pdf Filesize

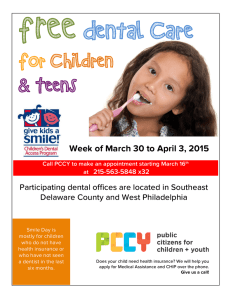

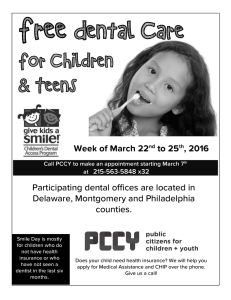

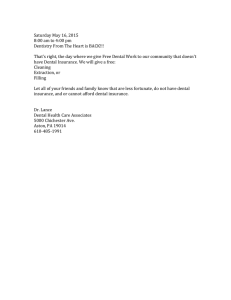

advertisement