 7.4.2 of the IEC 99-4 Standard. The procedure consisted of eighteen rectangular wave shape discharges applied to each sample. These discharges were arranged in six groups of three consecutive operations with a time interval between consecutive operations of 50 to 60 sec. The samples were allowed to cool to near ambient temperature between groups of discharges. -2- Test Results Figure No.1 measures the surge impedance and confirms the virtual duration of the transmission line generator. The samples were exposed to the air at still air temperature of 20 oC during the tests. A summary of data recorded during this test is shown in Table 1. Figure 1 Zg = 10451 V / 850.2 A Zg = 12.29 Ohms Time Duration = 2400 µS Table 1 Summary Data - Long Duration Current Impulse Withstand Test Impulse Number 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 I (A) 740 721 709 729 710 702 727 715 704 720 705 711 730 711 704 737 718 692 Sample 1 V (kV) 17.79 17.95 18.08 17.84 18.00 18.13 17.87 18.01 18.14 17.89 18.05 18.19 17.87 18.01 18.16 17.90 18.06 18.14 E (kJ) 34.23 33.70 33.32 33.72 33.22 32.97 33.66 33.44 33.16 33.40 33.02 33.54 33.85 33.22 33.15 34.25 33.62 32.60 I (A) 735 722 711 728 714 703 728 712 703 729 706 694 727 713 698 723 710 695 Sample 2 V (kV) E (kJ) 17.81 33.96 17.95 33.61 18.08 33.31 17.84 33.70 17.98 33.28 18.13 33.04 17.85 33.72 18.01 33.27 18.11 33.02 17.87 33.80 18.03 32.96 18.13 32.61 17.87 33.69 18.03 33.29 18.13 32.88 17.87 33.61 18.01 33.16 18.12 32.69 -3- I (A) 725 711 700 720 706 696 721 706 698 712 711 695 714 697 689 717 700 692 Sample 3 V (kV) E (kJ) 17.87 33.64 18.03 33.25 18.16 32.97 17.92 33.47 18.08 33.12 18.19 32.82 17.95 33.58 18.11 33.20 18.20 33.04 17.94 33.17 18.11 33.41 18.22 32.80 17.93 33.23 18.09 32.69 18.20 32.53 17.97 33.36 18.09 32.89 18.20 32.75 Figure 2 is an oscillographics record of the first, ninth and eighteen transmission line discharge through the test sample No. 1. Figure 2 Sample No. 1, Shot 1 Discharge Current = 740 A Discharge Voltage = 17.79 kV Energy Under the V-I Curve = 34.23 kJ Sample No. 1, Shot 9 Discharge Current = 704 A Discharge Voltage = 18.14 kV Energy Under the V-I Curve = 33.16 kJ Sample No. 1, Shot 18 Discharge Current = 692 A Discharge Voltage = 18.14 kV Energy Under the V-I Curve = 32.60 kJ -4- Figure 3 is an oscillographics record of the first, ninth and eighteenth transmission line discharge through the test sample No. 2. Figure 3 Sample No. 2, Shot 1 Discharge Current = 735 A Discharge Voltage = 17.81 kV Energy Under the V-I Curve = 33.96 kJ Sample No. 2, Shot 9 Discharge Current = 703 A Discharge Voltage = 18.14 kV Energy Under the V-I Curve = 33.02 kJ Sample No. 2, Shot 18 Discharge Current = 695 A Discharge Voltage = 18.12 kV Energy Under the V-I Curve = 32.69 kJ Figure 4 is an oscillographics record of the first, ninth and eighteenth transmission line discharge through the test sample No. 3. -5- Figure 4 Sample No. 3, Shot 1 Discharge Current = 725A Discharge Voltage = 17.87 kV Energy Under the V-I Curve = 33.64 kJ Sample No. 3, Shot 9 Discharge Current = 698 A Discharge Voltage = 18.20 kV Energy Under the V-I Curve = 33.04 kJ Sample No. 3, Shot 18 Discharge Current = 692 A Discharge Voltage = 18.20 kV Energy Under the V-I Curve = 32.75 kJ -6- After successful completion of the eighteen-shot test, the 10 kA, 8/20 µS discharge voltage of each test sample was measured. The results of the residual voltage measurements are given in the following table and they show that all three samples had less than the permissible 5% change. Summary Data - Residual Voltage Measurement Comparisons 10 kA, 8/20 µS Impulse SAMPLE NO. 1 2 3 RESIDUAL VOLTAGE (KV) INITIAL FINAL 22.343 22.311 22.311 22.359 22.408 22.472 PERCENT CHANGE -0.14 0.22 0.29 Test Summary The three prorated test samples successfully completed the Long Duration Current Impulse Withstand Test per Clause 10.8.4 of IEC 99-4, 2004 Standard. In all cases, the change in 10 kA, 8/20 µS residual voltage was less than the allowed 5% limit. Disassembly revealed no evidence of physical damage to the three test samples. Therefore, the three test samples have successfully fulfilled the Long Duration Current Impulse Withstand requirement of a PVN Line Discharge Class 3 Arrester. -7- IEC Type Test Report Report No. EU1344-HR-04 Type PVN Polymer Arrester 10,000 A Line Discharge Class 3 Accelerated Aging Procedure This report records the results of type tests made on Type PVN 10 kA Line Discharge Class 3 arresters, rated up to 228 kV. Tests were performed in accordance with procedures of IEC Standard 60099-4, Ed. 2.0, 2005, “Surge arresters - Part 4: Metal-oxide surge arresters without gaps for a.c. systems.” To the best of our knowledge and within the usual limits of testing practice, tests performed on these arresters demonstrate compliance with the relevant clauses of the referenced standard. Dennis. W. Lenk P.E. Principal Engineer Michael G. Comber Manager, Engineering Date: 1/16/2006 EU1516-H-04 IEC TYPE TEST REPORT Accelerated Aging Procedure TESTS PERFORMED: Accelerated aging tests were performed on three resistor elements, 60mm diameter x 41mm length. The tests were conducted in accordance with Clause 8.5.2 of IEC 60099-4. The test samples were placed in an air oven and energized at a voltage equal to the corrected maximum continuous operating voltage, Uct, for 1000 hours. The temperature of the samples was maintained at 115 °C ± 2 °C for the duration of the test. Power dissipation was measured on each sample throughout the 1000 h test period. Clause 8.5.2 of IEC 60099-4 defines three power dissipation values: • P1ct, measured 1 h to 2 h after the initial voltage application • P2ct, measured after 1000 h • P3ct, the minimum value attained during the 1000 h test period. If P2ct is equal to or less than 1.1 times P3ct, then the switching surge operating duty test of Clause 8.5.5 of IEC 6099-4 is to be performed on new resistors. Furthermore, if P2ct is equal to or less than P1ct, then the rated voltage and continuous operating voltage used for the operating duty test are not subject to any modification. RESULTS: Figure 1 graphically displays the measurements made on the three samples during the 1000 h test period. Table 1 summarizes the values of P1ct, P2ct and P3ct for each sample. The requirements that P2ct is equal to or less than 1.1 times P3ct, and P2ct is equal to or less than P1ct are met for all three samples. Consequently, no modification needs to be made to the rated voltage and continuous operating voltage in the operating duty test, and the operating duty test can be performed on new resistors. Table 1. Power dissipation values Sample Number Power dissipation at 2 h P1ct (W) Power dissipation at 1000 h P2ct (W) Minimum power dissipation P3ct (W) 1 2 3 2.57 2.40 2.49 2.12 2.06 2.07 2.12 2.02 2.04 -2- IEC Type Test Report Report No. EU1344-HR-05 Type PVN Polymer Arrester 10,000 A Line Discharge Class 3 heat dissipation behaviour of test samples This report records the results of this type test made on IEC 10 kA Class 3 arresters rated 3 thru 228 kV in accordance with IEC Standard 60099-4, 2004 “Surge arresters - Part 4: Metal-oxide surge arresters without gaps for a.c. systems.” To the best of our knowledge and within the usual limits of testing practice, tests performed on IEC 10 KA Class 3 Arresters demonstrate full compliance with the relevant clause of the referenced standard. Dennis. W. Lenk P.E. Principal Engineer M. G. Comber Manager, Engineering Date: 1/16/2006 IEC Type Test Report heat dissipation behaviour of Type PVN ARRESTER VERSUS PROrated arrester SECTION iec clause 10.8.5 /aNNEX B Purpose The purpose of this test is to verify that the thermal cooling curve for the Type PVN prorated section , when internally heated, will cool slower than that of a full size PVN arrester unit. Procedure The full size arrester and the prorated section were heated up by applying a temporary overvoltage to the test samples. The test procedure is defined in Annex B of CEI\IEC 99-4 Standard. The full size arrester unit was instrumented with three (3) internal thermocouples, located at 1/4, 1/2, and 3/4 locations in the mov disc stack. The average temperature of the three arrester thermocouples was calculated for each 5 minute interval to develop the arrester unit cooling curve. The prorated section was instrumented with a single thermocouple and its cooling rated monitored at 5 minute intervals. Summary The following cooling curve confirms that the cooling rate of the PVN prorated section is slower than that of the full size PVN arrester unit, proving the thermal equivalency of the prorated section to the full size arrester. -2- IEC Type Test Report Report No. EU1344-HR-06 Type PVN Polymer Arrester 10,000 A Line Discharge Class 3 Switching surge Operating Duty Test This report records the results of this type test made on 10 kA Class arresters rated 3 thru 228 kV in accordance with IEC Standard 60099-4, 2001 “Surge arresters Part 4: Metal-oxide surge arresters without gaps for a.c. systems.” To the best of our knowledge and within the usual limits of testing practice, tests performed on 10 kA Class 3 Arresters demonstrate full compliance with the relevant clause of the referenced standard. D. W. Lenk P.E. Principal Engineer M.G. Comber Manager, Engineering Date: IEC Type Test Report switching surge Operating Duty Test iec clause 10.8.5 Sample Preparation The switching surge operating duty test was performed on the three thermally prorated test samples consisting of two 60 mm diameter, 35 mm long ZnO discs. Test Procedure 1) Initial Measurements: • At room temperature, the reference voltage was measured at 1mA reference current for each test sample. • At room temperature, the initial residual voltage was measured at 10 kA, 8/20 µS for each test sample also. 2) Conditioning: • With each sample energized at 60 Hz voltage 1.20x Uc*, a conditioning test consisting of four groups of five 10 kA 8/20 uS lightning current impulses was applied to the each thermal equivalent section. The interval between the impulses was between 50 s and 60 s and the interval between groups was between 25 min. and 30 min. The impulses were timed to occur 600 before the crest of the 60 Hz voltage having the same polarity as the impulse. Tests were in still air at 20 0C. • While assembled into an open air test fixture, each sample was next subjected to two 100 kA 4/10 uS current impulses with the samples cooled to ambient between shots. 3) Switching Surge Operating Duty Test: • The samples were assembled into the prorated models, placed in an oven and heated to 60 0C +/- 3 0C. Within 3 minutes after removal from the oven, each section was subjected to two transmission line discharge, 50 to 60 seconds apart. Then, within 90 msec. of the last long duration impulse, rated voltage (Ur) was applied for 10 seconds immediately followed by MCOV (Uc) for 30 min. During the recovery period, the power dissipation was monitored. • After the complete test sequence each test section was cooled to near ambient temperature and the 10 kA, 8/20 µS discharge voltage test was repeated. The percentage change in 10 kA, 8/20 µS residual voltage measured before and after the test was calculated . • A visual inspection verified that no damage occurred. Test Results -2- Before the switching surge operating duty test, the initial measurements and prorated section parameters are defined in Table 1: Table 1 Test Parameters Sample #1 Sample #2 Sample #3 Initial Residual Voltage @ 10 kA, 8/20 µS Reference Current: Iref Reference Voltage (peak): Vref Maximum COV (rms): Uc Maximum Rating (rms): Ur (1.224Uc) 22.44 kV 1 mA 12.974 kV 7.78 kV 9.523 kV 22.42 kV 1 mA 13.028 kV 7.81 kV 9.562 kV 22.42 kV 1 mA 12.959 kV 7.77 kV 9.511 kV A summary of data recorded for three samples during 20 shots conditioning test is shown in Table 2. The samples were exposed to the air at still air temperature of 20 oC during the tests. Table 2 Summary Data - Conditioning IMPULSE SAMPLE NO. 1 SAMPLE NO. 2 SAMPLE NO. 3 NUMBER I (KA) I (KA) I (KA) 1 10.456 10.408 9.981 2 10.368 10.443 10.057 3 10.271 10.404 10.769 4 10.372 10.421 10.535 5 10.460 10.444 10.564 6 10.414 10.440 10.890 7 10.333 10.385 10.978 8 10.352 10.395 11.043 9 10.385 10.404 10.958 10 10.303 10.349 10.802 11 10.404 10.300 10.509 12 10.316 10.267 10.515 13 10.212 10.408 10.421 14 10.180 10.310 10.290 15 10.251 10.232 10.336 16 10.261 10.313 10.546 17 10.232 10.228 10.590 18 10.189 10.271 10.466 19 10.225 10.297 10.486 20 10.261 10.261 10.440 After successful completion of the 20 shot test, each sample was subjected to two 100 kA 4/10 µS impulses as specified in the Standard (figure 8). Following Table 3 shows the first and second 100 kA impulses for all samples. Measured waveshape was 4.2/10.2 uS SHOTS Table 3 Summary Data - 100 kA 4/10 µS SAMPLE NO. 1 SAMPLE NO. 2 -3- SAMPLE NO. 3 NUMBER 1 2 I (KA) 107.480 102.290 I (KA) 102.080 102.430 I (KA) 102.500 102.780 Figure 1 shows oscillograms of the 100 kA impulse duty on the three test sections. Figure 1 Sample No. 1 First 100 kA Impulse Discharge Current = 107.48 kA Discharge Voltage = 35.95 kV Second 100 kA Impulse Discharge Current = 102.29 kA Discharge Voltage = 35.38 kV Sample No. 2 First 100 kA Impulse -4- Discharge Current = 102.08 kA Discharge Voltage = 35.32 kV Second 100 kA Impulse Discharge Current = 102.43 kA Discharge Voltage = 35.36 kV Sample No. 3 First 100 kA Impulse Discharge Current = 102.50 kA Discharge Voltage = 35.42 kV Second 100 kA Impulse -5- Discharge Current = 102.78 kA Discharge Voltage = 35.42 kV The transmission line generator and prorated section parameters are defined in Table 4: Table 4 Test Parameters Sample #1 Sample #2 Sample #3 Reference Voltage: Vref Maximum Rating (rms): Ur Arrester Classification Line Discharge Class Virtual Duration of Peak (90-90%) Max. Generator Impedance: Z g Min. Generator Charging Voltage: UL 12.974 kV 9.523 kV 10 kA 3 2400 µS 12.38 Ω 26.664 kV 13.028 kV 9.562 kV 10 kA 3 2400 µS 12.43 Ω 26.774 kV 12.959 kV 9.511 kV 10 kA 3 2400 µS 12.36 Ω 26.631 kV Figure 2 measures the surge impedance and confirms the virtual duration of the transmission line generator. A summary of data recorded during this test is shown in Table 5. Figure 2 Zg = 10451 V / 850.2 A Zg = 12.29 Ohms Time Duration = 2400 µS Table 5 Summary Data - Energy Dissipation During the Long Duration Current Impulse: -6- Impulse Number I (A) 1 712 2 691 Sample 1 V (kV) E (kJ) 18.06 33.56 18.29 32.93 Sample 2 I (A) V (kV) E (kJ) 745 18.14 35.21 720 18.35 34.39 Sample 3 I (A) V (kV) E (kJ) 743 18.14 35.09 698 18.33 33.36 The oscillograms during the Long Duration Current Impulse test are shown in Figure 3 Figure 3 Sample No. 1: First LD Impulse Discharge Current = 712.3 A Discharge Voltage = 18.06 kV Second LD Impulse Discharge Current = 691.5 A Discharge Voltage = 18.29 kV Sample No. 2: First LD Impulse -7- Discharge Current = 745.0 A Discharge Voltage = 18.14 kV Second LD Impulse Discharge Current = 720.2 A Discharge Voltage = 18.35 kV Sample No. 3: First LD Impulse Discharge Current = 743.4 A Discharge Voltage = 17.14 kV Second LD Impulse -8- Discharge Current = 698.7 A Discharge Voltage = 18.33 kV Thermal stability was verified during the recovery period by continuous measurement of the power dissipation of the test sample. Periodic values are show in Table 6 and they indicate that all three samples were stable. Table 6 Summary Data - Power Dissipation in Thermal Models During Recovery per IEC RECOVERY TIME 0 SEC 30 SEC 1 MIN. 2 MIN. 5 MIN. 10 MIN. 20 MIN. 30 MIN. SAMPLE NO. 1 POWER LOSS (W) 21.9 19.8 19.0 18.6 15.7 12.7 9.8 8.2 SAMPLE NO. 2 POWER LOSS (W) 24.1 20.6 19.4 17.1 14.4 11.2 9.6 7.8 SAMPLE NO. 3 POWER LOSS (W) 26.2 24.3 22.6 20.3 17.4 15.0 12.2 10.4 The results of the residual voltage measurements are given in Table 7 and they show that all three samples had less than the permissible 5% change. Table 7 Summary Data - Residual Voltage Measurement Comparisons 10 kA, 8/20 µS Impulse RESIDUAL VOLTAGE (KV) PERCENT SAMPLE NO. INITIAL FINAL CHANGE 1 22.44 22.55 0.49 2 22.42 22.52 0.45 3 22.42 22.55 0.58 Test Summary The three prorated test samples successfully completed the operating duty test per Clause 10.8.5 of IEC 99-4, 2004 standard. There was no evidence of puncture, flashover or -9- cracking of the non-linear metal oxide resistors in any of the three samples. Also, all three samples were thermally stable as demonstrated in Table 6. The change in the residual voltage measured before and after the test was less than 5%. Therefore, the three test samples have successfully fulfilled the operating duty test requirement of a Class 3 Type PVN Arrester. - 10 - IEC Type Test Report Report No. EU1344-HR-07 Polymer Arrester 10,000 A Line Discharge Class 3 partial discharge This report records the results of this type test made on 10 kA Class 3 arresters rated 3 thru 228 kV in accordance with IEC Standard 60099-4-2004 “Surge Arresters- Part 4: Metal oxide surge arresters without gaps for ac systems” To the best of our knowledge and within the usual limits of testing practice, tests performed on IEC 10 kA Class 3 arresters demonstrate full compliance with the relevant clause of the referenced standard. Dennis W. Lenk P.E. Principal Engineer M.G. Comber Manager, Engineering Date: 1/16/2006 IEC Type Test Report partial discharge IEc clause 10.8.8 TITLE: Internal Partial Discharge Clause 10.8.8 of IEC 60099-4 refers to Clause 8.8, which requires that the longest electrical unit of the arrester design be subjected to an internal partial discharge type test. Under the prescribed testing procedure, the partial discharge level at 1.05 times the continuous operating voltage of the unit shall not exceed 10 pC. Clause 9.1 c) of this same standard requires that all manufactured units be subjected to an internal partial discharge test that is identical to that of Clause 8.8, and that the partial discharge level of all units produced shall not exceed 10 pC. Routine test reports are provided on request verifying that this requirement has been met. By performing the routine testing of units according to Clause 9.1 c), the type test requirements of Clause 10.8.8 are automatically met. -2- IEC Type Test Report Report No. EU1344-HR-08 Type PVN Polymer Arrester 10,000 A Line Discharge Class 3 Power Frequency Voltage Versus Time Characteristic This report records the results of this type test made on 10 kA Class 3 arresters rated 3 thru 228 kV in accordance with IEC Standard 60099-4, 2004 “Surge arresters - Part 4: Metal-oxide surge arresters without gaps for a.c. systems.” To the best of our knowledge and within the usual limits of testing practice, tests performed on 10 kA Type PVN Class 3 arresters demonstrate full compliance with the relevant clause of the referenced standard. D. W. Lenk P.E. Principal Engineer ____________________________ M. G. Comber Manager, Engineering Date: 1/16/2006 IEC Type Test Report power frequency voltage versus time characteristics iec Annex D The claimed power frequency voltage capability for the IEC 10 kA Type PVN Class 3 design is summarized in Figure 1. The test procedure is listed below: 1. Preheat to 60 ± 3°C; 2. Apply two long duration discharge spaced 60 seconds apart; 3. Within 100 ms of the second discharge, apply the selected p. u. of voltage for a time greater than the abscissa value on Figure 1; 4. Apply the recovery voltage (U c ) for 30 minutes and monitor the power loss to confirm stability. The 10 kA Class 3 arrester data points met the claimed TOV requirements specified by the TOV withstand curve. POWER FREQUENCY VERSUS TIME FOR TYPE PVN CLASS 3 PER IEC 994 ANNEX D 1.6 PER UNIT VOLTAGE TIMES Uc 1.5 1.4 1.3 1.2 1.1 1 0.01 0.1 1 10 100 1000 OVERVOLTAGE DURATION-SECONDS DEMONSTRATED WITHSTAND DATA POINTS PU*Uc -2- PRIOR DUTY TOV CURVE PU*Uc 10000 IEC Type Test Report Report No. EU1344-HR-09 Type PVN Polymer Arrester 10,000 A Line Discharge Class 3 Short Circuit Test This report records the results of this type test made on 10 kA Class 3 arresters rated 3 thru 228 kV in accordance with IEC Standard 60099-4, 1998 “Surge arresters - Part 4: Metal-oxide surge arresters without gaps for a.c. systems.” To the best of our knowledge and within the usual limits of testing practice, tests performed on 10 kA Type PVN Class 3 arresters demonstrate full compliance with the relevant clause of the referenced standard. D. W. Lenk P.E. Principal Engineer M. G. Comber Manager, Engineering Date: IEC Type Test Report short circuit test INTRODUCTION: The high current and low current pressure relief tests were performed per Section 5.11 of IEC 60099-4-1998 Standard. For the high current tests, an additional timed reclose was performed on each test specimen approximately 20 cycles after completion of the required 12 cycle test. The high current tests were performed in the IREQ High Power Laboratory in Montreal. SAMPLE PREPARATION: The fuse wire was used to short out the mov disc elements. Two shorting methods were used. The "shorted" mode of failure consisted of externally locating a fuse wire along the outside contour of the stack of mov disc elements between the mov discs and the fiberglass-epoxy wrap. The "puncture" mode of failure consisted of drilling a 4 mm diameter hole through the center of each mov disc and then running a wire through the center of the stack of discs. For the high current tests, the longest available single unit arrester ( 48 kV MCOV ) was tested. TEST PROCEDURE: To achieve the high levels of fault current, the high current pressure relief tests were performed per Section 8.13.3.4 with a reduced voltage source of 11.1 kV rms. Since the arrester arc resistance can significantly affect the required asymmetry, the claimable symmetrical rms current for the high current test procedure is calculated by dividing the 1st loop peak current by 2.6. The low current pressure relief tests were performed per Section 8.13.4. TEST RESULTS: The following table summarizes the results of the pressure relief testing. The low current sample successfully vented within .23 seconds after fault initiation. The high current tests were performed on the longest arrester units. In addition to the initial 12 cycle fault current duty required per the standard test procedure, both the "punctured" and the "shorted" test samples were immediately subjected to a fault current reclose condition. Both arresters successfully vented. The highest claimable symmetrical fault current of 83.4 kA rms for 12.5 cycles, followed in 20 cycles by a claimable 81.5 kA rms 3 cycle reclose was recorded on the "shorted" design. The lower peak kA values recorded on the "punctured" arrester configuration were the result of the high arc resistance of that design when subjected to the reduced voltage test procedure. Initial Fault Arrest MCOV Mode of Fail Test Volts kVrms 1st Loop Peak Act Symm Curr Claimed Symm Curr -2- Reclose Fault Fault Durat (Cyc) 1st Loop Peak Act Sym m Fault Durat (Cyc) Condition of Arrester after kAc kA rms kArms kAc 48 Shorted 11.3 217 120 83.4 12.5 212 Curr kArms 122 48 Punct 11.2 181 121 69.6 12.5 229 124 2.55 Shorted 15.0 .48 .48 60 Testing 3 3 Module Intact Housing Separated Module Intact Housing Separated Module Intact Housing Split CONCLUSION: The test arresters assembled with the longest mechanical unit met the test evaluation criteria as specified. In all tests, the arrester module remained intact after the completion of each test. The flexible polymer housing wall section split or separated, as intended, on all samples to allow venting of internal arcing gases to the outside of the arrester. In all cases, flames associated with the fault current test extinguished immediately after completion of the test, well within the allowed 2 minute duration. These tests have demonstrated the capability of the IEC 10 kA Type PVN Class 3 arrester design to successfully discharge a maximum claimable 83 kArms symmetrical fault current. -3- IEC Type Test Report Report No. EU1344-HR-10 Base Mounted Type PVN Polymer Arrester 10,000 A Line Discharge Class 3 BENDING MOMENT This report records the results of this type test made on IEC 10 kA Class 3 Type PVN arresters rated 3 thru 228 kV in accordance with IEC Standard 60099-4, 2004-05 “Surge arresters - Part 4: Metal-oxide surge arresters without gaps for a.c. systems.” To the best of our knowledge and within the usual limits of testing practice, tests performed on IEC 10 KA Class 3 Arresters demonstrate full compliance with the relevant clause of the referenced standard. Dennis. W. Lenk P.E. Principal Engineer M. G. Comber Manager, Engineering Date: 1/16/2006 IEC Type Test Report BENDING MOMENT TEST iec clause 10.8.9 Introduction Tests were performed in accordance with clause 10.8.9 of IEC Standard 60099-4, 2004-05. The purpose of this test was to verify the mechanical and electrical integrity of the arrester polymer housing after being subjected to its maximum permissible service load (MPSL) moment, followed by the boiling water immersion test specified in clause 10.8.10. Sample Preparation A 42 kV MCOV Class 3 PVN arrester was assembled for this test. Test Procedure The test arrester was subjected to PD, watts loss, and voltage tests prior to the bending moment and boiling water immersion test. The mechanical portion of the bending moment test consists of rigidly mounting the 3-lug arrester base casting and then apply an increasing load to the top end of the measure, continuously monitoring top end deflection as a function of the applied load. When the claimed maximum permissible service load was reach, the load was maintained for 60 seconds, after which the load was slowly released. After the load was removed, the residual deflection of the arrester top end was recorded. The water immersion portion of the bending moment test was performed per clause 10.8. 13 and consists of placing the mechanically stressed arrester into a boiling salt water bath for 42 hours, after which the same is cooled to room temperature and electrical tests are repeated. Test Results The test arrester was loaded to the maximum permissible service load bending moment claimed for this base mounted IEC Class 3 PVN design. The following trace shows the mechanical portion of the bending moment test. -2- Plot of Applied Moment Versus Time for PVN Arrester 25000 20000 Moment In-lbs 15000 Moment (in-lbs) 10000 5000 Residual deflection = .208" 0 0 50 100 150 200 250 Time- Seconds Subsequent to the bending moment test, the test arrester was subjected to 42 hours immersion in the specified salt water bath. After removal from the bath, the arrester was electrically tested. The following table compares the initial versus the final electrical test results. Sample Initial Final Initial PD Final PD Initial 17 Final 17 No. Watts @ Watts @ @ 1.05 @ 1.05 ma ma Uc Uc times Uc times Uc Voltage Voltage (pC) (pC kVc kVc 1 3.8 3.8 0 0 54.2 54.5 Test Conclusions Visual inspection confirmed that there was no damage to the arrester as a result of the bending moment test, followed by the water immersion test. The load-deflection plot shows a smooth time load curve for the arrester. Electrical tests performed before and after testing confirmed the electrical integrity of the test arrester. The 0 % watts loss was below the allowed 20% increase. Partial discharge was 0 pC, below the allowed 10 pC limit. The measured 17 ma voltage changed +0.5%, below the allowed 5% limit. The IEC Class 3 Type PVN base mounted arrester design successfully passed the bending moment test, as defined in IEC 60099-4 standard. -3- IEC Type Test Report Report No. EU1344-HR-11 Type PVN Polymer Arrester 10,000 A Line Discharge Class 3 Moisture Ingress Test This report records the results of type tests made on Type PVN IEC 10 kA Class 3 arresters in accordance with IEC Standard 60099-4, 2004-05 “Surge arresters - Part 4: Metal-oxide surge arresters without gaps for a.c. systems.” To the best of our knowledge and within the usual limits of testing practice, tests performed on Type PVN IEC 10 kA Class 3 arresters demonstrate full compliance with the relevant clauses of the referenced standard. __________________________ D. W. Lenk P.E. Principal Engineer _____________________________ M. G. Comber Manager, Engineering Date: 1/16/2006 IEC TYPE TEST REPORT Moisture Ingress Test IEC Clause 10.8.13 10 kA Class 3 Surge Arrester TEST SAMPLES: The moisture ingress test was performed on a PVN 19.5 kV MCOV arrester. Tests were performed to validate the seal integrity of the PVN design after being subjected to the claimed 10,000 inch-pound continuous cantilever rating. TEST PROCEDURE: Testing was performed per the procedures specified in Section 10.8.13 of IEC Std 60099-4. Prior to cantilever loading, the test arrester successfully passed the Bending Moment test specified in Clause 10.8.9 of 60099-4 standard. Per clause 10.8.13.2.2, the recommended arrester top end tightening torque was applied for 30 seconds to the top end of the arrester. The test arrester was rigidly mounted at its base and top end loading applied to develop 10,000 inch-pound base end cantilever load. Successive loading was performed at 0o, 90o, 180o, and 270o. The arrester was subjected to a combination of 10,000 inch-pound load rotations and temperature excursions for 96 hours as specified in Figure 6 of 60099-4 Standard. After completion of the thermomechanical preconditioning test, the arrester was placed into boiling salt water for 42 hours, as specified in Clause 10.8.13.3. Finally, electrical and physical tests were performed per Clause 10.8.13.4 to confirm the seal integrity of the test arrester. TEST RESULTS: The following table summarizes the results of the electrical tests performed before and after the moisture ingress test. Watts Loss @MCOV Initial 2.5 Watts Loss @MCOV Final 2.4 Watts Loss Change -4.0% 1.5 kA IR kVc Initial 72.91 1.5 kA IR kVc Final 71.37 1.5 kA IR kVc Change -2.1% Partial disch Pc Initial 1.0 Partial disch Pc Final 1.0 CONCLUSION: Per the test results summarized above, the electrical characteristics of the PVN arrester met the allowable limits specified in Clause 10.8.13.4. Visual examination revealed no evidence of mechanical damage. The above tests validated the seal integrity of the PVN arrester assembled with a 3-lug base end casting when loaded to the 10,000 inch-pound continuous cantilever rating. 2 IEC Type Test Report Report No. EU1344-HR-12 Type PVN Polymer Arrester 10,000 A Line Discharge Class 3 Radio Influence Voltage (RIV) This report records the results of type tests made on Type PVN 10 kA Line Discharge Class 3 arresters, rated up to 228 kV. Tests were performed in accordance with procedures of IEC Standard 60099-4, Ed. 2.0, 2004-05, “Surge arresters - Part 4: Metal-oxide surge arresters without gaps for a.c. systems.” To the best of our knowledge and within the usual limits of testing practice, tests performed on these arresters demonstrate compliance with the relevant clauses of the referenced standard. Dennis. W. Lenk P.E. Principal Engineer M. G. Comber Manager, Engineering Date: 1/16/2006 IEC TYPE TEST REPORT Radio Influence Voltage (RIV) TESTS PERFORMED: A fully-assembled arrester, with voltage rating Ur of 228 kV and continuous operating voltage Uc of 180 kV, was subjected to the RIV test at voltages in excess of those prescribed in Clause 10.8.12 of IEC 60099-4. The voltage application was as follows: • raised to 207 kV (1.15 Uc ) • lowered to 189 kV (1.05 Uc ) • held at 180 kV for 5 min • lowered in steps of approximately 0.1 Uc until reaching 0.5 Uc • increased in similar steps until reaching 189 kV (1.05 Uc) • held at 189 kV for 5 min • lowered again in steps of approximately 0.1 Uc until reaching 0.5 Uc RIV measurements were made at each voltage level. The variable-frequency RIV meter was tuned to 1 MHz for the measurements. RESULTS: Prior to installing the arrester in the test circuit, an open circuit test was run to determine the background noise of the circuit. The arrester was installed and the sequence of voltage applications described above was applied. Results of the RIV measurements are shown in Table 1. At all test voltage levels, the RIV was essentially at background noise level. 60099-4 allows a maximum RIV level of 2500 µV. -2- IEC IEC Type Test Report Report No. EU1344-HR-13 Base Mounted Polymer Arrester 10,000 A Line Discharge Class 3 WEATHER AGEING TEST This report records the results of this type test made on IEC 10 kA Class 3 arresters rated 3 thru 228 kV in accordance with IEC Standard 60099-4, 2001 “Surge arresters - Part 4: Metal-oxide surge arresters without gaps for a.c. systems.” To the best of our knowledge and within the usual limits of testing practice, tests performed on IEC 10 KA Class 3 arresters demonstrate full compliance with the relevant clause of the referenced standard. Dennis. W. Lenk P.E. Principal Engineer M. G. Comber Manager, Engineering Date: 1/16/2006 IEC Type Test Report WEATHER AGEING TEST iec clause 10.8.14.2.1 Introduction Tests were performed in accordance with clause 10.8.14.2.1 of IEC Standard 60099-4, 2005. The purpose of this test was to verify the electrical integrity of the arrester polymer housing after being subjected to 1000 hours in a salt fog environment. Sample Preparation A 115 kV MCOV PVN arrester (longest electrical unit) was assembled for this test. Test Procedure The 1000 hour weather ageing test was performed per clause 10.8.14.2.2 of IEC 60099-4. Test Results The test arrester successfully withstood the 1000 hour salt fog exposure test with no evidence of surface tracking, erosion, or puncturing. Per clause 10.8.14.3, the reference voltage change, as a result of the 1000 hour test, was less than the allowed 5%. In addition, the partial discharge measured at the completion of the test was less than the allowed 10pc. Test Conclusions The PVN IEC Class 3 arrester design successfully passed the 1000 hour salt fog weather ageing test, as defined in IEC 60099-4 standard. -2-